Preparation method of energetic metal coordination compound of 5-methyltetrazole

A technology of methyl tetrazole and metal coordination, applied in 1/11 groups of organic compounds without C-metal bonds, organic chemistry methods, organic chemistry and other directions, can solve the problems of high reaction temperature and low yield, and achieve High Purity, High Yield, High Yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 8.4 mg (0.1 mmol) of 5-methyltetrazole (Mtta) in 6 mL of distilled water, add 25.5 mg (0.15 mmol) of AgNO 3 , after stirring for 30 minutes, put it into a 15mL reaction kettle with a polytetrafluoroethylene liner, react at a constant temperature of 120°C for 72h, then lower it to 80°C and keep it for 12h, and then lower it to room temperature at a rate of 3°C / h to obtain the target The product 5-methyltetrazole energetic metal coordination compound has a yield of 92% and a purity of 99.9%.

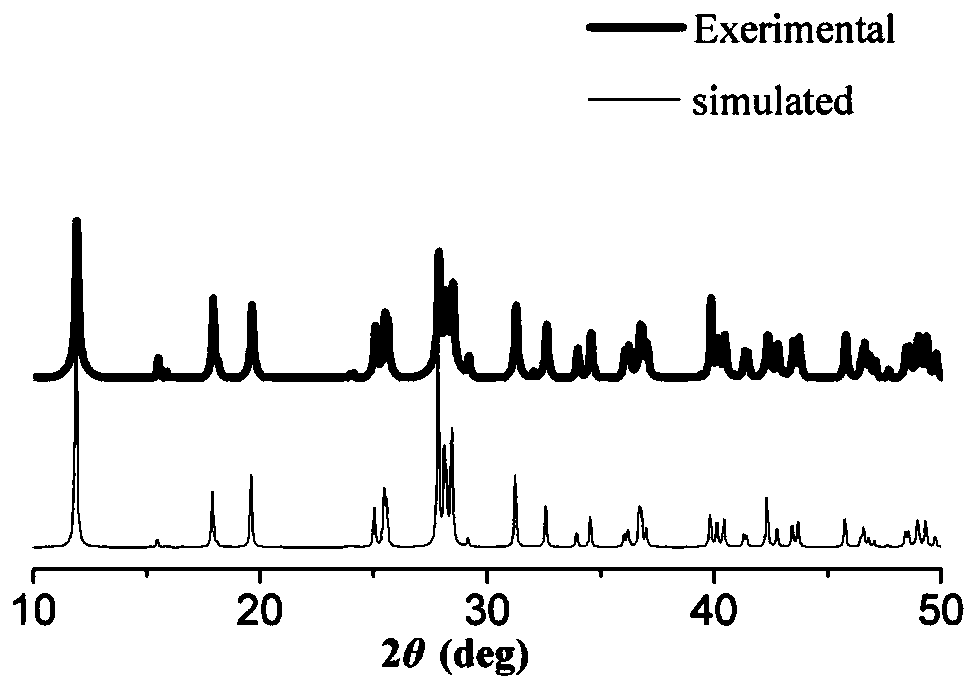

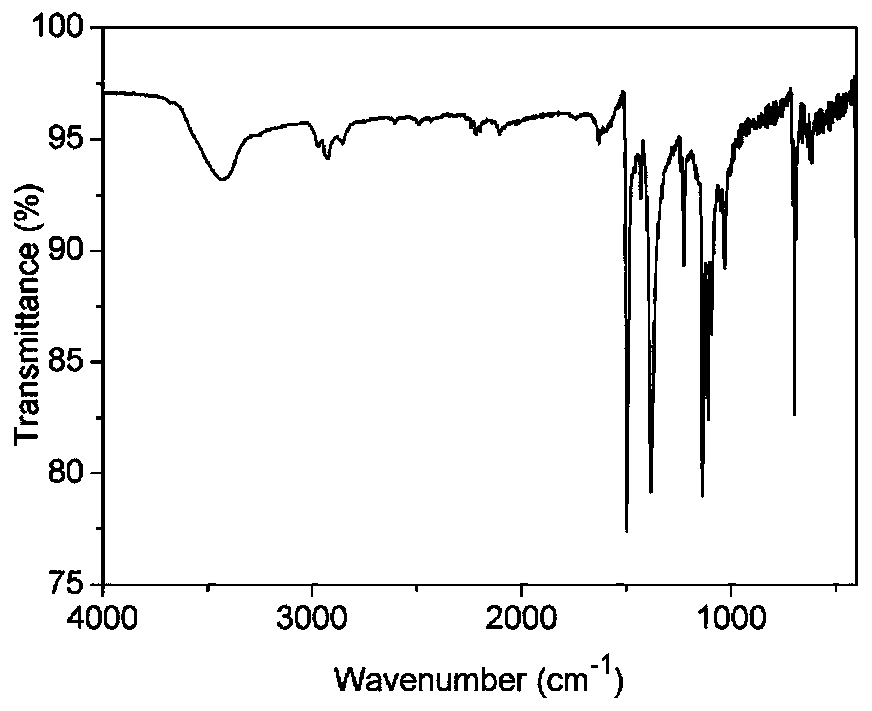

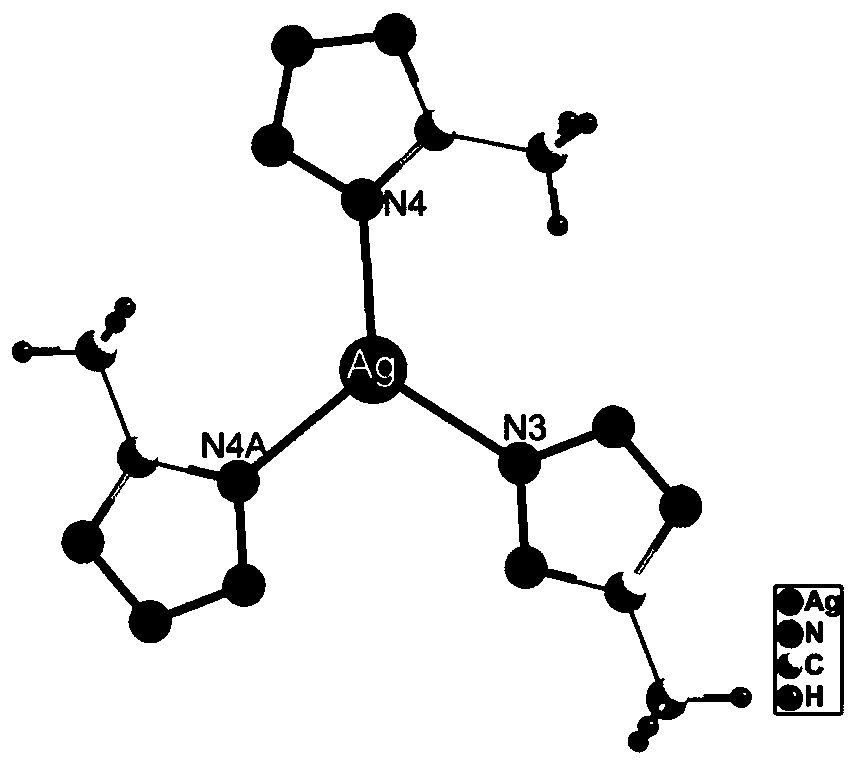

[0028] The powder diffraction pattern of the 5-methyltetrazole energetic metal coordination compound prepared in this example is shown in figure 1 , see the infrared spectrum figure 2 ,Depend on figure 1 and figure 2 The compound can be obtained as [Ag(Mtta)] n . The crystallographic data of the 5-methyltetrazole energetic metal coordination compound prepared in this example are shown in Table 1. Use the oxygen bomb calorimeter to measure the heat of combustion of t...

