Preparation of low aromatic and low viscosity narrow fraction injection liquid paraffine

A narrow-fraction, white oil technology, applied in the field of low-aromatic, low-viscosity, narrow-fraction injection white oil, can solve the problems of low oil viscosity, instability, poor performance and stability of injection white oil, etc. Single point, good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

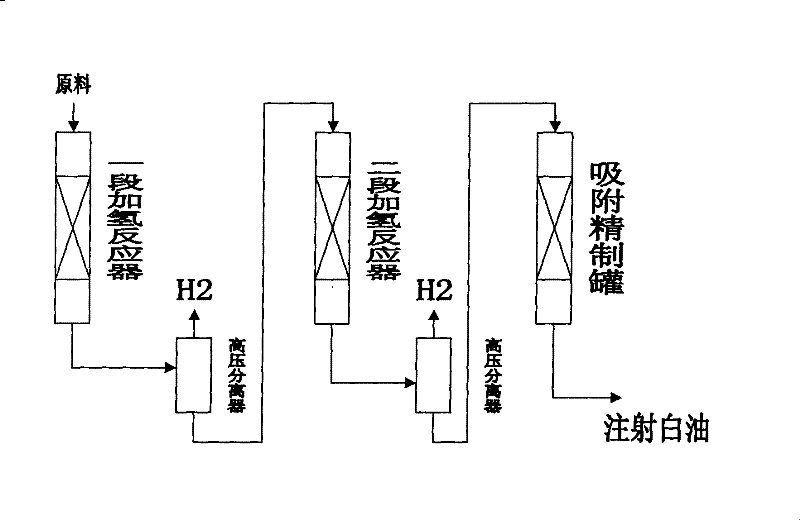

[0023] The present embodiment adopts paraffin wax raw material, through the following technological process (see attached figure 1 ) to obtain the injected white oil finished product:

[0024] 1. Preparation of raw materials

[0025] The paraffin base is distilled by a distillation method, and the distilled fraction at 270-320° C. is used as the white oil raw material for injection.

[0026] 2. Remove impurities from raw materials

[0027] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 500 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the reaction bed in the hydrogen reactor and is separated by a high-pressure separator for recycling. A typical Ni-Mo-W hydrogenation catalyst is used in the hydrogenation reaction, the pressure is controlled at 15.5MPa, the temperature is controlled at 230°C, and the volume space velocity is 1.0h -1 , through this segment of hydrogenation r...

Embodiment 2

[0038] The present embodiment adopts intermediate base crude oil as raw material, through the following technological process (see attached figure 1 ) to obtain the injected white oil finished product:

[0039] 1. Preparation of raw materials

[0040] The intermediate crude oil base is distilled by distillation method, and the distilled fraction at 279-312° C. is used as the white oil raw material for injection.

[0041] 2. Remove impurities from raw materials

[0042] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 750 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the reaction bed in the hydrogen reactor and is separated by a high-pressure separator for recycling. A typical Ni-Mo-W hydrogenation catalyst is used in the reaction, the pressure in the hydrogenation reaction is controlled at 16.0MPa, the temperature is controlled at 260°C, and the volume space velocity is 0.8h...

Embodiment 3

[0053]The present embodiment adopts paraffin wax raw material, through the following technological process (see attached figure 1 ) to obtain the injected white oil finished product:

[0054] 1. Preparation of raw materials

[0055] The paraffin-based oil is distilled by distillation, and the distilled fraction at 270-320°C is used as the raw material for white oil for injection.

[0056] 2. Remove impurities from raw materials

[0057] The hydrogen and white oil raw materials are simultaneously fed into the hydrogenation reactor at a volume ratio of 1000 to carry out the first-stage hydrogenation reaction. The hydrogen passes through the reaction bed in the hydrogen reactor and is separated by a high-pressure separator for recycling. A typical Ni-Mo-W hydrogenation catalyst is used in the reaction, the pressure in the hydrogenation reaction is controlled at 16.5MPa, the temperature is controlled at 290°C, and the volume space velocity is 0.5h -1 , through this segment of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com