Method for preparing copper-zinc-tin-sulfur film

A copper-zinc-tin-sulfur and thin-film technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven surface and poor crystallinity of copper-zinc-tin-sulfur thin films, and achieves a single component, regular and controllable morphology, Conditionally controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

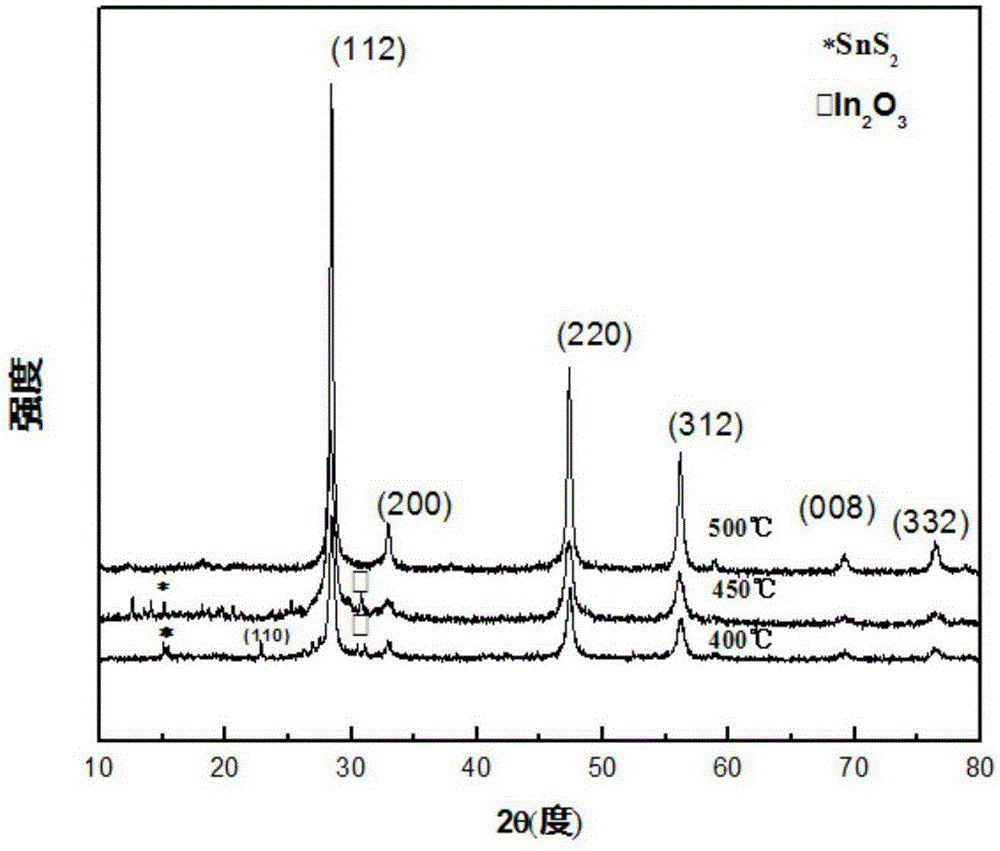

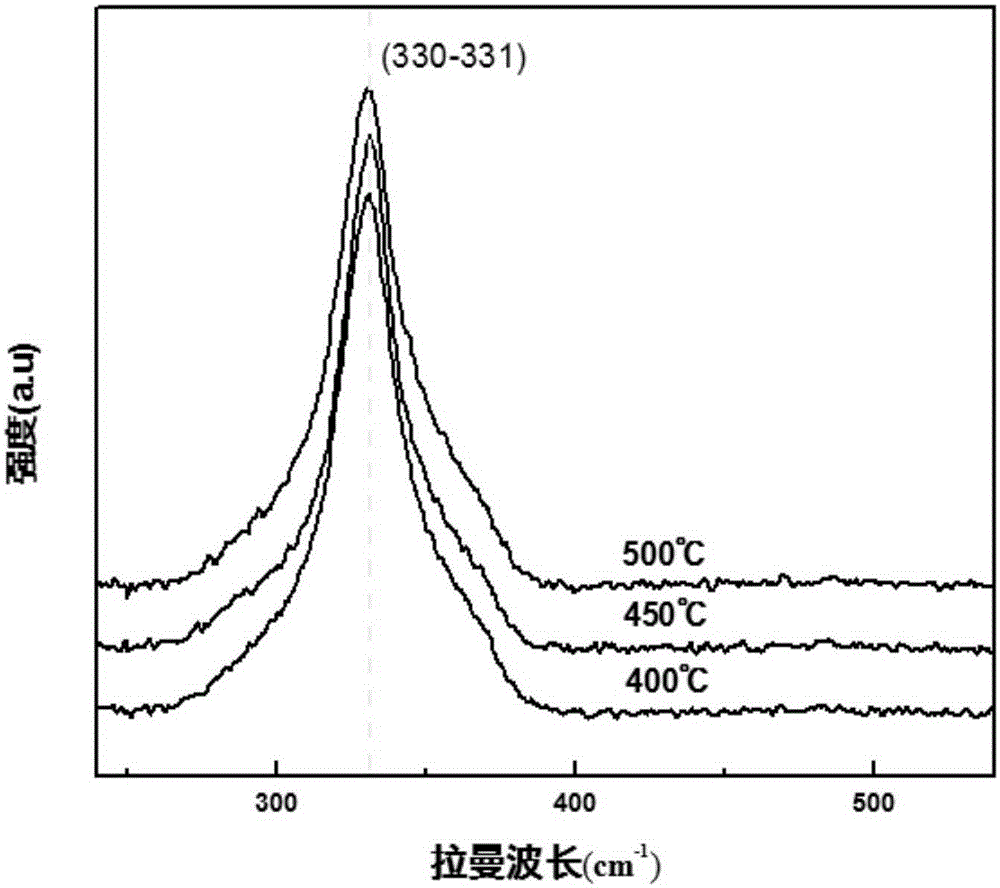

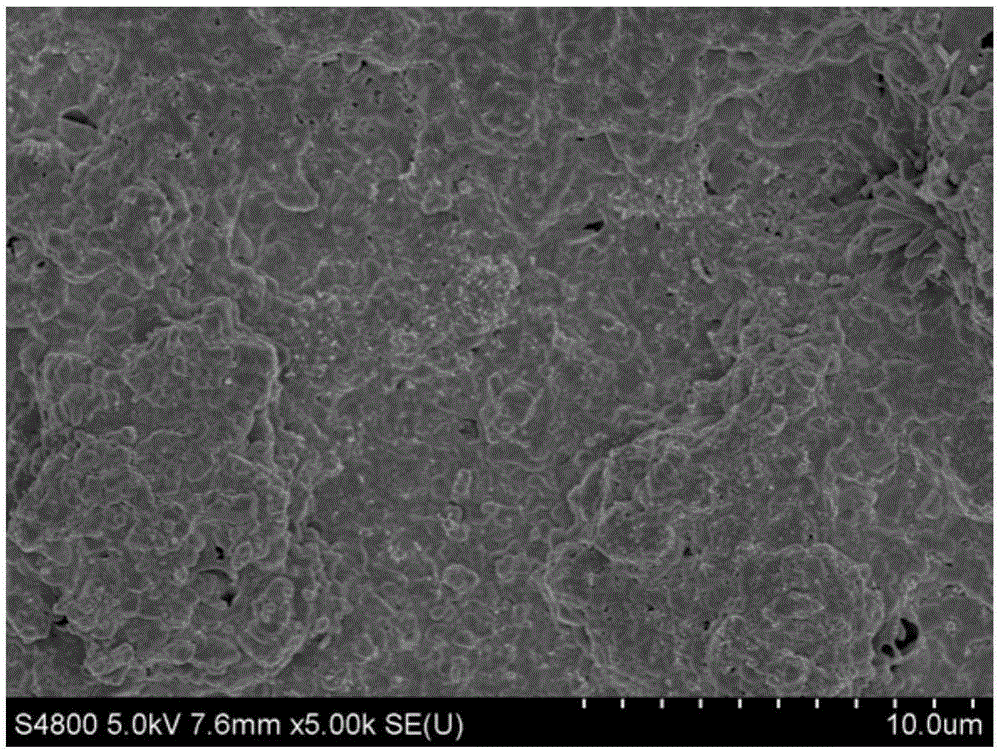

[0030] First, the process such as Figure 7 , the specific operation steps are as follows:

[0031] (1) Cut out an ITO glass sheet with a length of 2 cm and a width of 2 cm;

[0032] (2) Ultrasonic cleaning the cut ITO glass substrate in soap solution, acetone, ethanol, and deionized water for 20 minutes in sequence, and soaking in the prepared alkaline cleaning solution for 30 seconds after cleaning. Concentrated ammonia water: hydrogen peroxide: distilled water is mixed according to the volume ratio = 1:1:5, take it out and dry it for later use;

[0033] (3) Use analytical-grade cupric chloride, zinc chloride, stannous chloride, and thiourea as solutes, dissolve them in 50ml of solvent 2-methoxyethanol, heat in a water bath to 65°C, and stir until the solution turns orange Transparent. According to the molar concentration (M), the concentrations of copper chloride and zinc chloride in the solution are 1.6 and 1 respectively; the concentrations of stannous chloride and thi...

Embodiment 2

[0044] The operation steps are as follows:

[0045] (1) with step (1) in embodiment 1;

[0046] (2) with step (2) in embodiment 1;

[0047] (3) Analytical-grade cupric chloride, zinc chloride, stannous chloride, and thiourea were used as solutes, dissolved in 50 ml of methanol, and magnetically stirred at room temperature to dissolve until the solution was bright yellow and transparent. According to the molar concentration (M), the concentrations of copper chloride and zinc chloride in the solution are 0.15 and 0.2 respectively; the concentrations of stannous chloride and thiourea are 0.15 and 1. In this method, the addition of compounds containing copper, zinc, tin and sulfur will have a certain order. According to the order of thiourea→zinc chloride→stannous chloride→cupric chloride, add to the solvent to dissolve.

[0048] (4) with step (4) in embodiment 1;

[0049] (5) Put the wet film obtained in step (4) into a quartz boat, then push the quartz boat into the middle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com