Tobacco additive dropping pill with improved brittleness and preparation method thereof

A technology for cigarette additives and drop pills, which is applied in the fields of tobacco, applications, and smoke oil filters, etc. It can solve problems such as poor user experience, high plasticity and toughness of drop pills, and use of large force, so as to improve consumption experience and good Brittle feel, the effect of reducing the crushing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Configure glue solution 500ml according to the ratio listed in Table 1, and use the dropping pill machine to drop the cigarette additive dropping pill capsule. The dripping machine used in the present invention is existing in the prior art, and the present invention uses it to complete the task of the present invention.

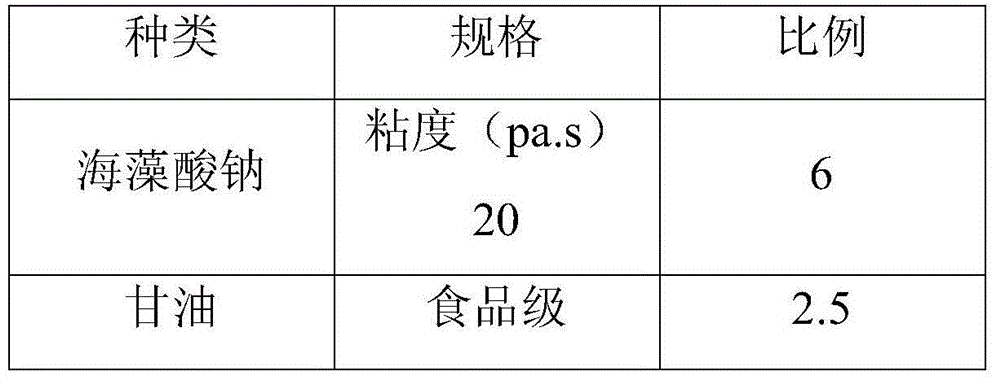

[0013] Table 1 Glue ratio

[0014]

[0015]

[0016] The configured glue drips smoothly, the crushing strength of the dripping pill is 3.6kPa, the thickness of the rubber is 100 microns, the diameter of the dripping pill is 3.5mm, the water content of the dripping pill is 10%, the dripping pill has a tough feeling when pinched hard, the rupture opening is straight, and there is a sound Not crisp enough.

Embodiment 2

[0018] Configure glue solution 500ml according to the ratio listed in Table 2, and use the dropping pill machine to drip the cigarette additive dropping pill capsule. The dripping machine used in the present invention is existing in the prior art, and the present invention uses it to complete the task of the present invention.

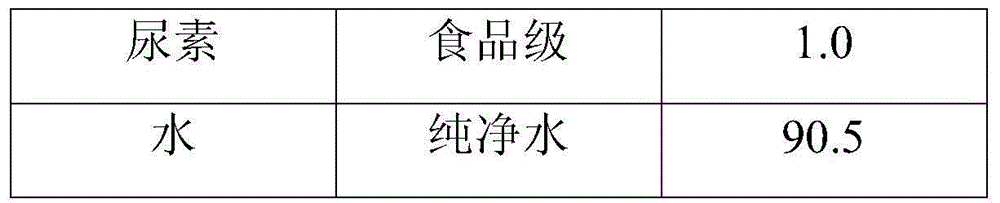

[0019] Table 2 Glue ratio

[0020]

[0021] The configured glue drips smoothly, the crushing strength of the dripping pill is 2.5kPa, the thickness of the rubber is 100 microns, the diameter of the dripping pill is 3.5mm, and the moisture content of the dripping pill is 5%. The sound is crisp.

Embodiment 3

[0023] Configure 500ml of glue solution according to the ratio listed in Table 3, and use the dropping pill machine to drop the cigarette additive dropping pill capsule. The dripping machine used in the present invention is existing in the prior art, and the present invention uses it to complete the task of the present invention.

[0024] Table 3 glue ratio

[0025]

[0026]

[0027] The configured glue drops smoothly, the crushing strength of the dripping pills is 1.2kPa, the thickness of the rubber skin is 100 microns, the diameter of the dripping pills is 3.5mm, and the moisture content of the dripping pills is 2.3%. The dripping pills are easy to crush and feel brittle, and the rupture opening is radial. , The cracking sound is crisp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com