Electro-servo hydraulic generator

An electric servo and generator technology, applied in the field of servo hydraulic system, can solve the problems of difficult maintenance, high manufacturing cost, slow response speed, etc., and achieve the effects of stable and reliable operation, simple and compact structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

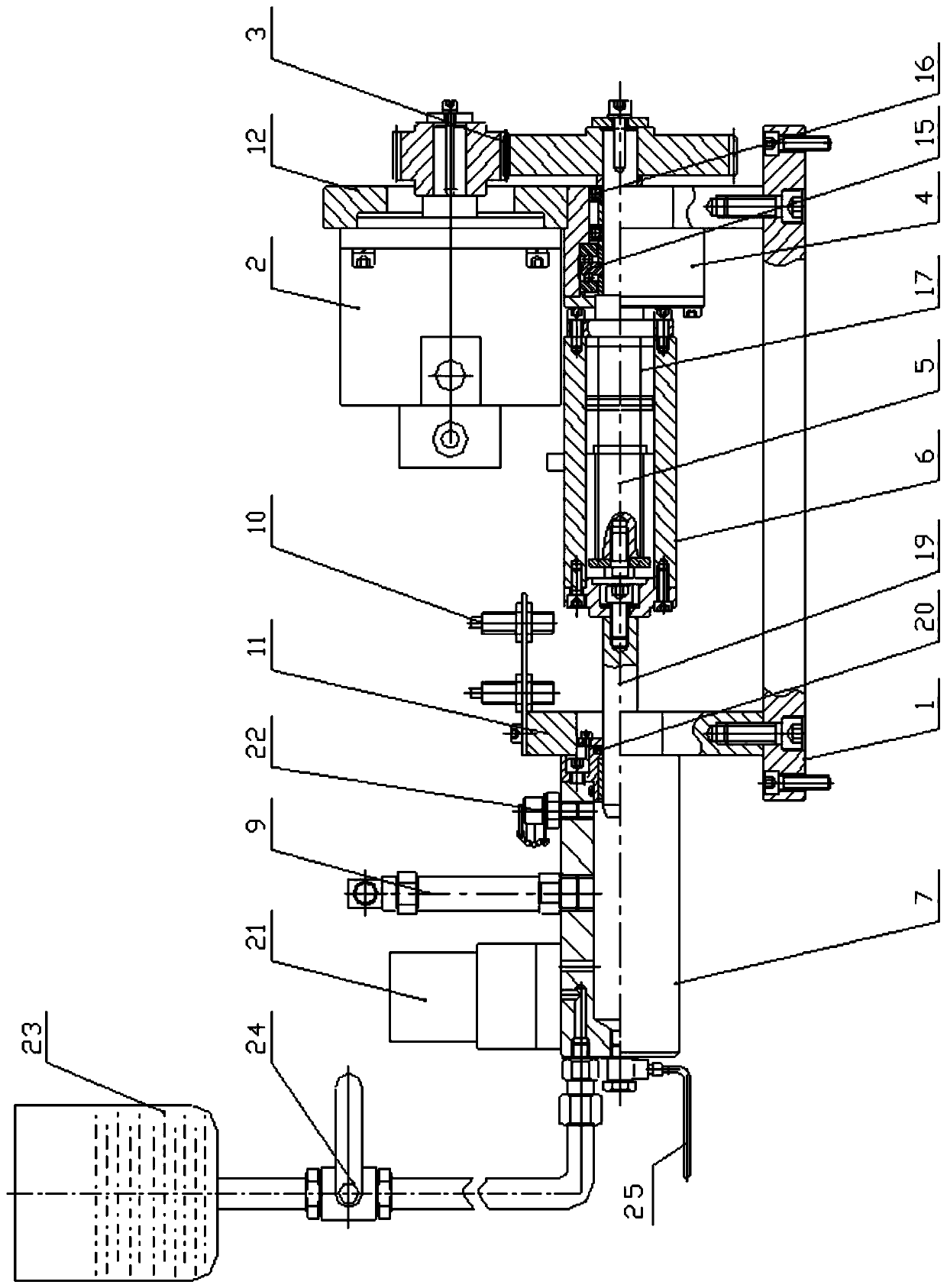

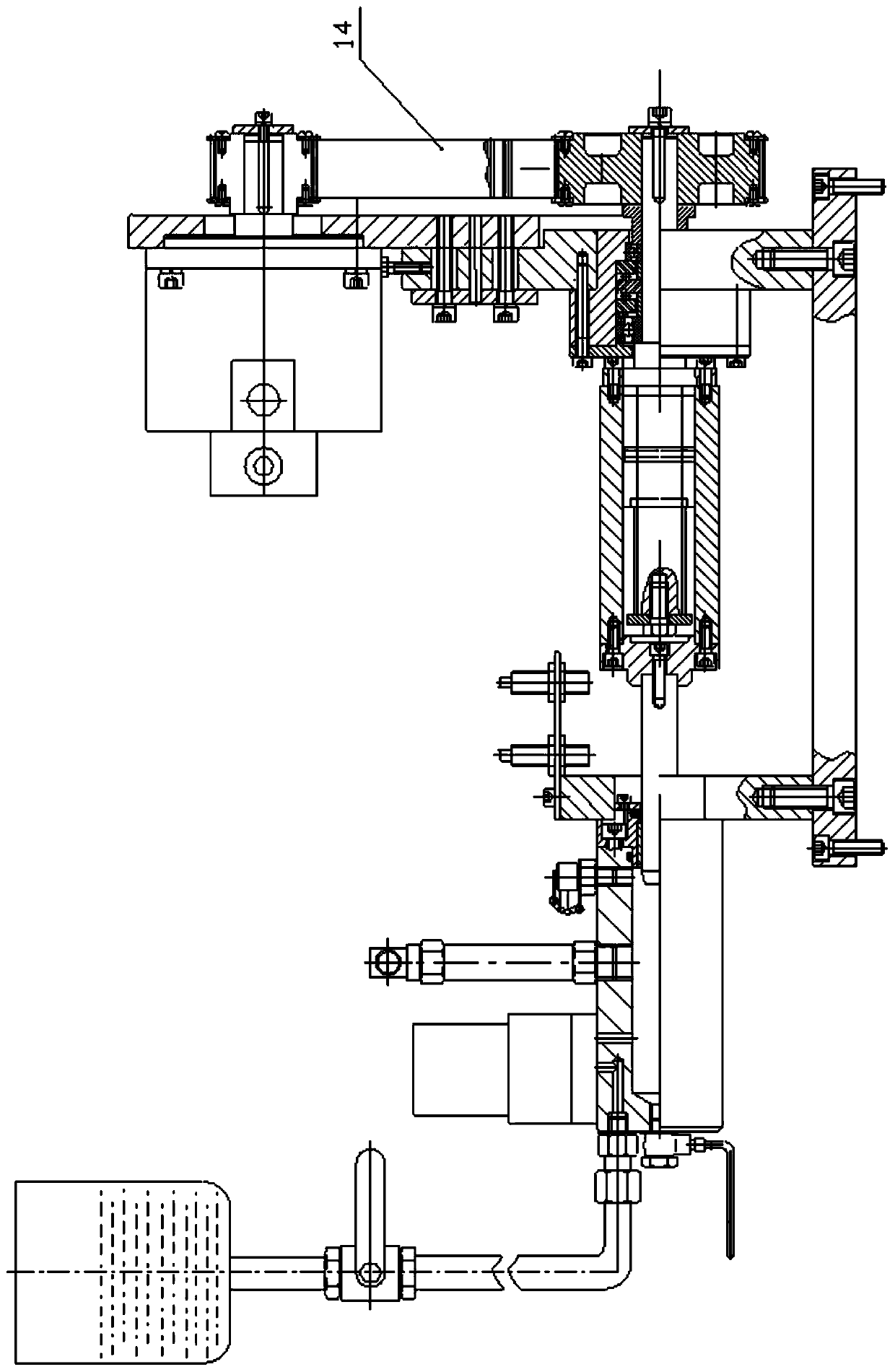

[0046] In order to clearly and completely describe the technical solution of the present invention and its specific working process, with reference to the accompanying drawings, the specific embodiments of the present invention are as follows:

[0047] The invention discloses an electric servo hydraulic generator, comprising: a stand, a servo motor, an intermediate transmission mechanism, a bearing seat assembly, a rolling screw pair, a guide assembly, a sensor assembly, an oil cylinder assembly and an oil cylinder control assembly.

