Apparatus and method for measuring spherical lens

A spherical lens and measuring device technology, which is applied to measuring devices, optical devices, phase influence characteristic measurement, etc., can solve the problems of complex structure of the measuring device and the inability to measure the refractive index and center thickness of spherical lenses at the same time. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. For the convenience of description, the present invention first describes the measuring device for the spherical lens.

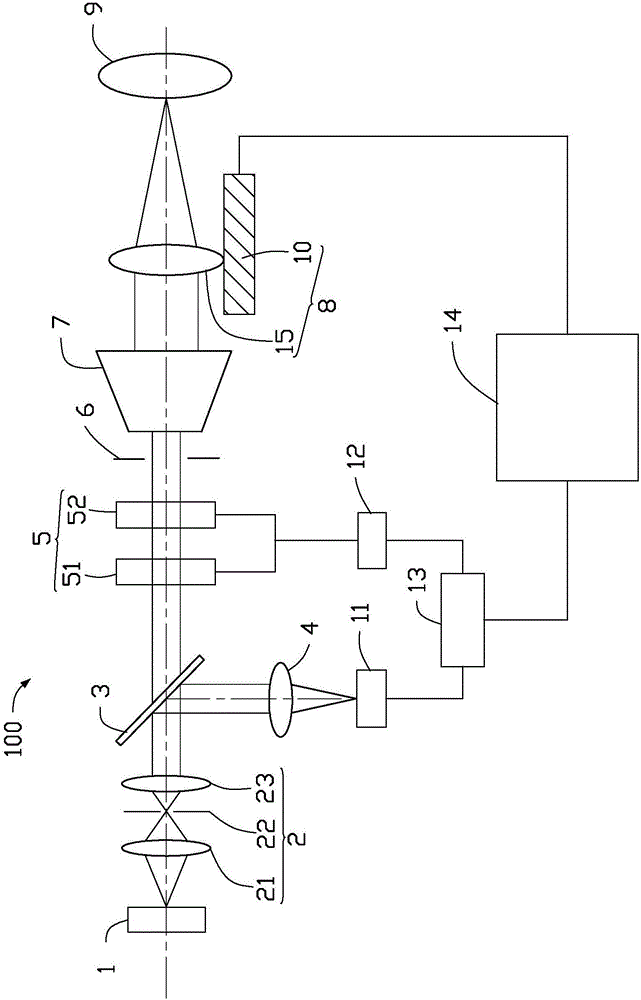

[0021] see figure 1 , The measuring device 100 of the spherical lens comprises: a laser module 1 for continuously outputting laser; It is divided into two beams of reflected light and transmitted light; an acoustic light frequency shifting module 5 is arranged on the optical path of the transmitted light output by the beam splitter 3 to form measurement light; an aperture 6 and a beam expander 7 are sequentially arranged at intervals The beam expansion light is formed on the optical path of the measurement light produced by the acousto-optic frequency shifting module 5; a measurement module 8 includes a first measuring mirror and a second measuring mirror, and the first measuring mirror and the second measuring mirror take turns Arranged on the optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com