Diphenylamino oxocarboxylic acid extraction agent and preparation method and application thereof

A technology of diphenylamino oxocarboxylic acid and extractant, which is applied in the field of diphenylamino oxocarboxylic acid extractant, can solve the problems of difficult separation of heavy rare earth elements and yttrium, low separation coefficient, etc., and achieve single component, chemical The effect of stable structure and stable extraction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

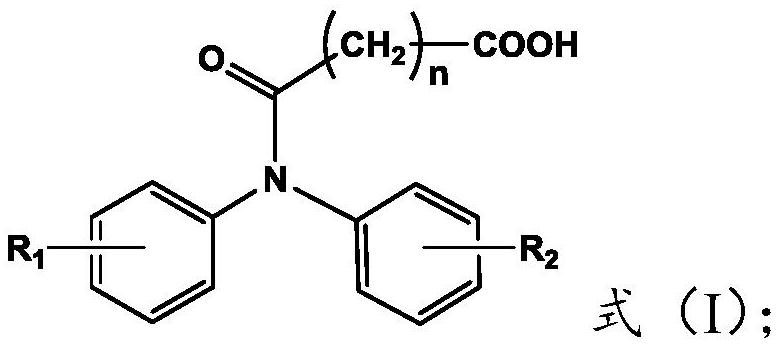

[0044] The present invention also provides a kind of preparation method of above-mentioned diphenylamino oxocarboxylic acid extraction agent, comprises the following steps:

[0045] A) After mixing dialkylaniline, alkyldiacid monoethyl chloride, organic solvent and organic base, react to obtain a reaction solution;

[0046] B) mixing the reaction solution with water to obtain an oil phase and a water phase;

[0047] C) Distilling the oil phase under reduced pressure to obtain monoethyl diphenylaminooxycarboxylate;

[0048] D) heating the monoethyl diphenylaminooxycarboxylate to reflux in a sodium hydroxide solution, acidifying and distilling under reduced pressure to obtain a diphenylaminooxycarboxylic acid extractant.

[0049] In some embodiments of the invention, step A) comprises:

[0050] a) mixing dialkylaniline, organic base and organic solvent to obtain a mixed solution;

[0051] b) mixing alkyldiacid monoethyl chloride with the mixed solution to react to obtain a re...

