Simulation wheel-grind forming machine for bitumen mixture specimens and specimen manufacture method

A technology of asphalt mixture and molding machine, which is applied in the preparation of test samples, analysis of materials, sampling, etc., which can solve the problems that the compaction state of rubber-tyred road rollers cannot be simulated, and achieve convenient rubber-tyred roller molding and easy parameter adjustment , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

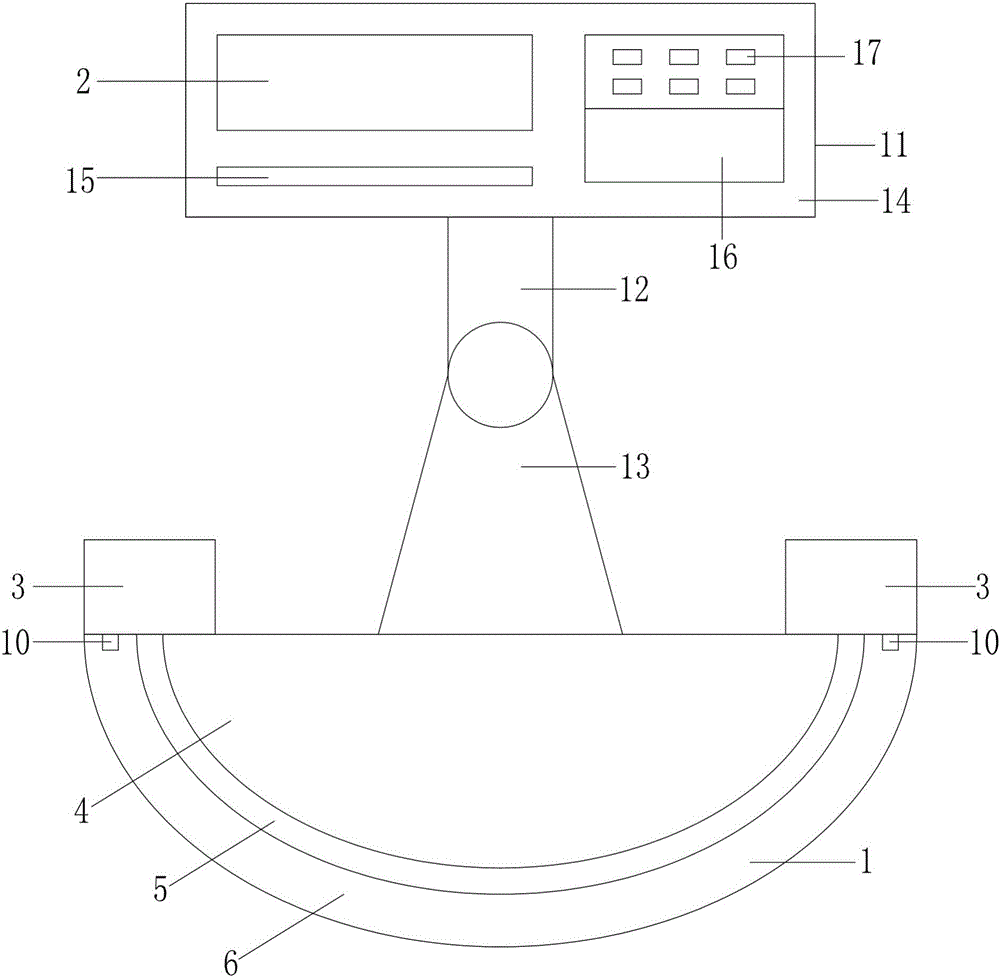

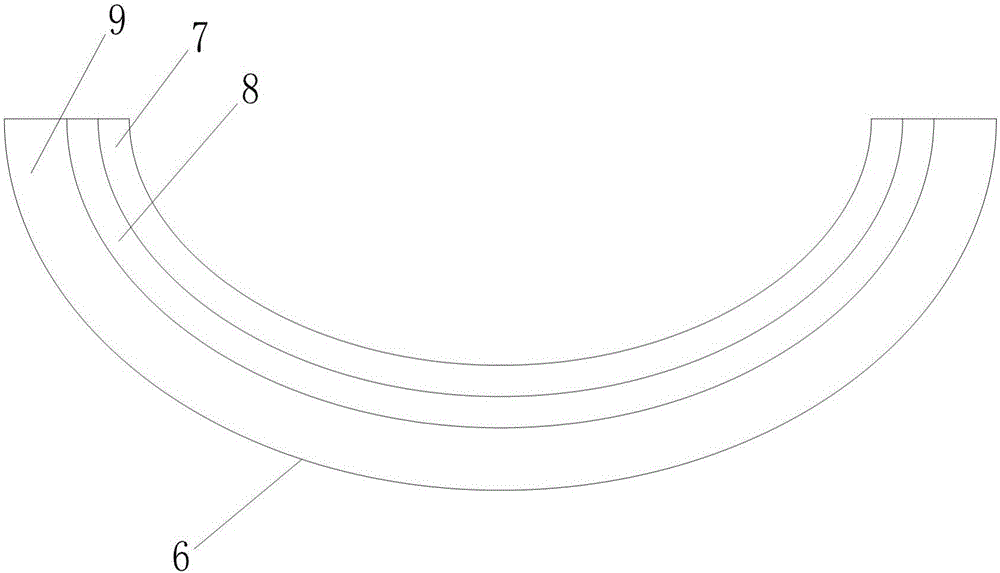

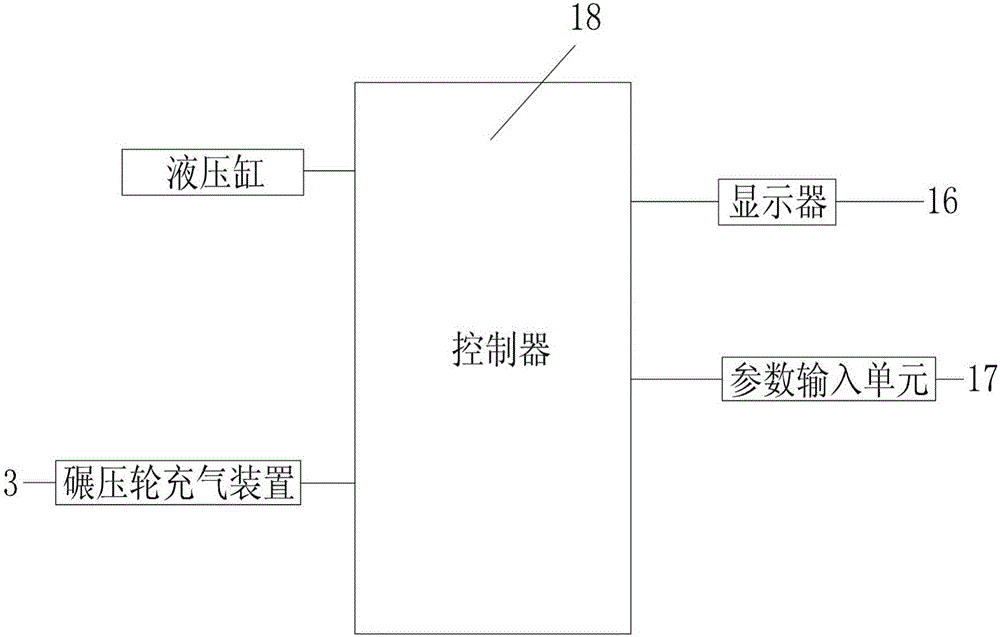

[0034] Such as Figure 1 ~ Figure 3 As shown, a simulated wheel rolling machine for asphalt mixture samples includes a rolling wheel 1, a rolling wheel drive device 2, a rolling wheel inflator 3, and a control box 11. The rolling wheel 1 includes a rim 4, a block The ring 5 and the tire 6, and the rolling wheel 1 has an arc shape as a whole. The retaining ring 5 and the tire 6 are respectively arc shaped. The outer edge of the rim 4 is provided with a retaining ring 5. The outer chord length of the rim 4 is 30cm. 6 is installed around the outer edge of the rim 4 through a retaining ring 5, and the inner chord length of the tire 6 is 30 cm. The rolling wheel drive device 2 includes a reduction mechanism, a frame 13, a hydraulic transmission rod 12, a hydraulic cylinder, a guide rail, and a transmission chain. The rolling wheel drive device 2 is arranged on the control box 11, and the reduction mechanism is powered by a motor and a reduction mechanism Power connection with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com