Patents

Literature

63results about How to "Guaranteed performance consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

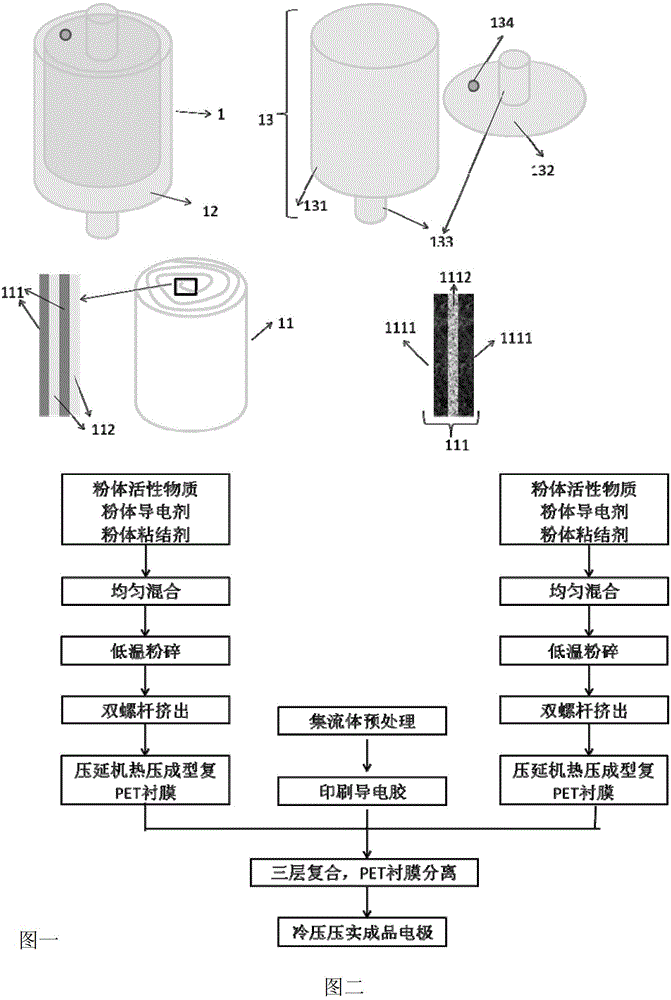

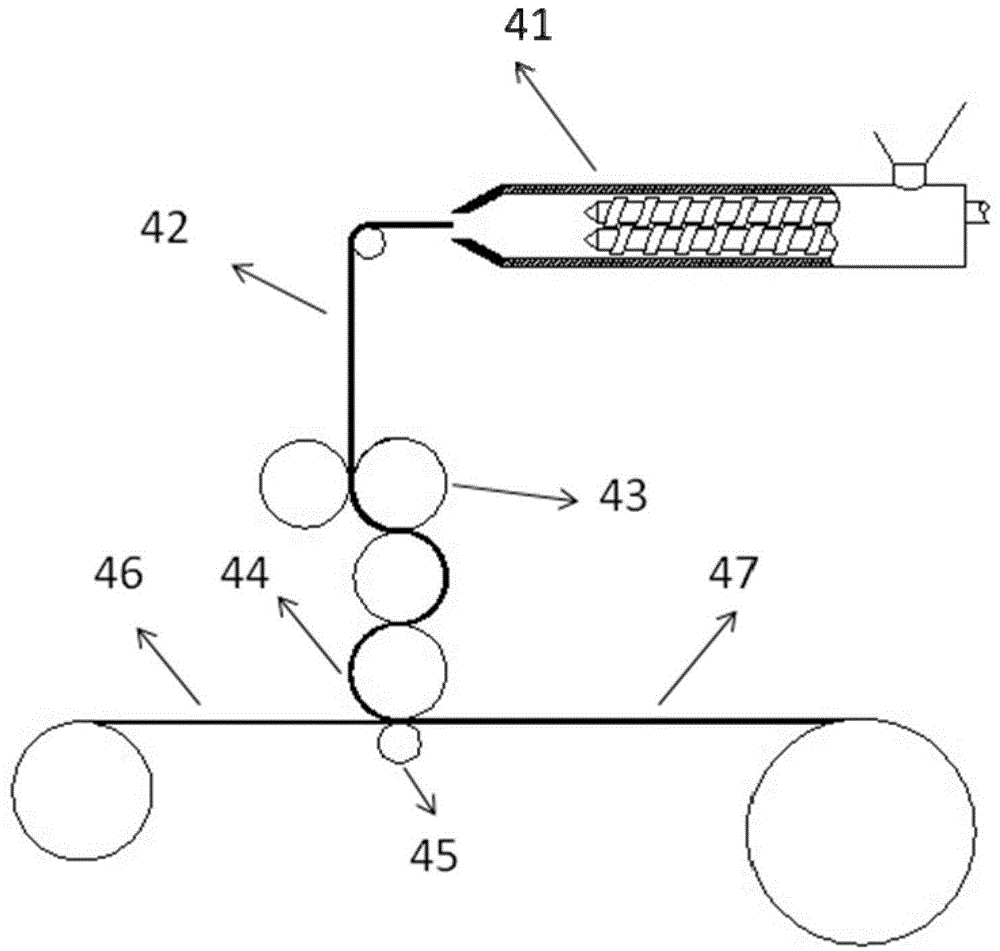

High performance super capacitor and manufacturing process thereof

ActiveCN102723211AWell mixedImprove the mixing effectElectrolytic capacitorsBiochemical engineeringSupercapacitor

The invention relates to a high performance super capacitor and a manufacturing process thereof. The super capacitor comprises an electrode core, an electrolyte and a shell. The manufacturing process comprises steps that: tabs and leading-out terminals of the prepared electrode core positive and negative poles are welded; the electrode core with the well-welded leading-out terminals is encased in the shell; the shell with the electrode core encased is put in a vacuum drying furnace for vacuum drying; and finally a vacuum liquid filling sealing test is carried out. In an aspect of the electrode manufacturing method, the manufacturing process of the invention abandons a method which uses a solvent for assisted processing, thus to the greatest degree, the purity of the electrode material is ensured. In addition, during the production process, the manufacturing process of the invention has no drying energy waste and drying time constraint, and therefore reduces cost, reduces energy loss, and improves working speed. The manufacturing process of the invention further adopts an advanced assembly process to avoid problems such as secondary pollution and processing consistency in the traditional assembly technology, and greatly improves the stability of the super capacitor.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

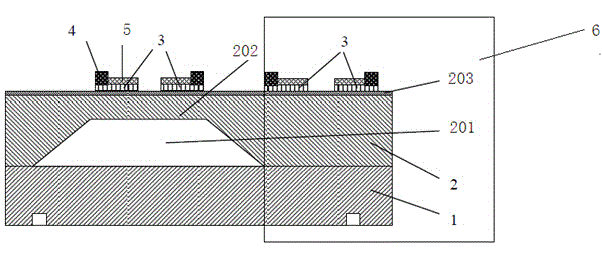

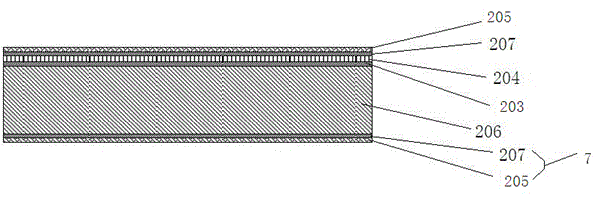

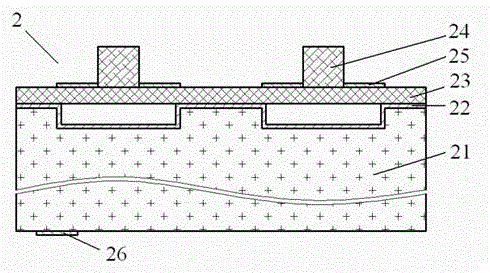

Temperature-integrated high-performance pressure sensor chip and manufacturing method thereof

ActiveCN104089727AGuaranteed performance consistencyUniform thicknessForce measurement using piezo-resistive materialsEtchingSilicon nitride

The invention discloses a temperature-integrated high-performance pressure sensor chip and a manufacturing method of the chip. The manufacturing method comprises the steps that an SOI silicon wafer is subjected to thermal oxidation to form a thin oxide layer, and then low-stress silicon nitride is subjected to LPCVD; photoetching is conducted on the reverse side of the SOI silicon wafer, a pressure sensitive film is obtained through wet etching, and a cavity is formed in the area of the pressure sensitive film; the silicon nitride and silicon oxide on the SOI silicon wafer are removed; a monocrystalline silicon substrate silicon wafer is subjected to thermal oxidation, alignment marks are formed in the reverse side of the monocrystalline silicon substrate silicon wafer through photoetching and corrosion, and the oxide layer is removed; the SOI silicon wafer and a monocrystalline silicon substrate are subjected to silicon-silicon bonding so that the cavity in the SOI silicon wafer can form an airtight cavity; top-layer silicon of the SOI silicon wafer is subjected to ion injection, photoetching and etching to form eight bulk resistors doped with monocrystalline silicon; metal sputtering, photoetching and corrosion are conducted to form metal guide lines, and the metal guide lines are connected with all the bulk resistors to form a measuring circuit. The temperature-integrated high-performance pressure sensor chip achieves simultaneous measurement of pressure and temperature, and overcomes the defect that device performance deteriorates due to reverse leakage currents of a PN junction of a pressure sensor at a high temperature.

Owner:LONGWAY TECH WUXI

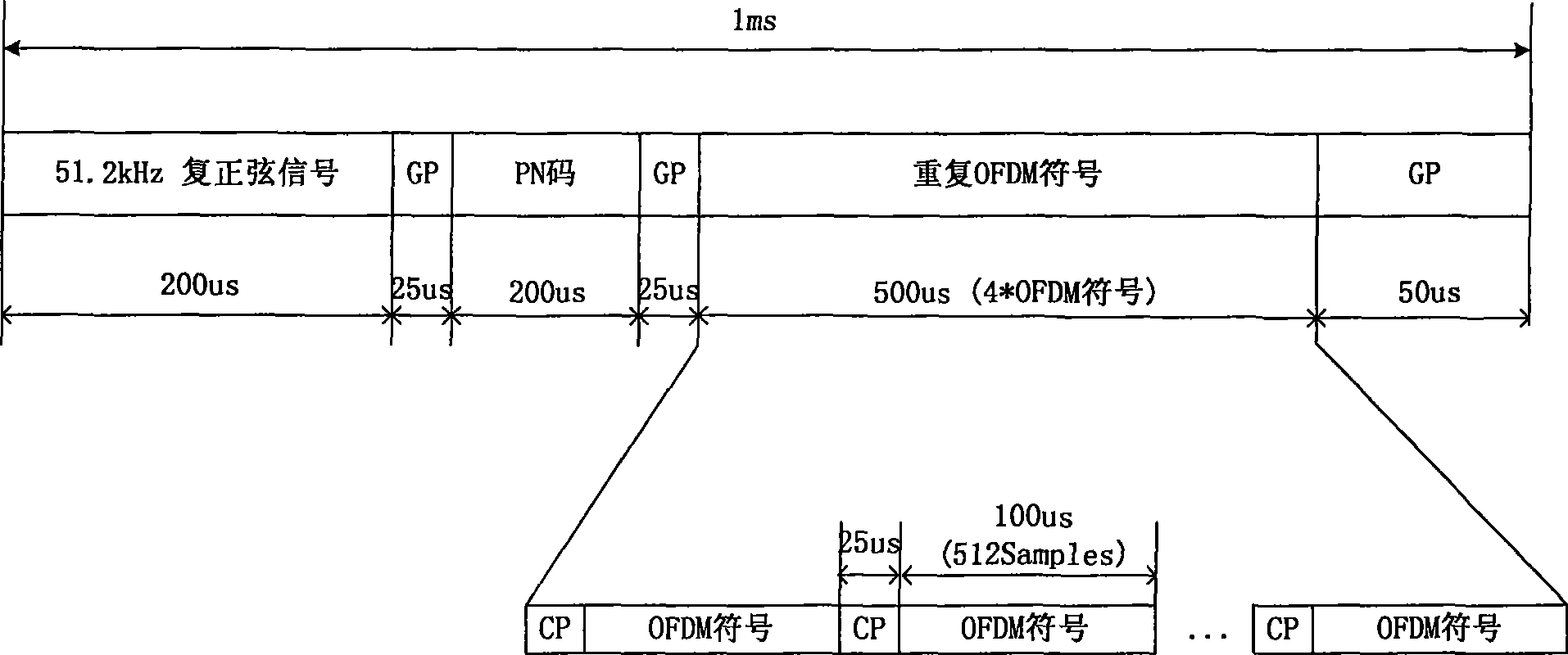

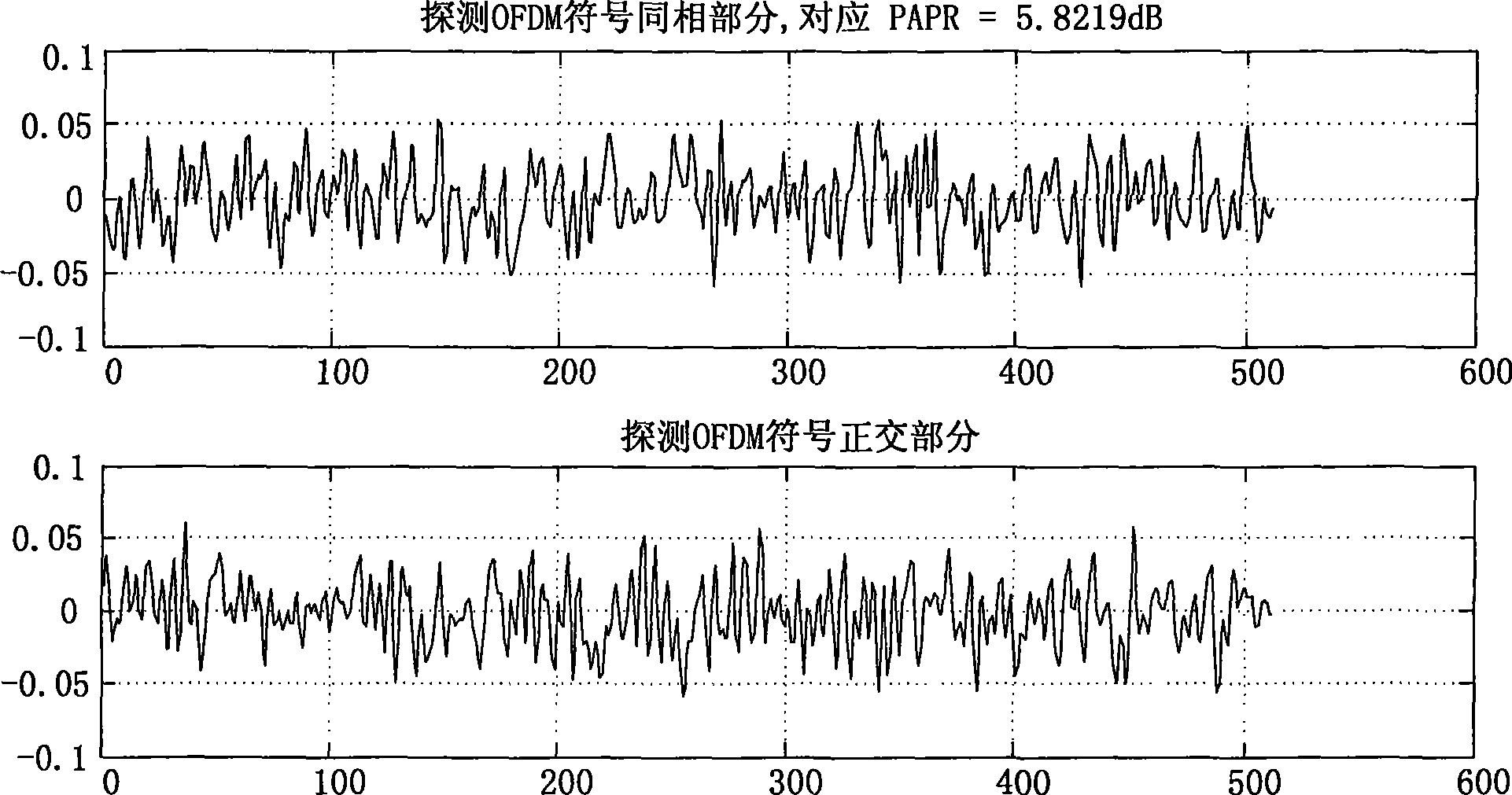

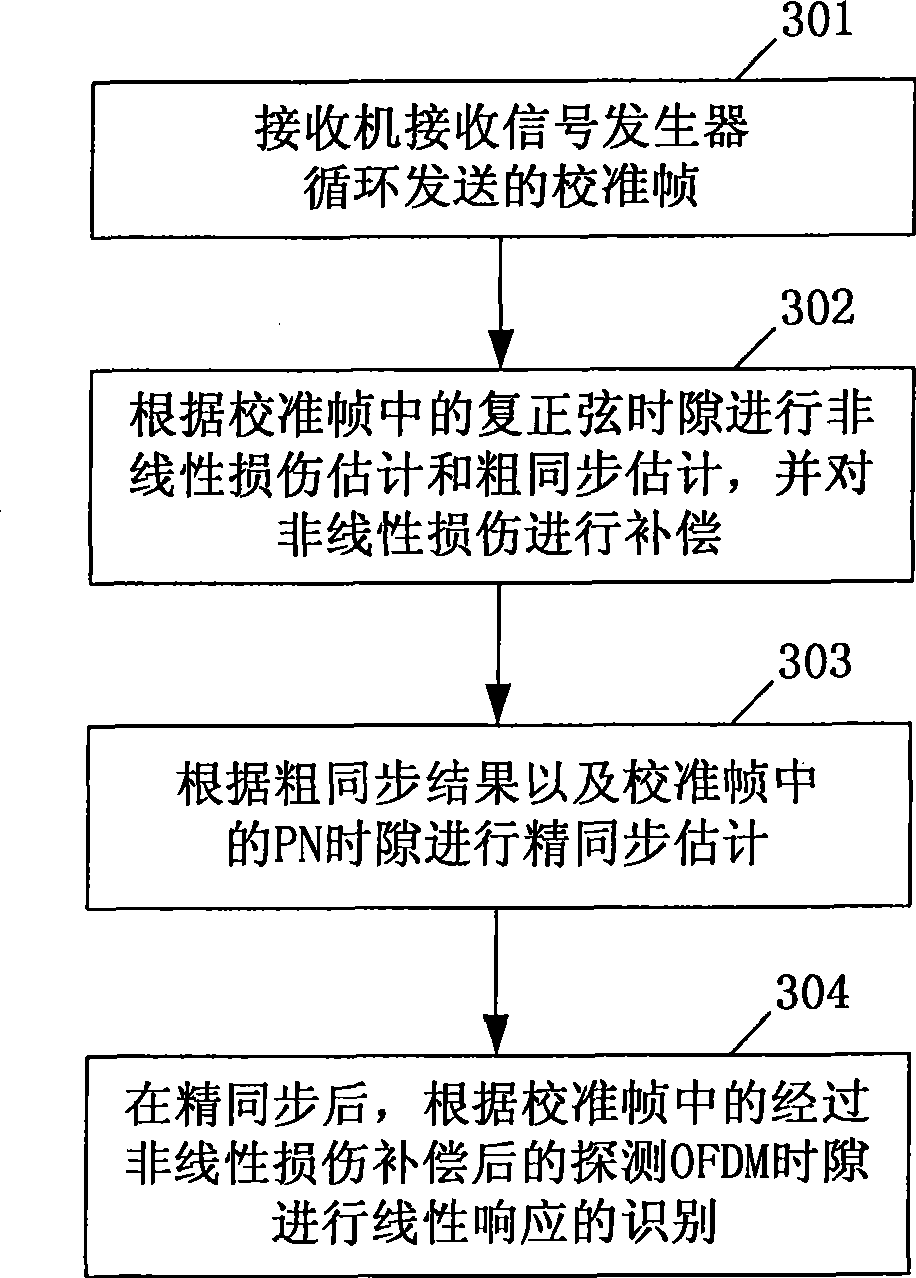

Receiving machine frequency response recognition method, apparatus and compensating method

InactiveCN101364967AImprove performanceImprove the maximum signal-to-noise ratioMulti-frequency code systemsPattern recognitionSignal-to-noise ratio (imaging)

The invention provides a recognition method for the frequency response of a receiver, and a device and a compensating method thereof. The recognition method comprises the following steps: firstly, a receiver receives calibration frames cyclically sent by a signal generator, and each calibration frame comprises a re-sinusoidal time slot, a PN time slot, a detection OFDM time slot and a plurality of protection time slots; secondly, nolinear damage estimation and coarse synchronizing estimation are performed according to the re-sinusoidal time slot in the calibration frame, and the nolinear damage is compensated; thirdly, precise synchronizing estimation is performed according to the coarse synchronizing estimation result and the PN time slot in the calibration frame; fourthly, after precise synchronizing, the recognition of linear response is carried out according to the detection OFDM time slot in the calibration frame after nolinear damage estimation. According to the invention, the channel frequency response of the receiver can be effectively recognized, and the frequency response can be compensated, so as to increase the maximum signal to noise ratio of the signal in the pass band of the receiver, so that the receiver performance can be enhanced equivalently.

