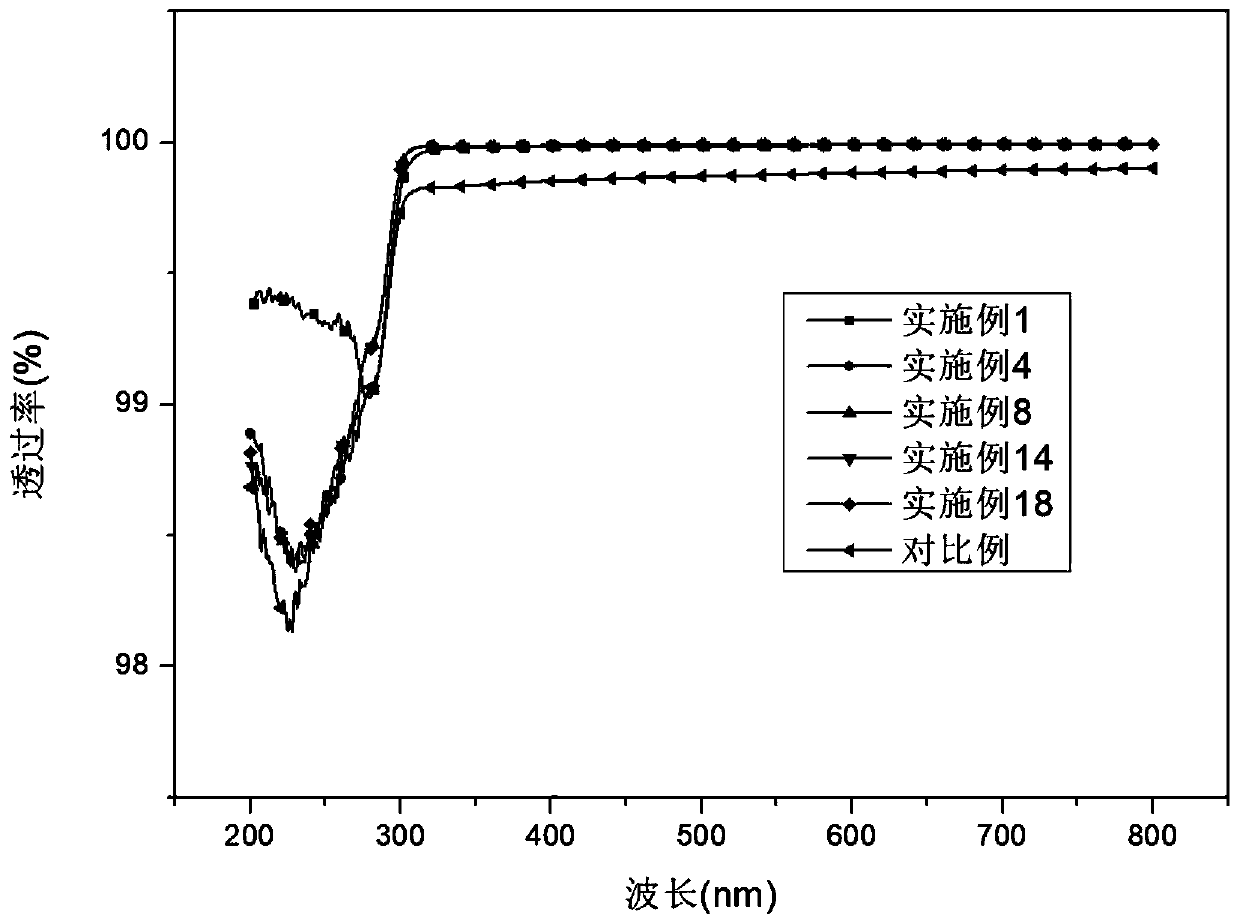

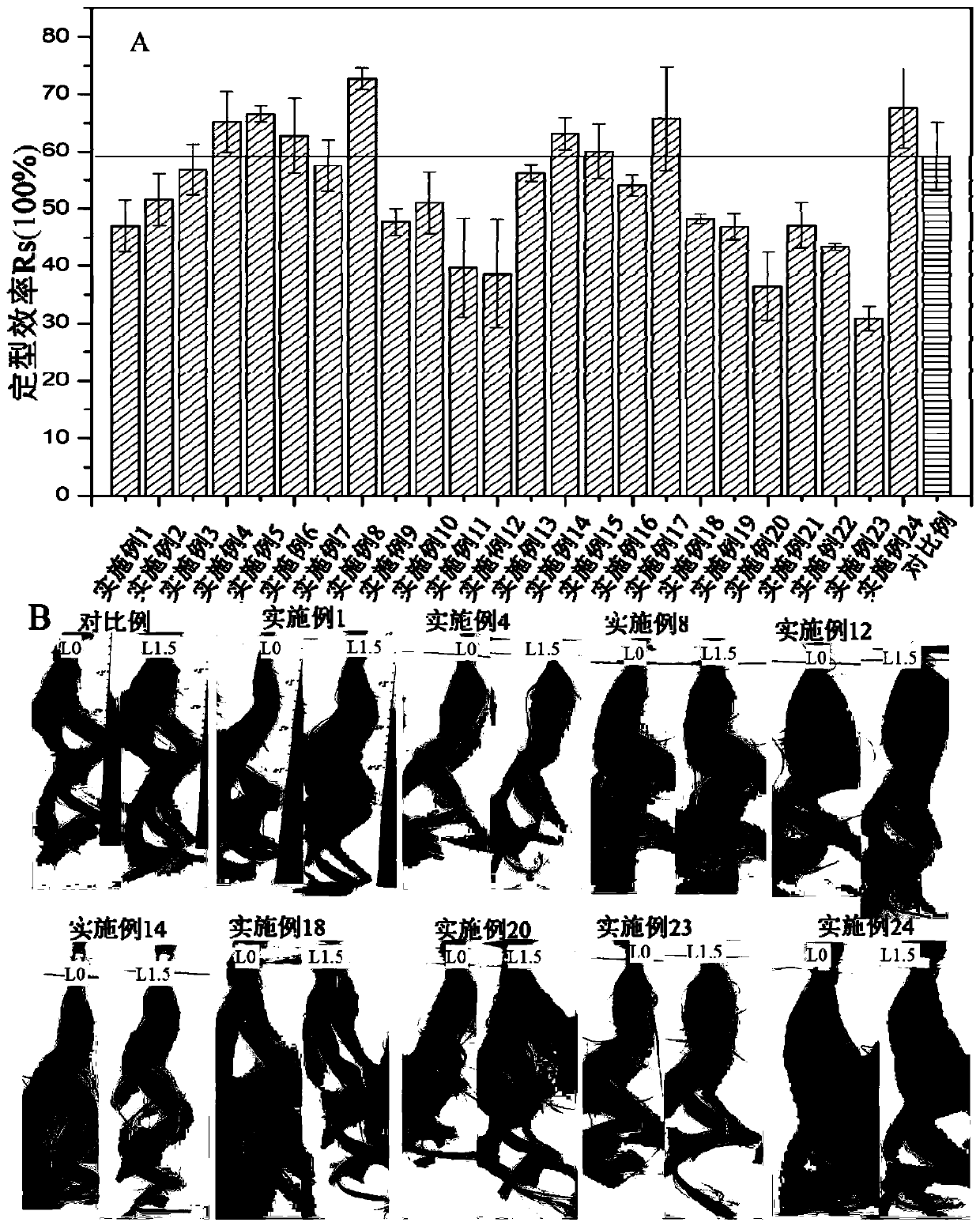

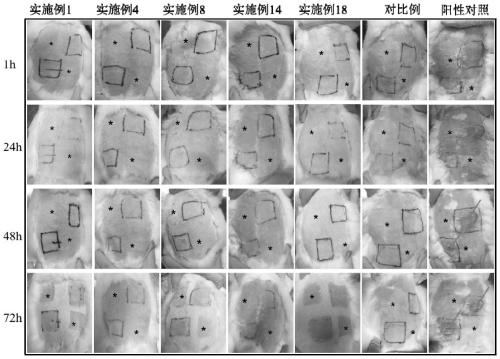

Application of plant oil-base waterborne polyurethane emulsion as styling product and hair styling product

A water-based polyurethane, vegetable oil-based technology, applied in cosmetic preparations, cosmetics, hair care and other directions, can solve the problems of toxicity, environmental pollution, complex components, etc., and achieve the effect of easy control, mature preparation process and single component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Put IPDI (in terms of isocyanate), castor oil-based polyol (abbreviated as COP, in terms of hydroxyl value), and DMBA (in terms of hydroxyl value) in a double-necked round bottom flask with a molar ratio of 1.7:1.0:0.69 , adjust the speed of the stirrer to 200r / min, mechanically stir and mix for 10min under 78°C oil bath heating, add DBTDL with a total mass of 0.3wt% of the material, and continue stirring for 2h (if the viscosity of the solution increases, add methyl ethyl ketone to the system (MEK) until the reaction system is flowable), then cooled to room temperature, added triethylamine to neutralize for 30min (neutralization degree 97%), then increased the rotating speed to 400r / min, added deionized water to emulsify for 2h, and finally transferred the emulsion to The MEK was removed by rotary evaporation in a single-necked round-bottomed flask to obtain an anionic vegetable oil-based water-based polyurethane emulsion with a solid content of 20%.

Embodiment 2

