Precise forming process of deep-hole button bit

A precision forming and ball tooth technology, applied in the field of metal plastic forming technology, can solve the problems of short life of forging die, high manufacturing cost, low material utilization rate, etc., and achieve the effect of improving overall strength and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

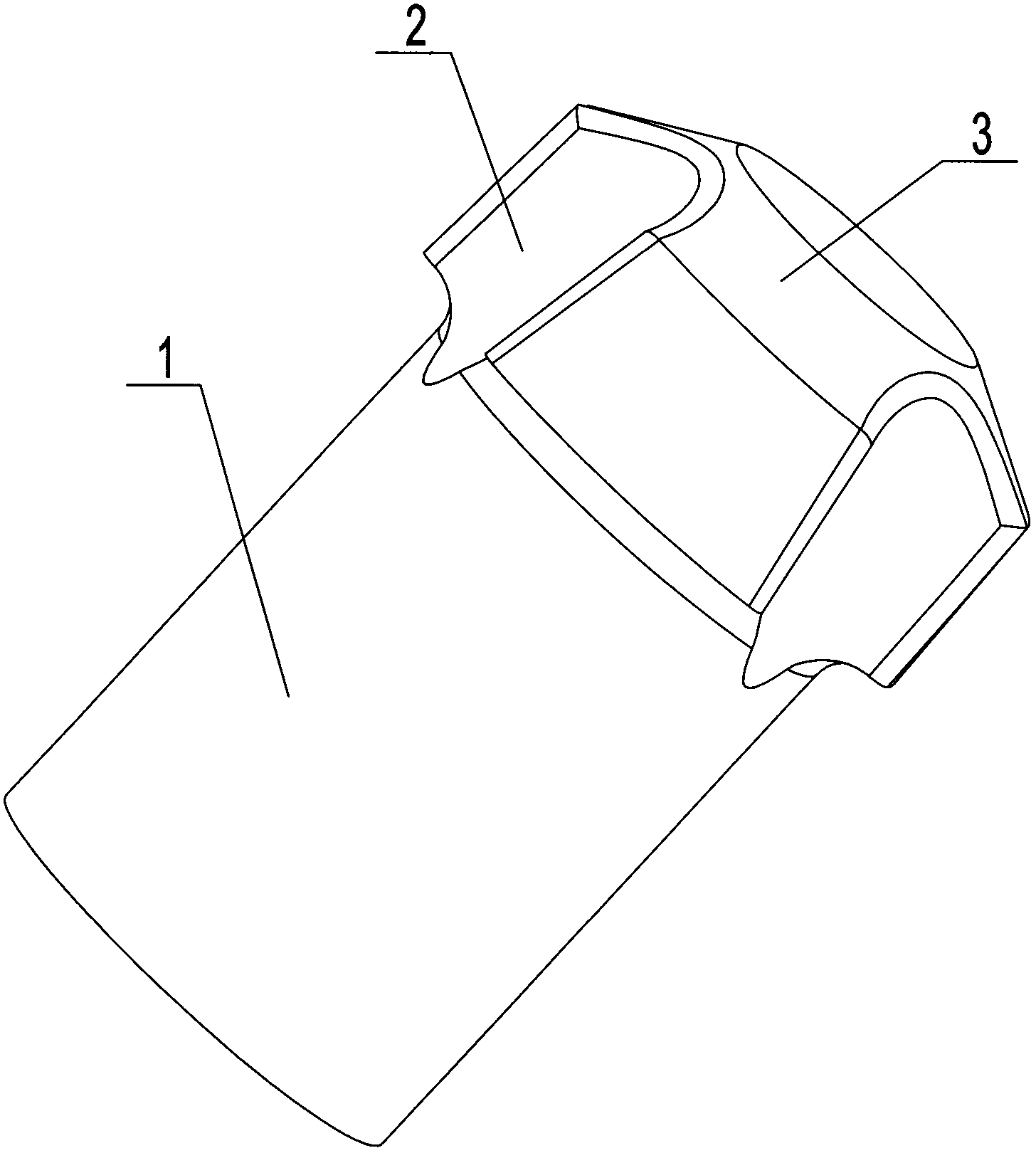

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below by means of the accompanying drawings and specific embodiments.

[0009] The precision forming process of the deep hole ball tooth drill bit includes the following process: pre-spheroidizing the billet, performing spheroidizing annealing, phosphorus, and saponification, and then using the method of back extrusion to obtain a large outer diameter and shallow hole depth. The cup-shaped parts with simple round holes are then annealed, phosphorus-treated, and saponified, and then the outer diameter and inner hole are continuously reduced and lengthened to obtain deep-hole parts by successively reducing the outer diameter. Diameter reduction depends on the specific analysis of specific parts. During back extrusion, since the inner hole of the part itself has a relatively large length and diameter, although the deformation has been reduced, the depth of back extrusion is still deeper than that of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com