Owner:ST ERICSSON SEMICON BEIJING

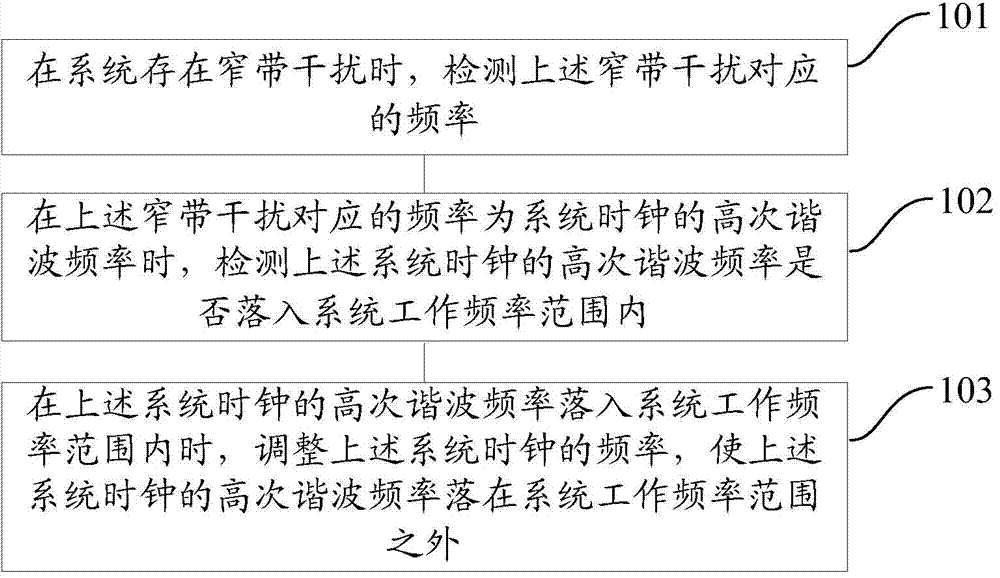

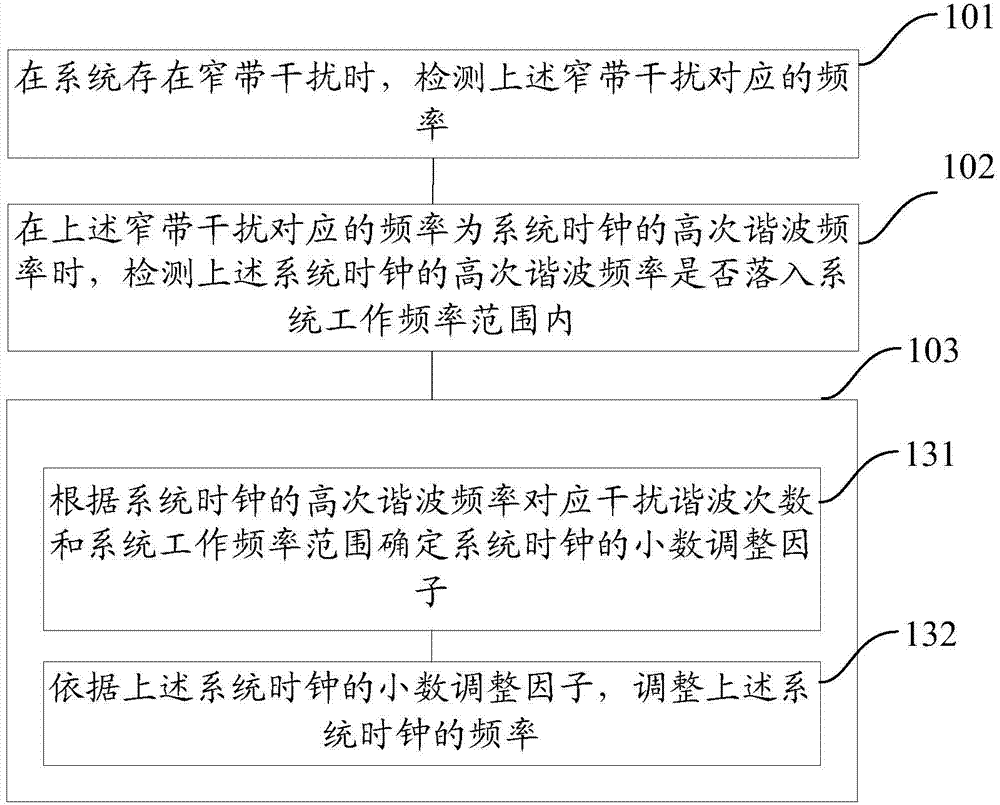

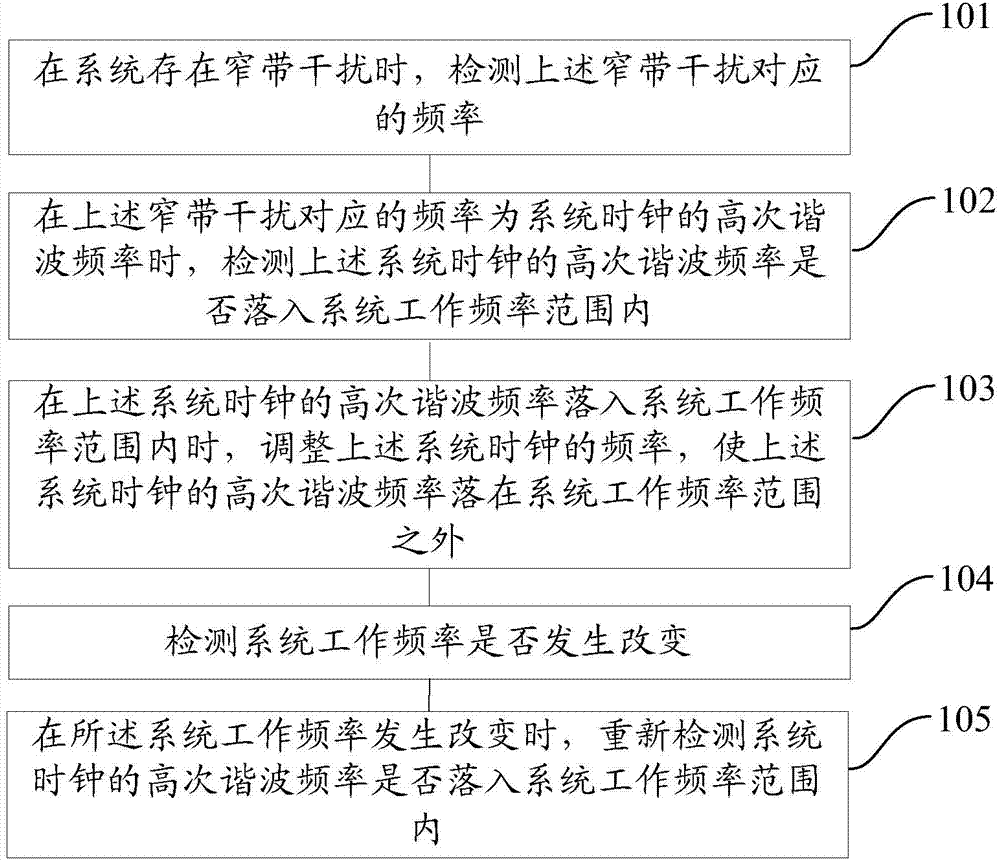

Method and device of restraining narrow-band interference

The invention provides a method and a device of restraining narrow-band interference. The method specifically comprises the following steps of detecting a frequency which corresponds to the narrow-band interference when a system has the narrow-band interference; detecting whether a higher harmonic frequency of a system clock falls into the operating frequency range of the system when the frequency which corresponds to the narrow-band interference is the higher harmonic frequency of the system clock; when the higher harmonic frequency of the system clock falls into the operating frequency range of the system, adjusting the frequency of the system clock so as to cause the higher harmonic frequency of the system clock to fall out of the operating frequency range of the system. According to the method and the system, the influence of the narrow-band interference of the system on the system performance is solved, and the equipment cost is reduced.

Owner:INNOFIDEI TECHNOLOGIES INC

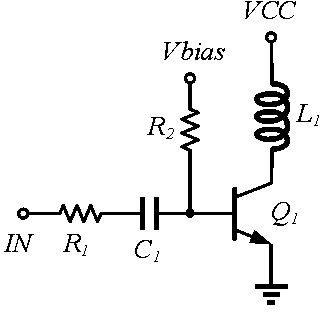

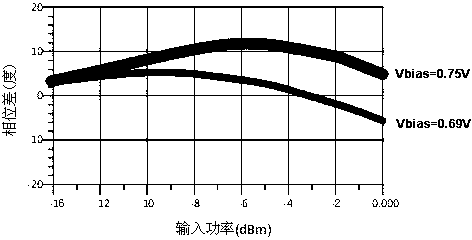

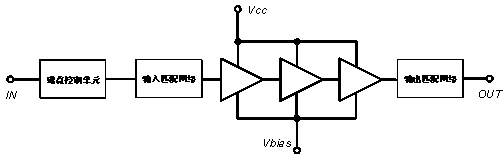

Gain control method for radio frequency power amplifier

InactiveCN103812463AGuaranteed performance consistencyUnchanged working statusGain controlTransceiverEngineering

The invention provides a gain control method for a radio frequency power amplifier. A gain control unit is concatenated before radio frequency signals are inputted to a matching network and provides at least two different radio frequency passages, and each radio frequency passage has different damping capacities for the radio frequency signals. Generally, impedance inputted and outputted by each radio frequency passage is matched with radio frequency system characteristic impedance, the gain control unit provides different radio frequency damping capacities in different gain / power modes, the input and output impedance states of the gain control unit remain unchanged in different damping capacity states, the working states of active devices in the radio frequency power amplifier constantly remain unchanged, so that phase characteristics and linearity remain unchanged, the input and output impedance states of the radio frequency power amplifier in different gain / power modes also remain unchanged, and the impedance of the radio frequency power amplifier is matched with that of a radio frequency transceiver, so that performance consistency of the radio frequency power amplifier and a whole radio frequency front end system is furthest ensured.

Owner:智坤(江苏)半导体有限公司 +1

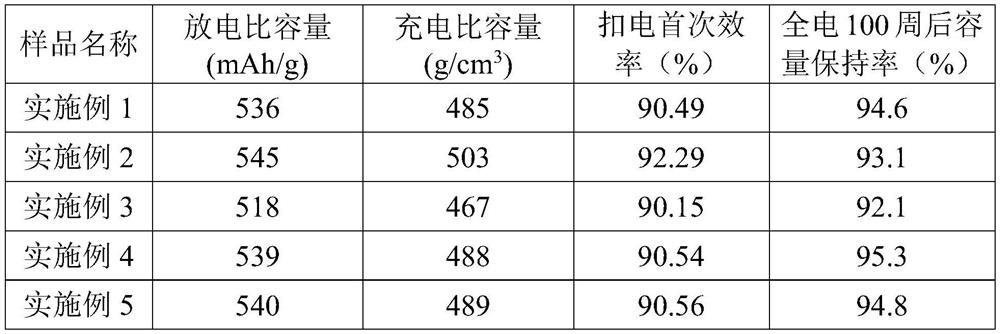

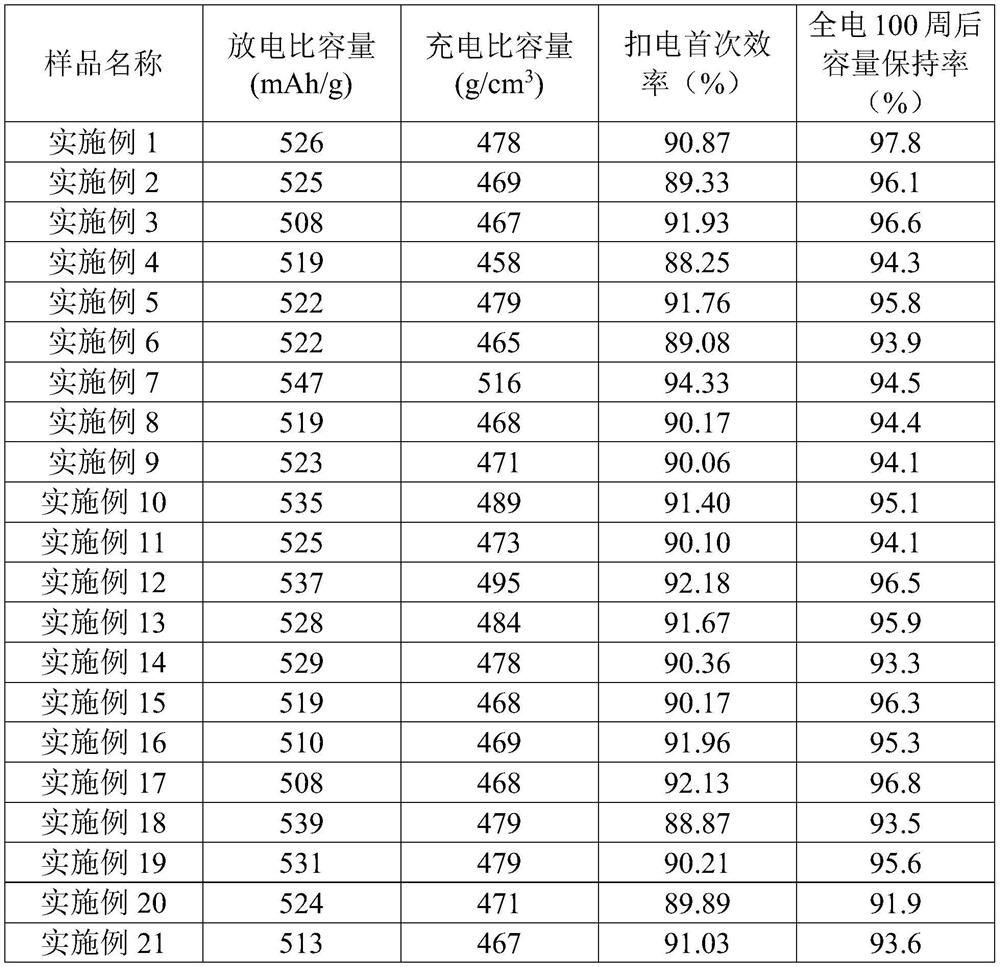

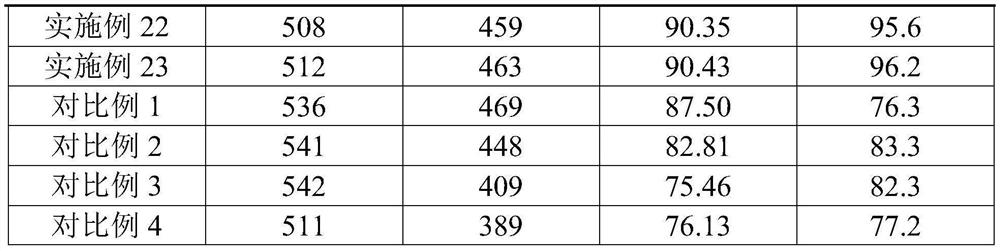

Hard carbon negative electrode composite material and preparation method and application thereof

InactiveCN113184827AMake up for consumptionReduce generationNegative electrodesCarbon preparation/purificationCarbon coatingElectrolytic agent

The invention relates to a hard carbon negative electrode composite material and a preparation method and application thereof, and the preparation method comprises the following steps: pretreating a carbon-containing raw material to prepare a hard carbon precursor; mixing the hard carbon precursor with a lithium-containing compound and a binder to prepare a solid pre-lithiated hard carbon precursor; carrying out sintering treatment on the pre-lithiated hard carbon precursor to prepare pre-lithiated hard carbon; and carrying out carbon coating treatment on the pre-lithiated hard carbon to form a carbon coating layer on the surface of the pre-lithiated hard carbon. Exogenous lithium is introduced into the surface and the bulk phase of hard carbon to form a lithium-carbon compound, so that a certain amount of lithium is filled in a stable structure and pores of the hard carbon in advance, and the consumption of effective lithium in the battery caused by first formation is made up. A carbon coating layer is matched to reduce the defects of the hard carbon surface and cover the lithium-carbon compound with relatively high chemical activity, so that the lithium supplement effect can be achieved, the side reaction of an active substance and an electrolyte can be reduced, the first coulombic efficiency can be synergistically improved, and the cycle life of the battery can be prolonged.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

