Sealed deep groove ball bearing waterproofness testing method and testing device

A technology for deep groove ball bearings and test methods, which is applied in the field of water resistance test methods for sealed deep groove ball bearings and devices using the test methods, and can solve problems that have not been reported in literature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

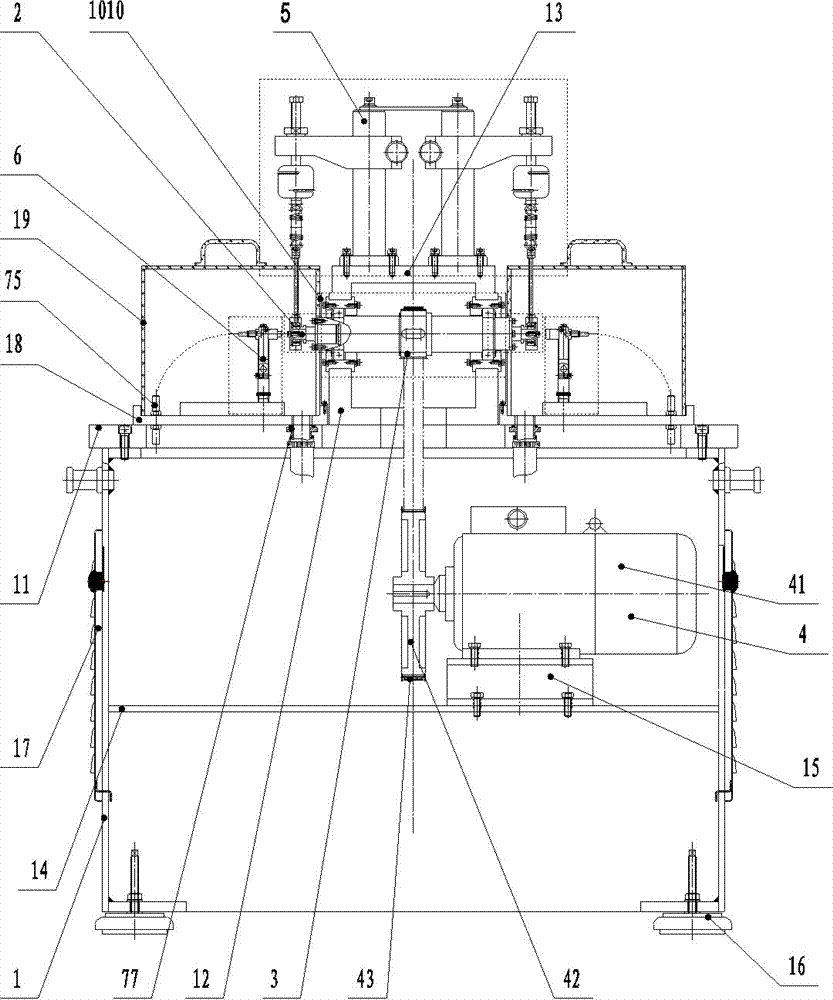

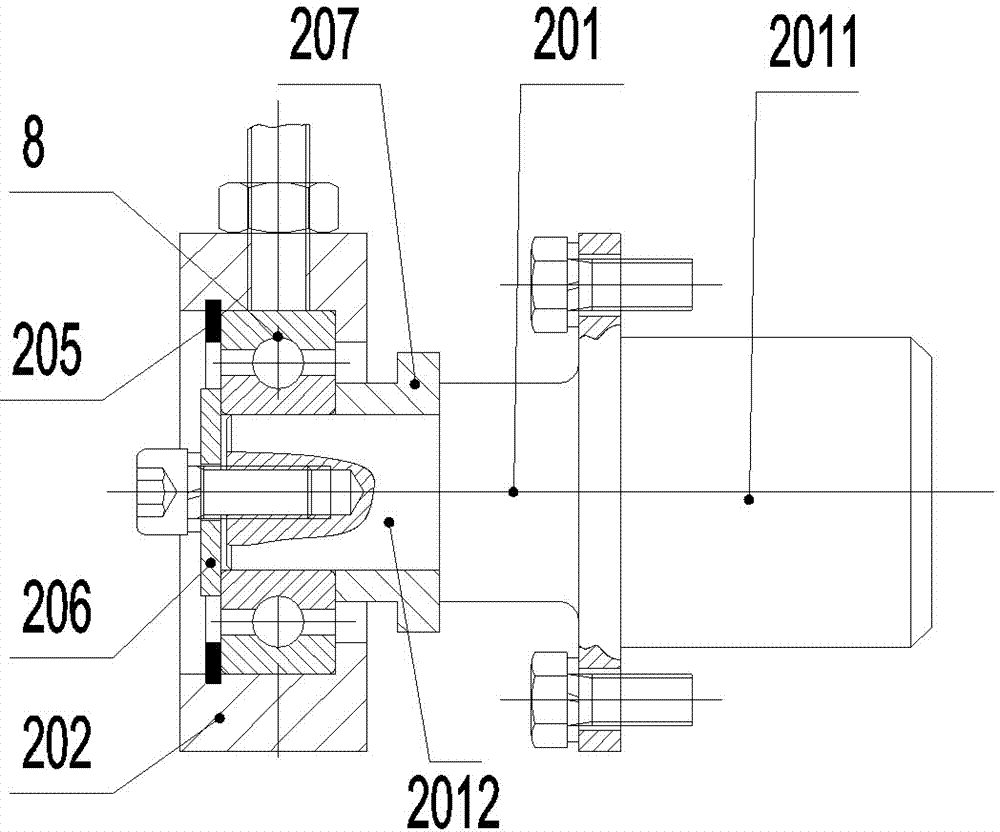

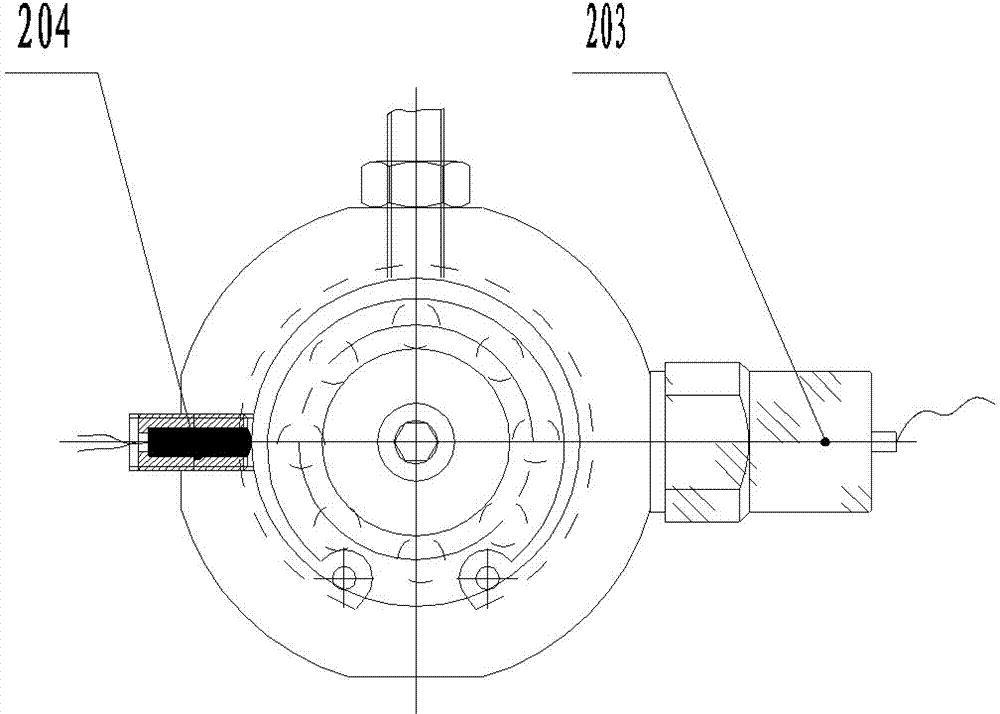

[0051] Embodiment 2 of the test method for water resistance of sealed deep groove ball bearings of the present invention comprises the following steps: the inner ring of the test bearing is driven to rotate through the transmission shaft outputting the rotational motion, and at the same time, a radial load is applied to the outer ring of the test bearing by a radial loading system. To the load, spray water to the end face of the test bearing through the water spray system at the same time; then test the waterproof performance of the test bearing. During the water spraying process, the temperature of the outer ring of the bearing and the vibration of the bearing are tested through the temperature sensor and the vibration sensor arranged on the outer ring of the test bearing. The radial loading system and the test bearing are fixedly connected through the bearing body sleeved on the outer ring of the bearing. The radial loading system includes, from bottom to top, a pull rod exte...

Embodiment 3

[0052] Embodiment 3 of the waterproof test method of sealed deep groove ball bearings of the present invention is different from the above embodiment of the waterproof test method of sealed deep groove ball bearings in that a test bearing is provided at both ends of the transmission shaft, which can simultaneously Two different bearings were tested for water resistance comparison.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com