CL-20-based energetic film spraying material and micro-spraying direct-writing forming method

A CL-20, spraying material technology, applied in the direction of additive processing of mixtures of solid materials and liquid materials, additive processing, coating devices, etc., to achieve the effect of reasonable design, good practical application and promotion value, and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

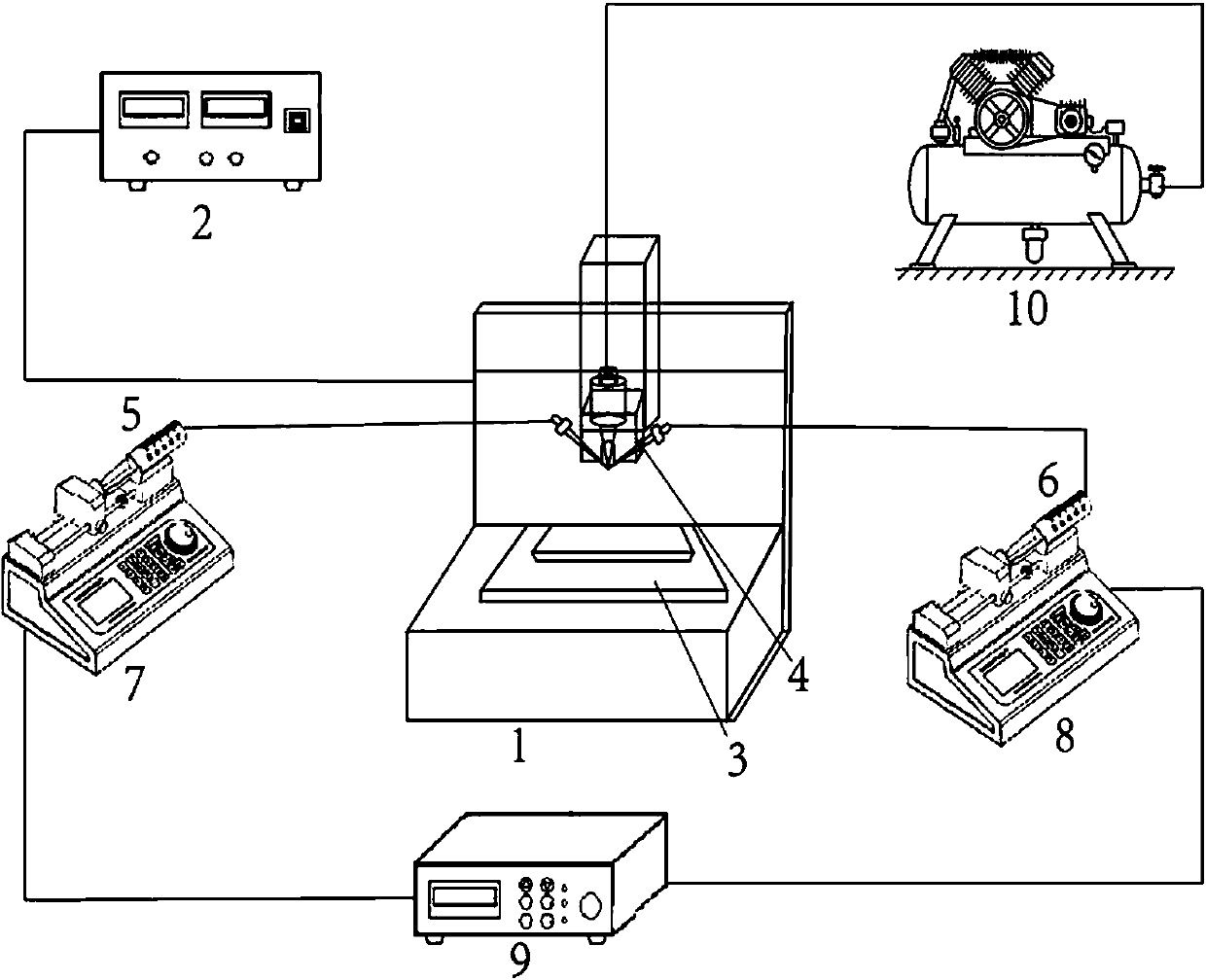

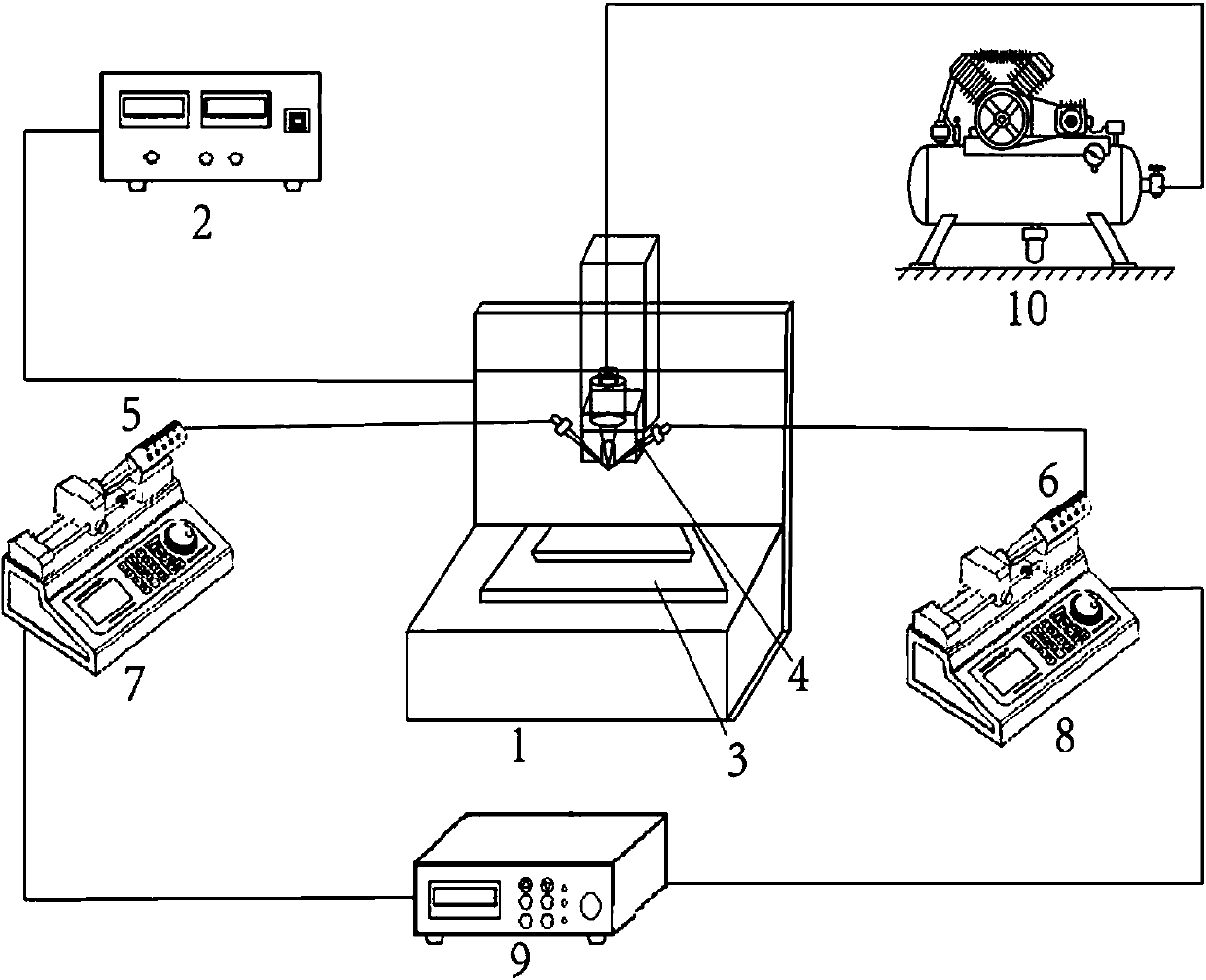

Method used

Image

Examples

Embodiment 1

[0034] A CL-20-based energetic film spraying material, including explosive spraying material and binder spraying material, the mass fraction of each component is as follows:

[0035] Explosive spraying materials: CL-20, 17.6 parts; ε-type CL-20 seed crystal, 0.6 parts; adhesion promoter PN-700 (Nanjing Pinning Coupling Agent Co., Ltd.), 0.46 parts; ethyl acetate, 40 parts.

[0036] Binder spraying material: EC (ethyl cellulose), 0.38 parts; GAP (polyazide glycidyl ether), 0.96 parts; ethanol, 40 parts.

[0037] The preparation and molding of this explosive ink comprises the following steps:

[0038] (1) Preparation of raw materials: Weigh the ink raw materials according to the above proportions and prepare them for later use.

[0039] (2) Spraying material configuration: at room temperature, add CL-20 and adhesion promoter PN-700 to ethyl acetate, assist in dissolution under stirring or ultrasound, and add ε-type CL-20 crystal after dissolution is complete Kind, made into ex...

Embodiment 2

[0044] A CL-20-based energetic film spraying material, the mass fraction of each component is: CL-20, 11 parts; ε-type CL-20 seed crystal, 1 part; binder, 1 part; auxiliary agent, 0.5 part; Organic solvent, 86.5 parts.

[0045]Wherein, the binder is a compound of nitrocellulose and fluororubber, and the mass ratio is 1:1.

[0046] The organic solvent is ethyl acetate.

[0047] The additive is a mixture of fluorocarbon surfactant YTY-70 (Shaanxi Yuteng Industrial Co., Ltd.) and leveling agent AKN-1131 (Qianyou Chemical), with a mass ratio of 1:1.

[0048] The preparation and molding of this explosive ink comprises the following steps:

[0049] (1) Preparation of raw materials: Weigh the ink raw materials according to the above proportions and prepare them for later use.

[0050] (2) Spraying material configuration: add each component into an organic solvent at room temperature, and dissolve under the action of stirring or ultrasonic to prepare a micro-spraying material.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com