Method for testing nano thickness thin film endurance character

A technology of fatigue characteristics and test methods, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of difficult film damage degree, insignificant change rules, fatigue characteristics research, etc., to achieve reliable test methods and operation. Simple, small test area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

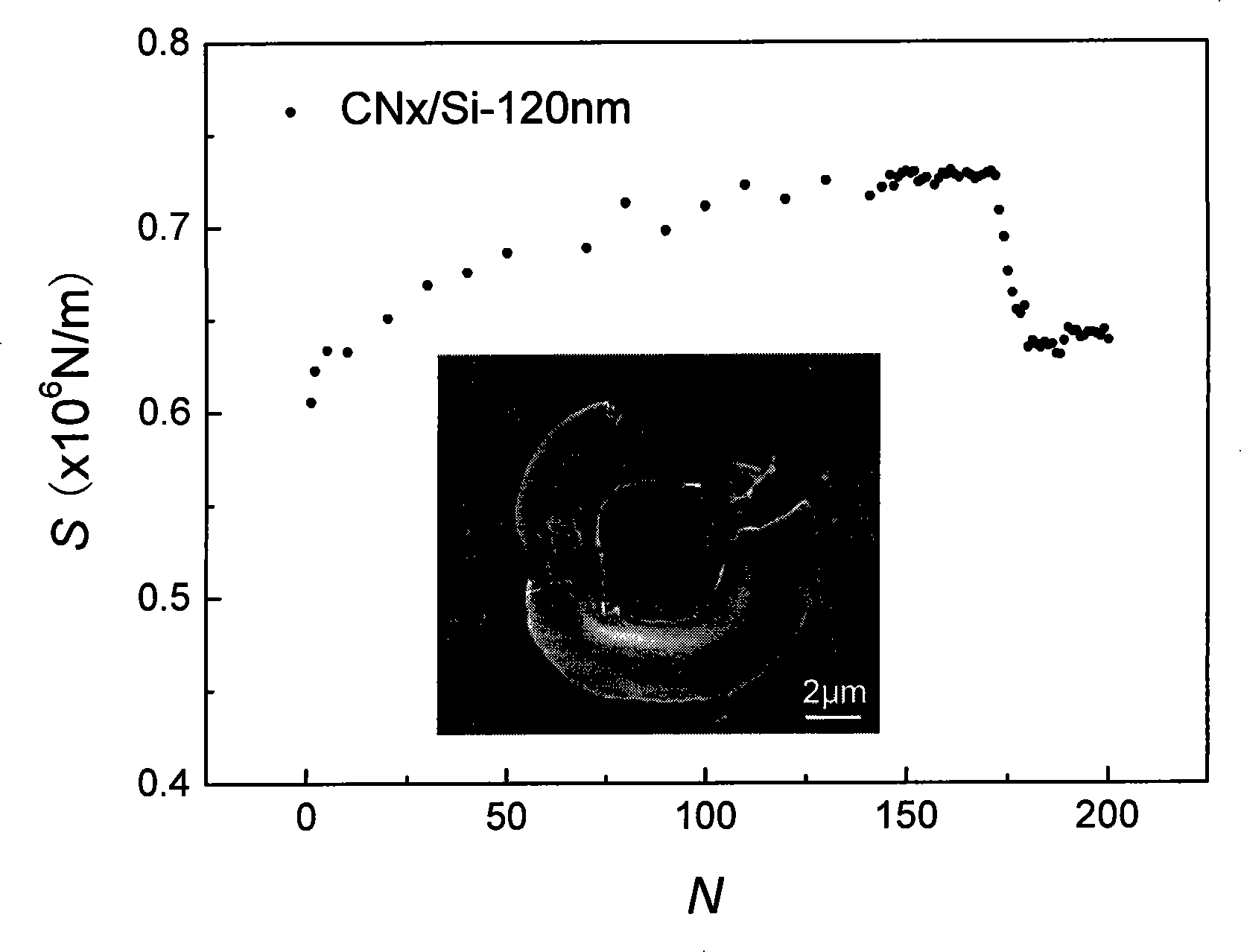

[0025] Two silicon-based carbon-nitride films (CNx / Si) with a length and width of 10mm and a total thickness of 0.5mm were used as test samples, one of which was 50nm thick and the other 120nm thick. Taking the test of these two samples as an example, the specific operation steps of the method of the present invention are illustrated. The steps are:

