Electrostatic force-driven miniature ultrasonic motor

A technology of ultrasonic motor and electrostatic force, applied in the direction of electrostatic generator/motor, generator/motor, electrical components, etc., can solve the problems of silicon semiconductor process incompatibility, etching process to be studied, PZT piezoelectric film is difficult to obtain, etc. , achieve the effect of reducing the size and ensuring the consistency of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

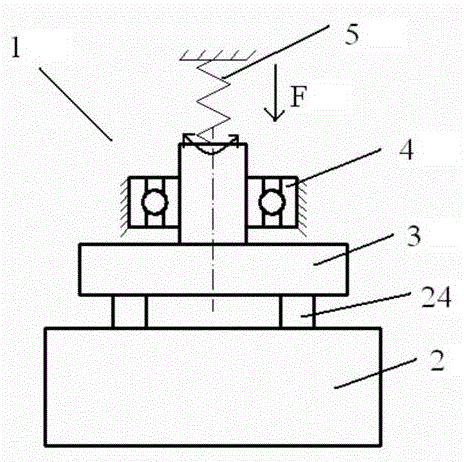

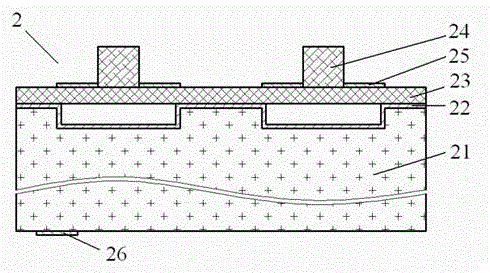

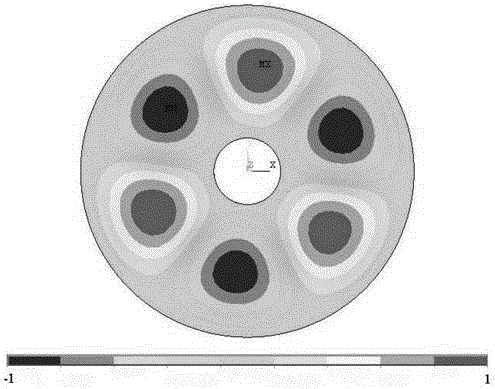

[0018] refer to figure 1 As shown, a micro-ultrasonic motor 1 driven by electrostatic force of the present invention includes: a silicon-based stator 2, a rotor 3, a bearing 4 and an elastic preloading device 5, and the upper surface of the silicon-based stator 2 is provided with a circle of evenly distributed Toothed protrusion 24; one end of the rotor 3 is sleeved in the bearing 4 for rotational movement, and the rotor 3 is in contact with the toothed protrusion 24 of the silicon-based stator 2; the elastic preloading device 5 is along the Axially apply a preload F to the rotor 3, so that a normal pressure is generated between the rotor 3 and the silicon-based stator 2, and the silicon-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com