Anti-impact and anti-corrosion coating

A corrosion-resistant and impact-resistant technology, applied in the field of impact-resistant and corrosion-resistant coatings, can solve the problems of impact resistance, insufficient wear resistance, affecting appearance, safety and hygiene, etc., to ensure performance consistency, improve thickening, and excellent resistance. grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

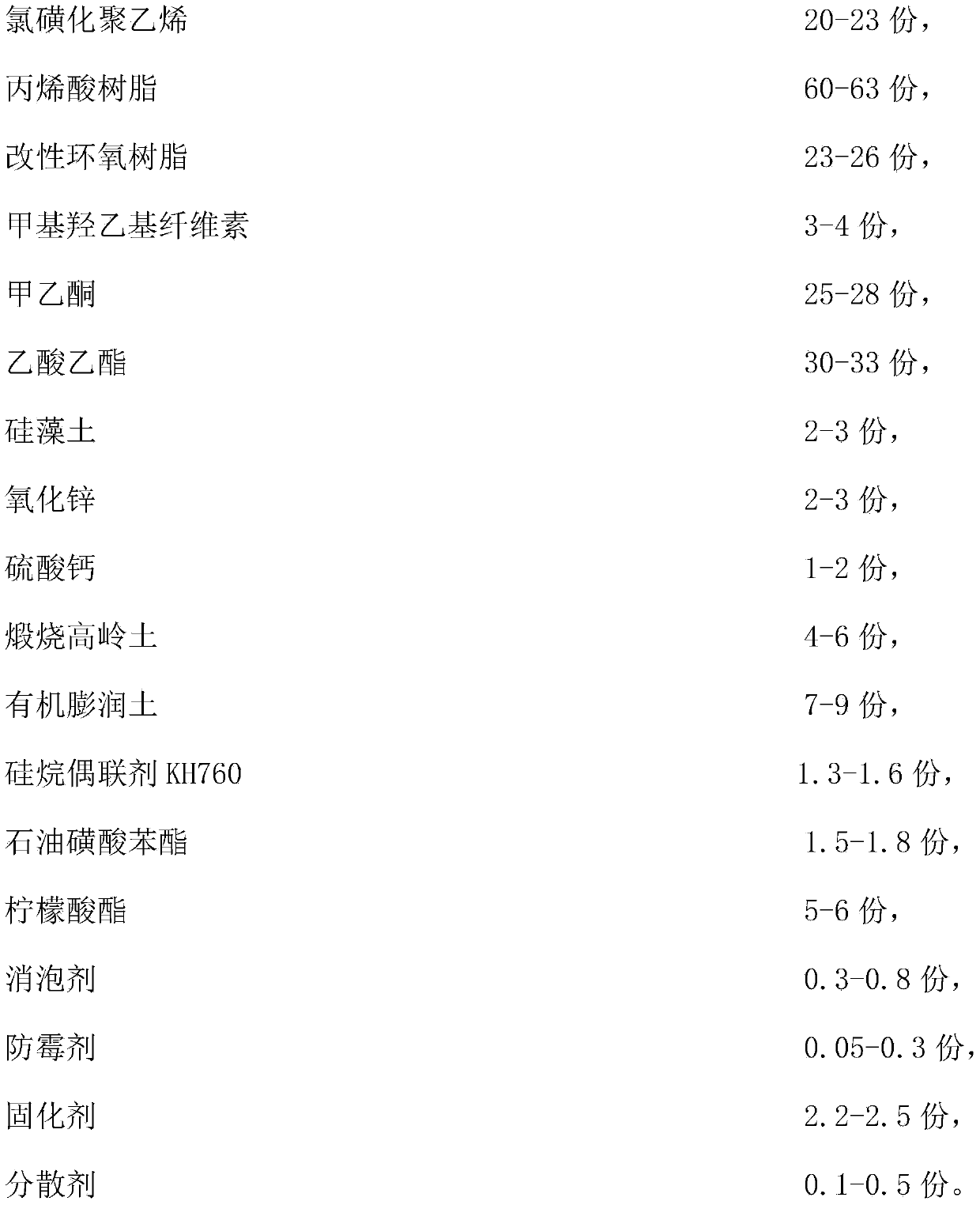

[0016] A kind of impact-resistant corrosion-resistant paint that the present invention proposes, its raw material comprises by weight:

[0017]

[0018]

[0019] Wherein the preparation method of modified epoxy resin comprises: 69 parts of epoxy resins and 32 parts of chloroprene rubbers are mixed homogeneously by weight, then add 52 parts of butyl acetates and mix homogeneously, continue to add 1.8 parts of dibenzoyl peroxide, After 0.26 parts of sulfur and 2.5 parts of zinc oxide, stir at a stirring speed of 415rpm. During the stirring process, raise the temperature to 87°C at a heating rate of 11°C / min, and then raise the temperature to 126°C at a heating rate of 0.5°C / min. , After 5.8 hours of heat preservation, it was cooled to room temperature to obtain a modified epoxy resin.

