High-melt-strength polypropylene material, and preparation method and application thereof

A polypropylene material with high melt strength technology, applied in the field of modified polypropylene, can solve the problems of affecting monomer grafting efficiency, limited reaction time in reaction extrusion process, and reduced number of graftable polypropylene free radicals, etc. Achieve the effects of easy industrial production, easy operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

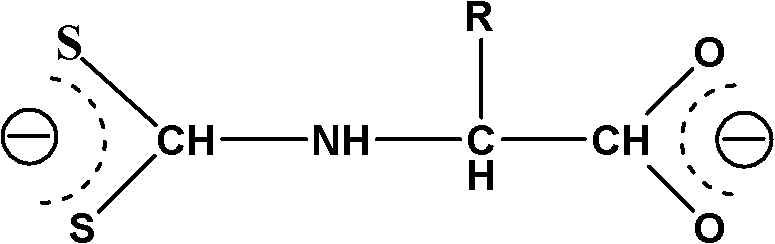

Method used

Image

Examples

Embodiment 1

[0053] A high-melt-strength polypropylene material prepared from the following components in parts by weight:

[0054] Polypropylene (MFR=3.2g / 10min): 99.79

[0055] Dicumyl peroxide: 0.01

[0057] Lanthanum stearate 0.05

[0058] Pentaerythritol triacrylate: 0.1;

[0059] Mix polypropylene, free radical stabilizer and inert processing aids uniformly and feed them into twin-screw extruder with L / D=54, D=35; initiator and multifunctional monomer are added to the mixture melt by liquid feeding device Medium; Melt extrusion and granulation at 150rpm and 10kg / h feed rate to obtain polypropylene material with high melt strength; extruder temperature settings: 170°C in the conveying section, 200°C in the reaction section, and 220°C in the extrusion section ℃. The resulting polypropylene material had a melt strength of 12 cN and a melt index of 3.5 g / 10 min.

Embodiment 2

[0061] A high-melt-strength polypropylene material prepared from the following components in parts by weight:

[0062] Polypropylene (MFR=3.2g / 10min): 97.7

[0063] Dicumyl peroxide: 0.1

[0065] Lanthanum stearate: 0.1

[0066] Pentaerythritol triacrylate: 2;

[0067] The preparation method of the high-melt-strength polypropylene material is the same as in Example 1. The melt strength of the obtained polypropylene material is 20cN, and the melt index is 2.2g / 10min.

Embodiment 3

[0069] A high-melt-strength polypropylene material prepared from the following components in parts by weight:

[0070] Polypropylene (MFR=3.2g / 10min): 92.7

[0071] Dicumyl peroxide: 0.1

[0072] Lanthanum oxide: 0.1

[0073] Lanthanum stearate: 0.1

[0074] Pentaerythritol triacrylate: 2

[0076] The preparation method of the high-melt-strength polypropylene material is the same as in Example 1. The melt strength of the obtained polypropylene material is 21cN, and the melt index is 2.0g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com