Embodiment 1

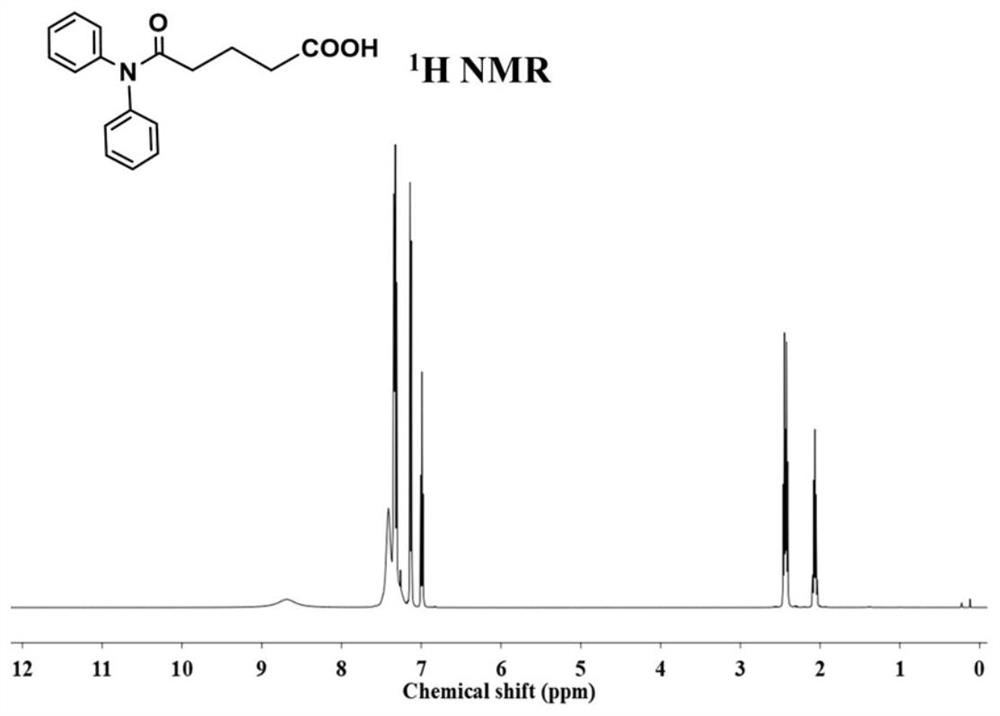

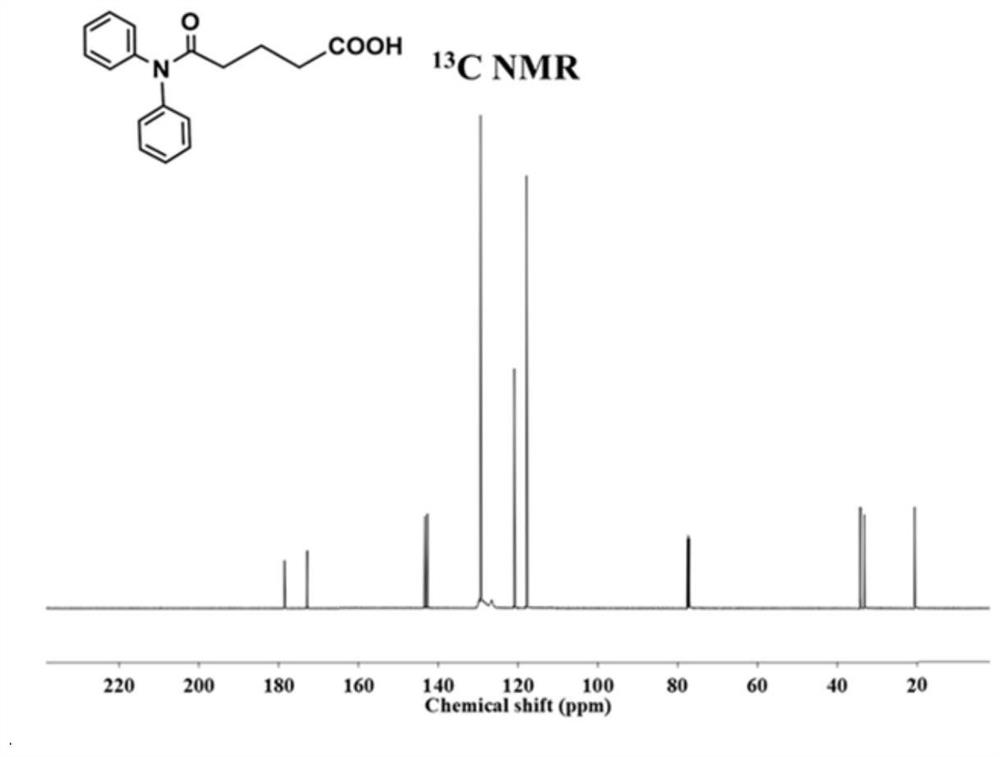

[0101] The chemical structure of 5-diphenylamino-5-oxopentanoic acid is shown in formula (I-1), namely R 1 and R 2 Both are H, and the value of n is 3;

[0102]

[0103] Its preparation steps are as follows:

[0104](1) Mix 16.9g of diphenylamine, 15.2g of triethylamine and 40mL of dichloromethane, stir evenly to obtain a mixed solution, and cool the mixed solution to 0°C with an ice-water bath.

[0105] (2) Add 17.9 g of monoethyl glutaric acid chloride to the mixed liquid, and stir and react at 0° C. for 30 min to obtain a reaction liquid.

[0106] (3) Add deionized water to the reaction solution, the reaction solution is divided into an oil phase and a water phase, and the oil phase is distilled under reduced pressure to obtain the crude product ethyl 5-diphenylamino-5-oxopentanoate.

[0107] (4) Heat ethyl 5-diphenylamino-5-oxopentanoate in 100 mL of a mixed solution containing 5 g of sodium hydroxide (solvents include ethanol and water, volume ratio 1:1) to 70° C. f...

Embodiment 2

[0113] The chemical structure of 3-(4,4'-dimethyldiphenylamino)-3-oxopropionic acid is shown in formula (I-2), ie R 1 and R 2 Both are methyl groups, and the value of n is 1;

[0114]

[0115] Its preparation steps are as follows:

[0116] (1) Mix 19.7g of 4,4'-dimethyldiphenylamine, 15.2g of triethylamine and 40mL of dichloromethane, stir evenly to obtain a mixed solution, and cool the mixed solution to 0°C with an ice-water bath.

[0117] (2) 15.0 g of monoethyl malonate chloride was added to the mixed liquid, and stirred and reacted at 0° C. for 30 min to obtain a reaction liquid.

[0118] (3) Add deionized water to the reaction solution, the reaction solution is divided into an oil phase and a water phase, and the oil phase is distilled under reduced pressure to obtain the crude product 3-(4,4'-dimethyldiphenylamino)-3 - ethyl oxopropionate.

[0119] (4) Mix ethyl 3-(4,4'-dimethyldiphenylamino)-3-oxopropanoate in 100mL containing 5g sodium hydroxide (solvents includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com