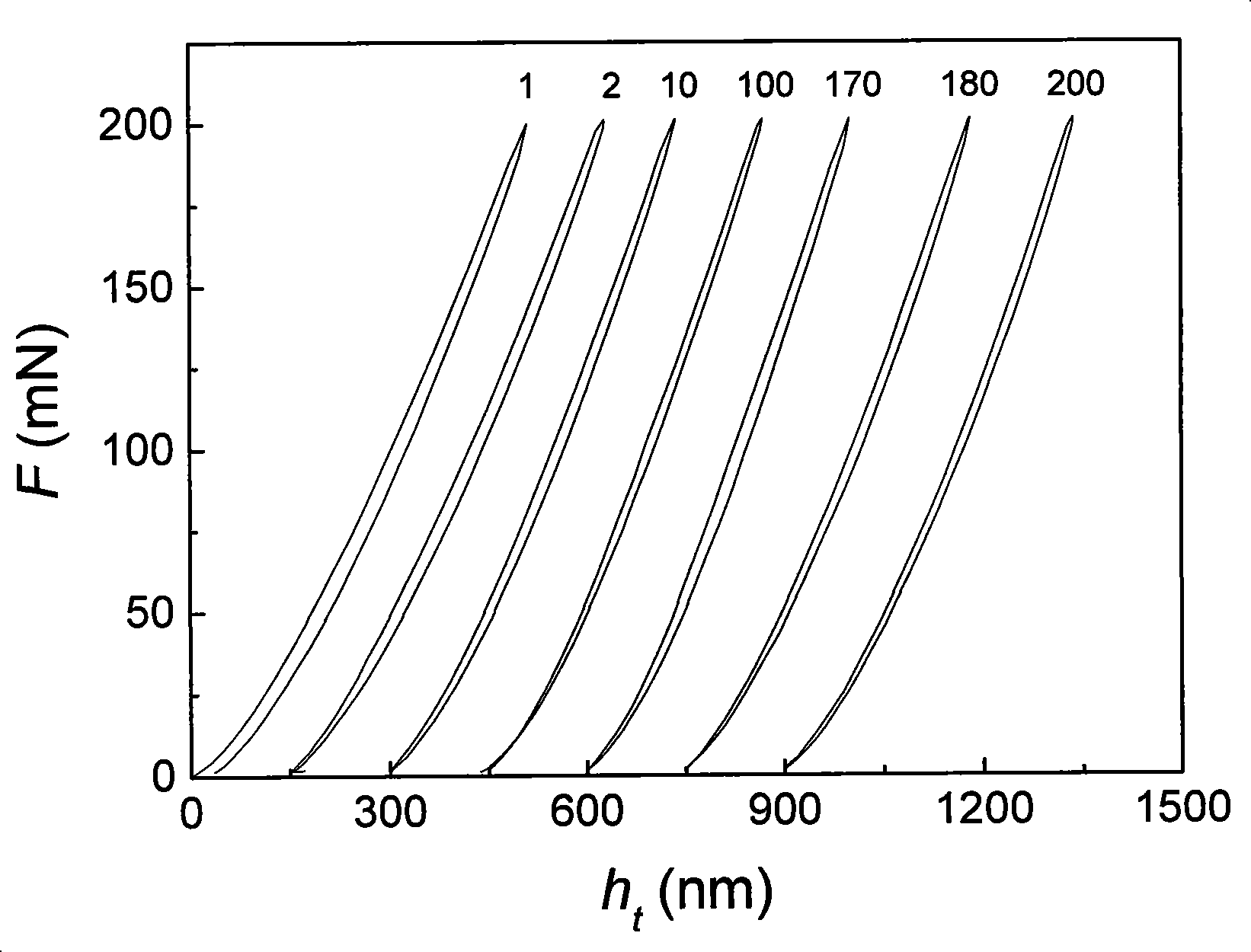

[0026] a. Using indentation equipment, the spherical indenter is used to conduct cyclic radial loading and unloading experiments on the nano-thickness film to be tested under the condition of a fixed peak load, and the load F and displacement h during the loading and unloading process are simultaneously detected by the sensor t The signal is sent to the data processing equipment for the following steps b, c, and d:

