Testing system and method for seepage field model of tunnel in construction and operation periods

A model test and seepage field technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as time-consuming, inability to complete the seepage field analysis in the tunnel construction stage, and single effect of simulating the groundwater level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

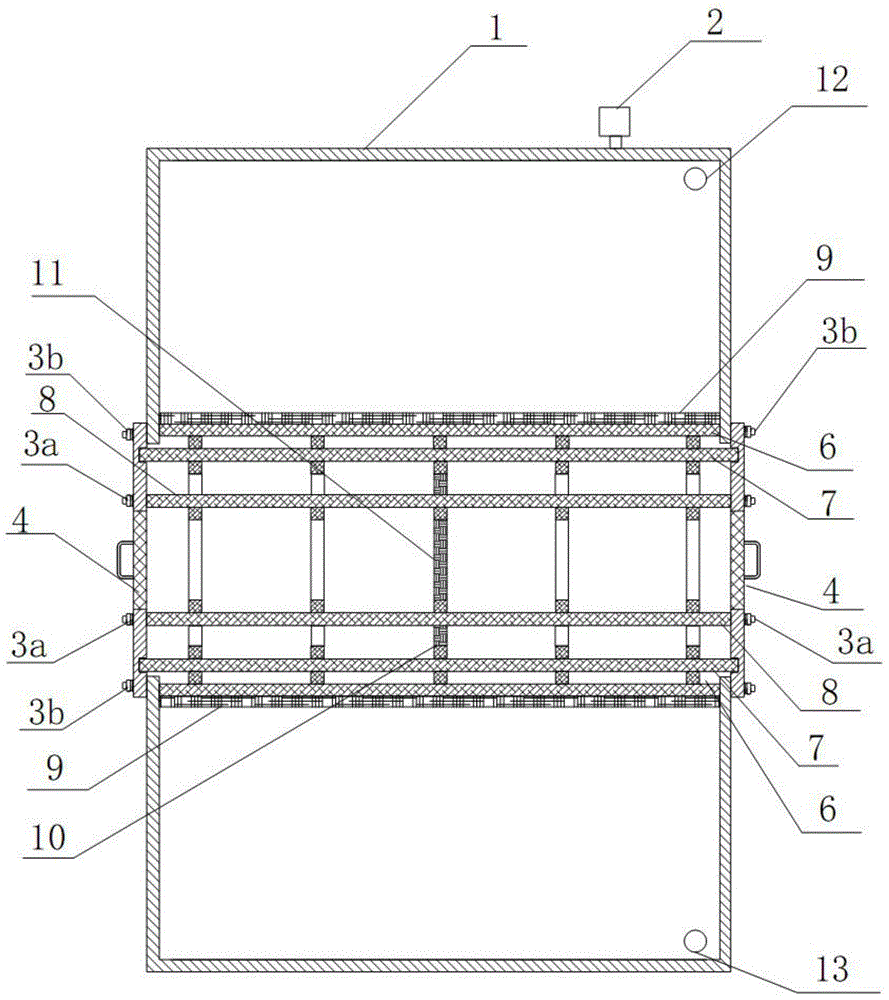

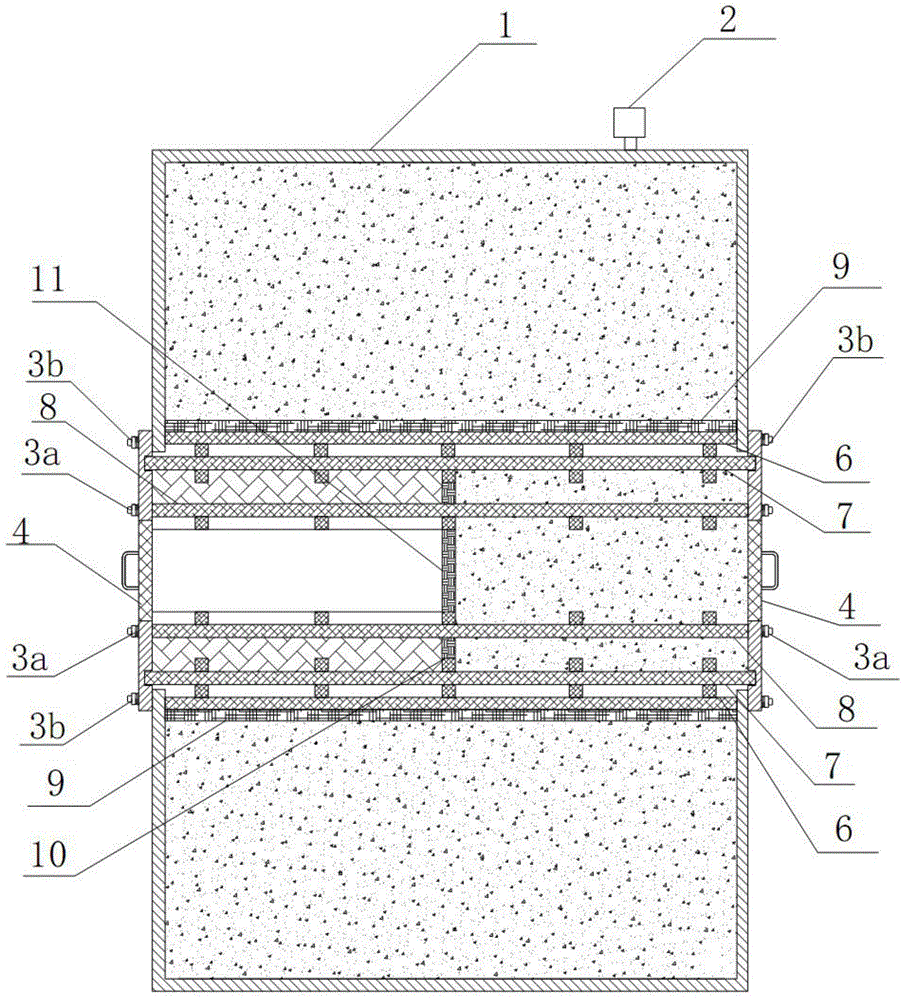

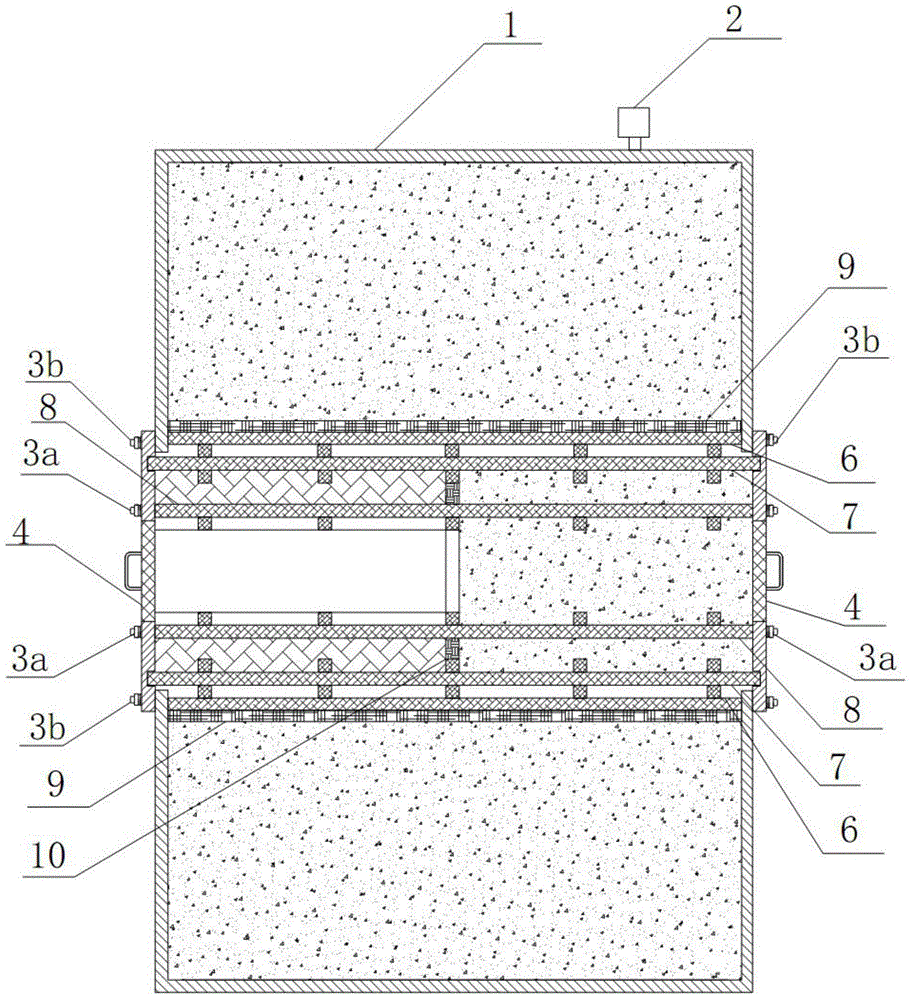

[0042] figure 1 As shown, a specific embodiment of the present invention is: a tunnel seepage field model test system during construction and operation, including a box body 1 of a seepage model box and a data acquisition device for collecting water pressure and seepage flow, and the box body 1 There is a pressure gauge 2 on the top, and an overflow hole 5 for drainage is provided at the bottom of the side wall of the box body 1. Its structural characteristics are:

[0043] The top of the side wall of the box body 1 is provided with an upper water inlet hole 12 of the model box, and the bottom end of the side wall is provided with a lower water inlet hole 13 of the model box; the opposite side walls of the box body 1 are provided with tunnel holes;

[0044] The two ends of the fixed reinforcement cage 6 are welded and fixed on the inner wall of the hole edge of the tunnel hole, the two ends of the outer reinforcement cage 7 and the inner reinforcement cage 8 inside the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com