Riveting joint geometric parameter detection method

A detection method and a technology of geometric parameters, which are applied in the field of detection of geometric parameters of riveted joints, can solve the problems of being unsuitable for industrial production, labor-intensive, and time-consuming, and achieve the effects of reducing measurement errors, improving measurement efficiency, and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

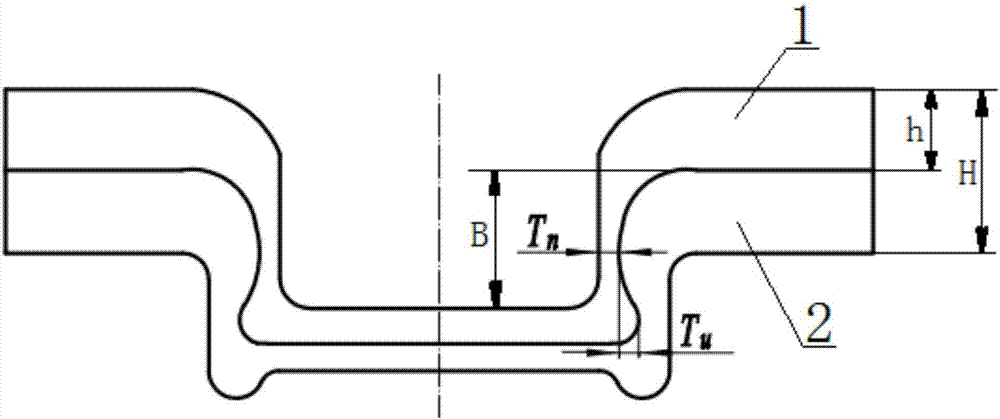

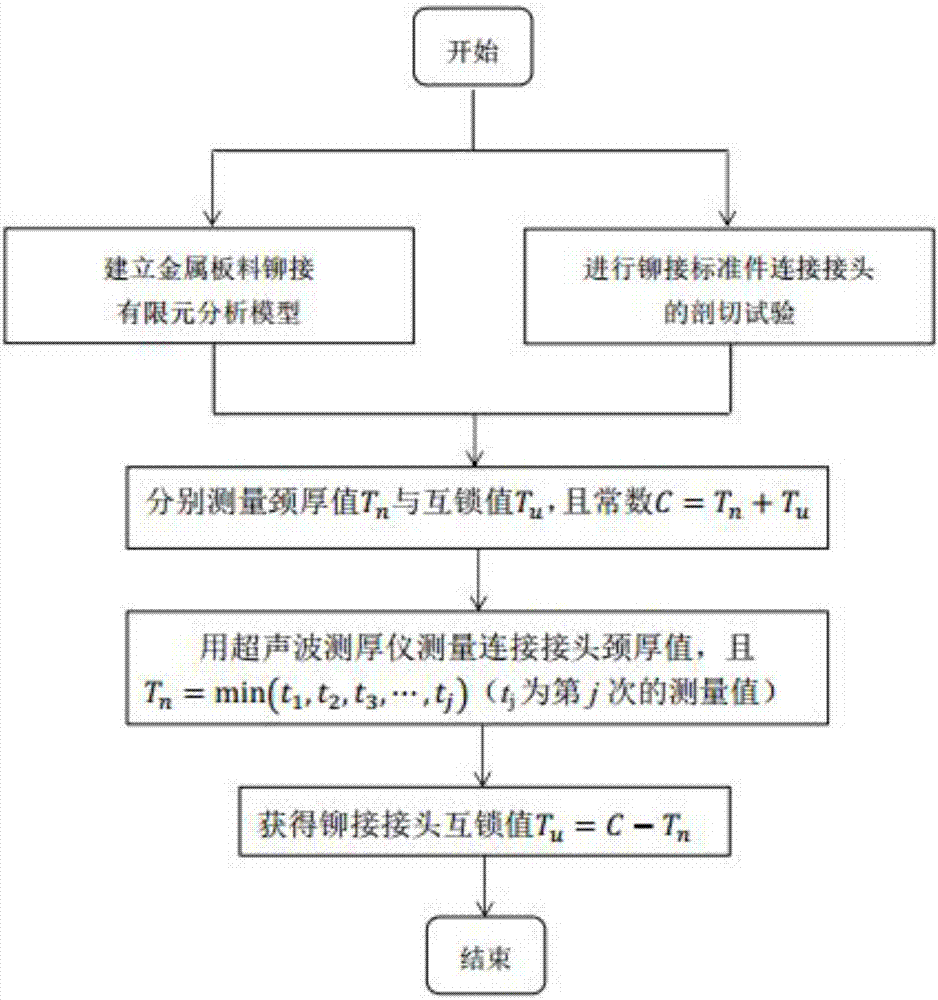

[0052] Step 1: Establish a steel and aluminum riveting analysis model in the finite element software, where the upper sheet is a 1.6mm thick steel plate DP590, and the lower sheet is a 1.5mm thick aluminum alloy AA6061-T6;