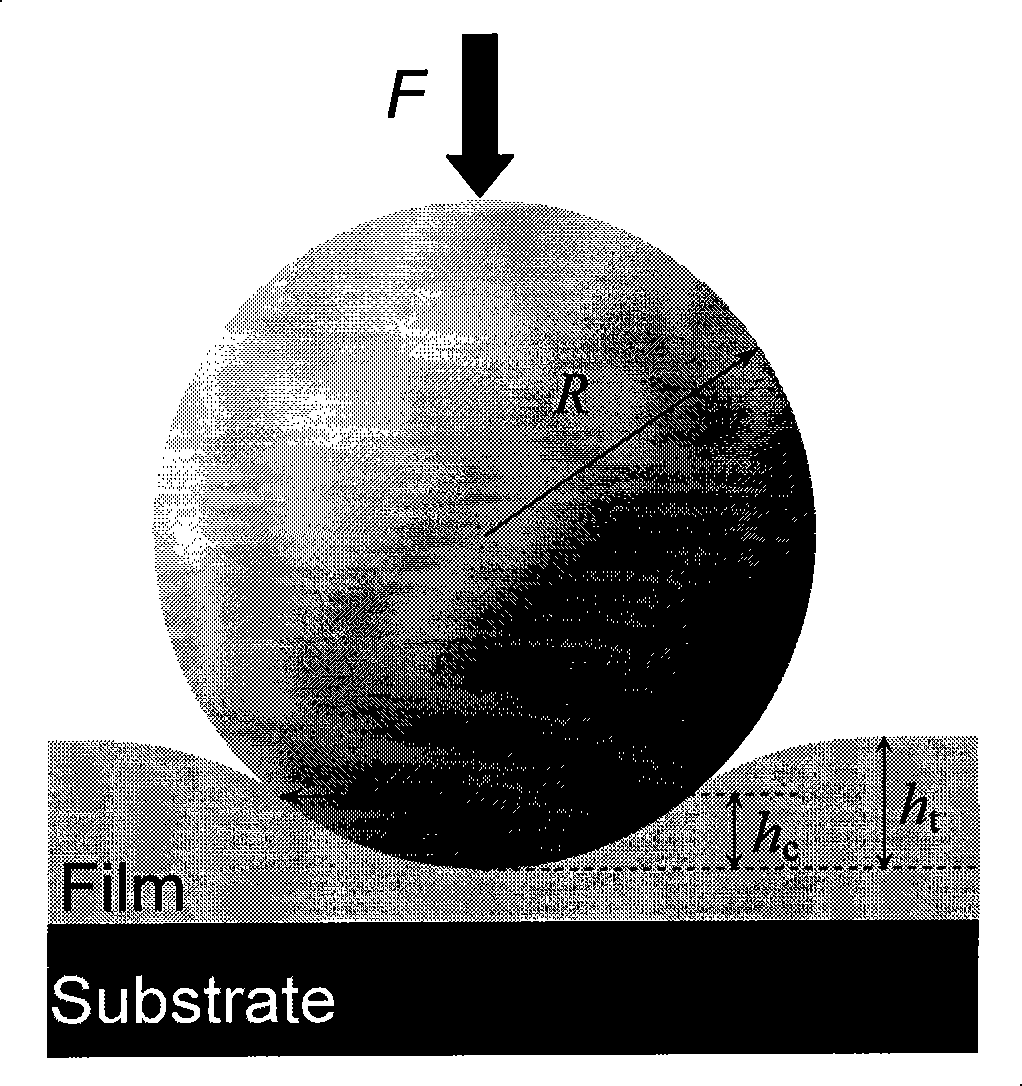

[0027] figure 1 That is, the schematic diagram of the test when the spherical indenter is pressed into the test sample material, where Film is the film on the surface, Substrate is the base layer, and R is the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com