[0039] Put IPDI (calculated by isocyanate), castor oil-based polyol (abbreviated as COP, calculated by hydroxyl value), and DMBA (calculated by hydroxyl value) in a double-necked round bottom flask with a molar ratio of 1.85:1.0:0.84 , adjust the speed of the stirrer to 200r / min, and after heating with an oil bath at 78°C for 10 minutes, add DBTDL with 0.2wt% of the total mass of the material and continue to stir for 2 hours (if the viscosity of the solution increases, add MEK to the system until the reaction system can flow), then cooled to room temperature, adding triethylamine to neutralize for 30min (neutralization degree is 97%), then raising the rotating speed to 450r / min, adding deionized water to emulsify for 2h, finally transferring the emulsion to a single-necked round bottom flask and spinning The MEK is removed by steaming to obtain an anionic vegetable oil-based water-based polyurethane emulsion with a solid content of 10%.

Embodiment 3

[0041] Put IPDI (in terms of isocyanate), castor oil-based polyol (abbreviated as COP in terms of hydroxyl value), and DMBA (in terms of hydroxyl group) in a molar ratio of 2.0:1.0:0.99 in a double-necked round-bottomed flask, Adjust the rotation speed of the agitator to 200r / min, mechanically stir and mix for 10min under heating in an oil bath at 78°C, add DBTDL with a total mass of 0.5wt% of the material, and continue stirring for 2h (if the viscosity of the solution increases, add acetone to the system until the reaction system can flow ), then cooled to room temperature, adding triethylamine to neutralize for 30min (neutralization degree 97%) and then raising the rotating speed to 500r / min, adding deionized water to emulsify for 2h, and finally transferring the emulsion to a single-necked round-bottomed flask for rotary evaporation to remove Acetone can obtain the anionic vegetable oil-based water-based polyurethane emulsion with a solid content of 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com