Precision measurement device and method for optical material refractive index

A technology for precision measurement and optical materials, which is applied in measurement devices, optical devices, phase influence characteristic measurement, etc. It can solve problems such as narrow application fields, inability to achieve non-destructive online measurement of optical materials to be measured, and critical angle differences, etc. The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

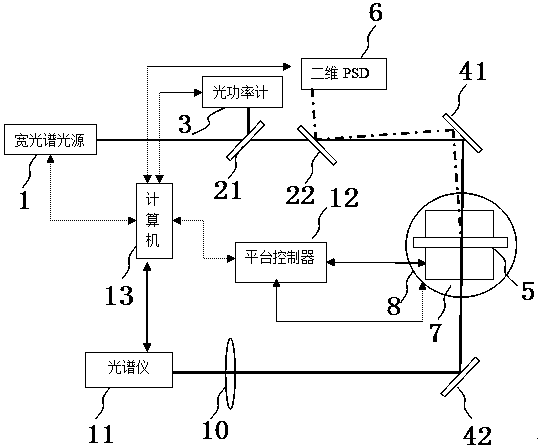

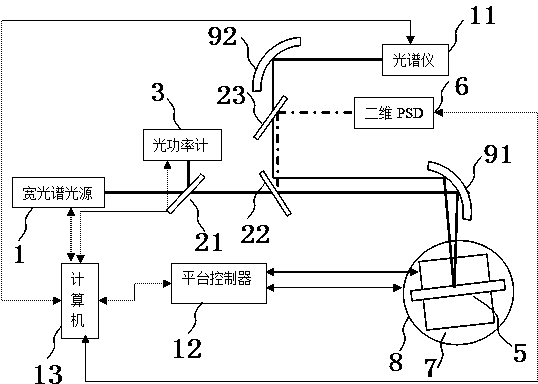

[0048] Such as figure 1 As shown, a transmission-type precision measuring device for the refractive index of optical materials includes a wide-spectrum light source 1, a first beam splitter 21, a second beam splitter 22, an optical power meter 3, a first high reflective mirror 41, a second high reflector Mirror 42, sample to be tested 5, two-dimensional PSD (ie, two-dimensional position sensitive detector) 6, two-dimensional precision mobile loading platform 7, angular displacement platform 8, lens 10, spectrometer 11, platform controller 12 and computer 13 . The platform controller 12 is a Zolix SC300 series platform controller.

[0049] The output optical path of the wide-spectrum light source 1 is provided with a first beam splitter 21, the reflection optical path of the first beam splitter 21 is provided with an optical power meter 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com