Embodiment 2

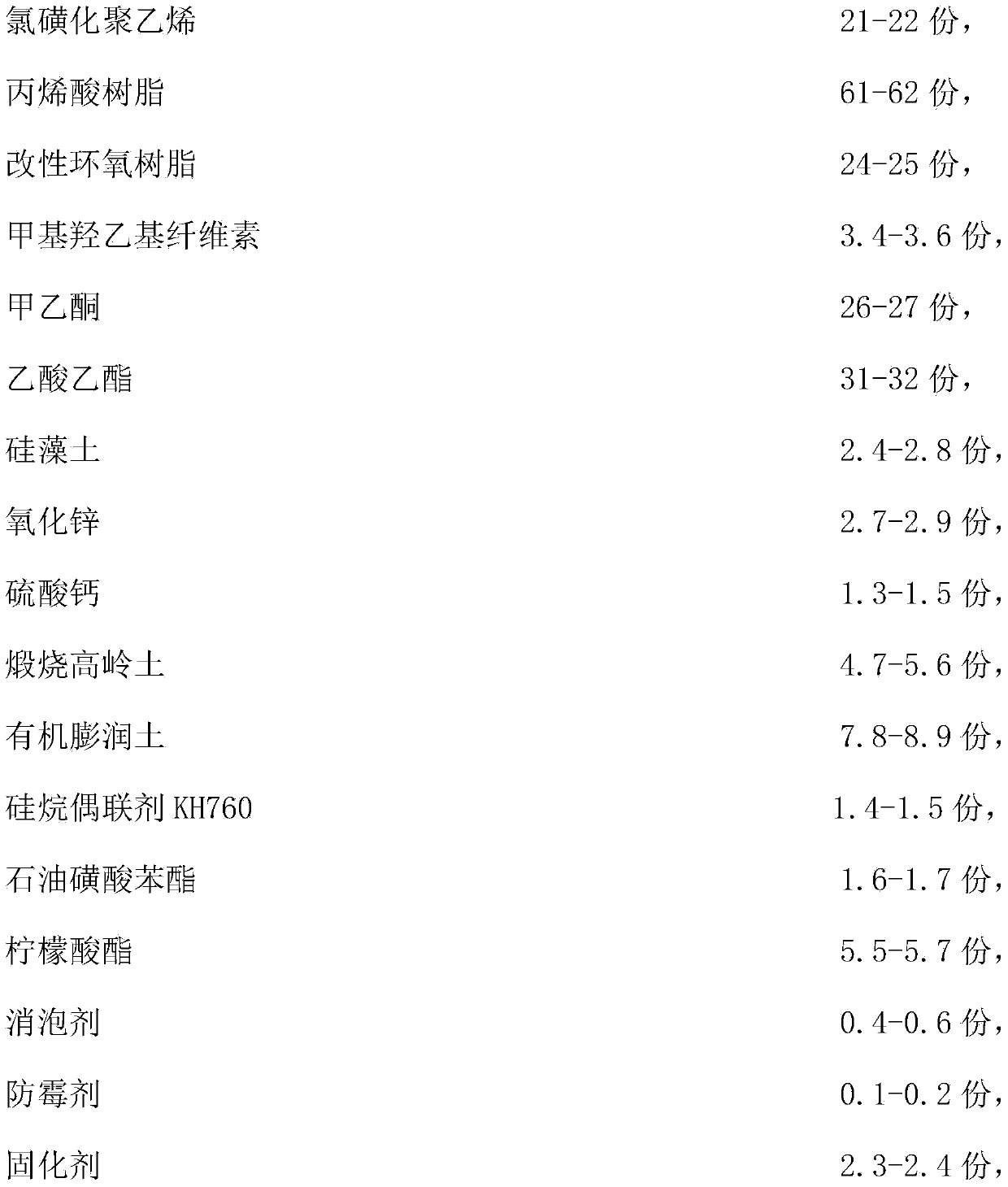

[0021] A kind of impact-resistant corrosion-resistant paint that the present invention proposes, its raw material comprises by weight:

[0022]

[0023]

[0024] Wherein the preparation method of modified epoxy resin comprises: 72 parts of epoxy resins and 29 parts of chloroprene rubbers are mixed homogeneously by weight, then add 53 parts of butyl acetates and mix homogeneously, continue to add 1.7 parts of dibenzoyl peroxide, After 0.3 parts of sulfur and 2 parts of zinc oxide, stir at a stirring speed of 420rpm. During the stirring process, raise the temperature to 89°C at a heating rate of 10°C / min, and then raise the temperature to 128°C at a heating rate of 0.3°C / min. , after 5 hours of heat preservation, cooled to room temperature to obtain modified epoxy resin.

Embodiment 3

[0026] A kind of impact-resistant corrosion-resistant paint that the present invention proposes, its raw material comprises by weight:

[0027]

[0028]

[0029] Wherein the preparation method of modified epoxy resin comprises: 68 parts of epoxy resins and 33 parts of chloroprene rubbers are mixed homogeneously by weight, then add 50 parts of butyl acetates and mix homogeneously, continue to add 2 parts of dibenzoyl peroxide, After 0.2 parts of sulfur and 3 parts of zinc oxide, stir at a stirring speed of 400rpm. During the stirring process, raise the temperature to 86°C at a heating rate of 12°C / min, and then raise the temperature to 125°C at a heating rate of 0.6°C / min. , After 6 hours of heat preservation, it was cooled to room temperature to obtain a modified epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com