Preparation method of hexanitrohexaazaisowurtzitane/p-benzoquinone cocrystal explosive

A technology of hexanitrohexaazide and isowurtzitane is applied in the field of energetic materials, which can solve the problem of no public literature report on the preparation of CL-20-PBQ eutectic explosive, and achieve the effects of saving manpower and material resources and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

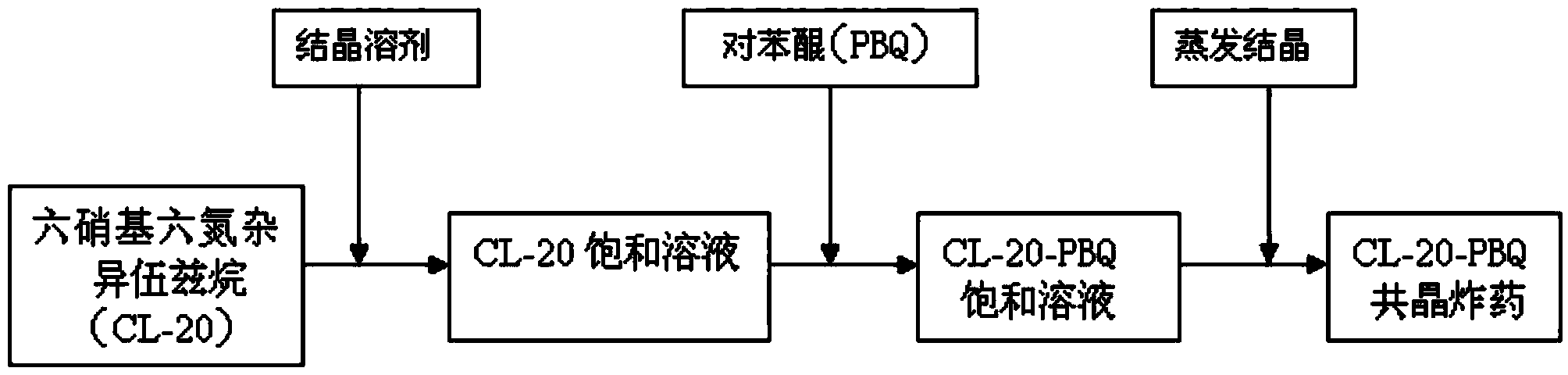

[0029] At room temperature, add 60ml of ethanol into the three-necked flask, then add a sufficient amount of CL-20 under stirring, raise the temperature to 30°C, dissolve and filter to obtain a saturated solution of CL-20. Then add a sufficient amount of PBQ, stir, dissolve, and filter, and the resulting filtrate is a saturated solution of CL-20-PBQ. Put the filtrate in a beaker, then put it still in a constant temperature box at 30°C, let the solvent evaporate, precipitate crystals, and dry to obtain CL-20-PBQ eutectic explosive.

Embodiment 2

[0031] At room temperature, add 50ml of methanol into the three-necked flask, then add enough CL-20 under stirring, raise the temperature to 35°C, dissolve and filter to obtain a saturated solution of CL-20. Then add a sufficient amount of PBQ, stir, dissolve, and filter, and the resulting filtrate is a saturated solution of CL-20-PBQ. Put the filtrate in a beaker, then put it still in a constant temperature box at 30°C, let the solvent evaporate, and precipitate crystals. Dry to obtain CL-20-PBQ eutectic explosive.

Embodiment 3

[0033] At room temperature, add 50ml of ethyl acetate into the three-necked flask, then add enough CL-20 under stirring, dissolve and filter to obtain a saturated solution of CL-20. Then add a sufficient amount of PBQ, stir, dissolve, and filter, and the resulting filtrate is a saturated solution of CL-20-PBQ. Put the filtrate in a beaker, then put it still in a constant temperature box at 30°C, let the solvent evaporate, precipitate crystals, and dry to obtain CL-20-PBQ eutectic explosive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com