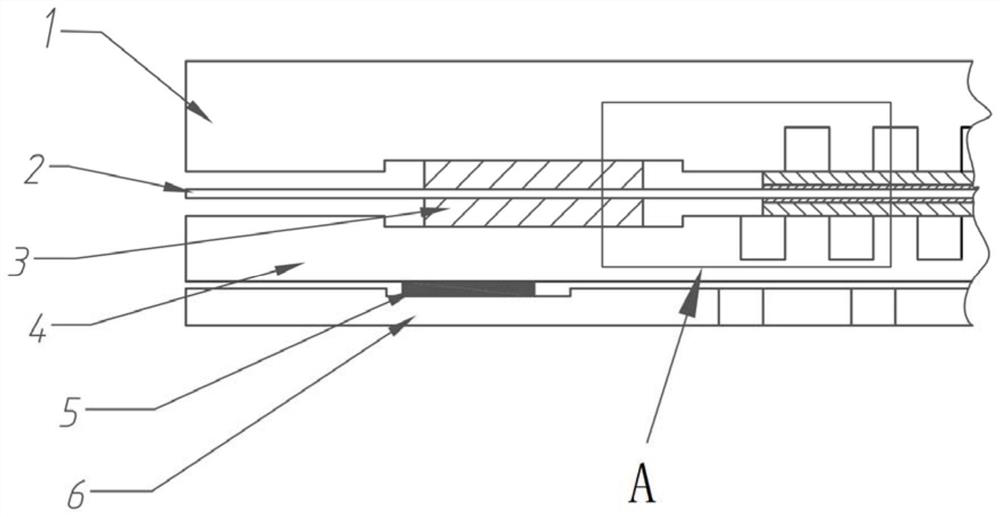

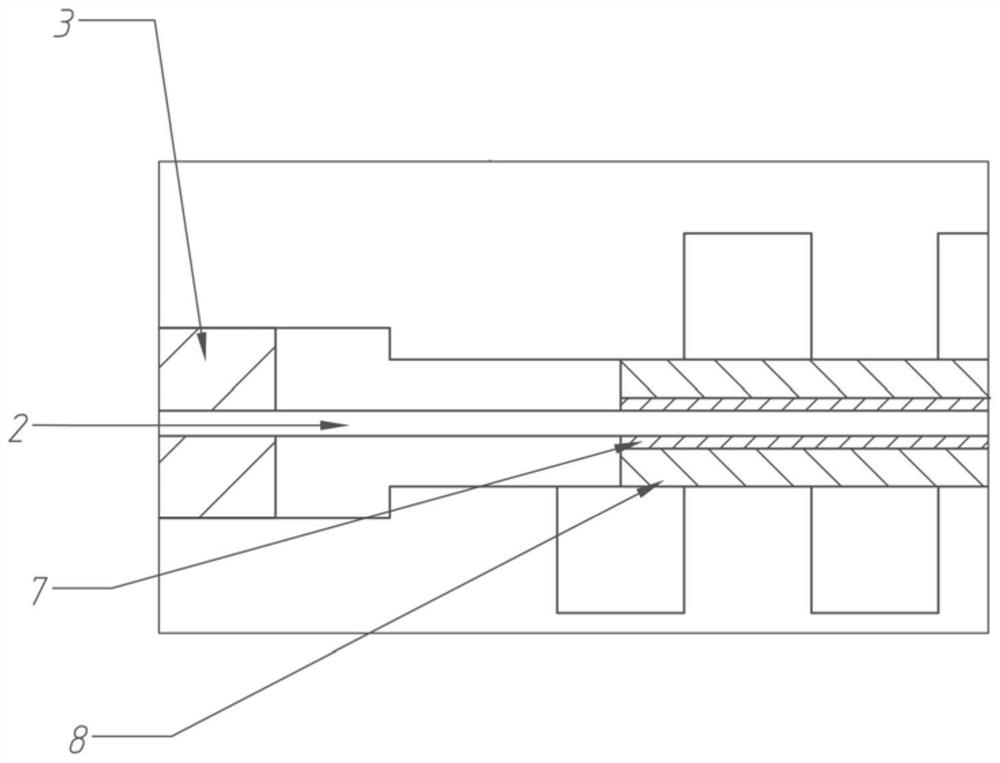

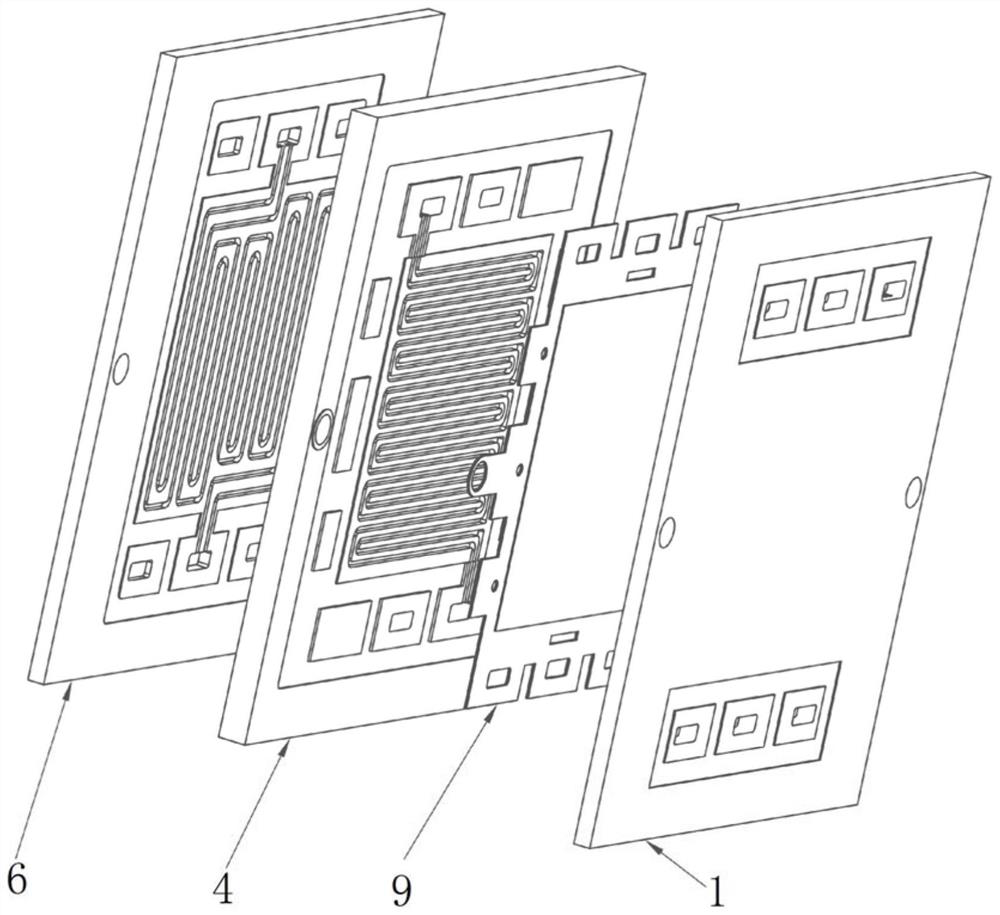

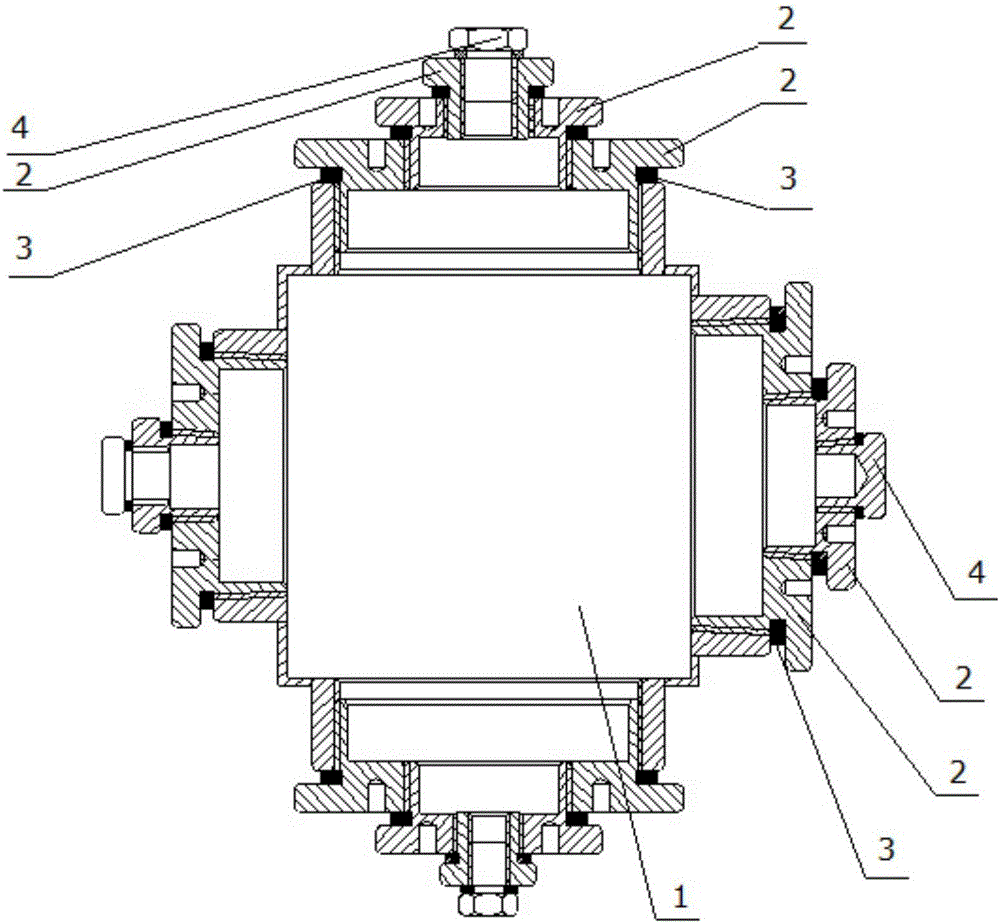

Integrated fuel cell unit cell and fuel cell stack

PendingCN111883797AThere is no problem of thickness size differenceNo compression issuesCollectors/separatorsChemical physicsFuel cells

The invention relates to an integrated fuel cell single cell and a fuel cell stack. The cell stack is formed by stacking and assembling a plurality of single cells, and each single cell comprises a cathode plate, a proton exchange membrane, an anode plate and a water plate which are stacked in sequence, wherein a catalyst layer and a gas diffusion layer are laminated on the front surface and the back surface of the proton exchange membrane at the flow field positions of the cathode plate and the anode plate, the peripheral side of the proton exchange membrane is fixed in the membrane electrodesupport body, and the proton exchange membrane and the membrane electrode support body form a complete plane; the membrane electrode support body, the proton exchange membrane, the catalytic layer and the gas diffusion layer are clamped between the cathode plate and the anode plate as a whole, and the cathode plate and the anode plate are hermetically connected through injected sealant. Comparedwith the prior art, the cell stack has the advantages of stable structure, excellent sealing performance, good durability, high power generation performance and the like.

Owner:TONGJI UNIV

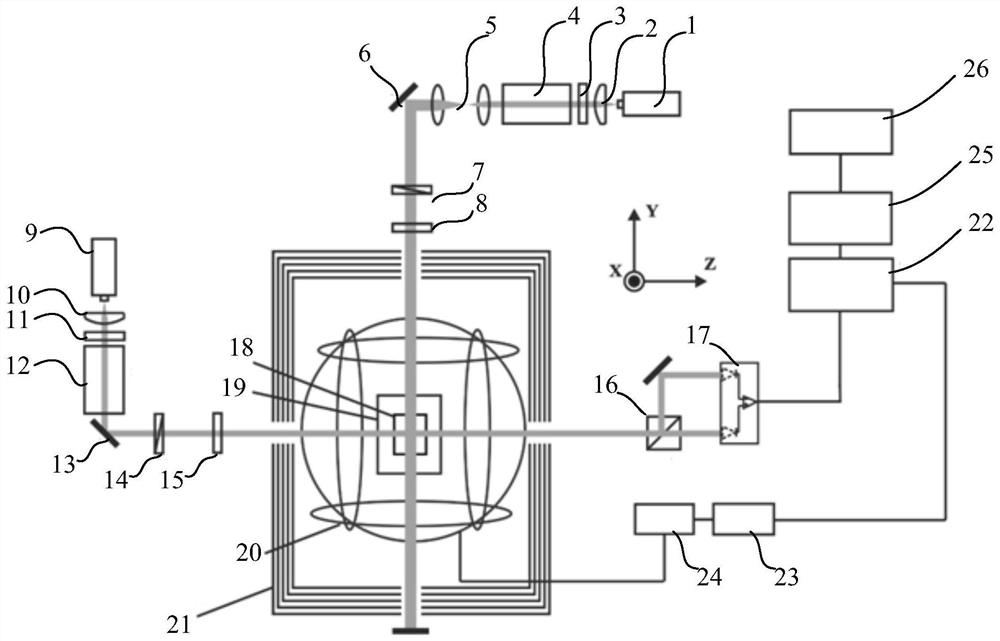

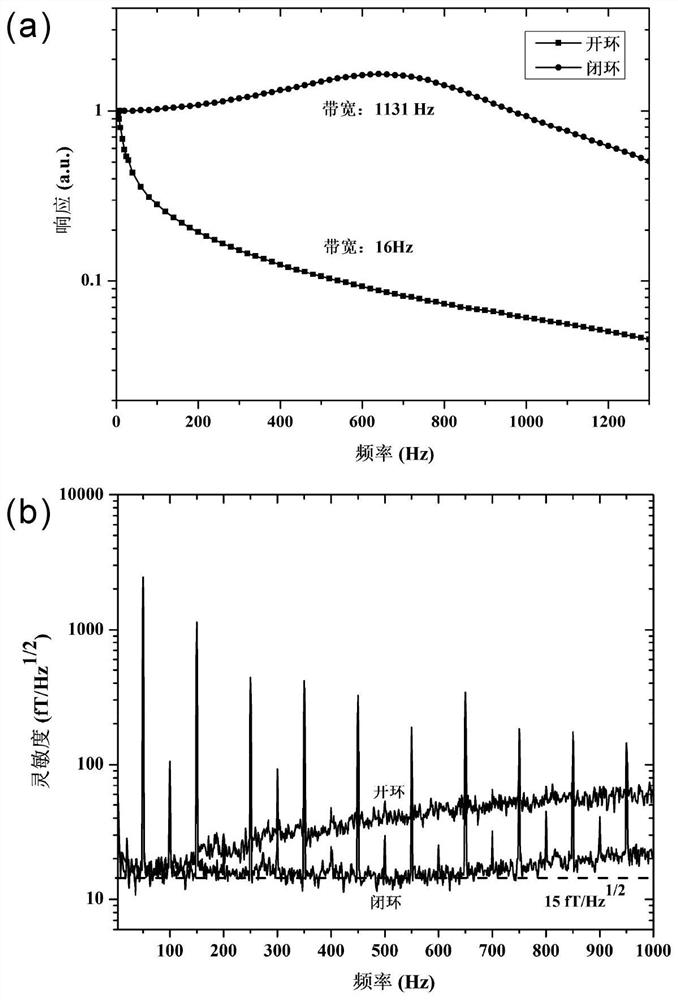

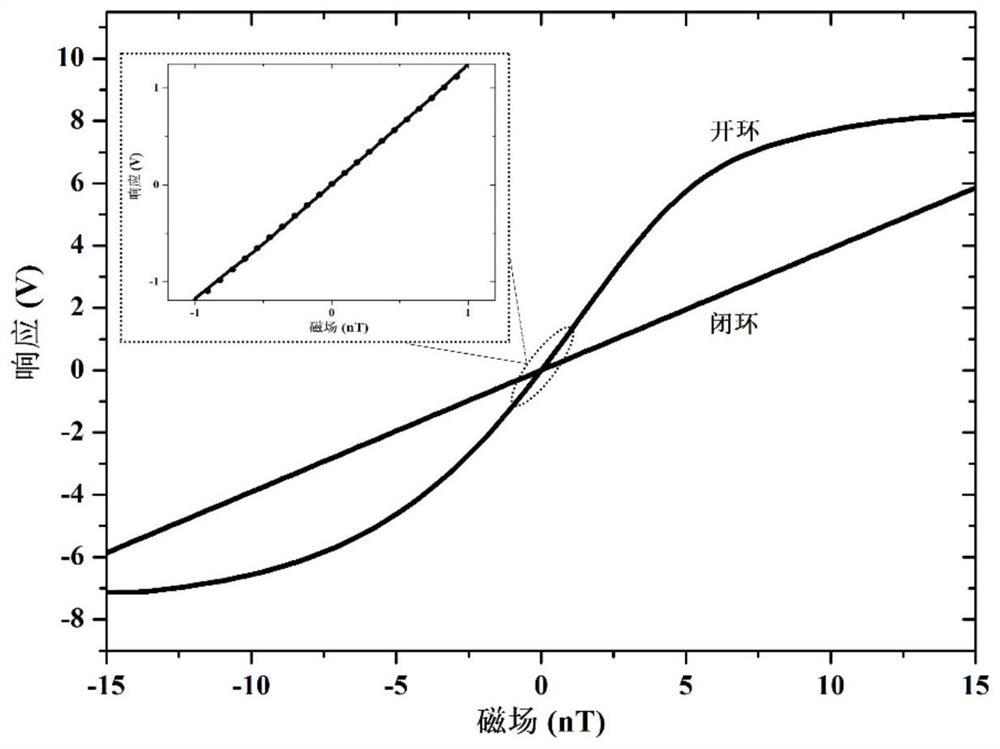

High-bandwidth high-sensitivity closed-loop SERF atom magnetometer device

ActiveCN112505595AImprove frequency response -3dB bandwidthImprove high-frequency detection sensitivityWater resource assessmentMagnetic field measurement using magneto-optic devicesHigh bandwidthLoop control

The invention provides a high-bandwidth high-sensitivity closed-loop SERF atom magnetometer device, which is characterized in that PID is introduced to form closed-loop control, so that the frequencyresponse -3dB bandwidth of a system is greatly improved, the kHz level can be reached, and the high-frequency detection sensitivity is improved. In addition, the bandwidth and the sensitivity curve ofthe SERF atom magnetometer can be freely and accurately controlled by adjusting three parameters of P, I and D, so that the sensitivity of the frequency range required by actual measurement reaches the highest. Besides, the measured magnetic field is compensated in real time through PID control, and the magnetic field in the direction of the detection axis is always locked at the zero point position, so that the response linear interval and the magnetic field measurement dynamic range of the device are greatly improved, and the shielding requirement on the external environment is weakened.

Owner:JIHUA LAB

Pulsed laser deposition device and method

PendingCN113445007AReduce energy lossImprove stabilityVacuum evaporation coatingSputtering coatingDeposition processPulsed laser deposition

The invention discloses a pulsed laser deposition device. The pulsed laser deposition device comprises a reaction cavity, a plurality of target machines, and a plurality of laser devices, wherein the reaction cavity is internally provided with a supporting column used for fixing a substrate table, a first heating element located above the substrate table and a second heating element located below the substrate table, target materials are fixed at the second ends of the target machines, the target materials are located above and / or below the substrate table in the reaction cavity, included angles are formed between the surfaces of the target materials and the surface of the substrate table, the plurality of laser devices respectively generate laser beams, the first heating element and the second heating element are both provided with notches, and the laser beams linearly reach the surfaces of the target materials in the direction parallel to the surface of the substrate table, and plasma formed by irradiating the surfaces of the target materials through the laser beams reaches the surface of the substrate table through the notches in the first heating element and the second heating element. According to the pulsed laser deposition device, a double-sided skew symmetry deposition process is adopted, so that film deposition can be carried out on both sides of the substrate table, and large-area, large-batch and high-quality film preparation is realized.

Owner:SONGSHAN LAKE MATERIALS LAB

Hard carbon negative electrode composite material and preparation method and application thereof

InactiveCN113184828AImprove conductivityIncrease loadNegative electrodesCarbon preparation/purificationCarbon coatingLithium compound

The invention relates to a hard carbon negative electrode composite material and a preparation method and application thereof, and the preparation method comprises the following steps: carrying out pre-oxidation treatment on a carbon source to prepare a pre-oxidized carbon source; mixing the pre-oxidized carbon source with a pore-forming agent, and preparing a hard carbon precursor with a pore structure through heat treatment; mixing the hard carbon precursor with a lithium-containing compound solution, and preparing a solid pre-lithiated hard carbon precursor by a solvothermal method; and performing carbon coating treatment on the pre-lithiated hard carbon precursor to form a carbon coating layer on the surface of the pre-lithiated hard carbon precursor. The pore-forming is beneficial to firm adhesion of a lithium-containing compound in the hard carbon or on the surface of the hard carbon in the pre-lithiation process; the hard carbon precursor is pre-lithiated by adopting a liquid phase-solvothermal method, so that the adhesive force can be enhanced, and the first-effect improvement amplitude of the pre-lithiated hard carbon can be accurately controlled by accurately controlling the addition amount of a lithium source; and the carbon coating layer can cover the lithium-carbon compound with high chemical activity, reduces the defects on the hard carbon surface, and synergistically improves the first coulombic efficiency and prolongs the cycle life of the battery.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Anti-impact and anti-corrosion coating

InactiveCN104194537AImprove wear resistanceIncrease elasticityChloropene polymer coatingsAnti-corrosive paintsSodium BentoniteAcrylic resin

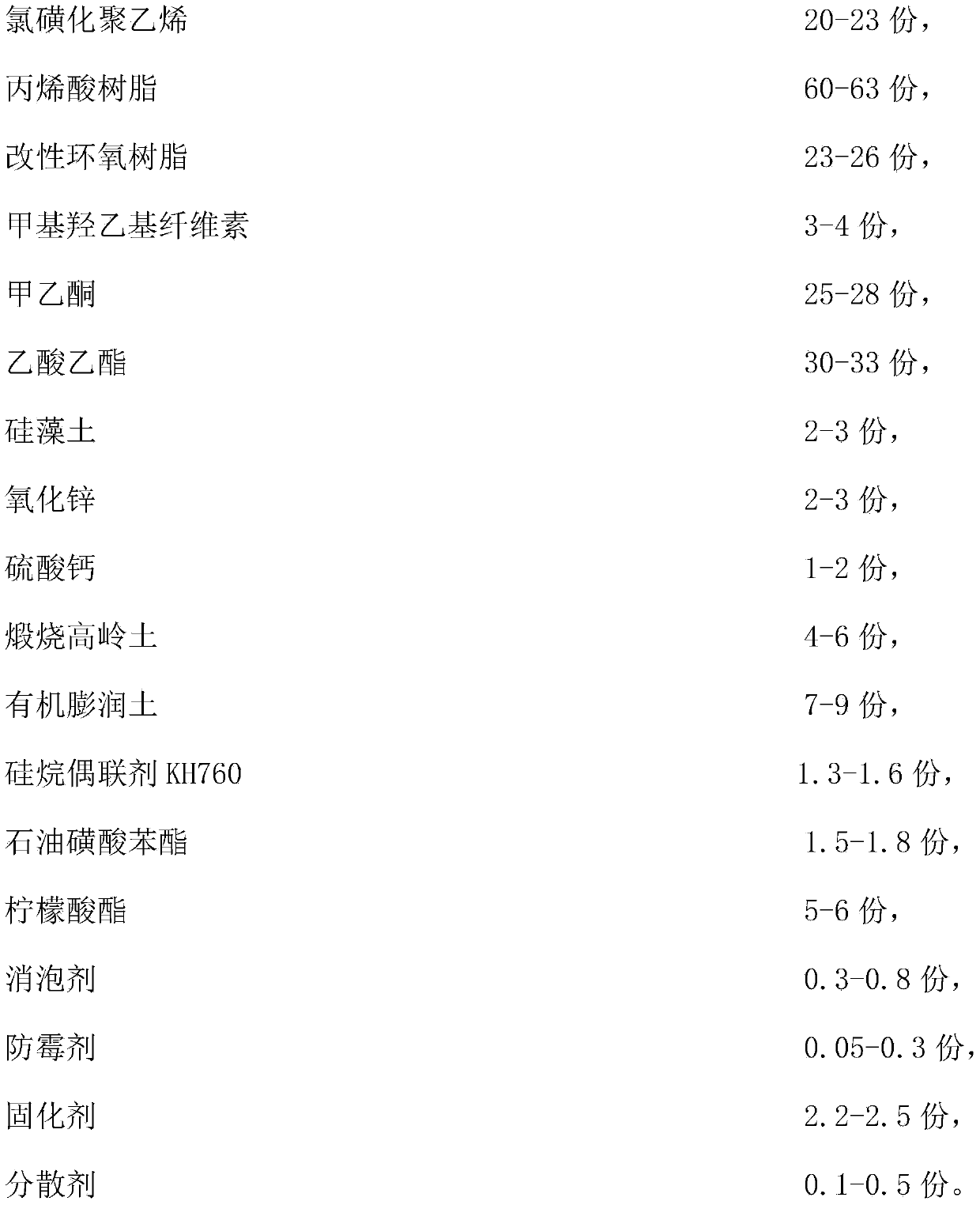

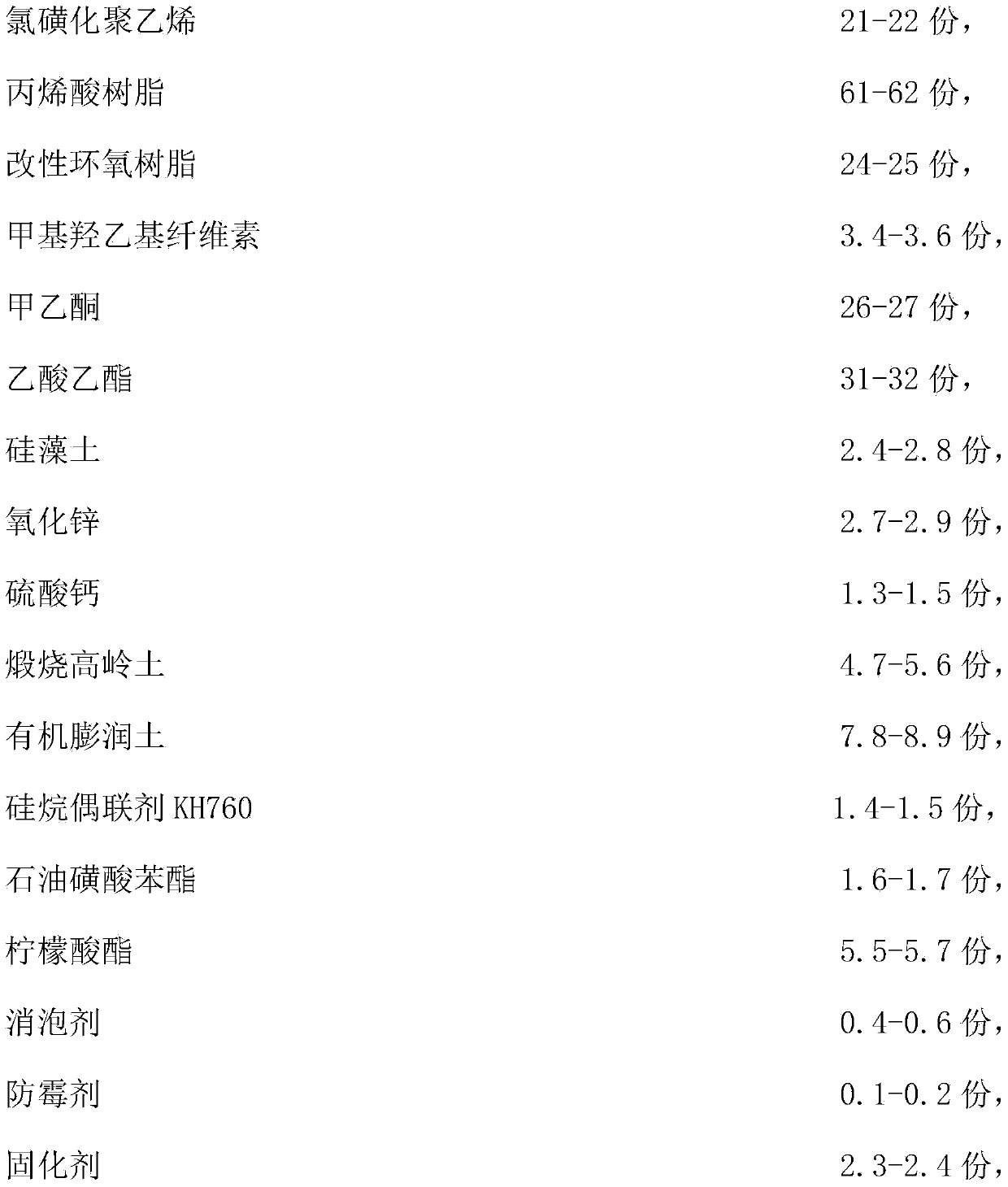

The invention discloses an anti-impact and anti-corrosion coating which comprises the raw materials in parts by weight: 20-23 parts of chlorosulfonated polyethylene, 60-63 parts of acrylic resin, 23-26 parts of modified epoxy resin, 3-4 parts of methyl hydroxyethyl cellulose, 25-28 parts of methyl ethyl ketone, 30-33 parts of ethyl acetate, 2-3 parts of kieselguhr, 2-3 parts of zinc oxide, 1-2 parts of calcium sulfate, 4-6 parts of calcined kaolin, 7-9 parts of organic bentonite, 1.3-1.6 parts of silane coupling agent KH760, 1.5-1.8 parts of phenyl petroleum sulfonate, 5-6 parts of citrate ester, 0.3-0.8 part of a defoaming agent, 0.05-0.3 part of a mildew preventive, 2.2-2.5 parts of a solidifying agent and 0.1-0.5 part of a dispersing agent. The anti-impact and anti-corrosion coating is excellent in impact resistance and corrosion resistance, is high in abrasion resistance and oil resistance, and is high in stability.

