Intelligent cable stress cone

A stress cone, intelligent technology, used in cable accessories, cable installation, electrical components, etc., to achieve low system cost, avoid power safety failures, and have little impact on mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

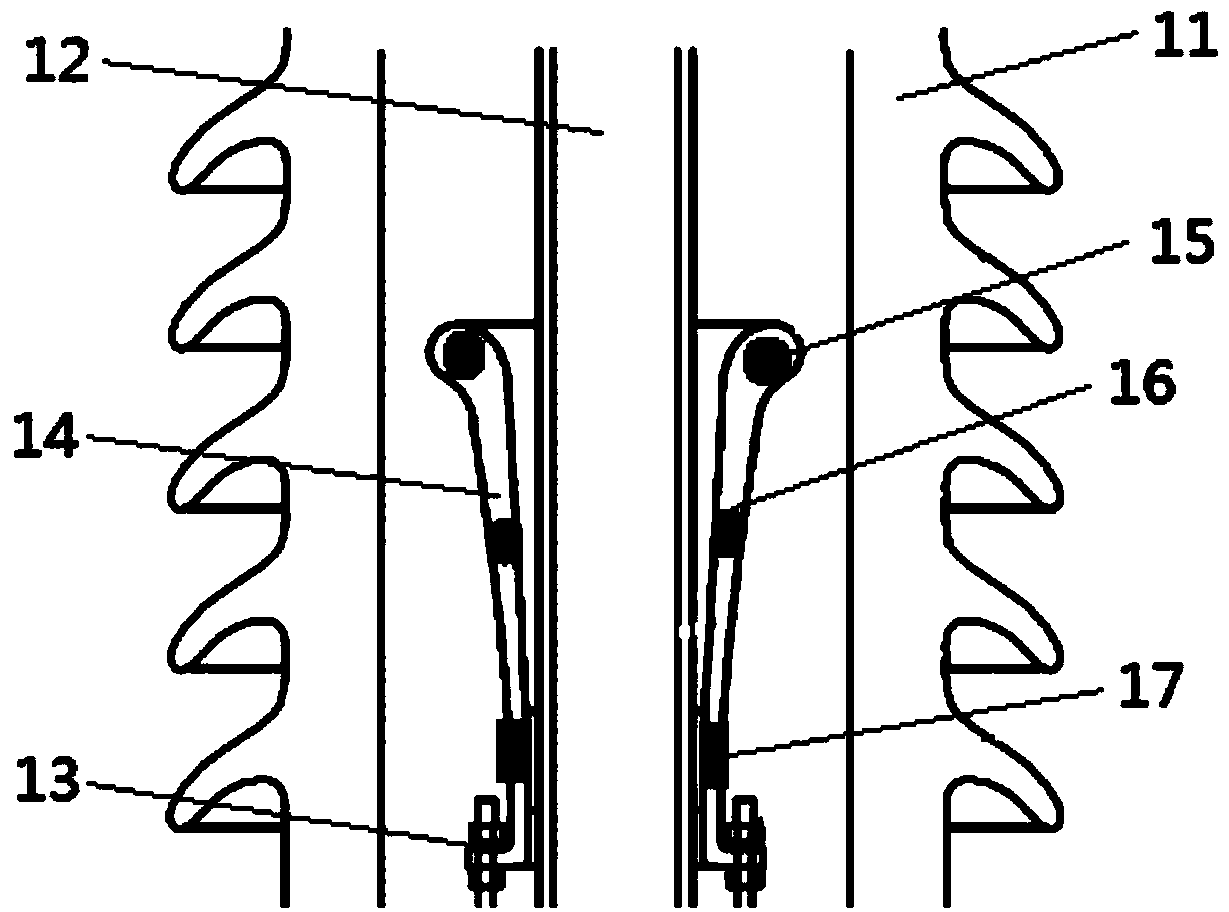

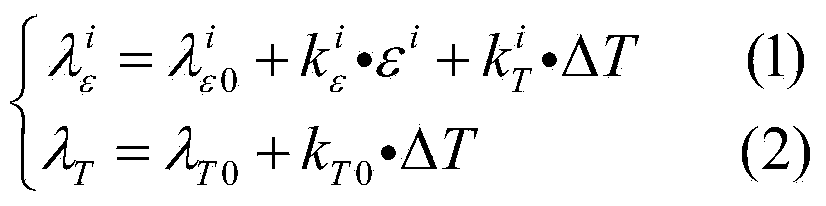

[0022] This embodiment provides an intelligent cable stress cone, the structure of which is as follows: figure 1 As shown, it includes porcelain bushing 11 and cable insulation 12. The cable insulation 12 is set inside the porcelain bushing 11, and also includes grounding bolts 13 and rubber stress cones 14. The rubber stress cones 14 are fixed close to the ground by grounding bolts 13. , the rubber stress cone 14 is provided with a stress sensing fiber grating and a temperature sensing fiber grating 21, the stress sensing fiber grating and the temperature sensing fiber grating 21 are connected in series by a tight-packed optical cable 22, and are poured on the rubber stress cone 14 It is pre-embedded in a spiral shape during production.

