Dry mixing building mortar

A masonry mortar and dry mixing technology, applied in the field of building materials, can solve problems such as occupation of cultivated land and pollution, and achieve the effects of improving compressive strength, reducing costs and reasonable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

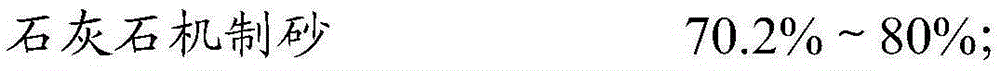

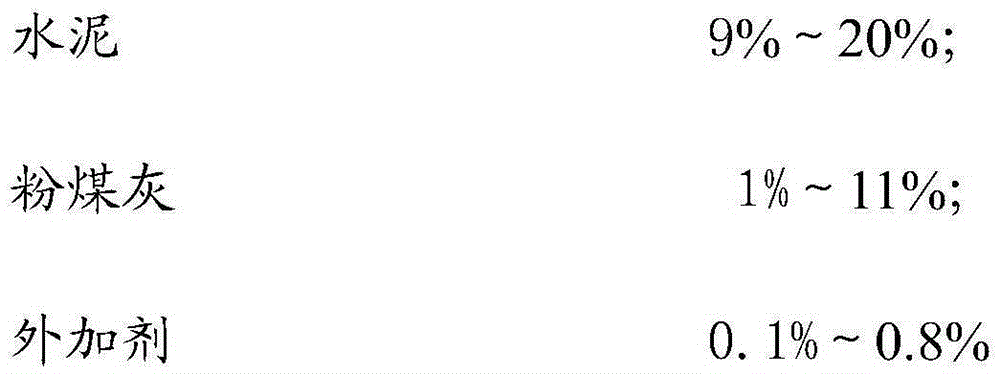

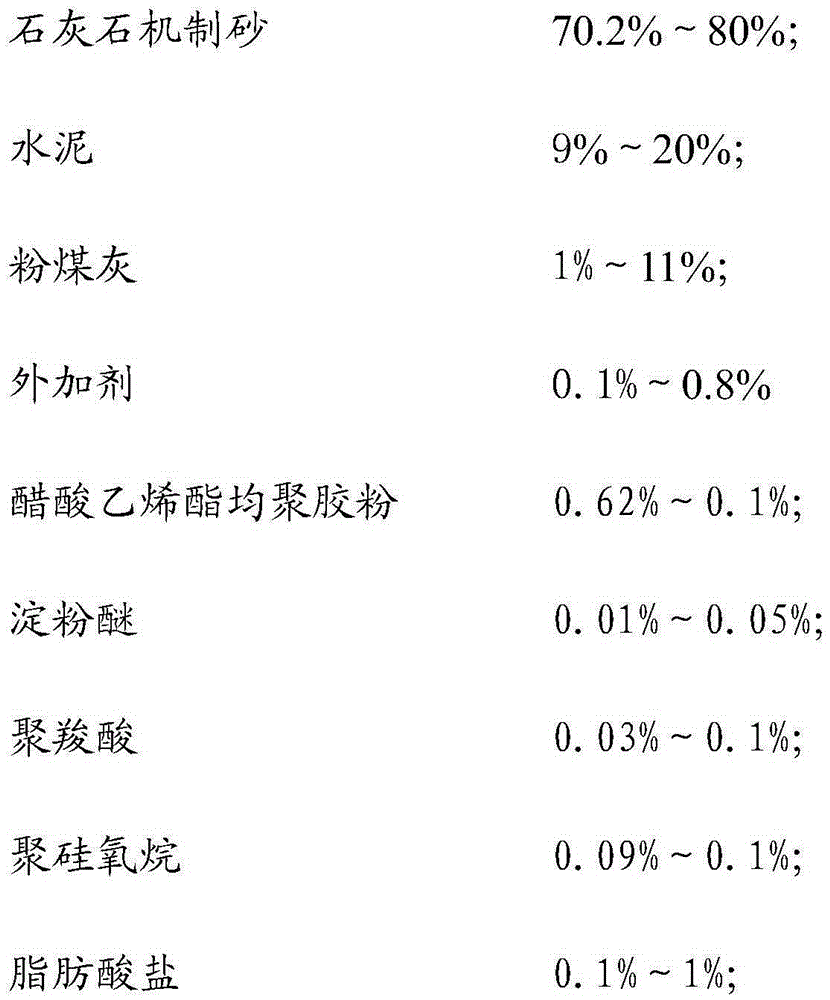

[0027] The invention relates to a kind of dry-mixed masonry mortar, which is characterized in that it comprises the following components in terms of mass percentage:

[0028]

[0029] Wherein, the admixture includes a modifier and a thickener, the modifier is a mixture of starch ether, polysiloxane and polycarboxylic acid, and the thickener is a vinyl acetate homopolymer Powder, the weight ratio of described vinyl acetate homopolymer powder, starch ether, polysiloxane, and polycarboxylic acid is vinyl acetate homopolymer powder: starch ether: polysiloxane: and polycarboxylate= 100:1.6:14.5:4.8.

[0030] Adding vinyl acetate homopolymer powder as a thickener, compared with traditional thickeners, can improve the following properties in dry-mixed mortar: 1. Water retention and workability of freshly mixed mortar; 2. Adhesion to different bases 3. Flexibility and deformation properties of mortar; 4. Flexural strength and cohesion; 5. Wear resistance; 6. Toughness; 7. Compactn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com