Owner:株洲四方威凯新材料有限公司

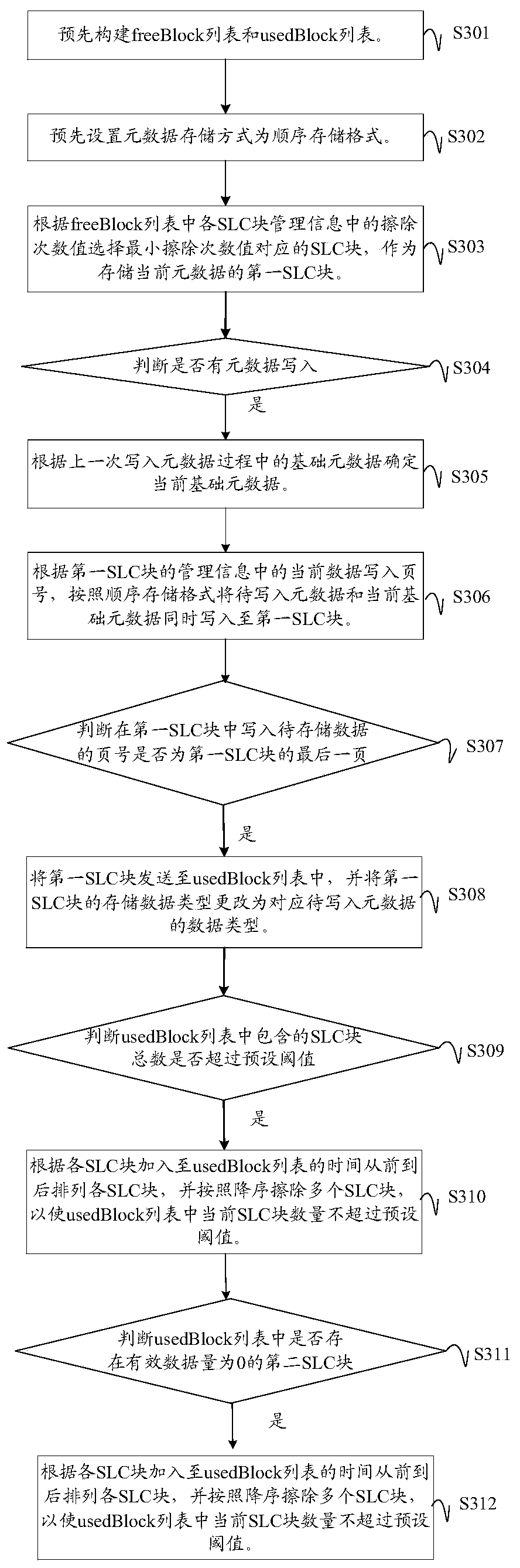

Metadata storage management method and device for solid state disk, equipment and storage medium

ActiveCN110673789AImprove stabilityGuaranteed performance consistencyInput/output to record carriersEnergy efficient computingData classMetadata management

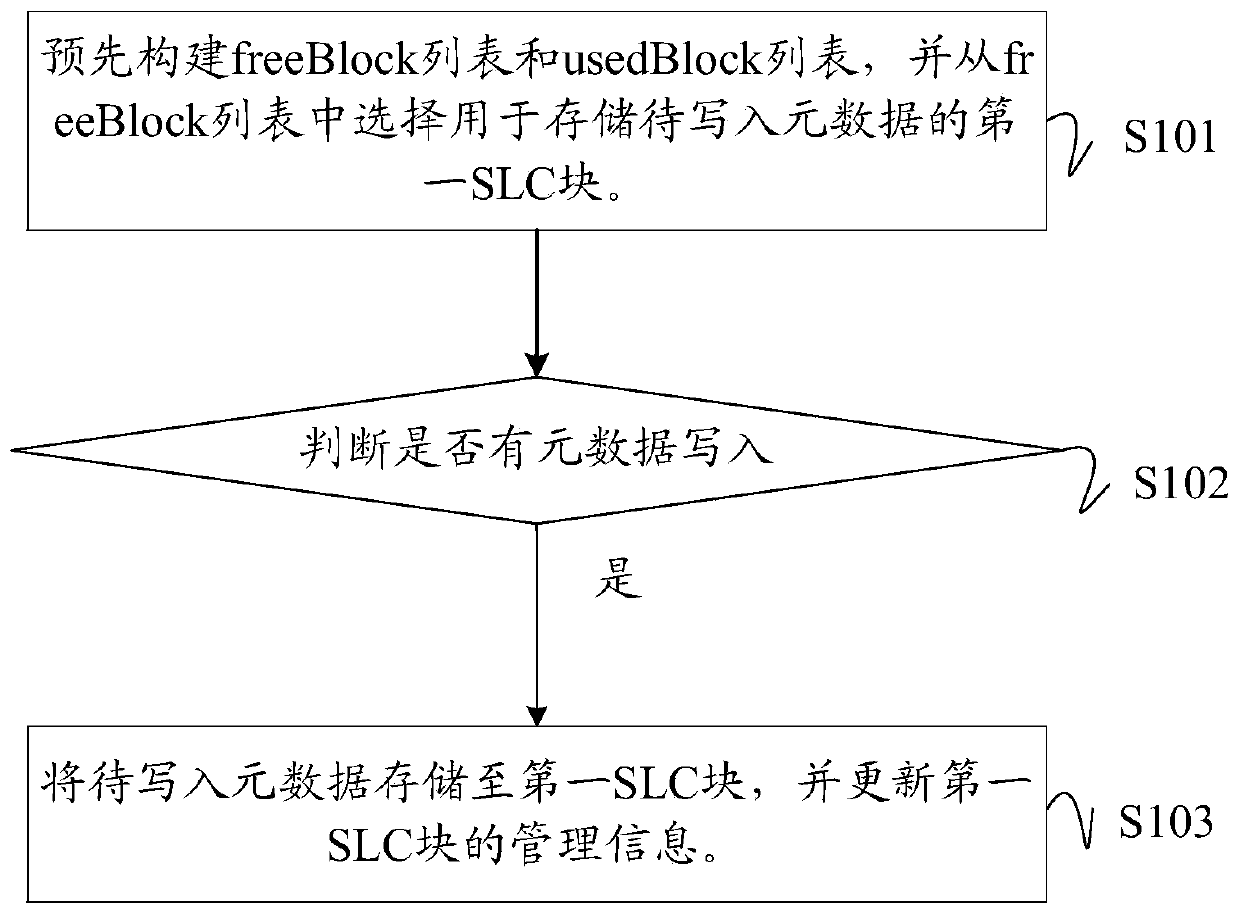

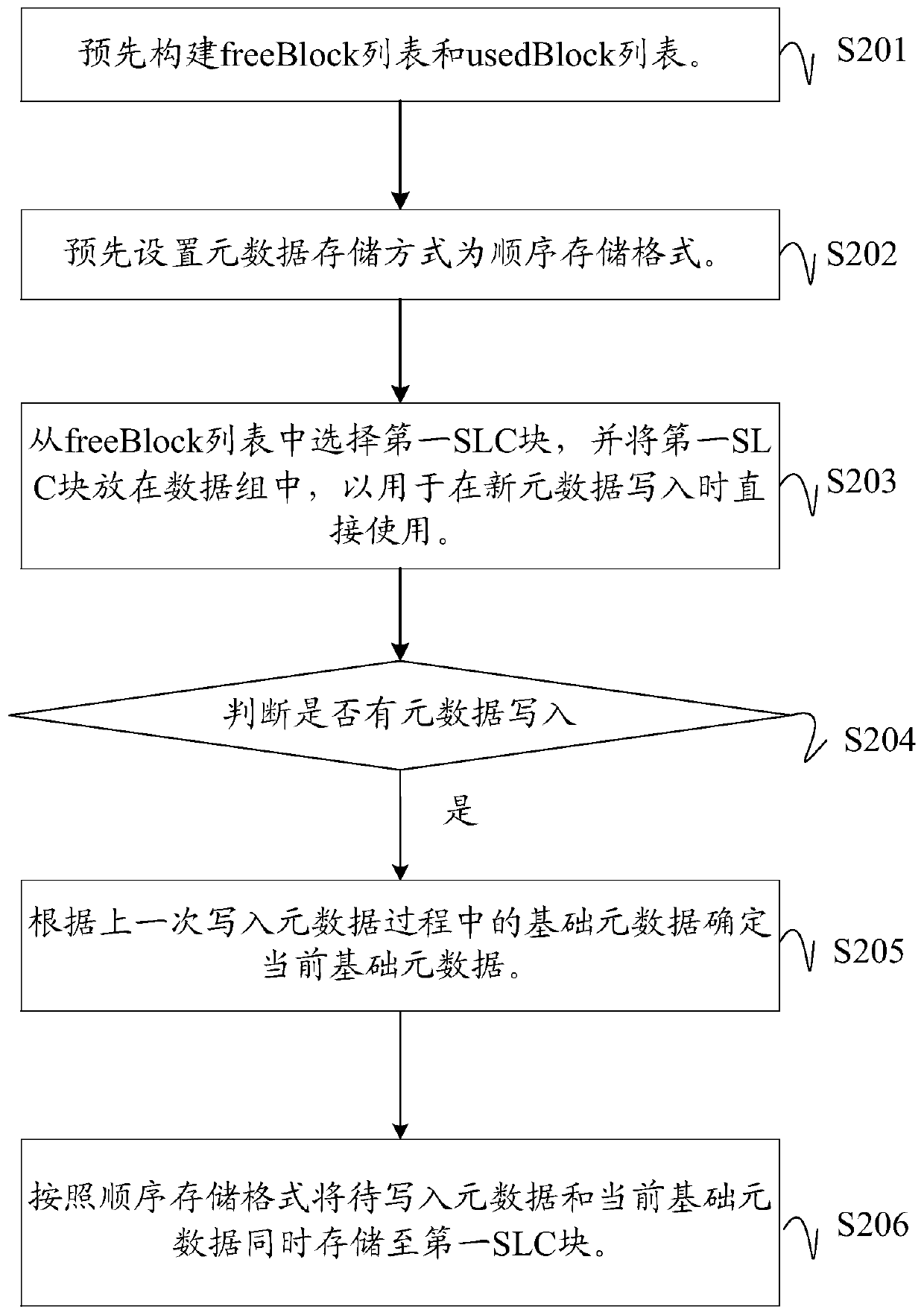

The embodiment of the invention discloses a metadata storage management method, device and equipment of a solid state disk and a computer readable storage medium. The method is applied to a solid state disk quota metadata management module. The metadata management module is used for managing metadata of the solid state disk and SLC blocks for storing the metadata. The method comprises the steps that a freeBlock list used for storing the SLC blocks into which data are not written and a usedBlock list used for storing the SLC blocks into which data are fully written are constructed in advance, and the first SLC block used for storing metadata to be written is selected from the freeBlock list; and when it is detected that metadata to be written in is written in, the metadata to be written inis stored in the first SLC block, and management information of the first SLC block is updated, wherein the management information comprises a storage data type, erasure times, a current data write-inpage number and read-write-erasure error information. According to the technical scheme, the accuracy of metadata stored in the solid state disk can be effectively guaranteed, so that the stability of the solid state disk is improved, and the fault probability is reduced.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

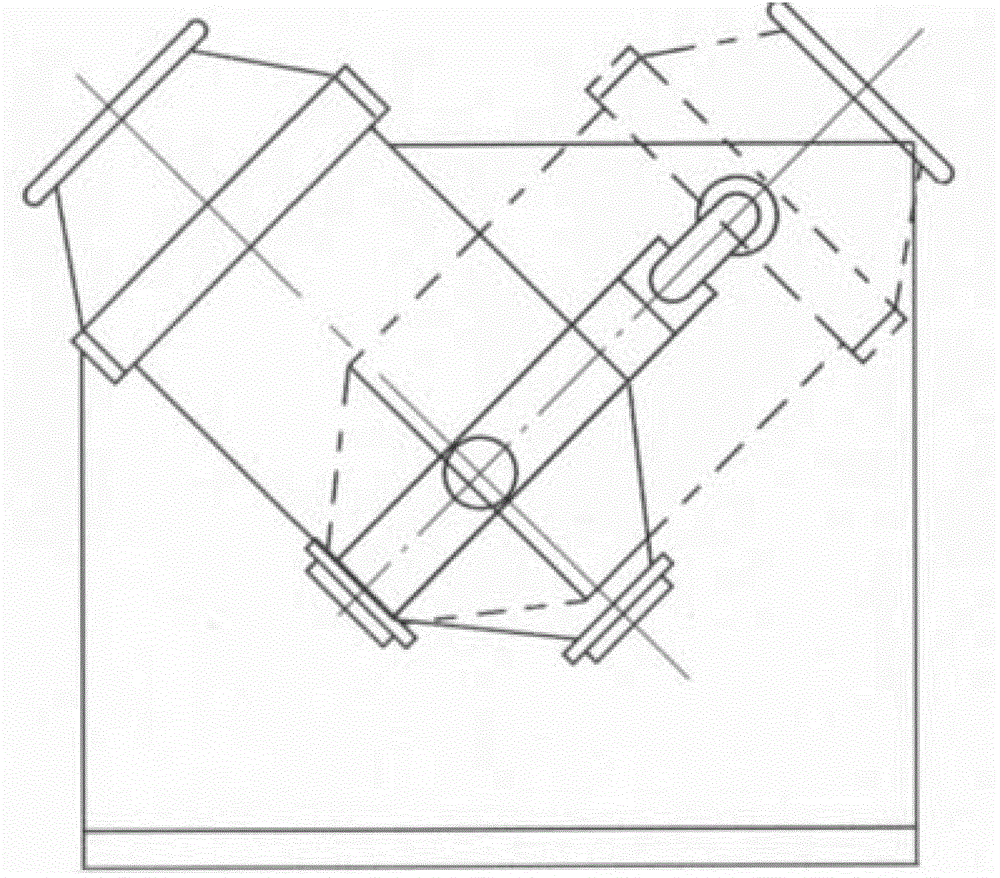

Mixer

The invention provides a mixer which comprises a feeding mechanism, a mixing mechanism and a preservation mechanism, wherein the feeding mechanism comprises a feeding bin; a stirring shaft is arranged on the center of the feeding bin; at least two stirring rods are symmetrically arranged on the stirring shaft; the mixing mechanism comprises a horizontal stirring bin; a stirring long shaft is arranged on the shaft center of the stirring bin; stirring blades are arranged on the stirring long shaft; the preservation mechanism comprises a preservation chamber; the preservation chamber is communicated with the stirring bin through a discharge hole; the stirring long shaft drives a linkage shaft to rotate through a steering gear; the top of the linkage shaft is connected to the top of the preservation chamber through a linkage base; and a discharge pipeline is arranged on the bottom of the preservation chamber. The mixer provided by the invention has the following advantages: by virtue of precise control of the preservation chamber, performance temperature of mixed raw materials can be kept, so that performance consistence of a formed product is guaranteed. The equipment is simple in structure, is automatic in operation, is low in energy consumption and is labor-saving.

Owner:天津德迈特汽车零部件有限公司

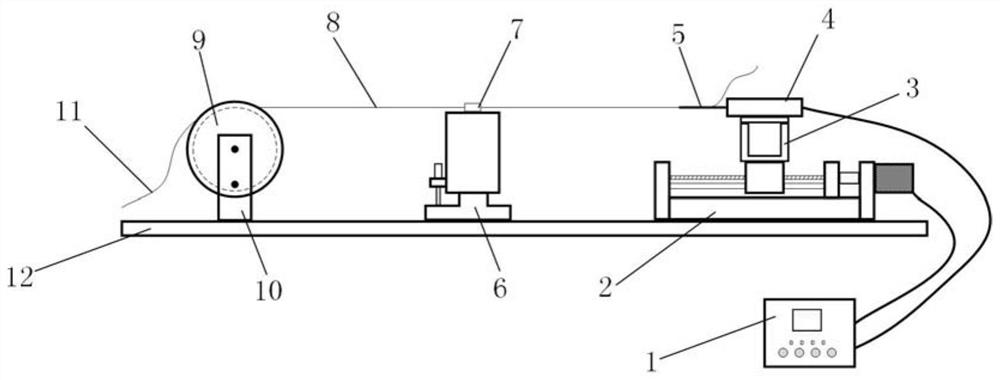

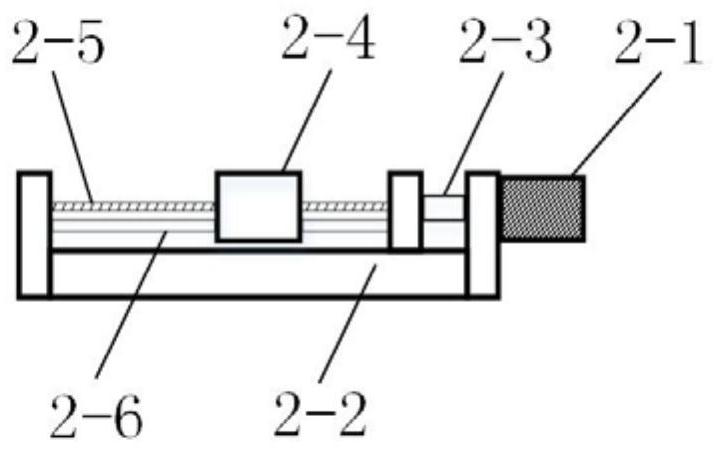

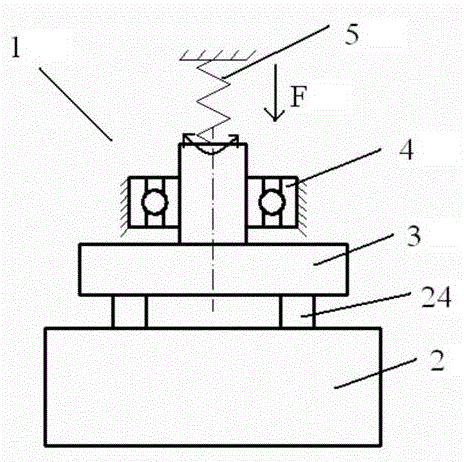

Optical fiber sensor packaging process prestress automatic control device and method

InactiveCN112710336AControl precise controlHigh control precisionProgramme controlComputer controlAutomatic controlEngineering

The invention discloses an optical fiber sensor packaging process prestress automatic control device and method. The device comprises a control module, a displacement module, a tension meter, a fine adjustment module, an optical fiber winding wheel and a base; the fine adjustment module is used for supporting an optical fiber sensor packaging structure, and the height of the fine adjustment module can be adjusted, so that an optical fiber is not subjected to external force in a vertical direction; one end of an optical fiber sensor tail fiber is wound and fixed on the optical fiber winding wheel, and the other end of the optical fiber sensor tail fiber is fixed on a tension meter connecting rod; the tension meter is installed on the displacement module through a supporting piece, moves in the direction of stretching or loosening the optical fiber along with the displacement module, sends a tension value to the control module in real time; and the control module compares the real-time tension value with a preset tension value to make a decision to control the displacement of the tension meter. According to the optical fiber sensor packaging process prestress automatic control device, closed-loop control can be performed on the prestress of an optical fiber sensor according to a preset value; the control device is simple in structure and high in control precision, can be copied, and can easily realize batch packaging of optical fiber sensors.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

