Temperature-integrated high-performance pressure sensor chip and manufacturing method thereof

A pressure sensor and manufacturing method technology, applied in the field of semiconductors, can solve the problems of discrete sensor performance, sensor temperature drift, and stability deterioration, and achieve the effects of overcoming device performance deterioration, improving mechanical properties, and improving electrical isolation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

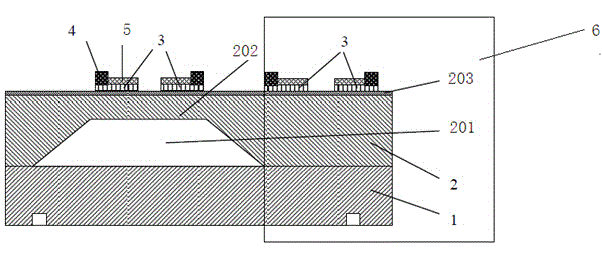

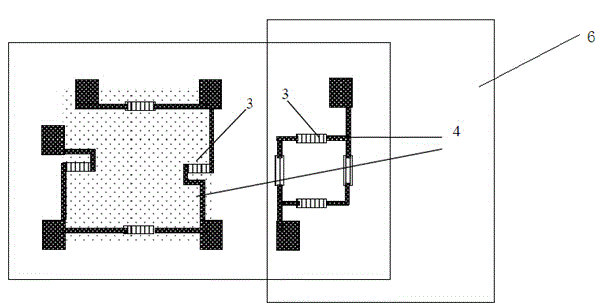

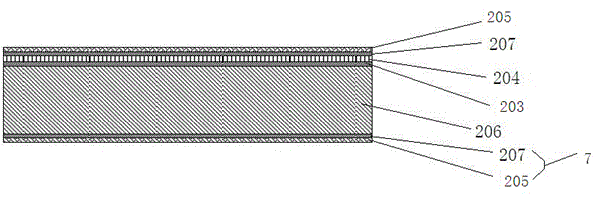

[0038] Such as figure 1 , figure 2 As shown, a high-performance pressure sensor chip with integrated temperature includes a single crystal silicon substrate 1; an SOI silicon wafer 2 with a cavity at the bottom; the single crystal silicon substrate 1 and the cavity of the SOI silicon wafer form a closed cavity 201, and form a pressure sensitive film 202; eight doped single crystal silicon body resistors 3 are arranged on the top layer silicon 204 of the SOI silicon wafer, and an oxide layer 203 is used to isolate the doped single crystal silicon body resistor 3 from the pressure sensitive film 202; Among them, four doped monocrystalline silicon bulk resistors 3 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com