Embodiment 2

[0033] Dissolve 8.4 mg (0.1 mmol) of methyl tetrazole (Mtta) in 6 mL of distilled water, add 17.0 mg (0.1 mmol) of AgNO 3 , that is, Mtta and AgNO 3 The molar ratio is 1:1. After stirring for 30 minutes, put it into a 15mL reaction kettle with a polytetrafluoroethylene liner, react at a constant temperature of 119°C for 71h, then lower it to 80°C and keep it for 12h, and then at a rate of 3°C / h The rate was lowered to room temperature, and the target product 5-methyltetrazole energetic metal coordination compound was obtained with a yield of 90% and a purity of 99.9%.

Embodiment 3

[0035] Dissolve 8.4 mg (0.1 mmol) of methyl tetrazole (Mtta) in 6 mL of distilled water, add 34.0 mg (0.2 mmol) of AgNO 3 , that is, Mtta and AgNO 3 The molar ratio is 1:2. After stirring for 30 minutes, put it into a 15mL reaction kettle with a polytetrafluoroethylene liner, react at a constant temperature of 121°C for 70h, then lower it to 82°C and keep it for 12h, and then at a rate of 3°C / h The rate was reduced to room temperature, and the target product 5-methyltetrazole energetic metal coordination compound was obtained with a yield of 91% and a purity of 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact sensitivity | aaaaa | aaaaa |

| Friction sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com