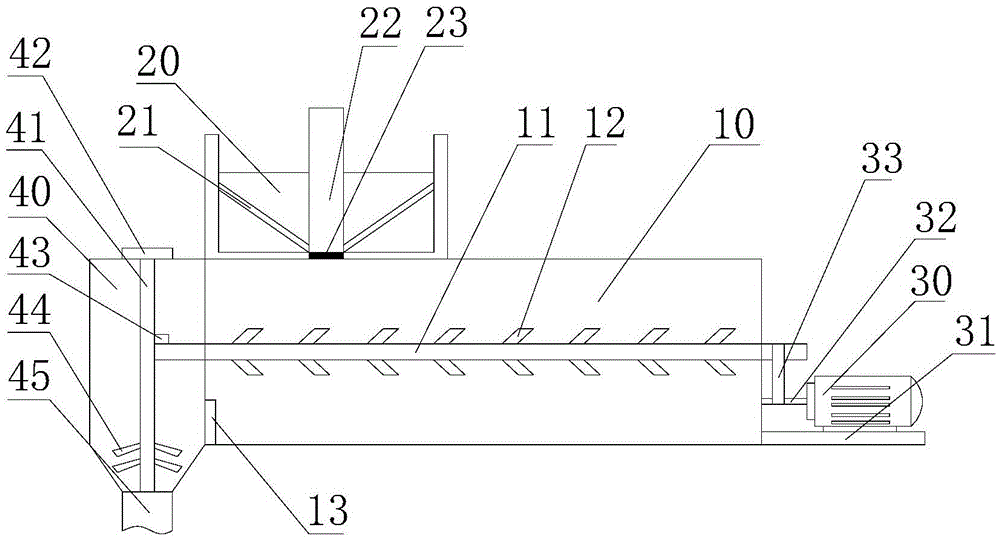

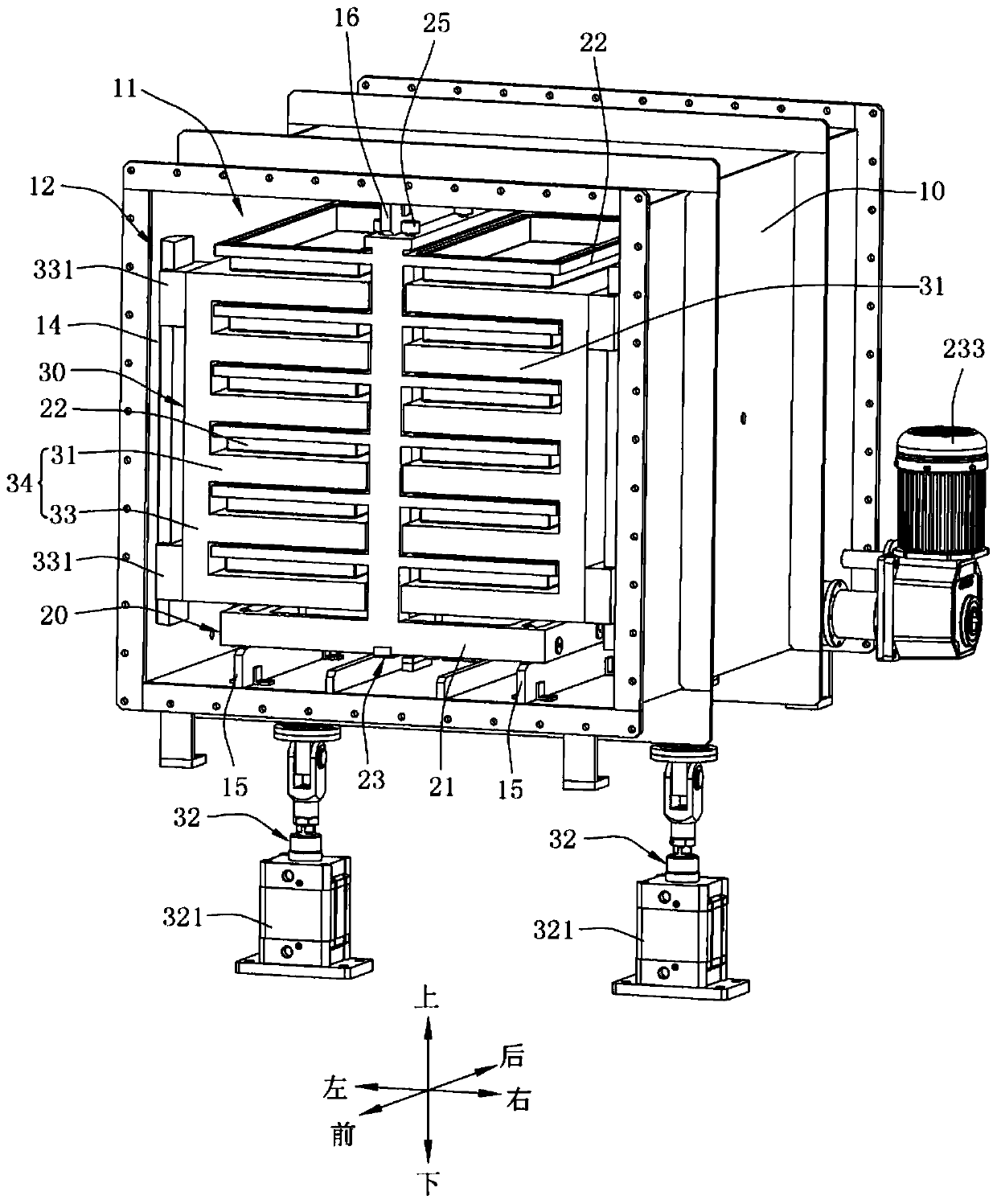

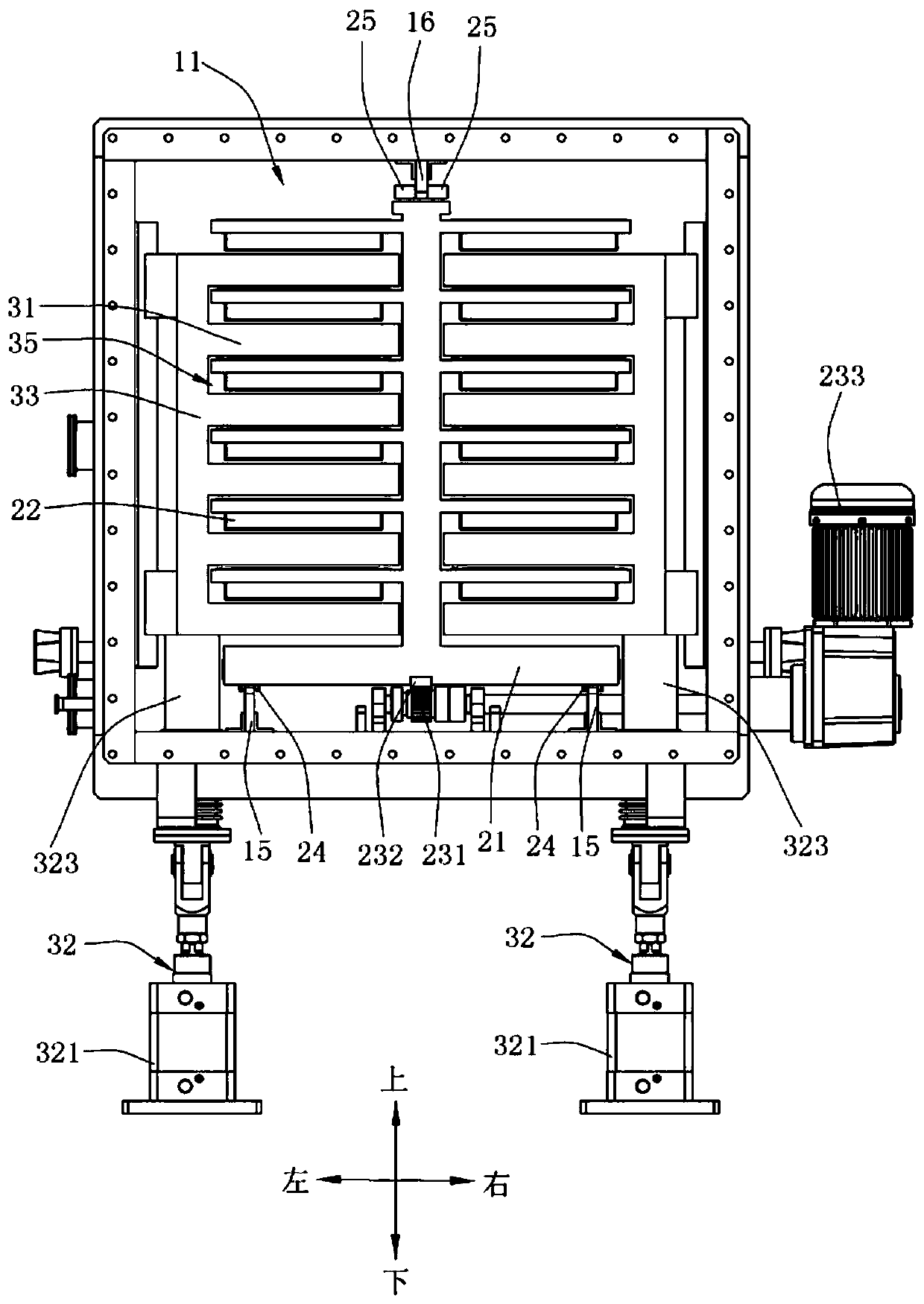

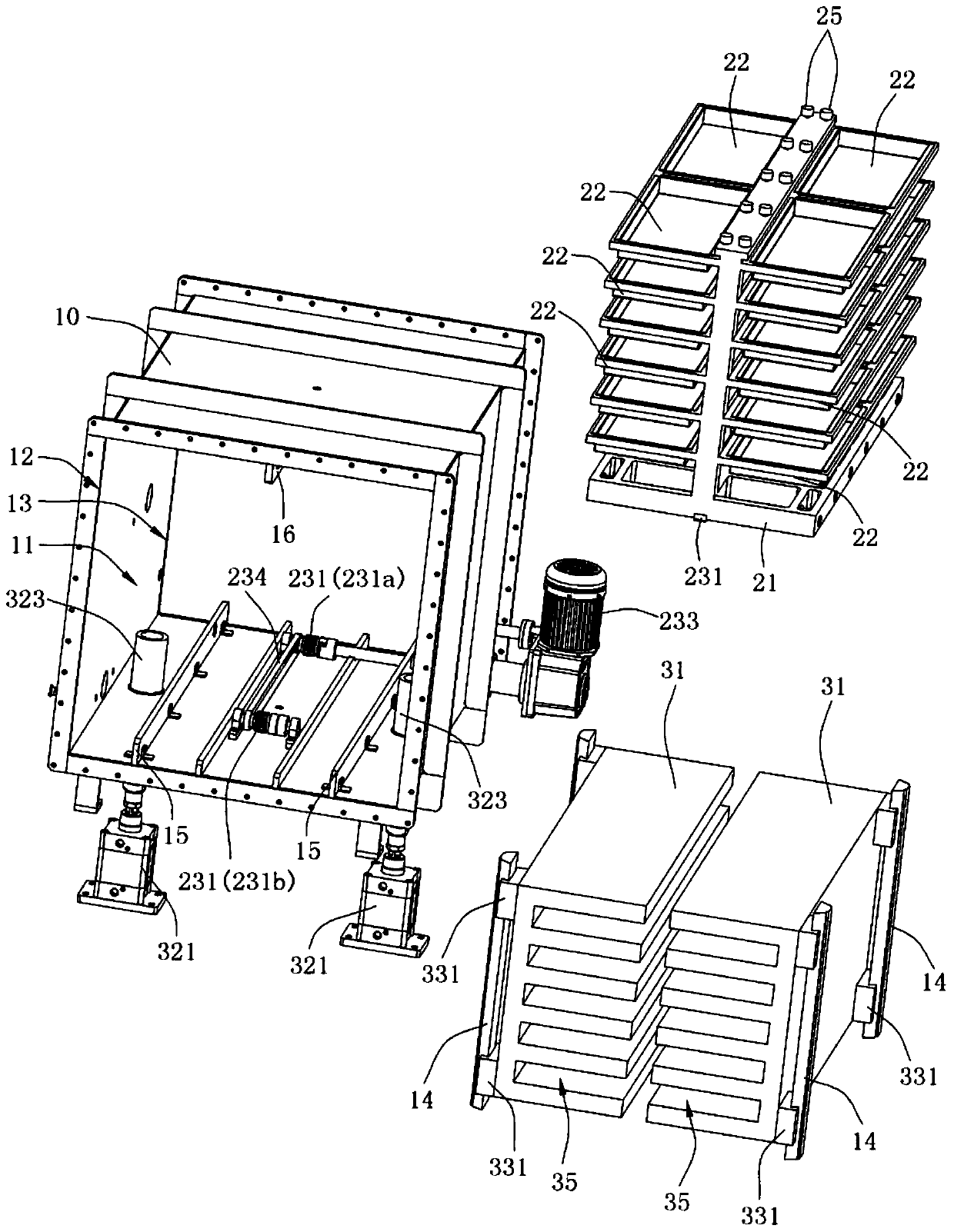

Powder heating and drying device

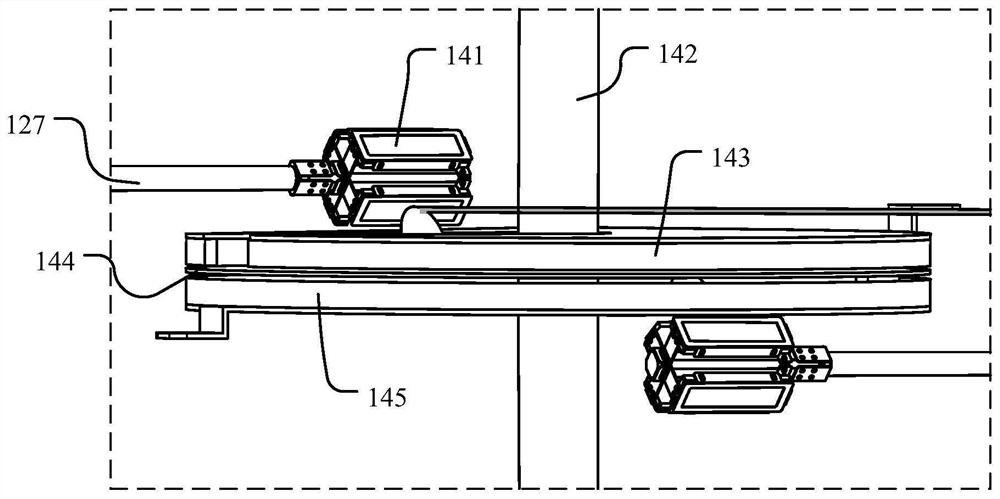

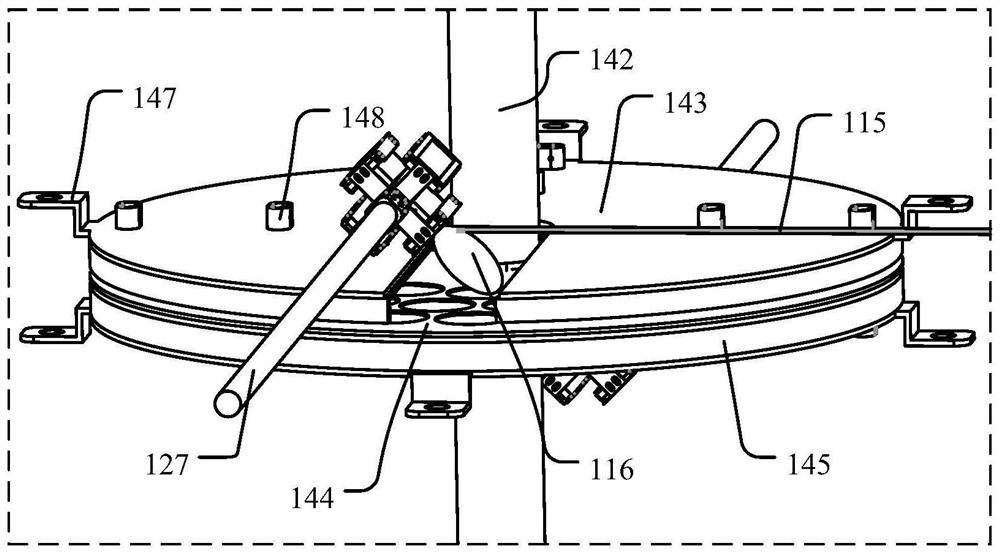

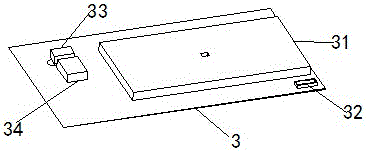

PendingCN111412727AImprove heating uniformityGuaranteed performance consistencyDrying solid materials with heatDrying solid materials without heatVacuum dryingBattery cell

The invention discloses a powder heating and drying device. The powder heating and drying device comprises a drying furnace, a material conveying mechanism, and a heating mechanism, wherein a vacuum drying cavity is formed inside the drying furnace; the material conveying mechanism comprises a material conveying vehicle, material boxes and a first driving assembly, the material boxes are arrangedon the material conveying vehicle, and the first driving assembly is used for driving the material conveying vehicle to enter and exit the vacuum drying cavity in the material conveying direction; andthe heating mechanism comprises heating plates and a second driving assembly, the heating plates are contained in the vacuum drying cavity, and the second driving assembly is used for driving the heating plates to make contact with or be separated from the material boxes. The powder heating and drying device has the advantages of being fast in heating speed, high in heating efficiency and high inheat effective value utilization, and the rapid and effective drying treatment process of battery powder or medicine powder and the like in the material boxes is achieved; and moreover, a contact type heating and heat radiation heating dual-heating mode is adopted, and the material boxes are uniformly heated favorably, so that the heating uniformity of materials such as the battery powder or themedicine powder is improved, the performance consistency of batteries or medicines and the like is maintained favorably, and the product yield is improved.