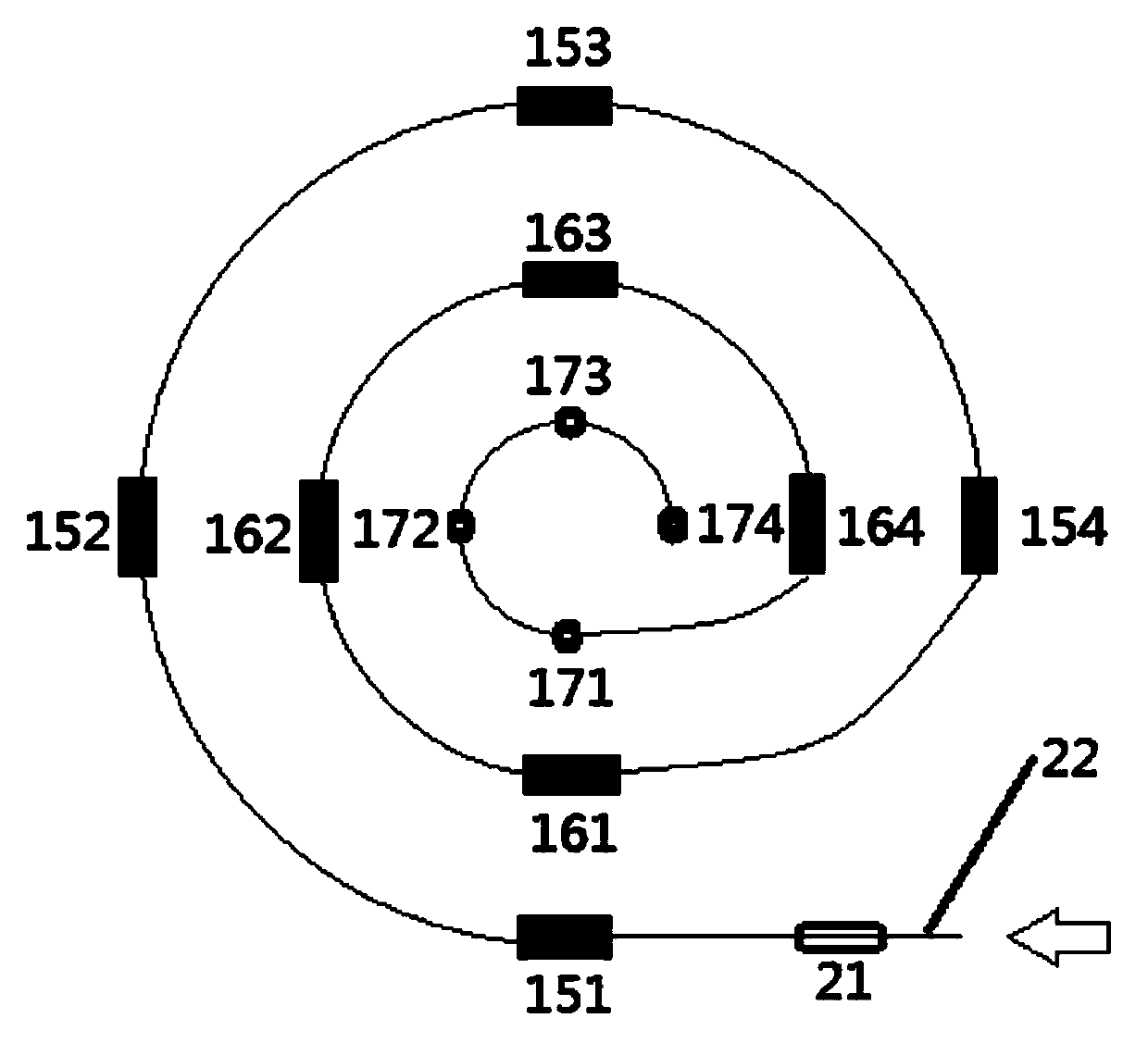

[0023] The stress-sensing fiber grating and the temperature-sensing fiber grating are connected in series by a tight-packed optical cable 22, and its layout is divided into three layers: top, middle and bottom according to the position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com