Hard carbon negative electrode composite material and preparation method and application thereof

A composite material and hard carbon technology, applied in the preparation/purification of carbon, negative electrodes, battery electrodes, etc., can solve problems such as difficulty in controlling the amount of lithium fluoride attached, inconsistent pre-lithiation degrees, inconsistent material properties, etc. The effect of simplifying the production process and chemical process, reducing the amount of liquid injection, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

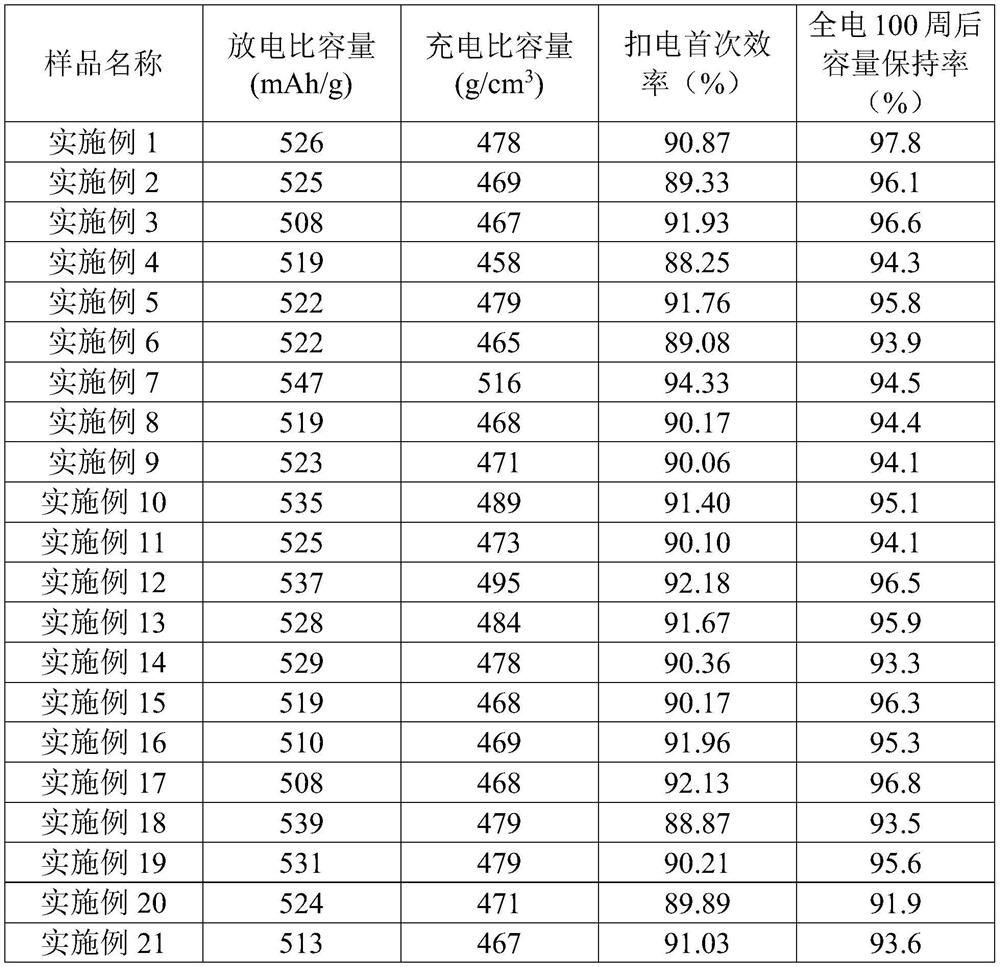

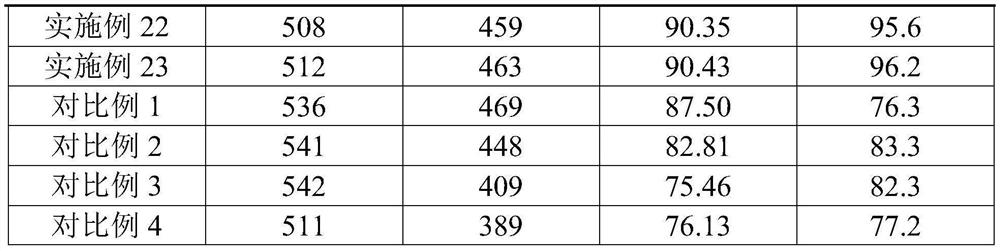

Examples

preparation example Construction

[0046] A method for preparing a hard carbon negative electrode composite material, comprising the steps of:

[0047] Pre-oxidizing the carbon source to prepare a pre-oxidized carbon source;

[0048] mixing the pre-oxidized carbon source and a pore-forming agent, and preparing a hard carbon precursor with a porosity of 2% to 30% by heat treatment;

[0049] mixing the hard carbon precursor with a lithium-containing compound solution, and preparing a solid pre-lithiated hard carbon precursor by a solvothermal method;

[0050] Carrying out carbon coating treatment on the pre-lithiated hard carbon precursor to form a carbon coating layer on the surface of the pre-lithiated hard carbon precursor.

[0051] Specifically, the preparation method of the hard carbon negative electrode composite material provided by the present invention includes the following steps:

[0052] S100: Pre-oxidize the carbon source to prepare a pre-oxidized carbon source

[0053] In order to avoid the relat...

Embodiment 1

[0086] This embodiment provides a hard carbon negative electrode composite material and a preparation method thereof. Specific steps are as follows:

[0087] (1) Grinding and pulverizing 1000 g of sucrose into a powder with a particle size of D50 = 80 μm, and keeping it warm at 200° C. for 10 h in an air atmosphere to obtain a pre-oxidized carbon source.

[0088] (2) 100g of pre-oxidized carbon source and 5g of potassium hydroxide are ball milled and heat-treated in a nitrogen atmosphere at a temperature of 700°C for 3 hours to prepare a hard carbon precursor with a porosity of 24%;

[0089] (3) Using a ball mill to pulverize the hard carbon precursor obtained in step (2) to obtain a hard carbon precursor with D50=15 μm, cleaning and drying;

[0090] (4) Add 10.0g of the hard carbon precursor dried in step (3) and 50g of a 10wt% lithium carbonate aqueous solution to the hydrothermal kettle, heat at 180°C for 10h, separate the solid from the liquid and dry to obtain a surface-...

Embodiment 2

[0093] This example provides a hard carbon negative electrode composite material and its preparation method. The difference from Example 1 is that the heat-treated carbon source in step (1) is replaced by sucrose with crushed coconut shell with D50=100 μm. The particle size of the finished hard carbon negative electrode composite material finally obtained is D50=5 μm, the thickness of the carbon coating layer is 50 nm, and the weight ratio of the carbon coating layer is 2.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com