Dialkylaminophenoxy acetic acid extracting agent and preparation method and application thereof

A technology of dialkylaminophenoxyacetic acid and alkylaminophenoxyacetic acid, which is applied in the field of dialkylaminophenoxyacetic acid extraction agent and its preparation, can solve the problem of difficult separation of heavy rare earth elements, low separation coefficient, high separation coefficient, etc. problem, to achieve the effect of single component, improved separation coefficient and stable extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of dialkylaminophenoxyacetic acid extractant, comprising the following steps:

[0040] a) Mixing p-nitrophenol, sodium haloacetate, alkali, alcohol and water, and heating to reflux for reaction to obtain p-nitrophenoxycarboxylate;

[0041] b) hydrogenating and reducing the p-nitrophenoxycarboxylate to obtain p-aminophenoxycarboxylate;

[0042] c) reacting the p-aminophenoxycarboxylate with a halogenated hydrocarbon to carry out an alkylation reaction, and then acidifying after completion of the reaction to obtain a dialkylaminophenoxyacetic acid extractant with a structure shown in formula (I);

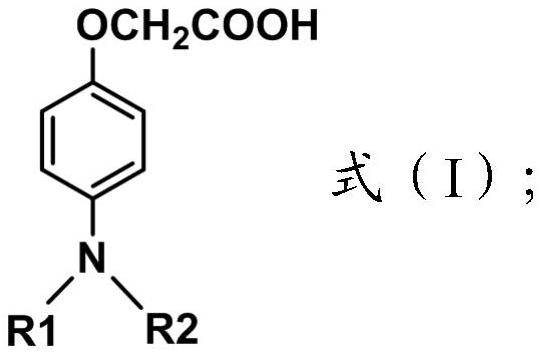

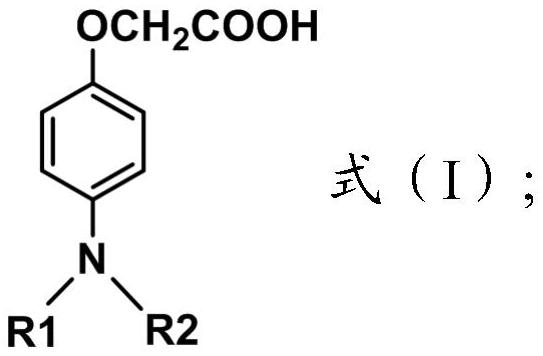

[0043]

[0044] Wherein, R1 and R2 are independently selected from C 1 ~C 10 The alkyl group, more specifically can be C 1 Alkyl, C 2 Alkyl, C 3 Alkyl, C 4 Alkyl, C 5 Alkyl, C 6 Alkyl, C 7 Alkyl, C 8 Alkyl, C 9 Alkyl or C 10 alkyl.

[0045]In the preparation method provided by the invention, firstl...

Embodiment 1

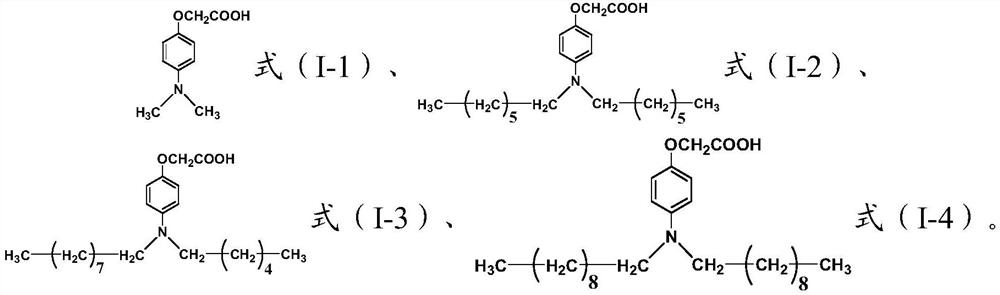

[0070] The extractant is 4-N,N-dimethylaminophenoxyacetic acid, that is, in the formula (I), R1 is a methyl group, and R2 is a methyl group, and its chemical structure is specifically shown in the formula (I-1):

[0071]

[0072] 4-N, the preparation method of N-dimethylaminophenoxyacetic acid is as follows:

[0073] Put 0.1 mol of p-nitrophenol, 100 mL of a mixed solvent of ethanol and water with a volume ratio of 1:1 in a three-necked flask, add 0.1 mol of sodium hydroxide, and stir to dissolve. Then add 0.15mol sodium chloroacetate and 0.2g KI, heat to 110°C, condense and reflux for 0.5h. Cool to room temperature after the reaction, evaporate the solvent, and wash with water to obtain p-nitrophenoxyacetate.

[0074] Then mix p-nitrophenoxyacetate, 5 mg of commercially available 10wt.% Pd / C catalyst and 100 mL of ethanol solvent, control the reaction temperature at 70 ° C, circulate hydrogen gas, react for 4 hours and cool to room temperature, after solid-liquid separati...

Embodiment 2

[0078] The extractant is 4-N,N-diheptylaminophenoxyacetic acid, that is, in formula (I), R1 is heptyl, R2 is heptyl, and its chemical structure is specifically shown in formula (I-2):

[0079]

[0080] The preparation method of 4-N,N-diheptylaminophenoxyacetic acid refers to Example 1, except that the alkylating agent used is 1-bromoheptane.

[0081] The results of acid-base titration and NMR characterization show that the purity of the extractant of 4-N,N-diheptylaminophenoxyacetic acid prepared in this example is greater than 95%, and the total yield of the preparation is greater than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com