Mounting structure of full PCB mounting-type closed loop Hall current sensor

A technology of Hall current and installation structure, applied in voltage/current isolation, parts and instruments of electrical measuring instruments, etc. The effect of improving the ability of interference, reducing the size and volume, and widening the linear measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

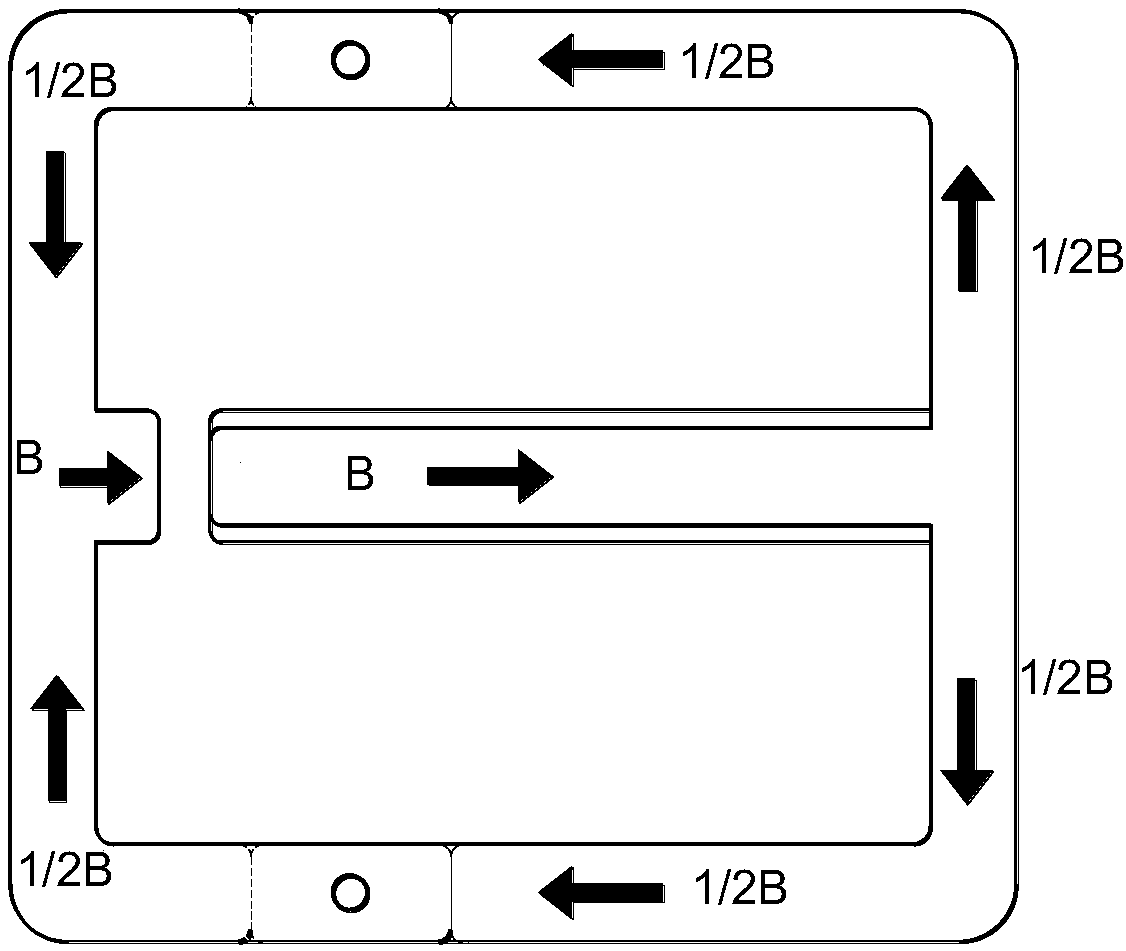

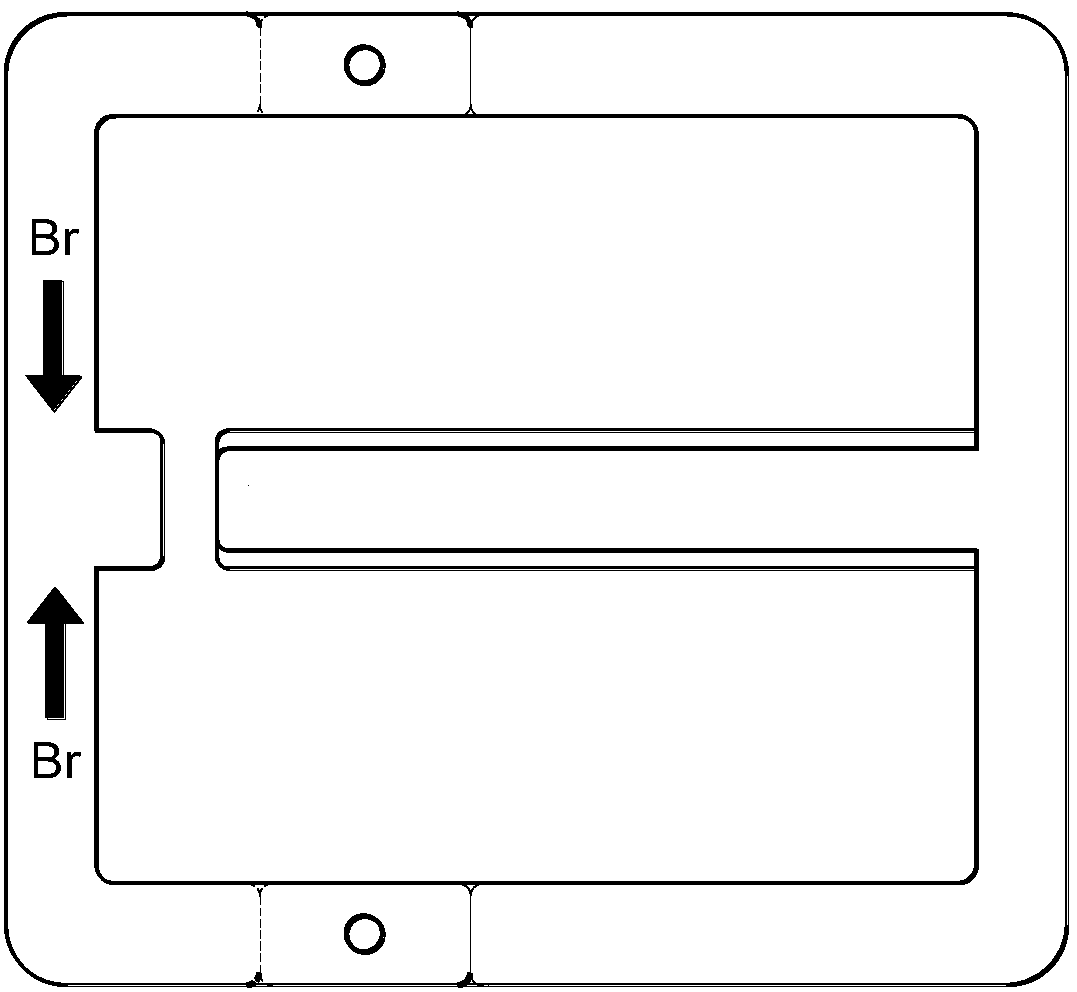

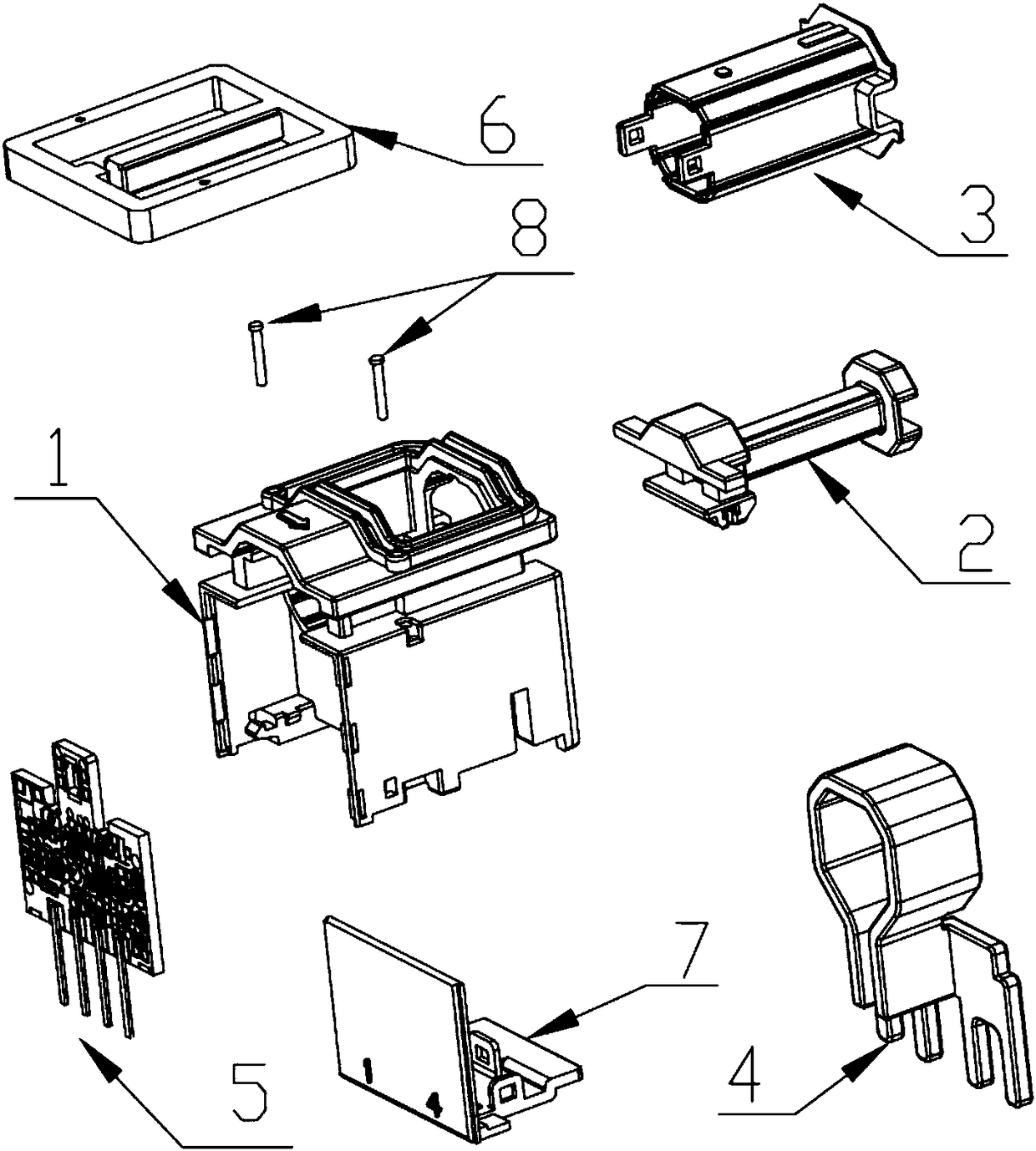

[0057] The installation structure of the fully PCB-mounted closed-loop Hall current sensor of this embodiment includes a housing and a cover plate when necessary, a magnetic core, two fixing pins, two skeletons and coil windings, and a PCB board. The skeleton and the cover plate, PCB board and magnetic core when necessary are installed on the shell. There is a secondary winding on the inner frame, and a primary winding on the outer frame. The inner and outer frames and the coil winding are located on the center column of the magnetic core; The air gap is located near the end of the central column of the magnetic core; there is a Hall element in the air gap, and the Hall element is a chip package; the window part of the Hall element on the PCB is inserted into the slot of the inner frame and connected to the air gap of the magnetic core Connected, the secondary winding is connected to the circuit on the PCB board.

[0058] The specific implementation steps are:

[0059] 1. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com