Preparation of low aromatic and low viscosity narrow fraction injection liquid paraffine

A narrow-cut, white oil technology, applied in the field of low-aromatic and low-viscosity narrow-cut injection white oil, can solve the problems of low oil viscosity, instability, poor performance stability of injection white oil, etc., and achieve single product components and stable performance. The effect of good performance and narrow distillation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

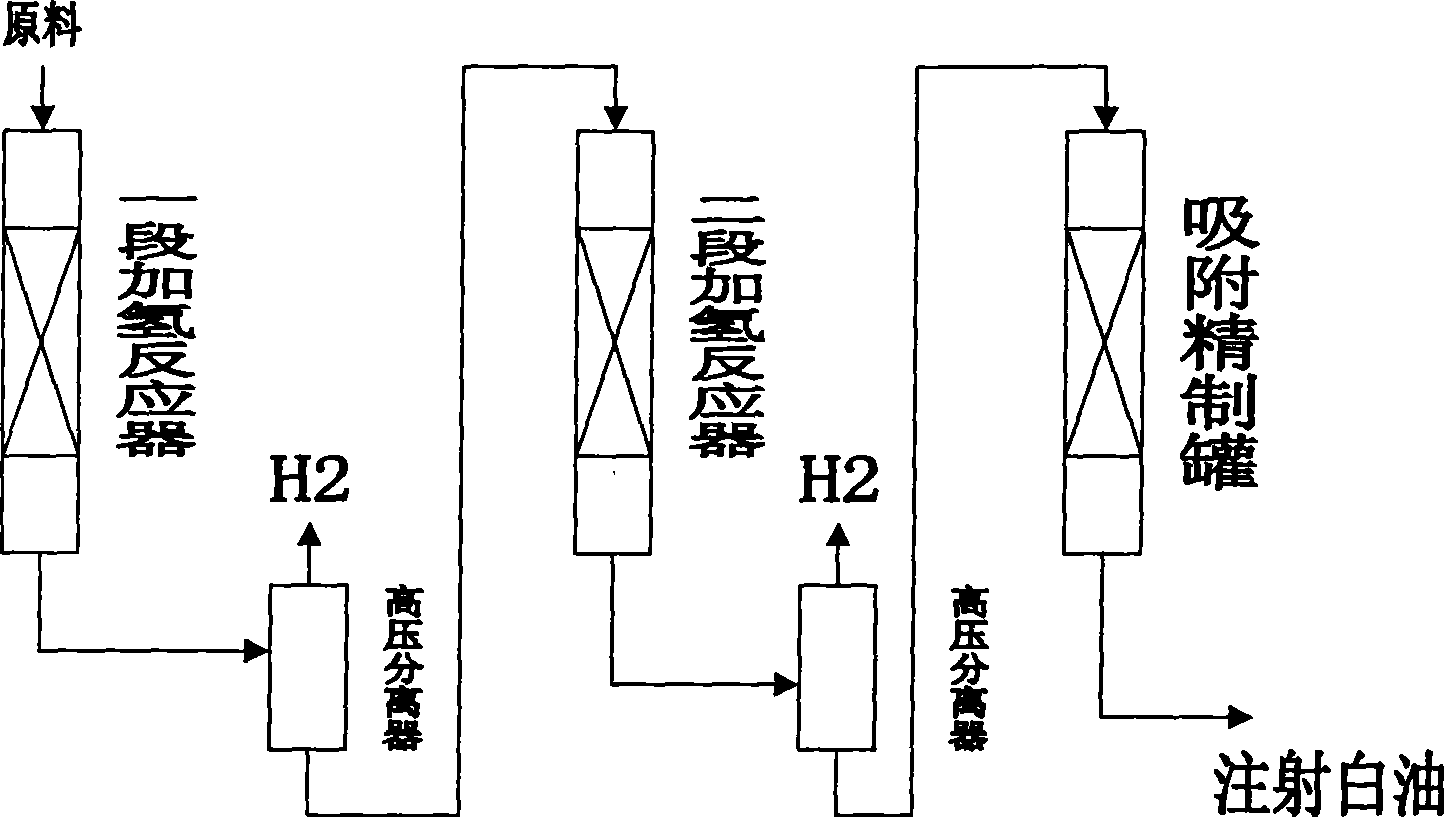

[0023] The present embodiment adopts paraffin wax raw material, through the following technological process (see attached figure 1 ) to obtain the injected white oil finished product:

[0024] 1. Preparation of raw materials

[0025] The paraffin base is distilled by a distillation method, and the distilled fraction at 270-320° C. is used as the white oil raw material for injection.

[0026] 2. Remove impurities from raw materials

[0027] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 500 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the reaction bed in the hydrogen reactor and is separated by a high-pressure separator for recycling. A typical Ni-Mo-W hydrogenation catalyst is used in the hydrogenation reaction, the pressure is controlled at 15.5MPa, the temperature is controlled at 230°C, and the volume space velocity is 1.0h -1 , through this segment of hydrogenation r...

Embodiment 2

[0038] Wooden embodiment adopts intermediate base crude oil as raw material, by following technological process (please refer to appendix figure 1 ) to obtain the injected white oil finished product:

[0039] 1. Preparation of raw materials

[0040] The intermediate crude oil base is distilled by distillation method, and the distilled fraction at 279-312° C. is used as the white oil raw material for injection.

[0041] 2. Remove impurities from raw materials

[0042] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 750 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the reaction bed in the hydrogen reactor and is separated by a high-pressure separator for recycling. A typical Ni-Mo-W hydrogenation catalyst is used in the reaction, the pressure in the hydrogenation reaction is controlled at 16.0MPa, the temperature is controlled at 260°C, and the volume space velocity is 0.8h ...

Embodiment 3

[0053] The present embodiment adopts paraffin wax raw material, through the following technological process (see attached figure 1 ) to obtain the injected white oil finished product:

[0054] 1. Preparation of raw materials

[0055] The paraffin-based oil is distilled by distillation, and the distilled fraction at 270-320°C is used as the raw material for white oil for injection.

[0056] 2. Remove impurities from raw materials

[0057] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 1000 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the reaction bed in the hydrogen reactor and is separated by a high-pressure separator for recycling. A typical Ni-Mo-W hydrogenation catalyst is used in the reaction, the pressure in the hydrogenation reaction is controlled at 16.5MPa, the temperature is controlled at 290°C, and the volume space velocity is 0.5h -1 , through this segment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com