Shaft force measuring sensor

A technology for measuring sensors and sensor substrates, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problem that the range and installation size of the axial force sensor cannot be taken into account at the same time, and achieve the effect of low cost, high reliability and wide frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

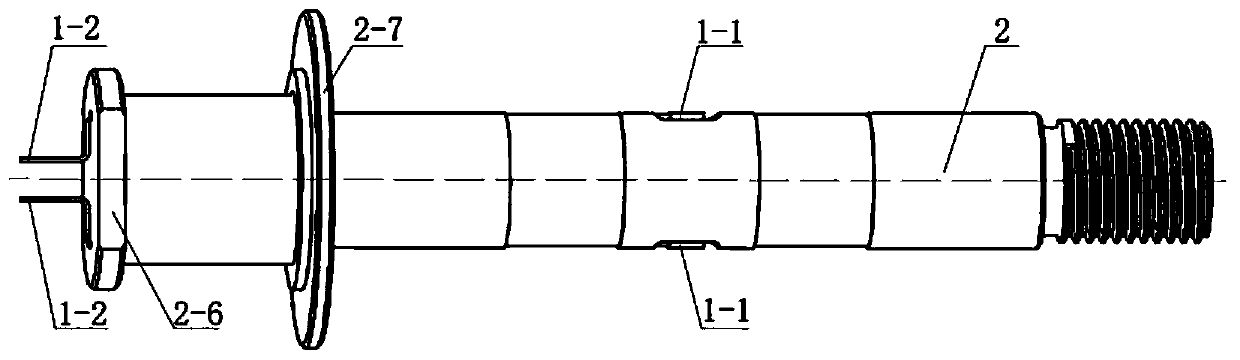

[0028] The resistance of the sensitive element 1 and the resistance strain gauge 1-1 is 120Ω.

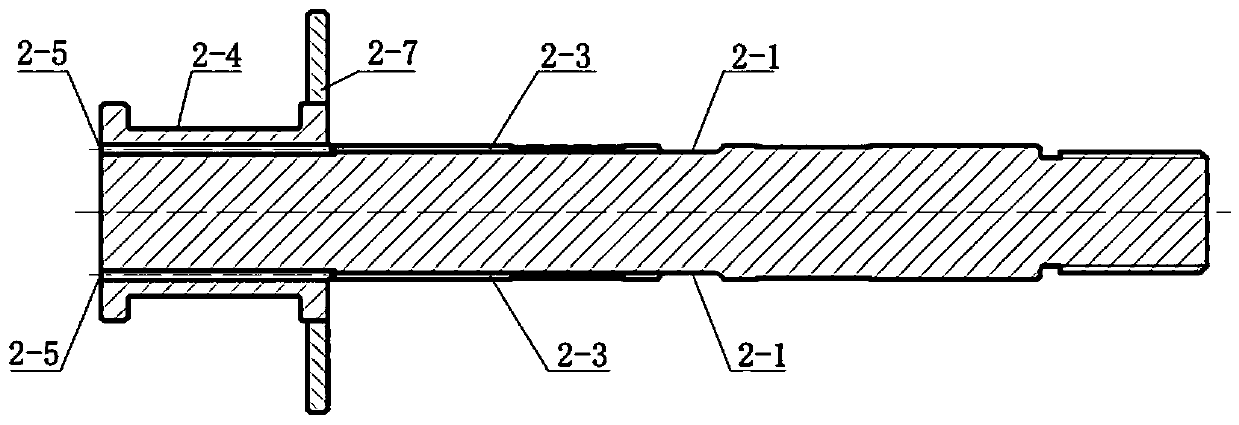

[0029] The assembly part of the sensor base 2 is a second cylinder with a matching dimension of φ40mm.

[0030] The sensor base 2 has M36 external threads on the peripheral surface of the second cylinder tail end.

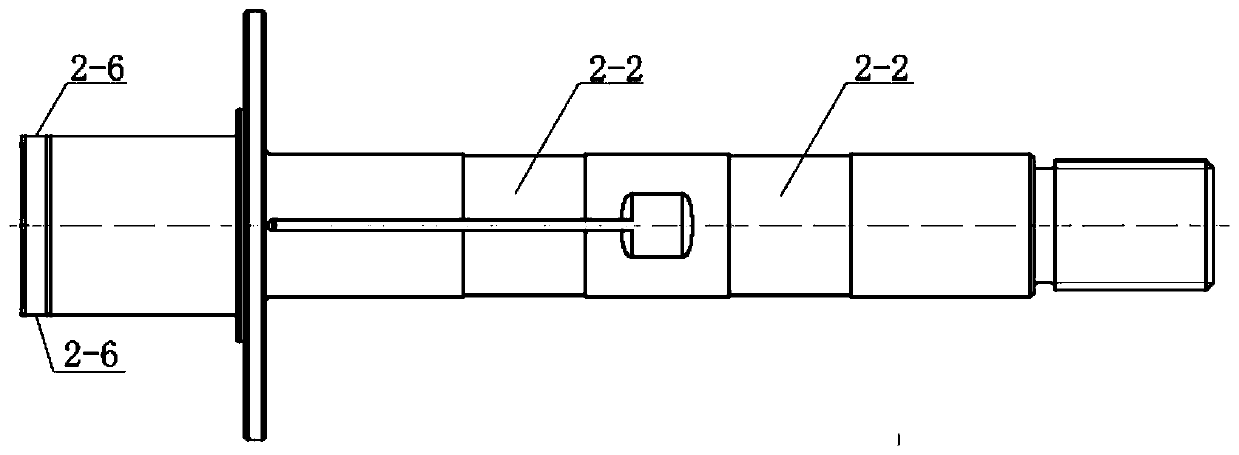

[0031] In the sensor base 2, the first annular groove 2-2 on the second cylinder is 34mm wide and 0.5mm deep, and the first plane 2-1 between the two first annular grooves 2-2 is 14mm long and 2mm deep .

[0032] In the sensor substrate 2, the two wiring slots 2-3 on the second cylinder are 2mm wide and 2mm deep. The diameter of the two wiring holes 2-5 on the top end surface of the first cylinder is φ2mm.

[0033] In the sensor base 2, the second annular groove 2-4 on the outer circumference of the first cylinder has a width of 52 mm and a diameter of φ50 mm. Both the top boss and the bottom boss have a width of 8mm and a diameter of φ65mm, and the distance between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com