Owner:SHENZHEN TIME HIGH TECH EQUIP

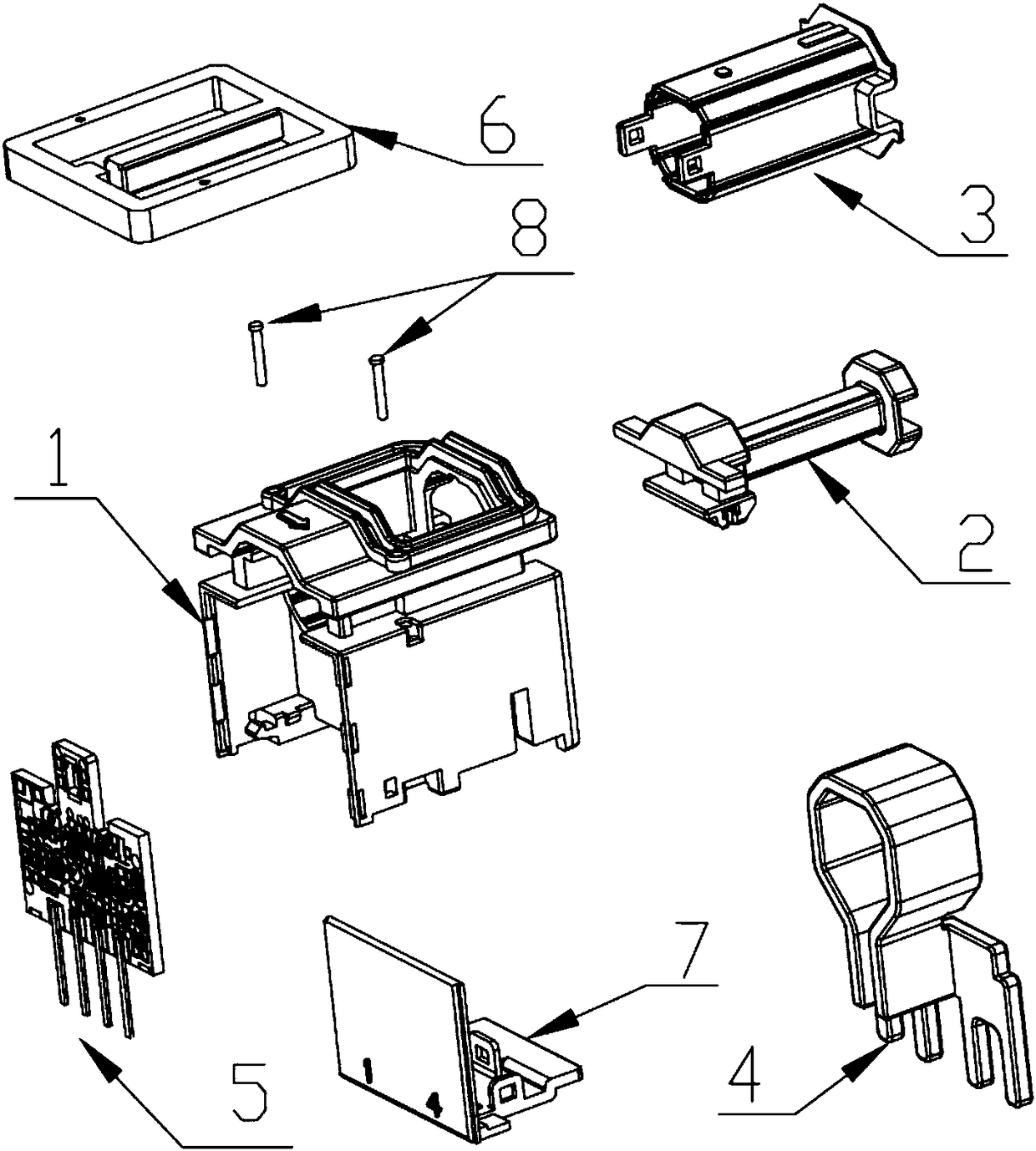

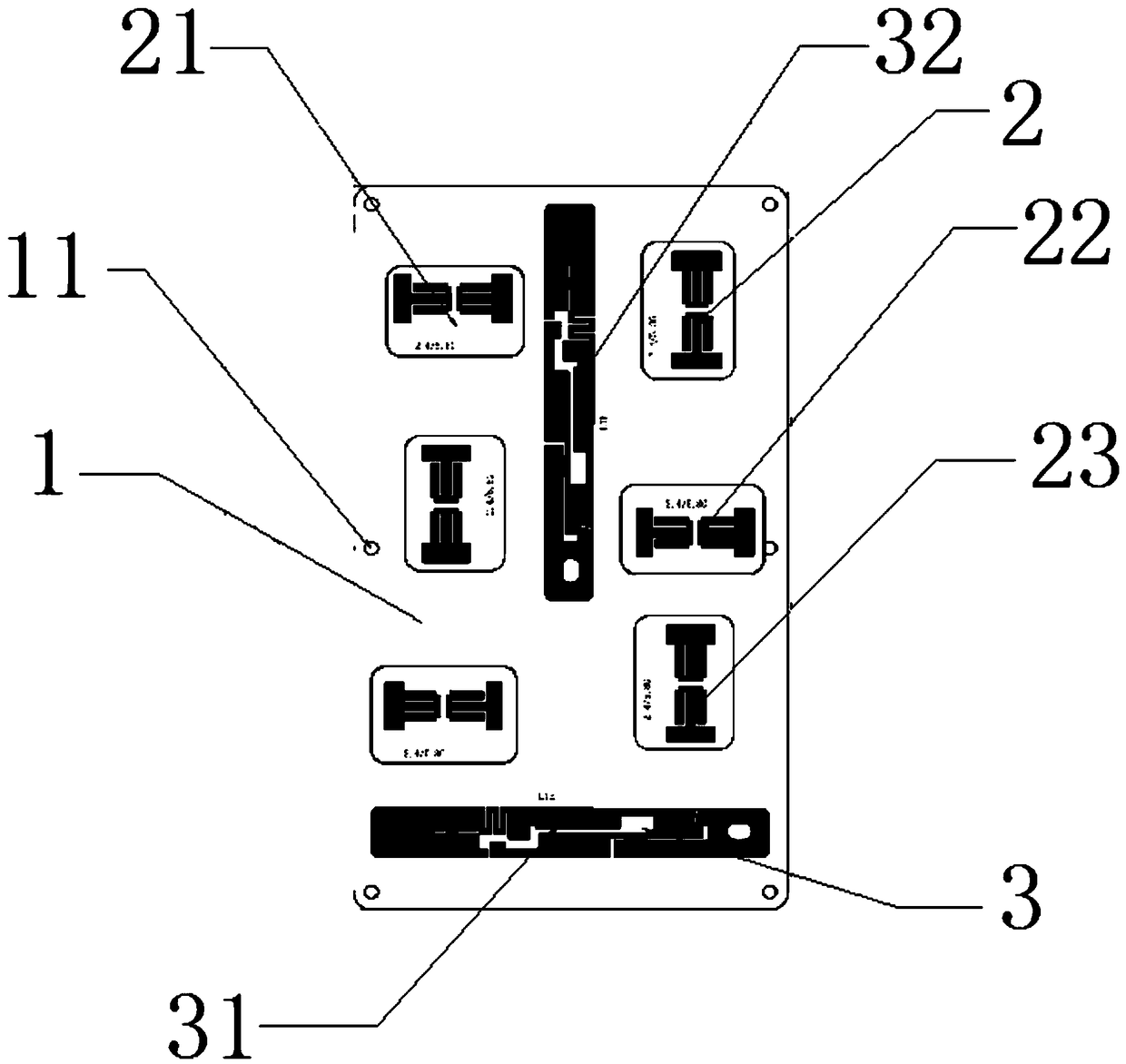

Mounting structure of full PCB mounting-type closed loop Hall current sensor

PendingCN108535527AReduce overall form factorIncrease productivityElectrical measurement instrument detailsElectrical testingHall elementClosed loop

A mounting structure of a full PCB mounting-type closed loop Hall current sensor relates to the field of Hall current sensor mounting structure components. According to the invention, a magnetic core,a skeleton, a PCB are all mounted on a housing. An air gap is arranged near the tail end of a central post of the magnetic core. A sheet packaged Hall element is arranged in the air gap. The skeletonincludes an inner skeleton and an outer skeleton. A part of the PCB pasted with a window of the Hall element is inserted into a slot the inner skeleton and communicates with the air gap of the magnetic core. The secondary winding is connected with a circuit on the PCB. The housing is provided with mounting holes for the inner skeleton and the outer skeleton. The housing is provided with a pin mounting hole or slot used for mounting a primary winding. The housing is provided with a slot used for mounting and fixing the magnetic core and a fixing needle hole. The housing is provided with a clipused for mounting the PCB. According to the invention, aims of simple structure, mounting convenience, higher anti-interference capability and wider application range are achieved.

Owner:南京普肯传感科技有限公司

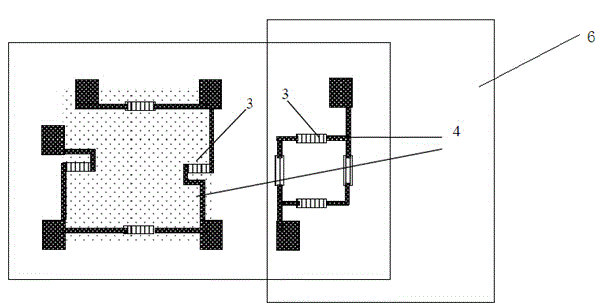

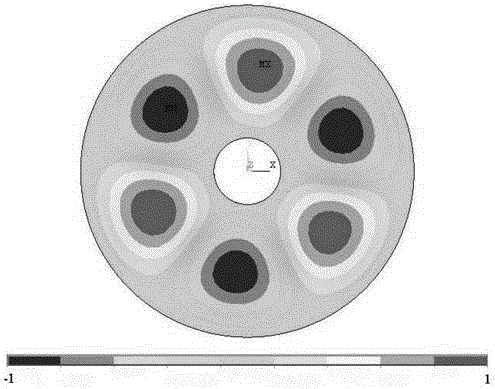

Electrostatic force-driven miniature ultrasonic motor

ActiveCN104883089ASmall sizeGuaranteed performance consistencyElectrostatic generators/motorsEngineeringUltrasonic motor

The invention discloses an electrostatic force-driven miniature ultrasonic motor. The electrostatic force-driven miniature ultrasonic motor includes silicon-based stator, a rotor, a bearing and an elastic pre-pressure device, and an upper surface of the silicon-based stator is provided with a tooth-shaped protrusion; one end of the rotor sleeves in the bearing to perform rotational motion, and the stator is in contact with the tooth-shaped protrusion of the silicon-based stator; and the elastic pre-pressure device applies pre-pressure to the rotor along an axial direction, so that normal pressure is generated between the rotor and the silicon-based stator, the silicon-based stator generates ultrasonic vibration under the function of driving voltage, and the tooth-shaped protrusion of the silicon-based stator drives the rotor to rotate through frictional force. The electrostatic force-driven miniature ultrasonic motor provided by the invention satisfies the characteristics of small size, simple structure, mature materials and preparation technology and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Treatment method of phenol-containing wastewater from power generation from rice husk pyrolysis

InactiveCN110437508ALow in phenolic concentrationNot easy to recyclePigment treatment with macromolecular organic compoundsChemical industryCross-link

The invention provides a treatment method of phenol-containing wastewater from power generation from rice husk pyrolysis, and belongs to the field of biomass energy chemical industry. The treatment method of the phenol-containing wastewater from power generation from rice husk pyrolysis comprises the following steps of (1) conducting rice husk pyrolysis to produce pyrolysis gas and pyrolysis carbon, subjecting the pyrolysis gas to spraying, washing and purifying to generate phenol-containing tar wastewater, and crushing the pyrolysis carbon through a crusher to produce 5-10-[mu]m silicon carbon black powder; (2) carrying out an acid-catalyzed reaction on the phenol-containing wastewater and formaldehyde to produce a biomass phenolic resin aqueous solution, and adding a cross-linking agentto promote polymerization of other tar; (3) modifying the silicon carbon black with resin; and (4) mixing modified silicon carbon black and rubber, conducting kneading and mixing through an internal mixer, and conducting extrusion and granulation to produce silicon carbon black / rubber master batch. By means of the proposed method, not only is the phenol-containing wastewater from power generationfrom rice husk pyrolysis treated, but also the silicon carbon black powder is modified, used as a reinforcing agent and applied into various rubber products, so that the proposed method is a rice huskresourceful and comprehensive utilization method with power generation by pyrolysis, production of the phenolic resin from the wastewater, modification of the silicon carbon black and production of the rubber master batch achieved.

