Nano eutectic explosive and preparation method thereof

A eutectic explosive, nanotechnology, applied in explosive processing equipment, explosives, offensive equipment and other directions, can solve problems such as potential safety hazards, achieve the effects of good safety, mild experimental conditions, and improved mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

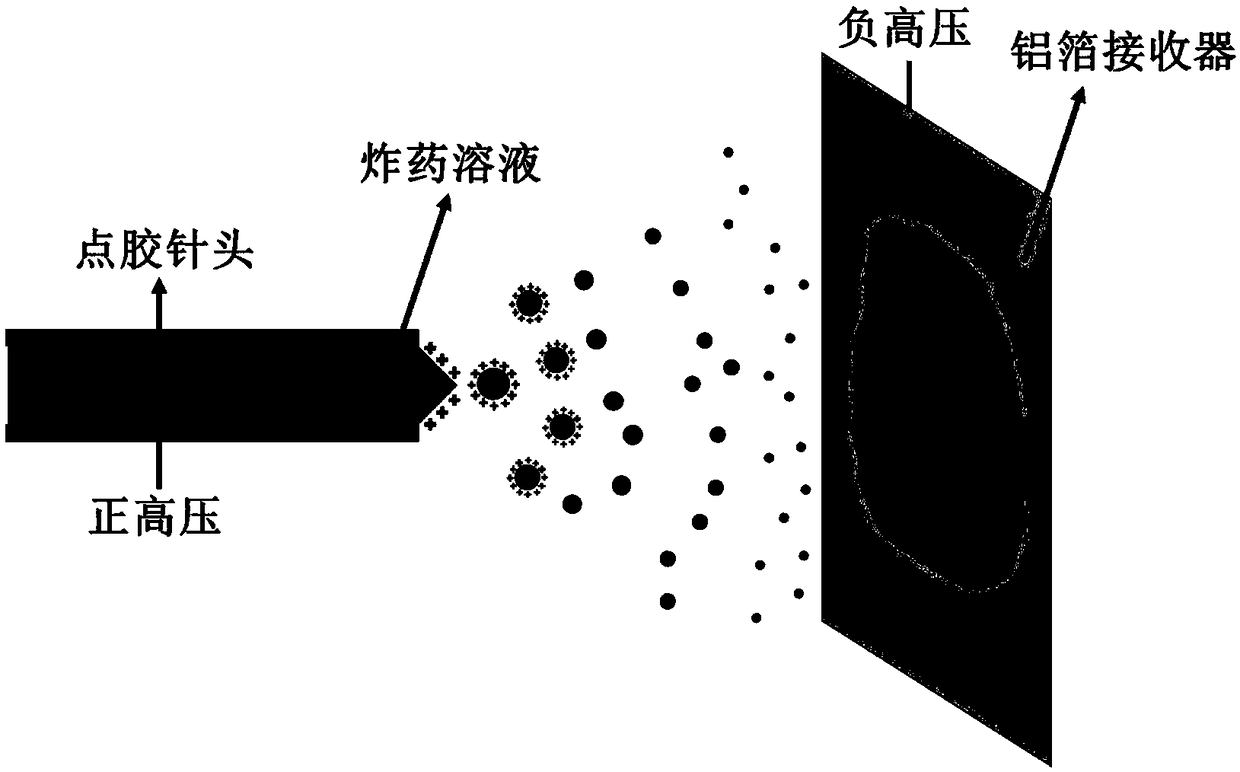

[0034] Weigh 0.0337g of hexanitrohexaazisopentazane and 0.0163g of 1,3,5-trinitrobenzene at room temperature, measure 3mL of acetone, and dissolve them completely at 25°C with a magnetic stirring speed of 500rpm It is a clear solution with a concentration of 2.1% by mass. Quickly fill the resulting solution into a 5mL plastic syringe, replace the syringe with a 27G flat apex metal needle, then install the syringe on the propulsion pump in the electrostatic spray device with an ambient temperature of 25°C, and set the propulsion pump The flow rate is 0.05mm / s, and the positive high voltage is connected to the metal flat top needle. Fix the aluminum foil as a collector on an insulating plate and connect it to a negative high voltage power supply. Adjust the distance from the flat top needle to the collector to 20cm. Turn on the switch of the propulsion pump, first adjust the negative voltage to -10kV, then adjust the positive voltage to 7kV, at this time a Taylor cone appears ...

Embodiment 2

[0036] Weigh 0.0404g of hexanitrohexaazisopentazane and 0.0196g of 1,3,5-trinitrobenzene at room temperature, measure 3mL of acetone, and dissolve them completely at 25°C with a magnetic stirring speed of 500rpm It is a clear solution with a concentration of 2.5% by mass. Quickly fill the resulting solution into a 5mL plastic syringe, replace the syringe with a 27G flat apex metal needle, then install the syringe on the propulsion pump in the electrostatic spray device with an ambient temperature of 26°C, and set the propulsion pump The flow rate is 0.06mm / s, and the positive high voltage is connected to the metal flat top needle. Fix the aluminum foil as a collector on an insulating plate and connect it to a negative high voltage power supply. Adjust the distance from the flat top needle to the collector to 20cm. Turn on the switch of the propulsion pump, first adjust the negative voltage to -10kV, then adjust the positive voltage to 7.5kV, at this time a Taylor cone appear...

Embodiment 3

[0038] Weigh 0.0538g of hexanitrohexaazisopentazane and 0.0212g of 1,3,5-trinitrobenzene at room temperature, measure 3mL of acetone, and dissolve them completely at 25°C with a magnetic stirring speed of 500rpm It is a clear solution with a mass percent concentration of 3.3%. Quickly fill the resulting solution into a 5mL plastic syringe, replace the syringe with a 27G flat apex metal needle, then install the syringe on the propulsion pump in the electrostatic spray device with an ambient temperature of 26°C, and set the propulsion pump The flow rate is 0.07mm / s, and the positive high voltage is connected to the metal flat top needle. Fix the aluminum foil as a collector on an insulating plate and connect it to a negative high voltage power supply. Adjust the distance from the flat top needle to the collector to 20cm. Turn on the switch of the propulsion pump, first adjust the negative voltage to -10kV, then adjust the positive voltage to 8kV, at this time a Taylor cone app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com