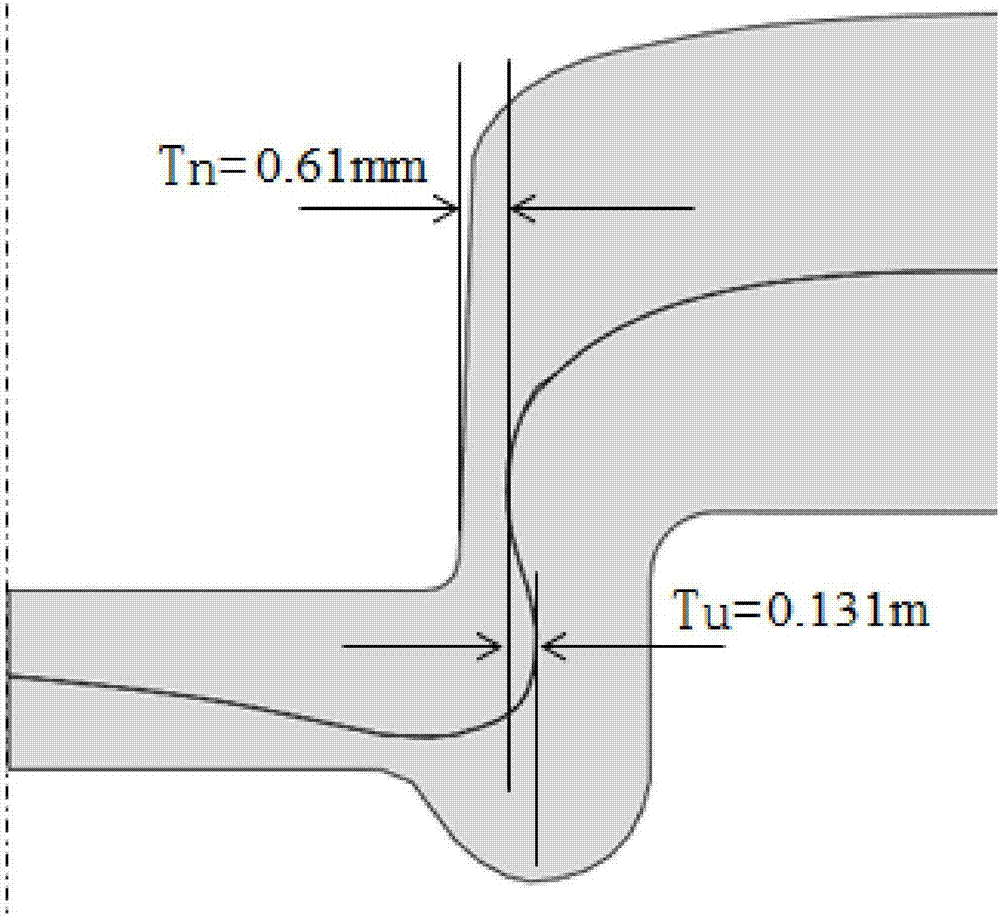

[0053] Step 2: Measure the neck thickness and interlock value of the model calculated by the finite element software, such as image 3 Shown, the neck thickness T n 0.61mm, interlock value T u is 0.131mm, the constant C is obtained by the following formula, where,

[0054] C=T n +T u =0.61+0.131=0.741mm

[0055] Choose L 25 (5 6 ) Orthogonal test table, in the finite element software, the impact of the punch diameter, punch draft angle, punch fillet, die groove depth and die depth on the neck thickness value and interlock value of the die is studied. The test table and simulation results are shown in Table 1, and the neck thickness value and interlock value of each group are analyzed, so that

[0056]

[0057] Among them, L 1 is the punch diame...

Embodiment ( 2

[0065] Step 1: Carry out self-piercing riveting tests on steel and aluminum without rivets. The upper sheet is 1.6mm thick steel plate DP590, and the lower sheet is 1.5mm thick aluminum alloy AA6061-T6. Two riveted joints under different process parameters Make a number.

[0066] Step 2: Cut 1# riveted joint, such as Figure 6 As shown, use the measuring tool to measure the neck thickness value and interlock value of the connection section, the neck thickness value T n 0.58mm, interlock value T u is 0.17mm, so the constant C is:

[0067] C=T n +T u =0.58+0.17=0.75mm

[0068] Step 3: Use an ultrasonic thickness gauge to measure the thickness of the upper sheet within the range of B several times along the inner side of the 2# riveted joint, and then select the minimum value from the multiple measurement results as the neck thickness of the riveted joint, namely:

[0069] T n =min(0.63, 0.61, 0.85, 0.56, 0.57, 0.73, 0.89) mm

[0070] Measurement result T n is 0.56mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com