Owner:JILIN UNIV

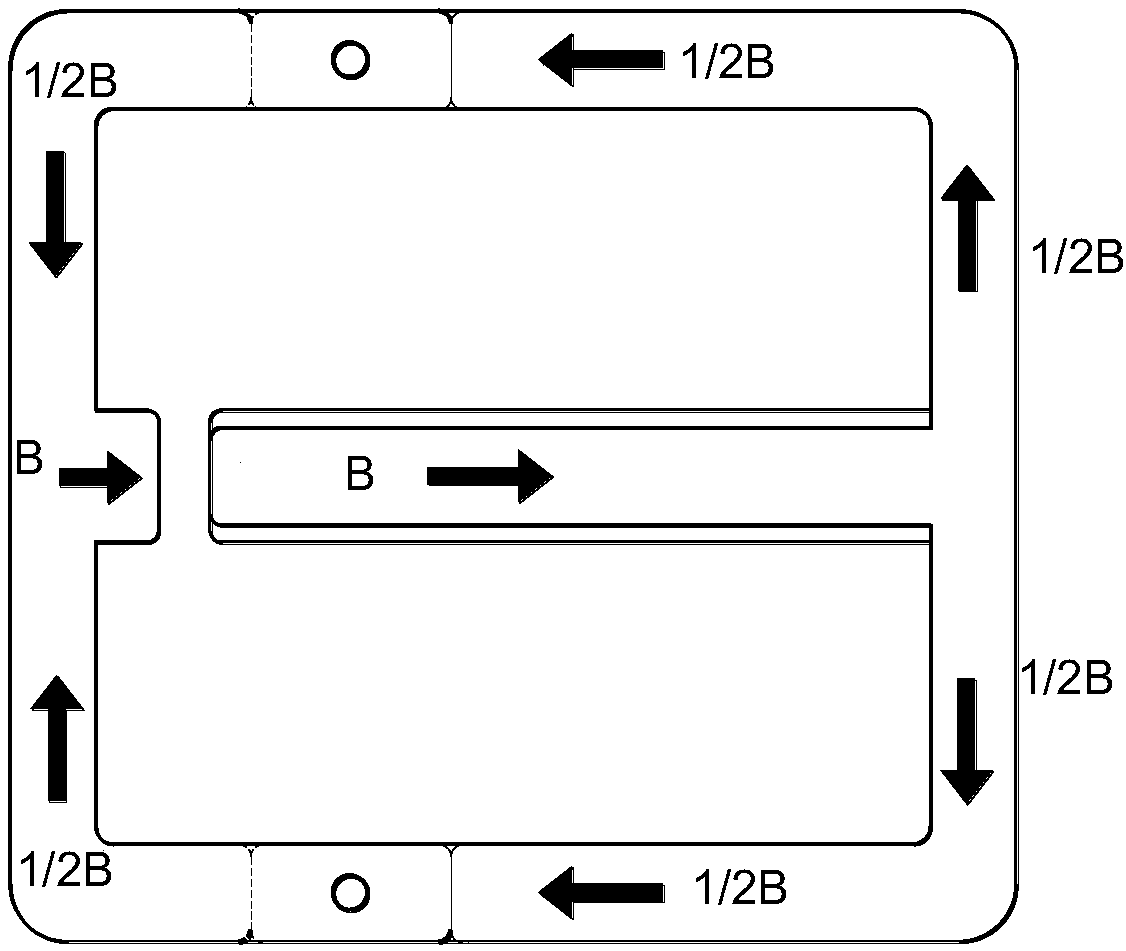

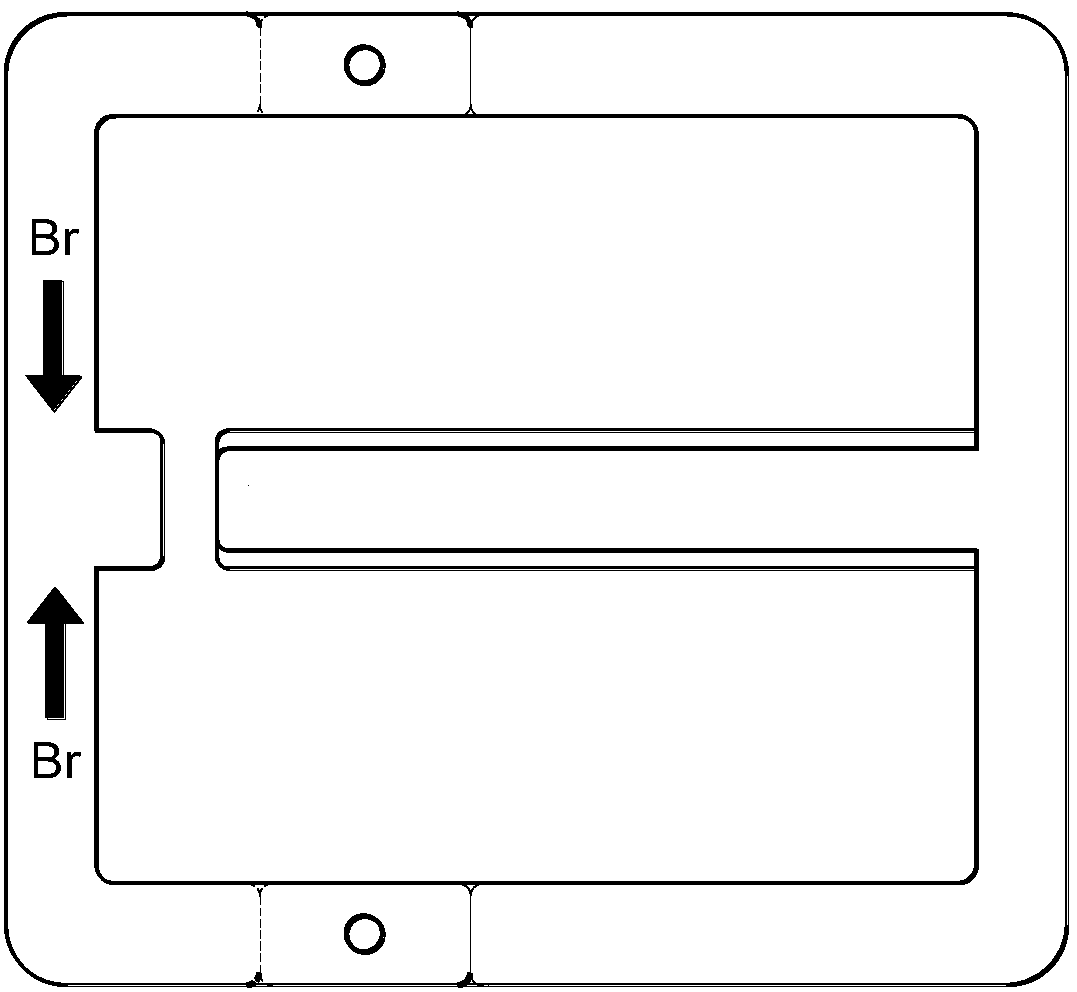

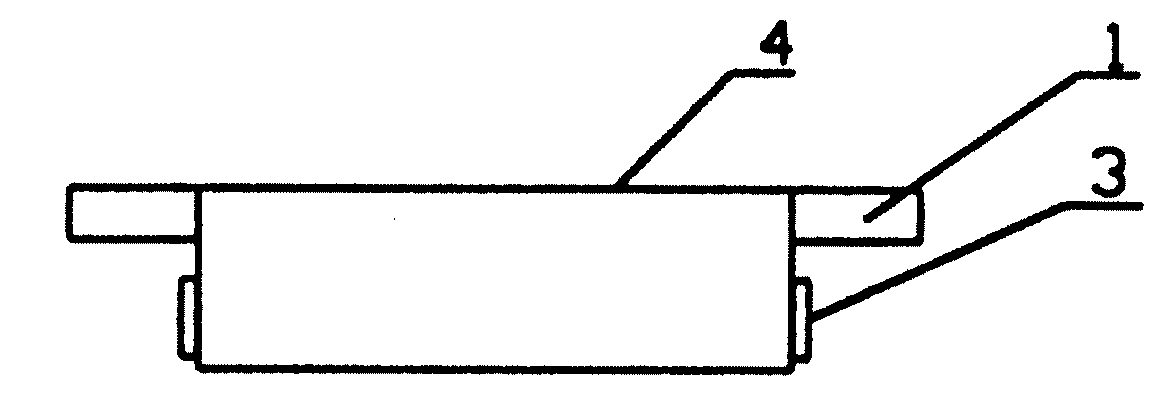

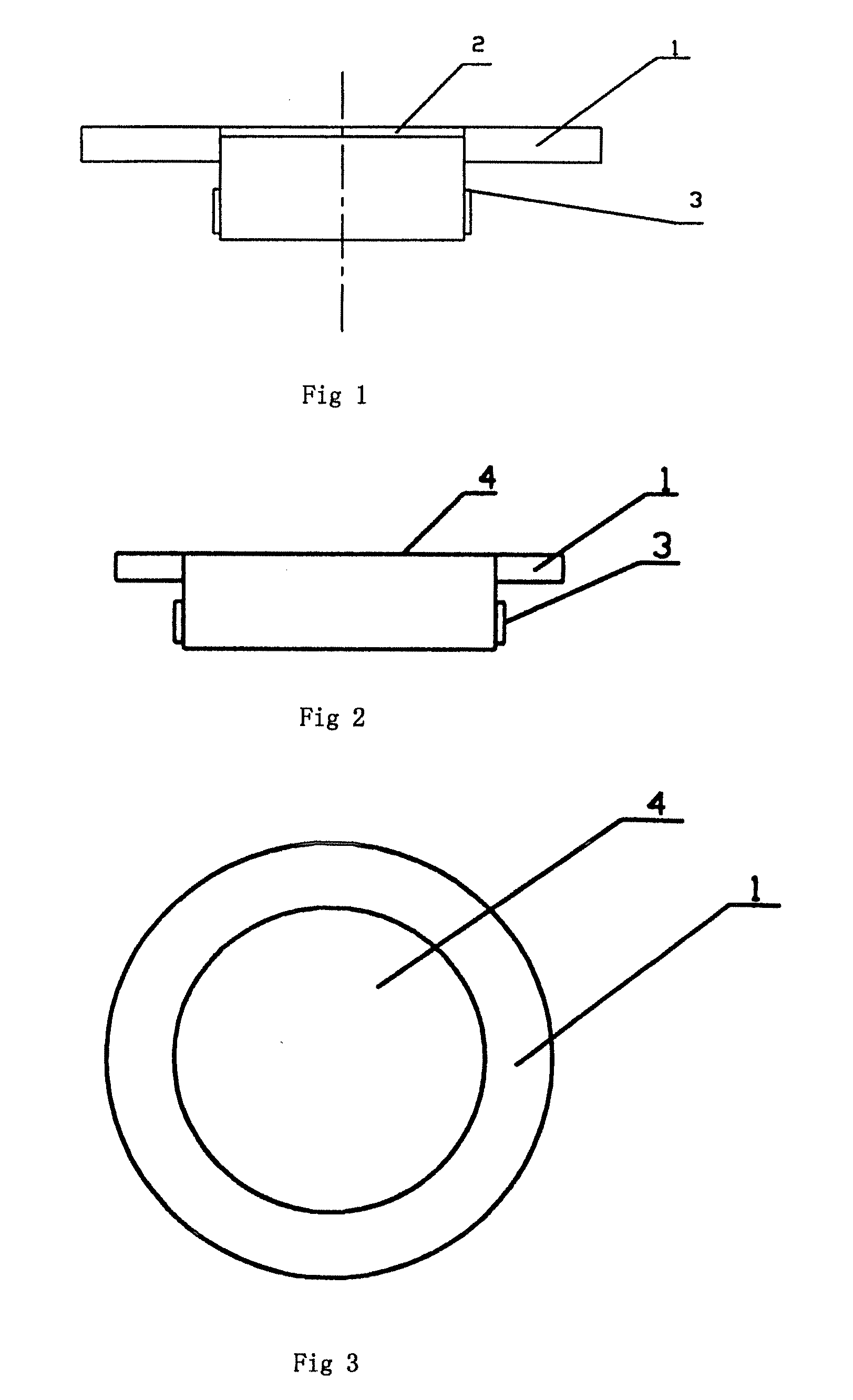

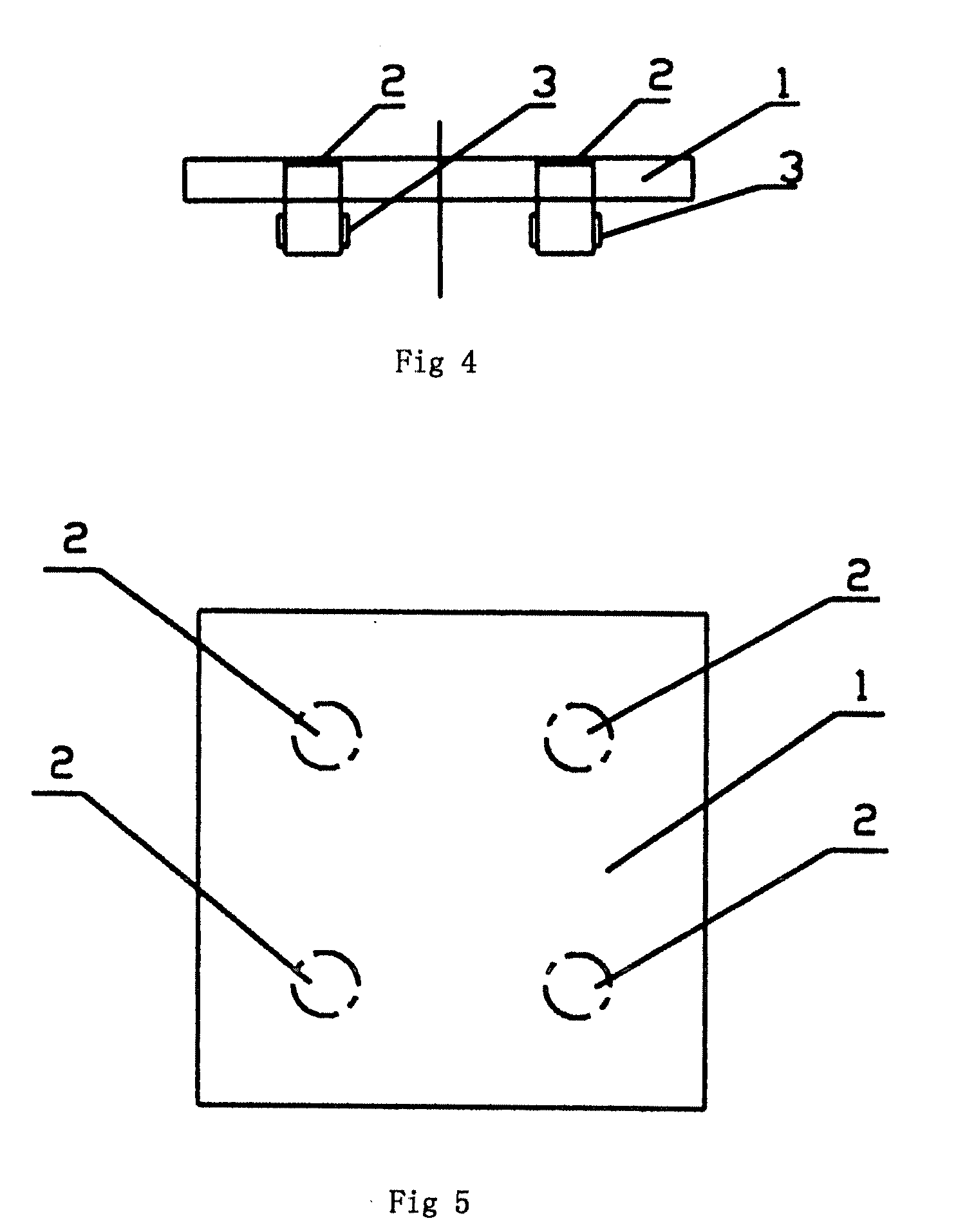

Vibrating system of panel form electrodynamic loudspeaker

InactiveUS20090262961A1Improve high frequency responseGuaranteed performance consistencyTransducer detailsDeaf-aid setsEngineeringLoudspeaker

The present invention discloses a vibrating system of flat-plate electrodynamic loudspeaker, which comprises a flat-plate vibrating plate and a voice coil mounted under the vibrating plate. The vibrating system is characterized in that the thickness of the vibrating plate within the voice coil is not more than ½ of that of the vibrating plate outside the voice coil. Alternatively, the vibrating plate within the voice coil can be replaced by a vibrating diaphragm. The thin plate within the voice coil according to the present invention can provide compensation for high frequency response, widen frequency band, and reduce the overall height of voice coil and vibrating plate. According to the present invention, a thin flat-plate loudspeaker that almost cover the full audio frequency bands can be designed, thereby producing a thin flat-plate full frequency speaker system to meet the demand of market.

Owner:ZHANG BAILIANG

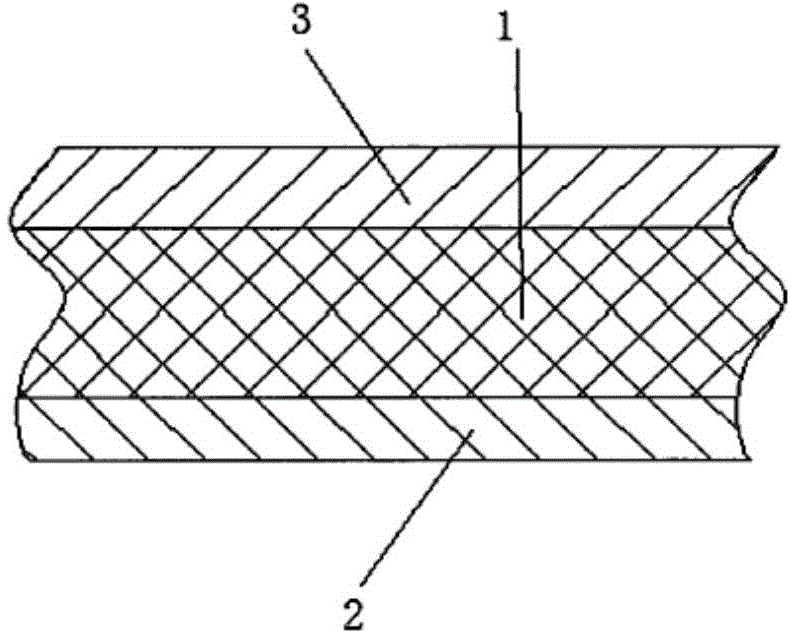

Three-layer composite material for hard glass packaging and preparation method thereof

ActiveCN104553134AGuaranteed performance consistencyImprove thermal conductivityMetal layered productsSurface layerAlloy

The invention relates to a three-layer composite material for hard glass packaging and a preparation method thereof and belongs to the technical field of composite materials. The three-layer composite material for hard glass packaging comprises an upper surface layer, a lower surface layer and a middle layer; the upper surface layer and the lower surface layer are made of controlled expansion alloy 4J29 materials; the middle layer is made of a pure copper material; the thickness ratio of the three layers is 4J29: Cu: 4J29=(10 to 20 percent):(60 to 80 percent):(10 to 20 percent). The three-layer composite material for hard glass packaging has the advantages that the material can be ideally matched with hard glass, has high thermal conductivity and high electric conductivity, is low in cost, adopts a simple processing technology and is easy to realize scale production; performance consistency of the material is ensured; the three-layer composite material is high in production efficiency and meets the demands of the market.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

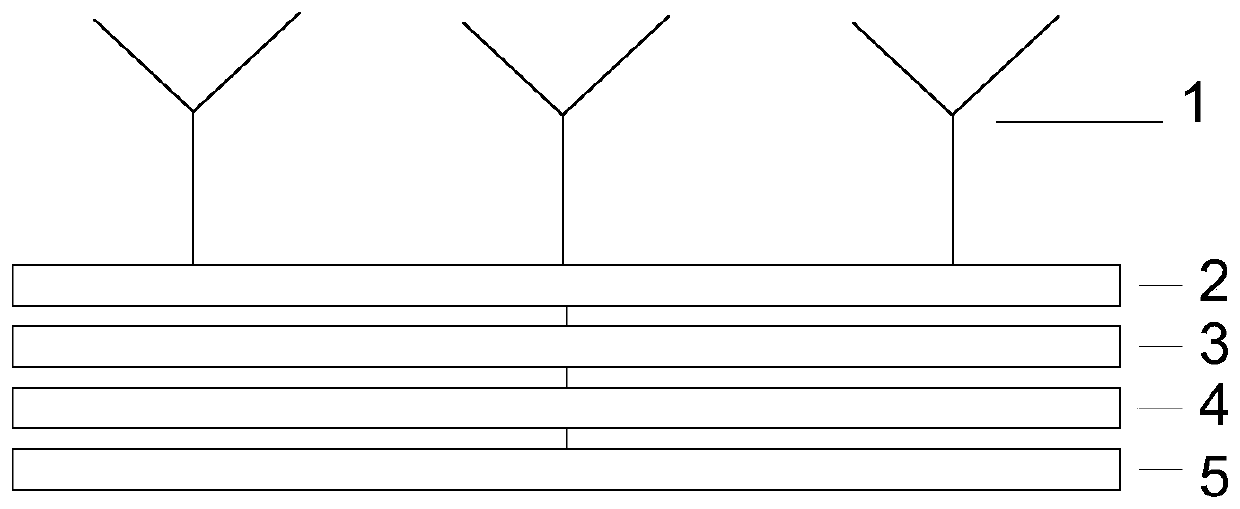

Antenna array with electrically adjustable inclination angle

PendingCN110011074ASmall sizeGuaranteed performance consistencyIndividually energised antenna arraysMulti bandVertical plane

The invention discloses an antenna array with an electrically adjustable inclination angle. The antenna array comprises at least one sub array having an independent vertical plane inclination angle adjusting function, and each sub array comprises an antenna radiation unit array, a plurality of power dividers, a plurality of digital phase shifters, a control circuit and a power distribution network; each antenna radiation unit array comprises a row of a plurality of radiation units, the output ends of the power dividers are connected with the same polarization of each two adjacent radiation units or each three adjacent radiation units; each digital phase shifter is a constant phase deviation multi-displacement phase shifter mode, and comprises an input end, an output end and a control end,the input ends are connected with the output end of a power division network, the output ends are connected with the input ends of the power dividers, and the control ends are connected with the control circuits; and the input end of the power division network is a radio frequency input ports of the sub arrays. The multi-band array antenna comprising a 5G system is high in part integration, smallin size and simple in assembling.

Owner:GUANGDONG BROADRADIO COMM TECH

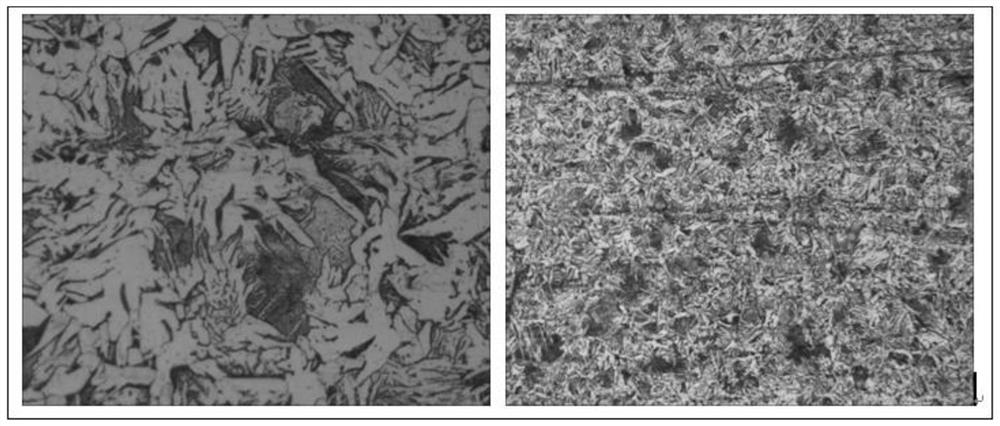

Method for producing specially-shaped micro-power mode copper alloy band of lead frame

InactiveCN103700594AUniform distribution of grainsEliminate internal stress in materialsSemiconductor/solid-state device manufacturingSmooth surfaceMethods of production

The invention relates to a method for producing a specially-shaped micro-power mode copper alloy band of a lead frame. The method comprises the following steps: cutting a blank copper band into a flat band blank by a cutting machine, forging the welded flat band blank by a special die, continuously carrying out heating, heat preserving and annealing in an online mode, then spraying water for cooling to a normal temperature, brushing the surface of the material, finishing, rolling, positioning for cutting edges, coiling a finished band material by a coiling machine in a follow-up way, coiling lining paper, packaging and warehousing. The method is simple, the production cycle is short, and the copper band has an even internal texture, a smooth surface and excellent material performance.

Owner:泰兴市永志电子器件有限公司

Luminous bacterium freeze-dried powder kit and preparation method thereof

ActiveCN111206000AGuaranteed performance consistencyStable initial luminescenceBacteriaChemiluminescene/bioluminescenceToxicityFreeze dry

The invention relates to the technical field of water quality detection kits, and particularly relates to a luminous bacterium freeze-dried powder kit and a preparation method thereof. The preparationmethod comprises the following steps of recovering strain freeze-dried powder, performing inoculated culture to obtain luminous bacterium liquid, performing 256-fold diluting on the luminous bacterium liquid, and detecting the luminous quantity of the diluted luminous bacterium liquid; sucking a certain volume of the diluted luminous bacterium liquid, and performing refrigerated centrifugation toobtain thalli; mixing the thalli with a protective agent to obtain a thallus mixed solution; performing vacuum freeze drying on the thallus mixed solution to obtain luminous bacterium freeze-dried powder; and forming the luminous bacterium freeze-dried powder kit by the luminous bacterium freeze-dried powder, a diluent, an osmotic pressure regulating solution and a quality control standard substance solution. According to the invention, the stability regulation and control of important parameters such as the initial luminous quantity, the CF value, the positive control value and the negativecontrol value of the kit in the production process are realized, the performance consistency between different preparation batches can be ensured, and the situation that deviation occurs when different batches of kits are used for evaluating the toxicity of a same water body is effectively avoided.

Owner:杭州绿洁科技股份有限公司

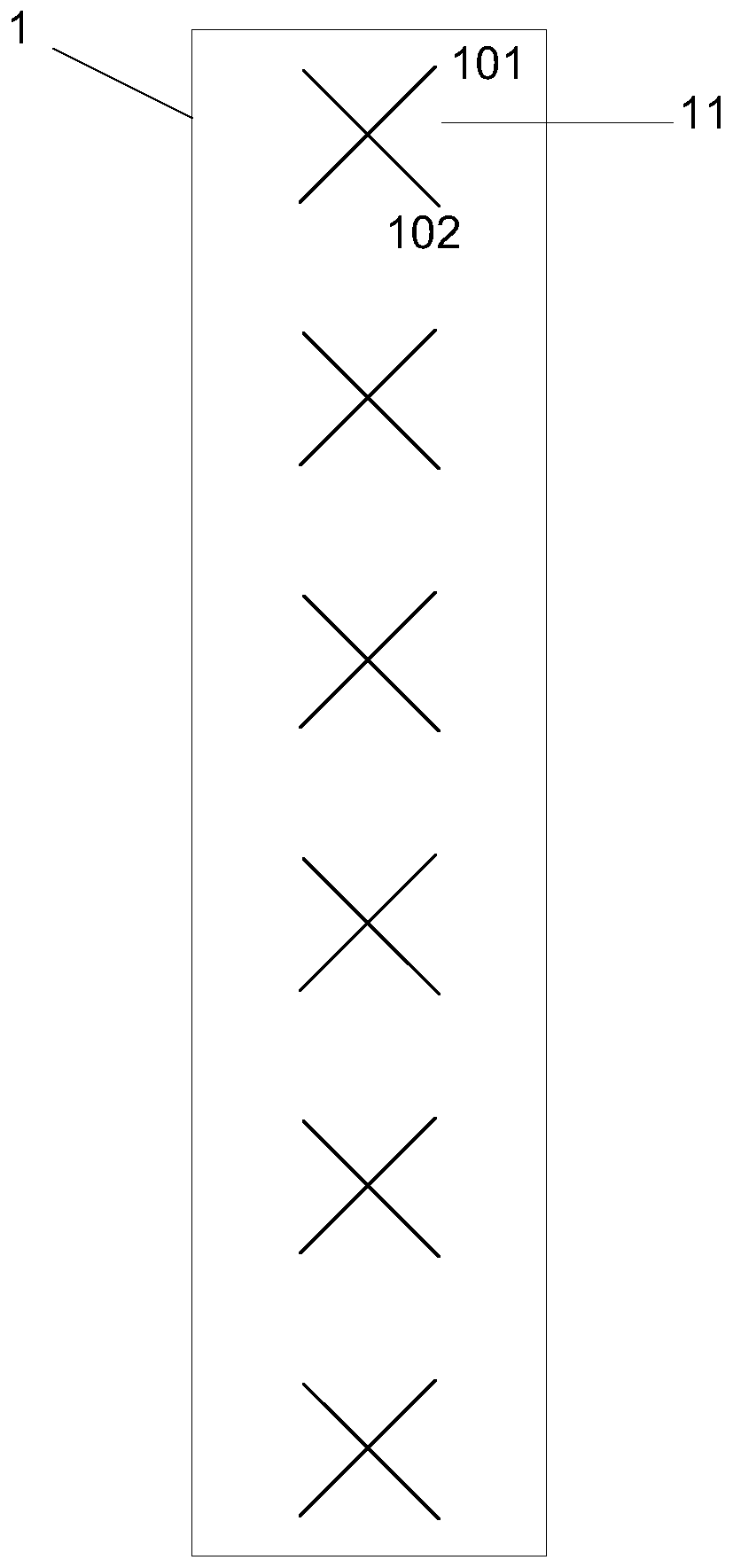

MIMO airborne antenna adopting WiFi and LTE

PendingCN108923110AGuaranteed performance consistencyLower the altitudeSimultaneous aerial operationsAntenna supports/mountingsElectromagnetic compatibilityMIMO

The invention discloses an MIMO airborne antenna adopting WiFi and LTE. The antenna comprises a plurality of WiFi antennas and LTE antennas arranged on a mounting plate, wherein the WiFi antennas comprise a first antenna unit and a second antenna unit; the LTE antennas comprise a horizontal antenna and a vertical antenna, wherein the horizontal antenna is arranged on one side of the upper end faceof the mounting plate and is parallel to the lower side edge of the upper end face of the mounting plate; the vertical antenna is perpendicular to the horizontal antenna; and the first antenna unit of the vertical antenna is separated from the second antenna unit. The technical problem to be solved by the invention is as follows: the novel antenna for passenger cabin coverage is used for improving the existing antenna defect, the antenna coverage performance of the wireless equipment on the aircraft is improved, the electromagnetic compatibility performance of the equipment is improved, and the consistency, reliability and installation convenience of equipment are ensured.

Owner:CETC AVIONICS

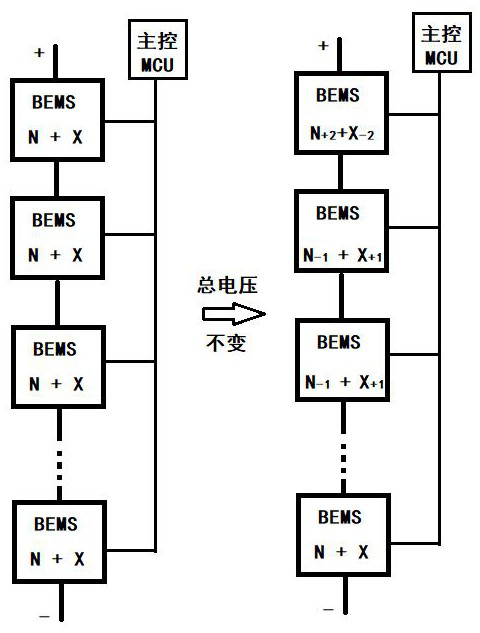

Flexible control method and device for dynamically reconstructing battery module

PendingCN113644328AGuaranteed performance consistencyGuaranteed work efficiencySecondary cells charging/dischargingElectric powerCharge and dischargeElectrical and Electronics engineering

The invention discloses a flexible control method and device for dynamically reconstructing a battery module, relates to a battery pack control technology, and aims to solve the problem that an existing dynamic reconstruction technology cannot solve the problem of module unit consistency existing in a series battery module applied to a high-voltage scene. The battery module is a series battery module formed by connecting n module units in series, wherein the ith module unit is formed by connecting Ni+Xi battery units in series. The charging / discharging control method comprises the following steps: in a charging / discharging process, performing dynamic iteration adjustment on Nx and Xx in each series module unit; in each iteration, adjusting the module unit with the highest virtual voltage and the module unit with the lowest virtual voltage in a synchronous equivalent reverse redundancy number mode; for the series module single body with the highest virtual voltage value, increasing the Nx while reducing the Xx; for the series module single body with the lowest virtual voltage value, reducing the Nx while increasing the Xx; and continuously carrying out iteration until all module units are fully charged / emptied. The method is suitable for charging and discharging control of the battery module.

