Fast-setting water-hardening sludge cold hardened pellet and preparation method thereof

A technology for cold-solidifying pellets and sludge, applied in chemical instruments and methods, clay preparation devices, cement mixing devices, etc. Environmental protection and comprehensive utilization of resources, good economic and environmental value, and the effect of ensuring particle integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

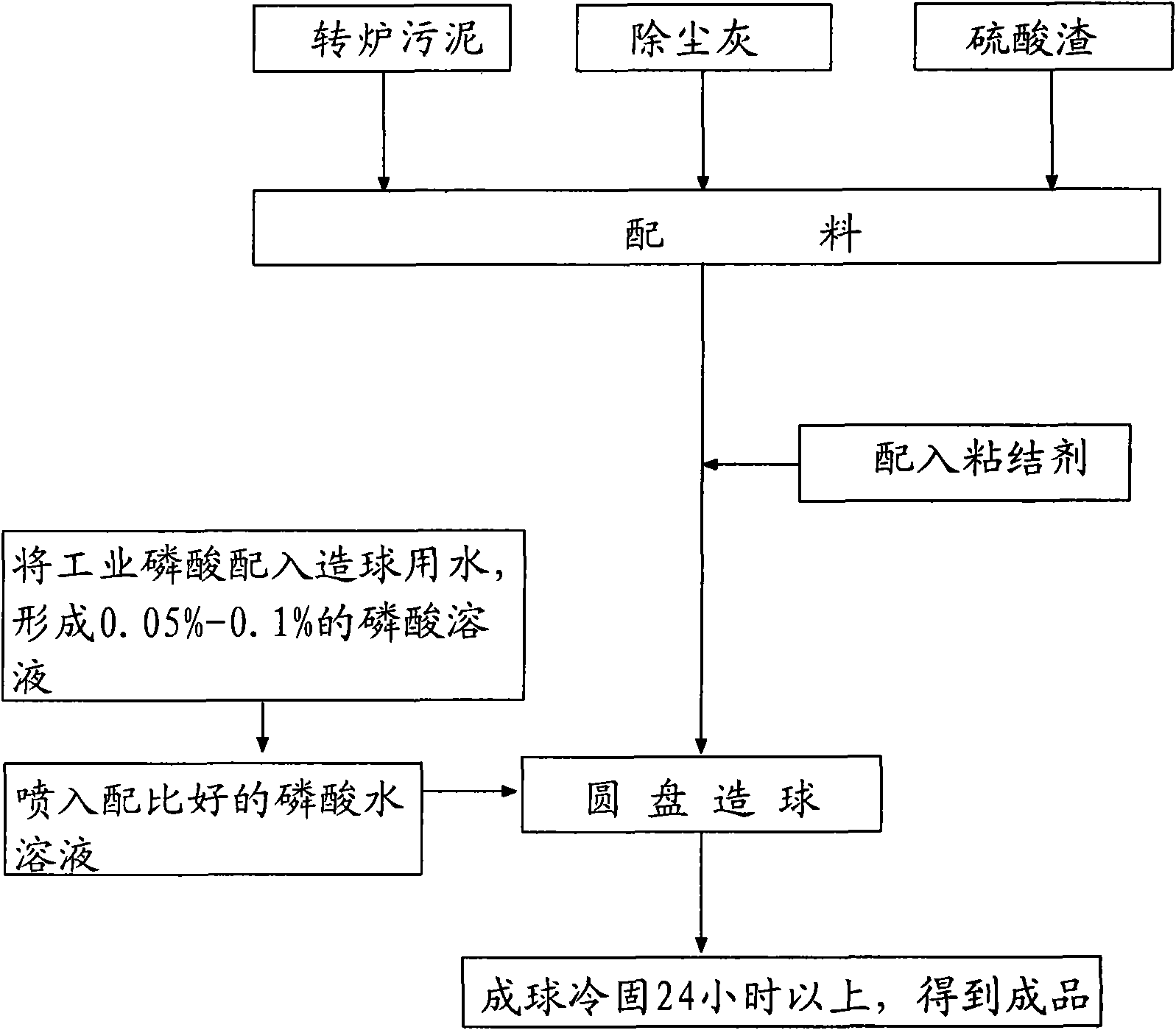

[0048] As shown in the figure, according to the percentage by weight, the feed materials are prepared in the following proportions: converter sludge 35%, dedusting ash 35%, sulfuric acid slag 23%; plus 7% sulphoaluminate cement as a binder.

[0049] Put the above added material into the mixer and turn it for 10 minutes to mix evenly, then add it to the disc pelletizer, start the pelletizer and rotate it at 5 rpm for 5 minutes, then increase the pelletizer speed to 10 rpm, and Spraying the phosphoric acid solution containing 0.05% phosphoric acid to form small balls with a diameter of 3-10 mm, and leaving the balls under natural conditions for more than 24 hours to obtain cold-set pellets.

Embodiment 2

[0051] According to the percentage by weight, the feed materials are prepared in the following proportions: 40% of converter sludge, 30% of dedusting ash, 22% of sulfuric acid slag; plus 8% of sulphoaluminate cement and phosphoric acid mixture as binder.

[0052]Put the above added material into the mixer and turn it for 10 minutes to mix evenly, then add it to the disc pelletizer, start the pelletizer and rotate it at 5 rpm for 5 minutes, then increase the pelletizer speed to 10 rpm, and Spray the phosphoric acid solution containing 0.1% phosphoric acid to form pellets with a diameter of 3-10 mm, and leave the pellets under natural conditions for more than 24 hours to obtain cold-set pellets.

Embodiment 3

[0054] According to the percentage by weight, the feed materials are prepared in the following proportions: 38% of converter sludge, 35% of dedusting ash, 20% of sulfuric acid slag; plus 7% of sulphoaluminate cement as a binder.

[0055] Put the above added material into the mixer and turn it for 10 minutes to mix evenly, then add it to the disc pelletizer, start the pelletizer and rotate it at 5 rpm for 5 minutes, then increase the pelletizer speed to 10 rpm, and Spraying the phosphoric acid solution containing 0.05% phosphoric acid to form small balls with a diameter of 3-10 mm, and leaving the balls under natural conditions for more than 24 hours to obtain cold-set pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com