Method for production of synthetic natural gas by utilization of methanol

A technology for synthesizing natural gas and methanol, which is applied in the production of bulk chemicals, gas fuels, petroleum industry, etc., can solve the problems of difficult control of process conditions, require staged reactions, and high requirements for reaction, and achieve significant economic and social benefits, The effect of single product component and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

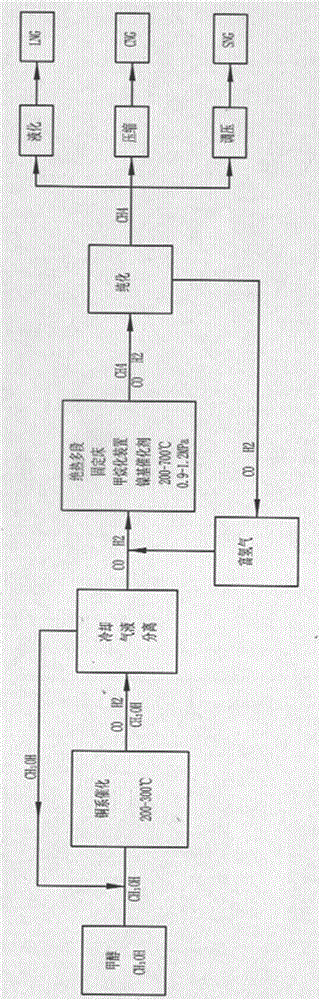

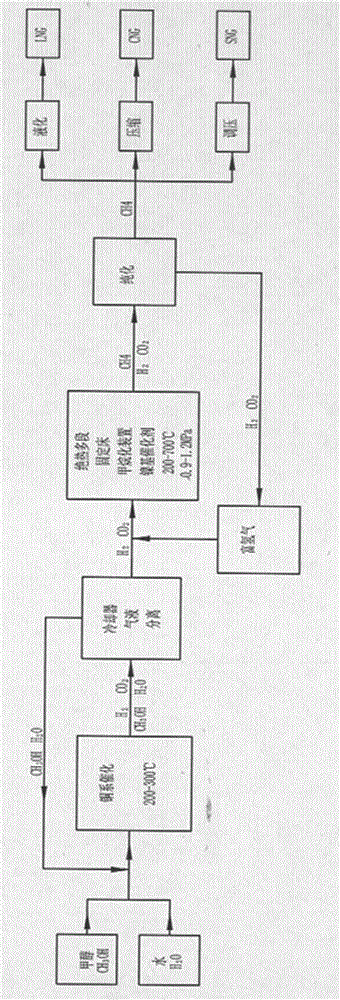

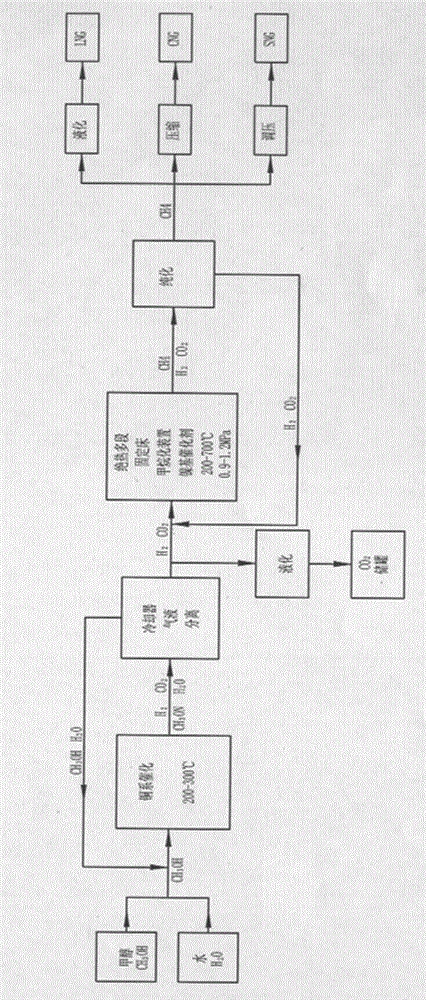

[0027] S1, such as figure 1 As shown, after methanol and pure water are vaporized in the converter at a pressure of 0.5 MPa and a temperature of 300°C, the molar ratio of methanol to water is 1:1, and a copper-based catalyst is used, and the copper-based catalyst is CuZnAl Catalyst, the mass ratio of described methanol and copper-based catalyst is 3200:1, methanol cracking is hydrogen and carbon dioxide gas mixture I;

[0028] S2. Combine the mixed gas I obtained in S1 with the hydrogen-rich gas that has been purified and desulfurized according to the 3H 2 +CO→CH 4 +H 2 O and 4H 2 +CO 2 →CH 4 +2H 2 CO, CO in the O formula 2 The theoretical consumption of hydrogen is used for batching to obtain mixed gas II; the hydrogen-rich gas is coke oven gas, and the H contained in the hydrogen-rich gas 2 The quality of > CO and CO contained in hydrogen-rich gas 2 The total mass of hydrogen consumed in methanation theory;

[0029] S3. Send the mixed gas II with a good ratio of S...

Embodiment 2

[0034] S1, such as figure 1 As shown, after methanol and pure water are vaporized in the converter at a pressure of 0.3MPa and a temperature of 200°C, the molar ratio of methanol to water is 1:1, and a copper-based catalyst is used, and the copper-based catalyst is a CuZnAl catalyst , the mass ratio of the methanol to the copper-based catalyst is 3200:1, and the methanol is cracked into hydrogen and carbon dioxide gas mixture I;

[0035] S2. Combine the mixed gas I obtained in S1 with the hydrogen-rich gas that has been purified and desulfurized according to the 3H 2 +CO→CH 4 +H 2 O and 4H 2 +CO 2 →CH 4 +2H 2 CO, CO in the O formula 2 The theoretical consumption of hydrogen is used for batching to obtain mixed gas II; the hydrogen-rich gas is coke oven gas tail gas, and the H contained in the hydrogen-rich gas 2 The quality of > CO and CO contained in hydrogen-rich gas 2 The total mass of hydrogen consumed in methanation theory;

[0036] S3. Send the mixed gas II wi...

Embodiment 3

[0041] S1, such as figure 1 As shown, after methanol and pure water are vaporized in the converter at a pressure of 2.5MPa and a temperature of 250°C, the molar ratio of methanol to water is 1:1, and a copper-based catalyst is used, and the copper-based catalyst is CuZnAl Catalyst, the mass ratio of described methanol and copper-based catalyst is 3200:1, methanol cracking is hydrogen and carbon dioxide gas mixture I;

[0042] S2. Combine the mixed gas I obtained in S1 with the hydrogen-rich gas that has been purified and desulfurized according to the 3H 2 +CO→CH 4 +H 2 O and 4H 2 +CO 2 →CH 4 +2H 2 CO, CO in the O formula 2 The theoretical consumption of hydrogen is used for batching to obtain mixed gas II; the hydrogen-rich gas is methanol purge gas, and the H contained in the hydrogen-rich gas 2 The quality of > CO and CO contained in hydrogen-rich gas 2 The total mass of hydrogen consumed in methanation theory;

[0043] S3. Send the mixed gas II with a good ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com