Owner:北京宝龙德科技有限责任公司

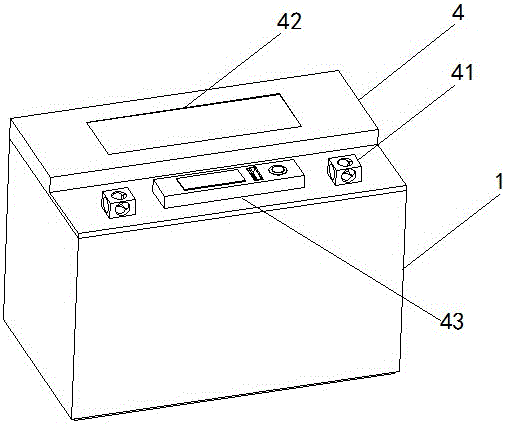

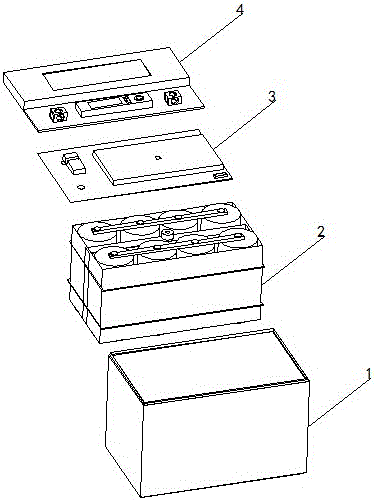

Multifunctional lithium ion battery

InactiveCN105161794AOvercome the defect of uneven heat distributionGuaranteed performance consistencyCurrent conducting connectionsSecondary cellsPhysical chemistryLithium-ion battery

The invention relates to the technical field of manufacturing of high-capacity lithium batteries and particularly relates to a multifunctional lithium ion battery. The adopted technical scheme is as follows: the lithium ion battery comprises a battery box used for containing a battery cell group, and a battery box upper cover used for covering an opening of the battery box, wherein the battery box upper cover is provided with positive and negative electrodes; the positive and negative electrodes, a protection circuit board, a bus bar and the battery cell group form a current loop; the battery cell group, the bus bar and the protection circuit board are installed inside the battery box, the battery cell group is installed on an opening of at least one layer of a clamping sleeve, and at least one heat dissipation layer is attached to the periphery of the battery cell group. The lithium ion battery has the advantages that the heat of part of high-temperature areas of part of lithium ion battery can be rapidly absorbed, and is dissipated to other areas of the lithium ion battery, so that the defect of the non-uniform heat distribution of the existing battery can be overcome, and the consistency of the performances of single battery cells of the battery cell group can be kept.

Owner:SHANTOU YIHE ELECTRIC POWER SCI & TECH CO LTD

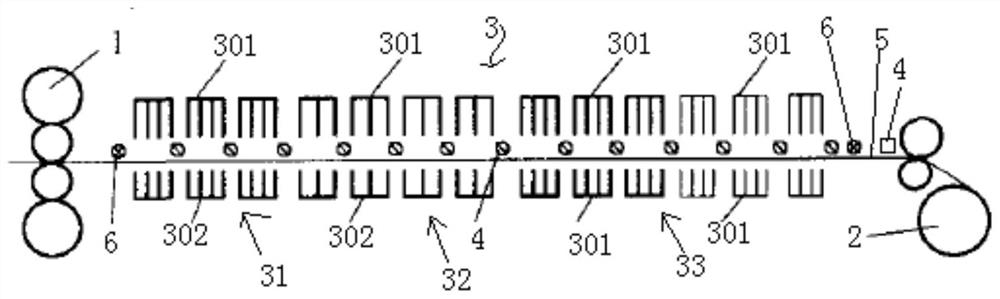

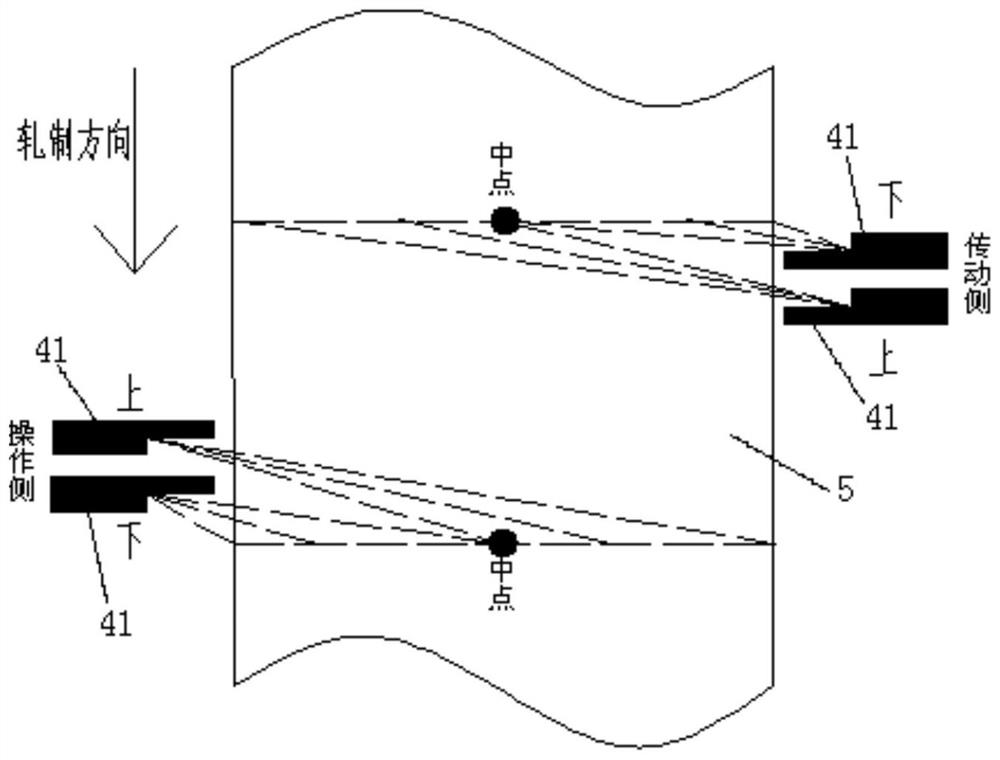

Hot-rolled strip steel laminar cooling device and control method thereof

PendingCN112404148AAvoid problems with poor coolingGuaranteed performance consistencyTemperature control deviceWork cooling devicesLaminar coolingStructural engineering

The invention provides a hot-rolled strip steel laminar cooling device and a control method thereof. The hot-rolled strip steel laminar cooling device and the control method thereof are used for solving the problem of water accumulation of a steel strip in the prior art. The hot-rolled strip steel laminar cooling device is located between a finishing mill group and a coiling machine and comprisesa middle cooling section and a tail end side water spraying group, the middle cooling section is used for cooling the steel strip, and the tail end side water spraying group is also used for cooling the steel strip. The tail end side water spraying group comprises at least one water spraying nozzle arranged on the side face in the steel strip conveying direction, the purging angles of the water spraying nozzles are larger than or equal to the width of the steel strip, the water spraying directions of the water spraying nozzles deviate to the steel strip conveying direction or the direction opposite to the steel strip conveying direction, and an acute angle is formed between the water spraying directions of the water spraying nozzles and the left-right direction. Accumulated water of the steel strip can be swept away.

Owner:CHONGQING IRON & STEEL CO LTD

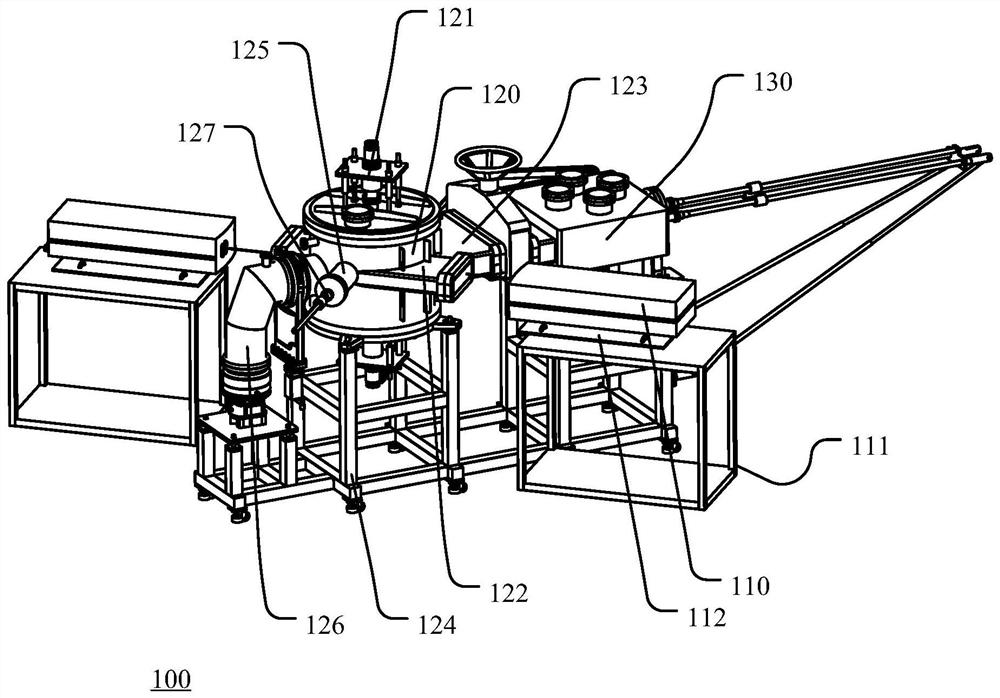

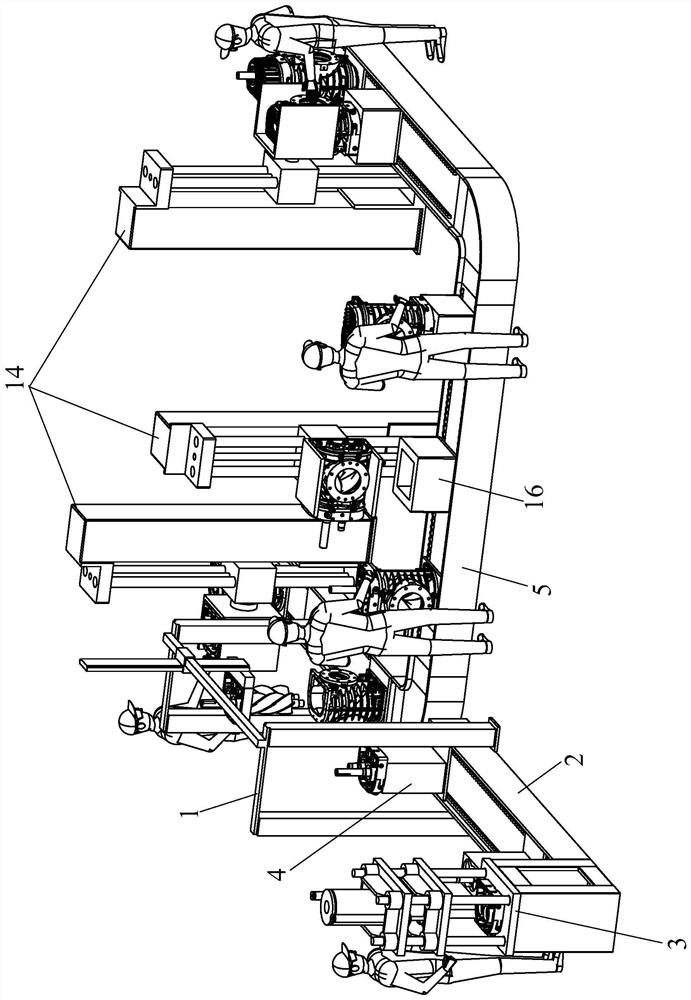

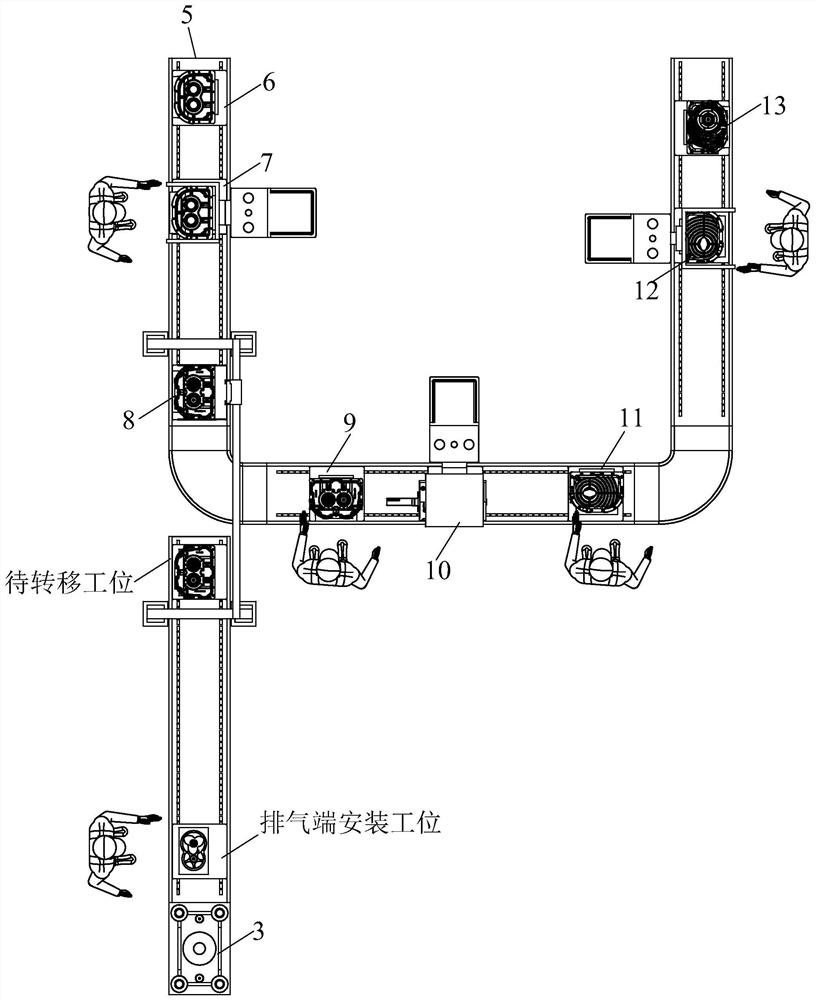

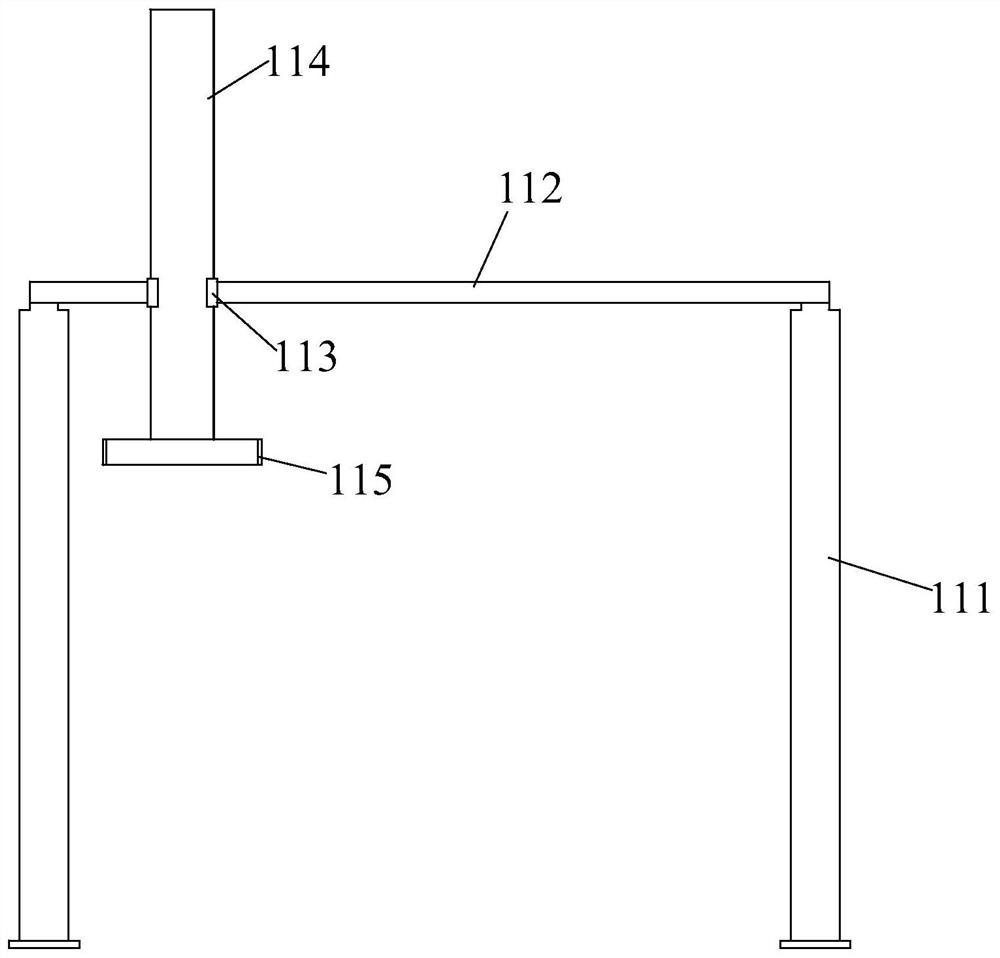

Dry oil-free screw compressor assembly line and assembly method

PendingCN111644846AReduce manual operationsImprove work efficiencyAssembly machinesMetal working apparatusStructural engineeringMechanical equipment

The invention relates to a dry oil-free screw compressor assembly line and an assembly method. The assembly line comprises a rotor assembly line, a shell assembly line and a transfer mechanism; the rotor assembly line is used to install an exhausting end of a compressor on a rotor; the shell assembly line is used to complete the assembly of the entire compressor, and the transfer mechanism is usedto transfer the rotor provided with the exhausting end onto the shell assembly line; the rotor assembly line comprises a number one roller way line body and a pressing fit machine, the shell assemblyline comprises a number two roller way line body, and a station for installing various parts at the end of a shell cover plate, a first shell turning station, a first shell assembly rotor station, asecond shell assembly rotor station, a second shell turning station, a shell cover plate installation station, a third shell turning station and a gear box installation station are sequentially arranged on the number two roller way line body according to assembly process steps. According to the assembly line, auxiliary mechanical equipment can be effectively used to entirely complete movement, turning, hoisting, pressing and rotation of workpieces, manpower operations are reduced, and work efficiency is improved.

Owner:杭州兴鑫科技有限公司

Explosion-proof accessory multifunctional protection test auxiliary apparatus

InactiveCN106404370AGuaranteed performance consistencyImprove accuracyMachine part testingSoftware engineeringEngineering

The invention discloses an explosion-proof accessory multifunctional protection test auxiliary apparatus. The apparatus takes a test casing as a main body, at least one surface of the test casing is outwardly provided with adapters with different dimensions layer by layer in a matched mode, the dimensions of an upper port and a lower port of an intermediate-layer adapter are different, the dimension of one end matches the dimension of an inner-layer adapter or the port of the test casing, the dimension of the other end matches the dimension of an outer-layer adapter, an outermost-layer adapter is connected with a plug, and sealing members are arranged at a connection position between the corresponding adapter and the test casing, between two adapters and between the corresponding adapter and the plug. The explosion-proof accessory multifunctional protection test auxiliary apparatus, as a simulation test box for a protection test, through connection of the casing, the adapters and the sealing members, can be applied to performing the protection test on explosion-proof accessories with different dimensions and different structures, can solve the problems of waste of resources, long test period and the like existing in conventional explosion-proof accessory protection test examination work, and can also be applied to an IPX8 protection diving test of a miniaturized electrical product.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

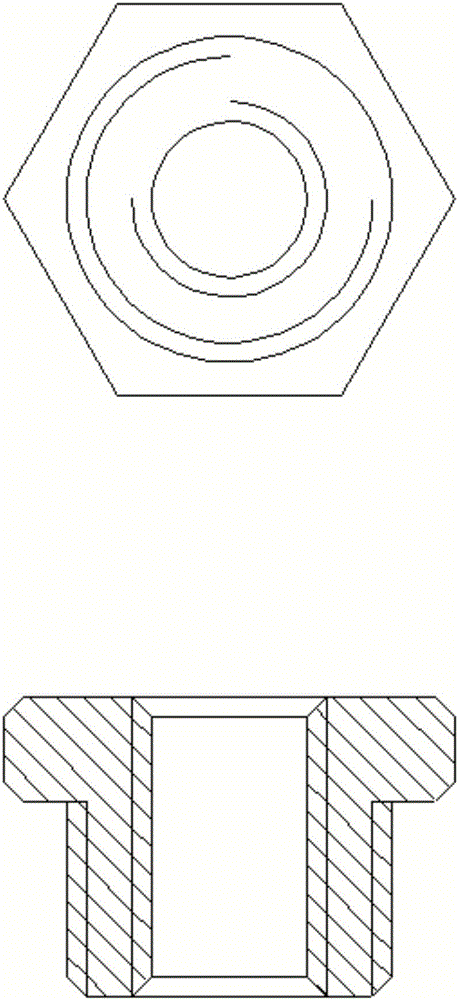

Preparation process of anti-DC transformer iron core

InactiveCN108847340AImprove consistencyLower skill requirementsTransformersTransformers/inductances coils/windings/connectionsHigh volume manufacturingDc transformers

The invention discloses a preparation process of an anti-DC transformer iron core. The preparation process comprises the following steps that a, mounting is conducted, specifically, the annular iron core is fixed to a clamp of an electric spark cutting machine; b, parameters of electric spark line cutting are set, specifically, the current is 1.5-3 A, the cutting speed is 1.0-1.5 mm / min, the diameter of an electrode wire is phi 0.16 mm, and the unilateral discharge gap is 0.01 mm; c, cutting is conducted, specifically, the electric spark cutting machine is started, thus a cutting tool conductscutting according to the linear trajectory passing through the circular center of the annular iron core, and an air gap is cut in the annular iron core; and d, an insulating sheet is mounted, specifically, the electric spark cutting machine is stopped, the annular iron core is removed from the clamp of the electric spark cutting machine, the insulating sheet with the required thickness is sandwiched in the machined air gap, and the size of the air gap is controlled. The preparation process is simple, the skill requirements for production workers are lowered, and the manufactured single-air-gap iron core has high consistency and is suitable for mass production.

Owner:河南合瑞电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com