A Cl-20-based press-packed high-energy insensitive explosive and its preparation method

A CL-20, high-energy technology, applied in the direction of explosives, non-explosive/non-thermal agent components, non-explosive desensitizers/passivators, etc., can solve the problem of limited energy output and safety performance, main explosive content and charge density Low, can not fully meet the requirements of the new reactive armor damage requirements, to achieve the effect of improving mechanical sensitivity, improving particle size and uniformity, increasing molding density and energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

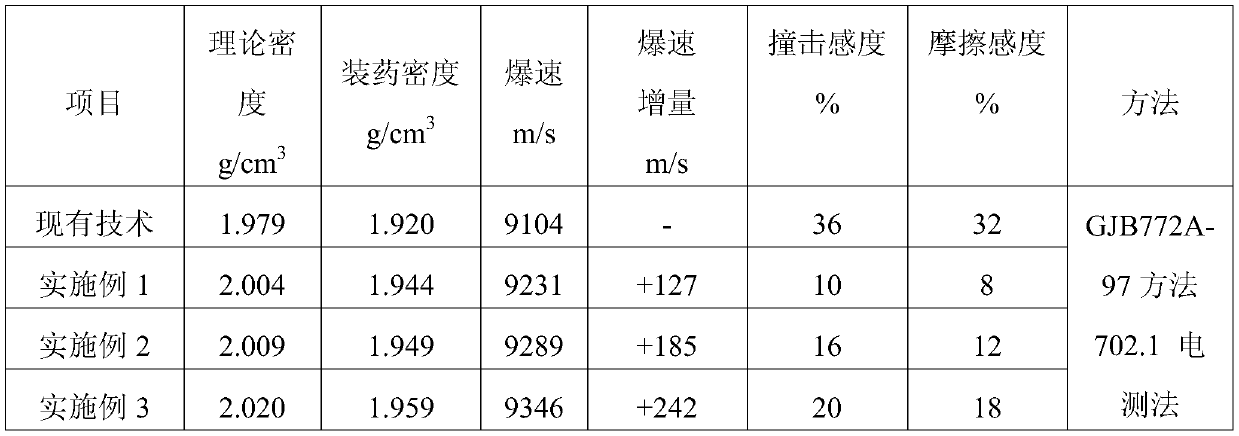

Embodiment 1

[0012] The present invention is implemented with reference to the following composition by mass percentage: 96.5% CL-20, 2% 202 emulsion, 0.8% calcium stearate, 0.7% graphite.

[0013] Kilogram scale preparation process:

[0014] (1) Add 8g of sodium stearate into 1L of water and heat and stir until it is completely dissolved. Weigh 56.3g of 202 emulsion with a solid content of 35.5% and add it to the sodium stearate solution, mix well, and place it at room temperature for use; weigh 8g of chlorinated Calcium is completely dissolved in water (the mass ratio of calcium chloride to water is 1:10) to make a solution;

[0015] (2) Put the prepared mixed solution of sodium stearate and 202 in a 5000ml jar, install the granulation equipment, heat up and stir, the stirring speed is about 500r / min, and the temperature rises to 80°C;

[0016] (3) Weigh 965g of CL-20 explosives and 2000ml of tap water into the bottle, stir to disperse evenly; add calcium chloride aqueous solution, stir...

Embodiment 2

[0021] The present invention is implemented with reference to the following composition by mass percentage: 97.0% CL-20, 2% 202 emulsion, 0.5% calcium stearate, 0.5% graphite. The preparation method of this embodiment refers to embodiment 1.

Embodiment 3

[0023] The present invention is implemented with reference to the following composition by mass percentage: 98.0% CL-20, 1% 202 emulsion, 0.5% calcium stearate, 0.5% graphite. The preparation method of this embodiment refers to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com