Three-layer composite material for hard glass packaging and preparation method thereof

A technology of composite materials and hard glass, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of poor consistency and low conductivity, and achieve consistent performance, high conductivity, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

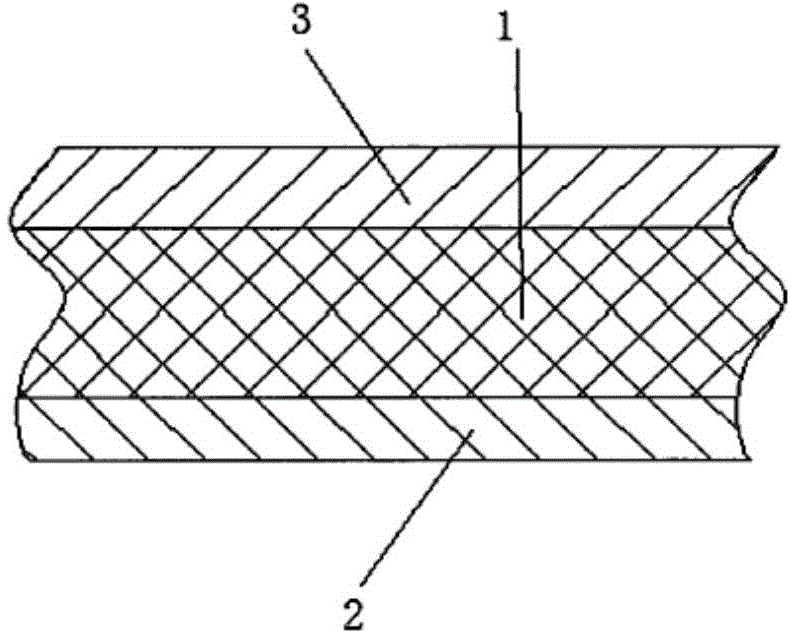

Image

Examples

Embodiment 1

[0019] The thickness ratio of 4J29: Cu: 4J29 = 15%: 70%: 15% of 4J29 strip and pure copper strip is selected, wherein the thickness of 4J29 strip is 0.6mm, and the thickness of pure copper strip is 2.8mm. The 4J29 strip is continuously annealed at 1080°C; the joint surface of the 4J29 strip and the pure copper strip is ground to remove the oxide film; at a rolling speed of .1.5m / min, continuous composite solid-phase rolling at room temperature is achieved 1.4mm three-layer composite strip; the composite strip is subjected to diffusion annealing, the heating temperature is 750°C, the holding time is 2 hours, nitrogen protection, bell-type slow cooling; the billet is rolled to 1.0mm at a deformation rate of 28.6%; The annealing temperature is 1000°C, and the belt speed is 3.5m / min for intermediate softening annealing; the finished product is rolled into 0.2mm with a deformation rate of 50%. The performance is as follows:

[0020] Tensile strength: 458MPa, thermal conductivity 1...

Embodiment 2

[0022] The thickness ratio of 4J29: Cu: 4J29 = 10%: 80%: 10% of 4J29 strip and pure copper strip is selected, wherein the thickness of 4J29 strip is 0.5mm, and the thickness of pure copper strip is 4.0mm. The 4J29 strip is continuously annealed at 1080°C; the joint surface of the 4J29 strip and the pure copper strip is ground to remove the oxide film; at a rolling speed of .1.0m / min, continuous composite solid-phase rolling at room temperature is achieved 1.5mm three-layer composite strip; the composite strip is subjected to diffusion annealing, the heating temperature is 750°C, the holding time is 2 hours, nitrogen protection, bell-type slow cooling; the billet is rolled to 1.05mm at a deformation rate of 30%; The annealing temperature is 1050°C, and the belt speed is 2.5m / min for intermediate softening annealing; the finished product is rolled into 0.15mm with a deformation rate of 40%. The performance is as follows:

[0023] Tensile strength: 430MPa, thermal conductivity 1...

Embodiment 3

[0025] The thickness ratio of 4J29: Cu: 4J29 = 20%: 60%: 20% of 4J29 strip and pure copper strip is selected, wherein the thickness of 4J29 strip is 0.6mm, and the thickness of pure copper strip is 1.8mm. The 4J29 strip is continuously annealed at 1080°C; the joint surface of the 4J29 strip and the pure copper strip is ground to remove the oxide film; at a rolling speed of .2.0m / min, continuous composite solid-phase rolling at room temperature is achieved 1.4mm three-layer composite strip; the composite strip is subjected to diffusion annealing, the heating temperature is 750°C, the holding time is 2 hours, nitrogen protection, bell-type slow cooling; the billet is rolled to 1.0mm at a deformation rate of 28.6%; The annealing temperature is 980°C, and the tape speed is 4.0m / min for intermediate softening annealing; the finished product is rolled into 0.15mm with a deformation rate of 60%. The performance is as follows:

[0026] Tensile strength: 520MPa, thermal conductivity 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com