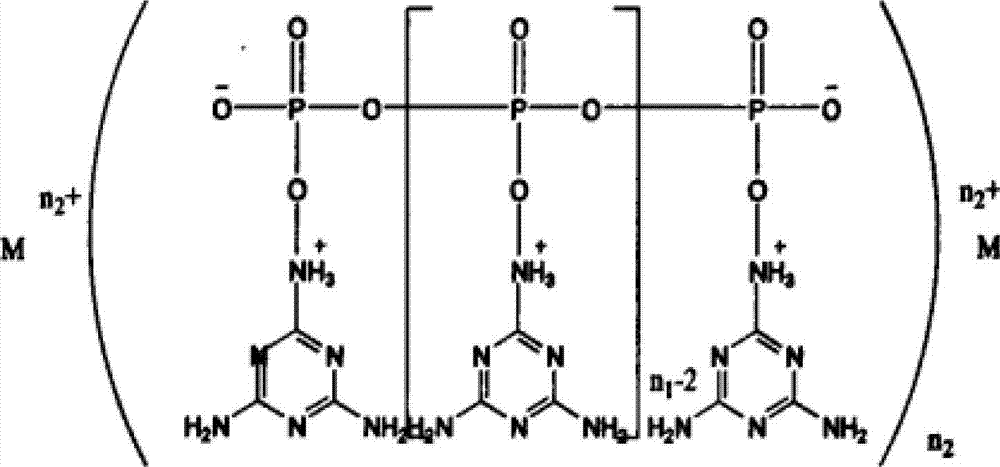

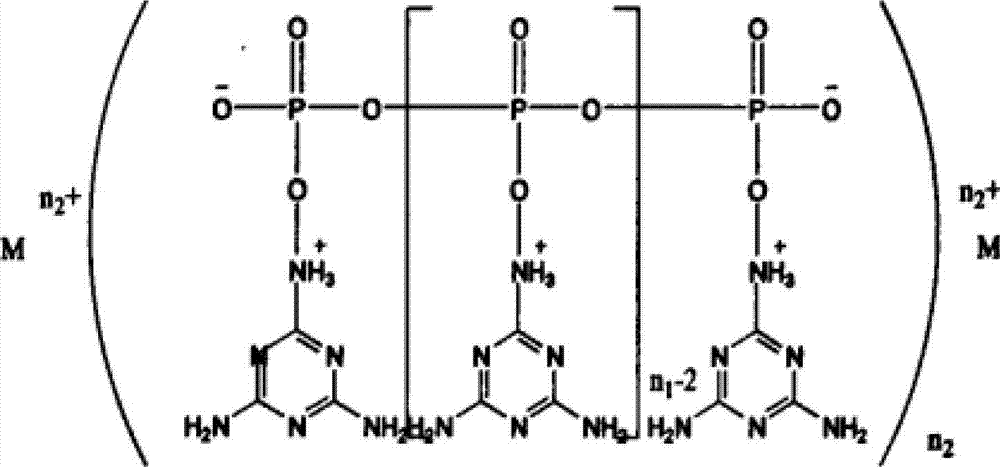

Halogen-free flame retardant and method for preparing same

A flame retardant and structural formula technology, applied in the field of halogen-free flame retardants and their preparation, can solve problems such as easy ignition, toxic hydrogen bromide gas, and molten droplets, so as to improve flame retardant performance and thermal stability , high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 3mol melamine into a three-necked flask filled with deionized water, heat up to 85-90°C under stirring, then add 4.8mol phosphoric acid at a rate of 1-2 drops / second, keep warm for 2.5 hours after the dropwise addition, and then cool to At room temperature, wash with deionized water 8 times, vacuum filter, and dry at 100°C for 4 hours to obtain MP2.92mol, the reaction yield is over 97.3%, and the purity of MP is 96.1%.

[0017] Place 2.92molMP in a muffle furnace, calcinate at 300-320°C for 5h, and grind to obtain 2.90molMPP as a white powder.

[0018] Put 2.90mol of MPP in a muffle furnace, add 0.7mol of melamine and 0.26mol of rare earth metal chloride, calcinate at 300-320°C for 3 hours, and grind to obtain white powder MMPP. Add 10% MMPP to polyethylene, and the oxygen index of polyethylene is from 17.6% to 22.56% of pure PE.

Embodiment 2

[0020] Add 1.5mol melamine to a three-necked flask filled with deionized water, heat up to 90-95°C under stirring, then add 2.3mol phosphoric acid at a rate of 1-3 drops / second, keep the temperature for 2 hours after the dropwise addition, and then cool to At room temperature, wash 6 times with deionized water, vacuum filter, and dry at 100°C for 4 hours to obtain MP1.44mol, the reaction yield is more than 96%, and the purity of MP is 95.4%.

[0021] Place 1.44molMP in a muffle furnace, calcinate at 300-310°C for 4h, and grind to obtain 1.41molMPP as a white powder.

[0022] Put 1.41mol MPP in a muffle furnace, add 0.31mol melamine and 0.096mol rare earth metal chloride, calcinate at 300-320°C for 2 hours, and grind to obtain white powder MMPP. Add 10% MMPP to polyethylene, and the oxygen index of polyethylene is from 17.6% to 21.56% of pure PE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com