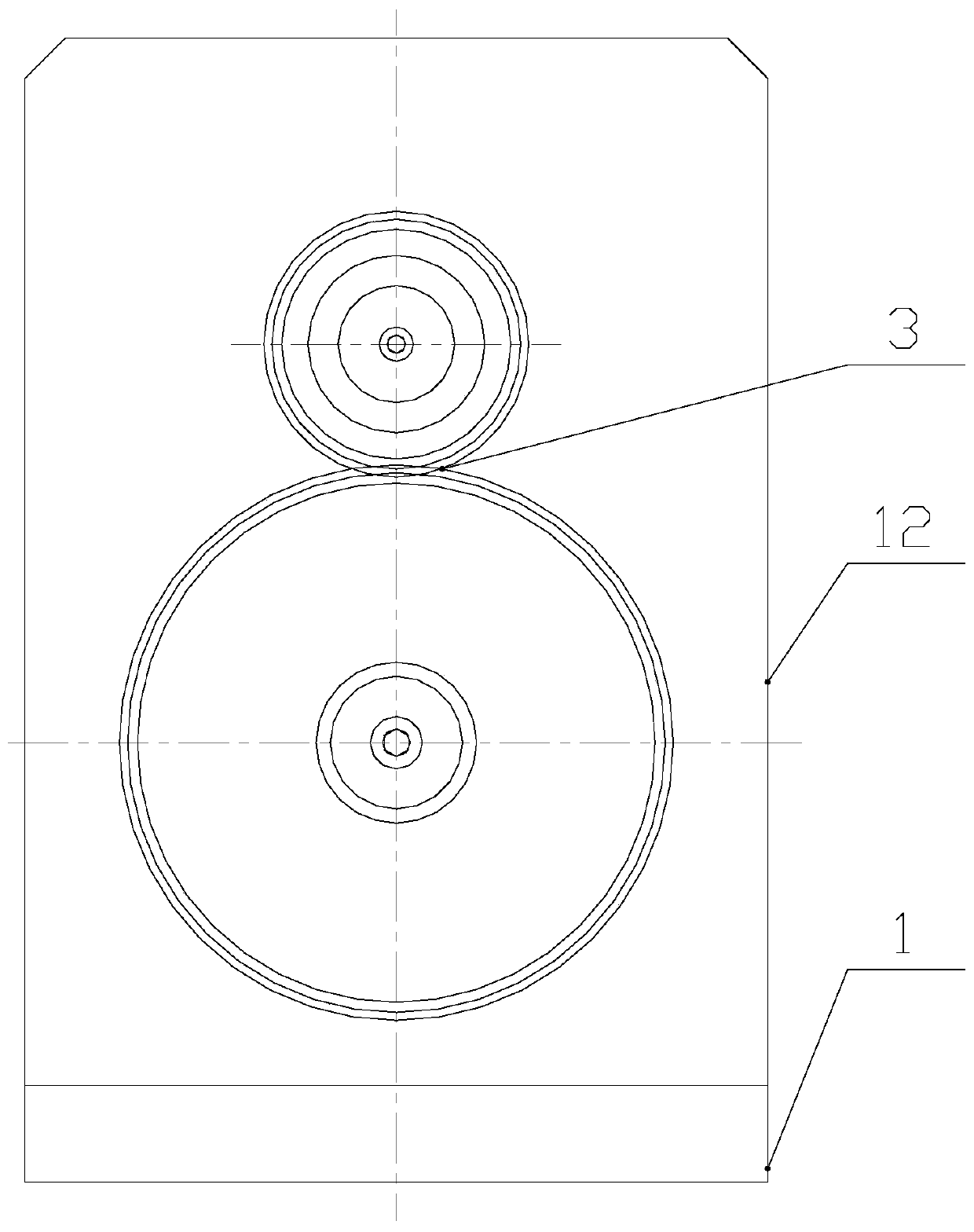

[0048] like figure 1 and Figure 4 As shown, the stand is the base of the entire generator, used to support and install other components, the stand is composed of a bottom plate 1, a left vertical plate 11 and a right vertical plate 12, wherein the bottom plate 1 is set horizontally, and the left vertical plate 11 It is vertically fixed on the left side of the top surface of the bottom plate 1 , and the right vertical plate 12 is vertically fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com