Optical fiber sensor packaging process prestress automatic control device and method

An automatic control device, fiber optic sensor technology, applied in program control, converting sensor output, using optical devices to transmit sensing components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

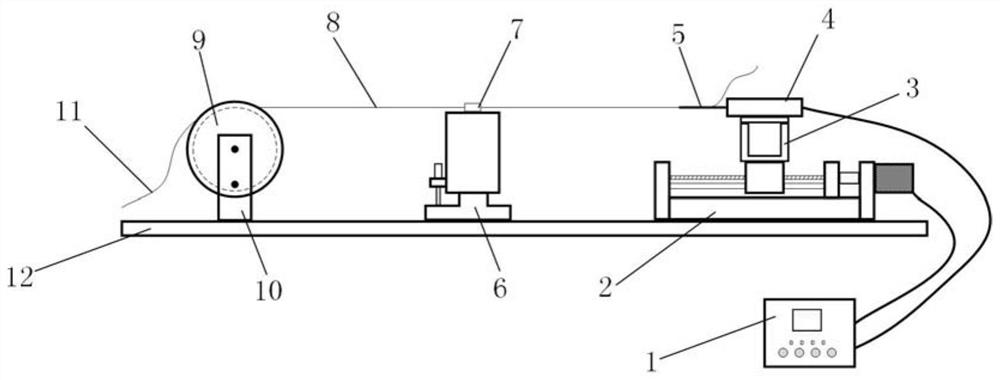

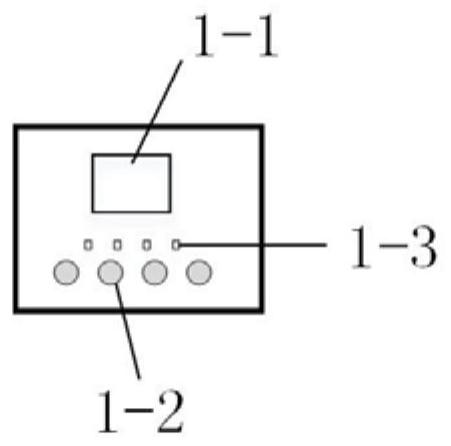

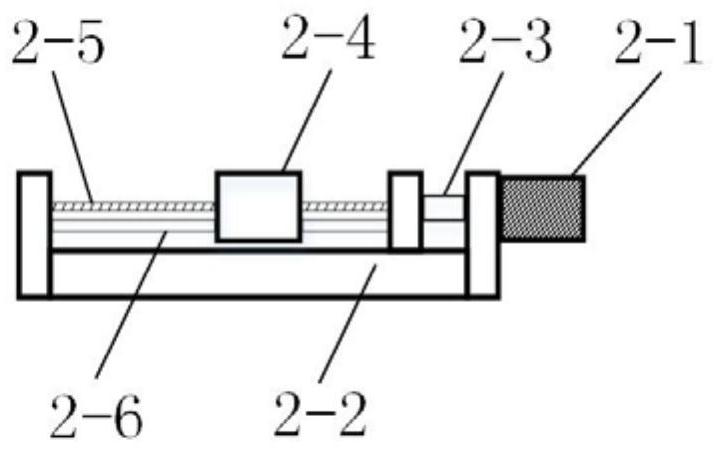

[0037] Such as figure 1 As shown, an automatic prestress control device for the packaging process of an optical fiber sensor includes a control module 1, a displacement module 2, a tension gauge 4, a fine-tuning module 6, an optical fiber winding wheel and a base 12; the fine-tuning module 6 is used to support the packaging structure of the optical fiber sensor 7. By adjusting the height of the fine-tuning module 6, the optical fiber sensor is free from external force in the vertical direction; one end of the optical fiber sensor pigtail 11 is wound and fixed on the fiber winding wheel, and the other end is fixed on the connecting rod 5 of the tension gauge 4; The tension meter 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com