Concrete absolute stress measurement device and method

A measuring device and concrete technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of not many researches on acoustic characteristics, the inability to accurately and completely reflect the stress state of concrete structures, etc., and achieve the measurement operation The effect of simplicity, low production cost and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

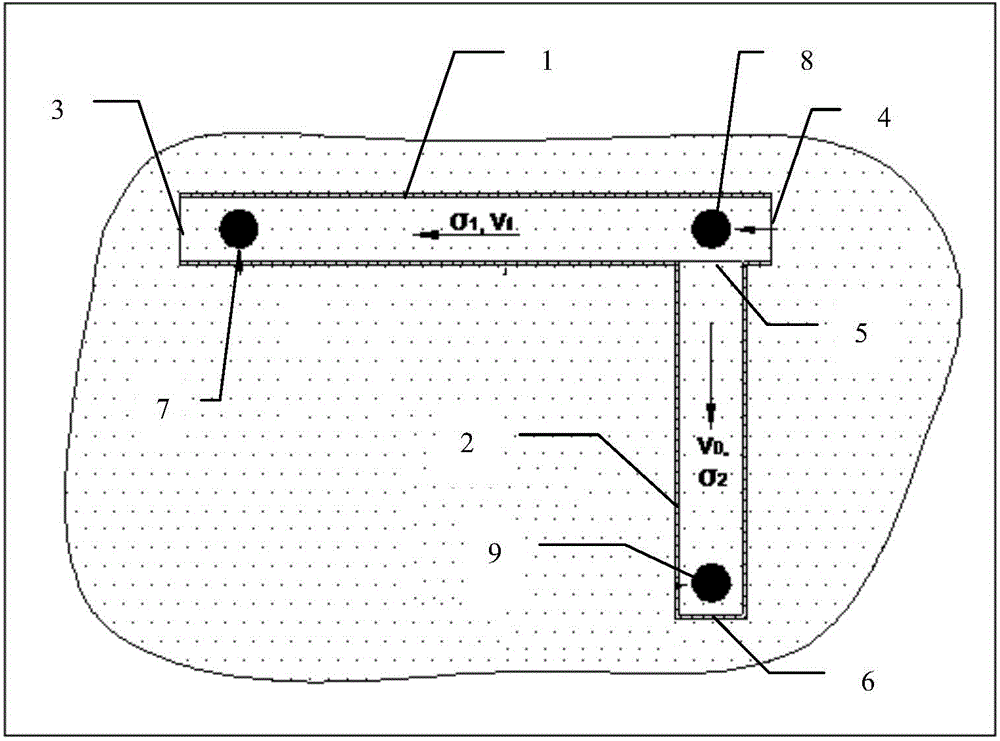

[0019] refer to figure 1 , a preferred embodiment of the present invention provides a concrete absolute stress measuring device, including a first stainless steel pipe 1 and a second stainless steel pipe 2, characterized in that the port A3 and port B4 of the first stainless steel pipe 1 are open, the second Two stainless steel tubes 2 are vertically arranged on the side of the first stainless steel tube 1 near the port B4, the port C5 of the second stainless steel tube 2 is an opening and communicates with the first stainless steel tube 1, and the port D6 of the second stainless steel tube 2 is sealed; Inside a stainless steel pipe 1, a first ultrasonic receiving probe 7 is arranged near the port A3, and an ultrasonic transmitting probe 8 is arranged above the port C; inside the second stainless steel pipe 2, near the port D, a The second u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com