Fast-setting water-hardening sludge cold hardened pellet and preparation method thereof

A technology for cold-solidifying pellets and sludge, applied in chemical instruments and methods, clay preparation devices, cement mixing devices, etc. Environmental pollution, the effect of ensuring particle integrity

Inactive Publication Date: 2011-02-16

CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In addition, sulfuric acid slag, as an iron-containing raw material, has been used in the sintering ironmaking process. The traditional method is to directly mix ore and sinter on a belt sintering machine. big problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

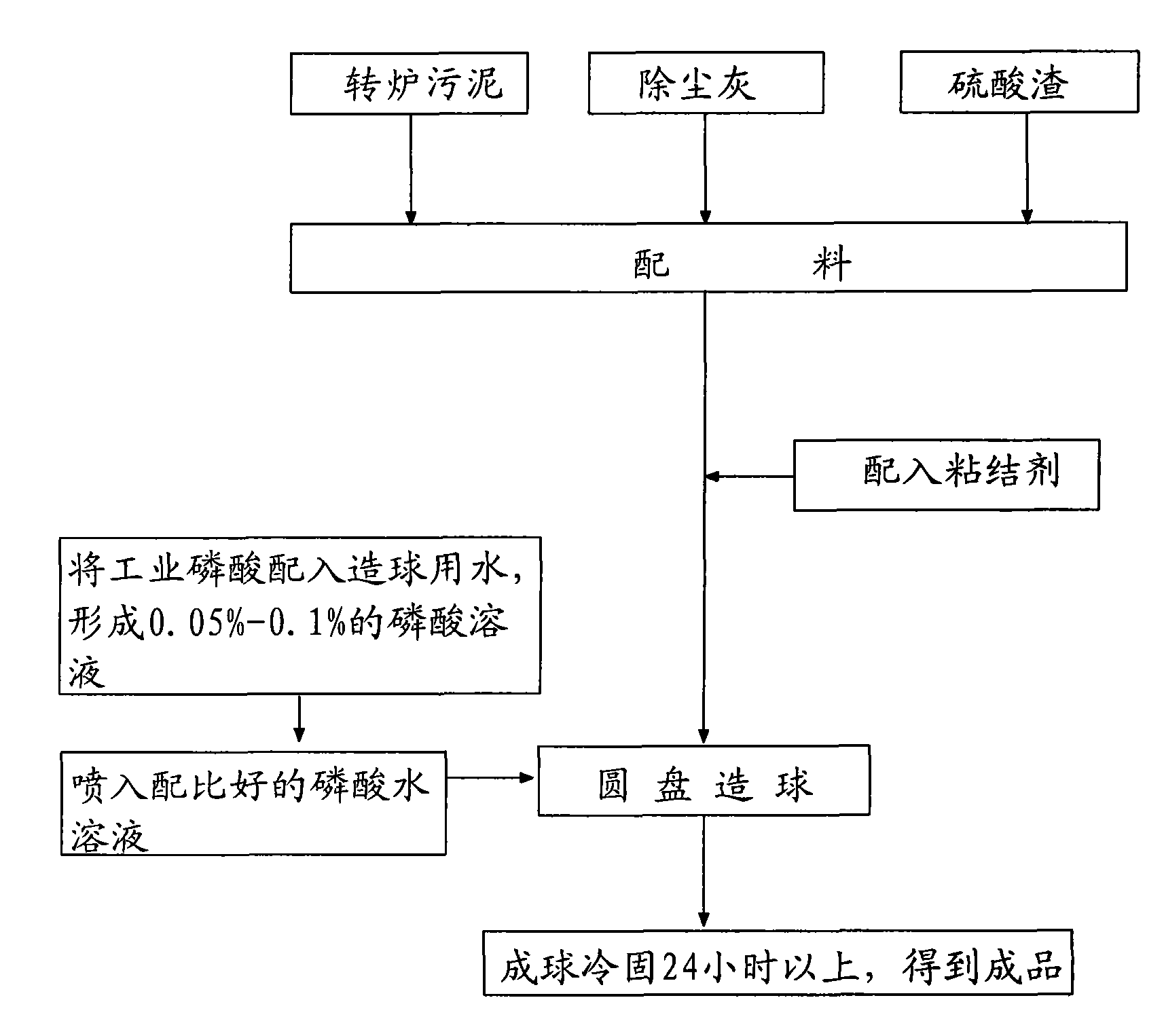

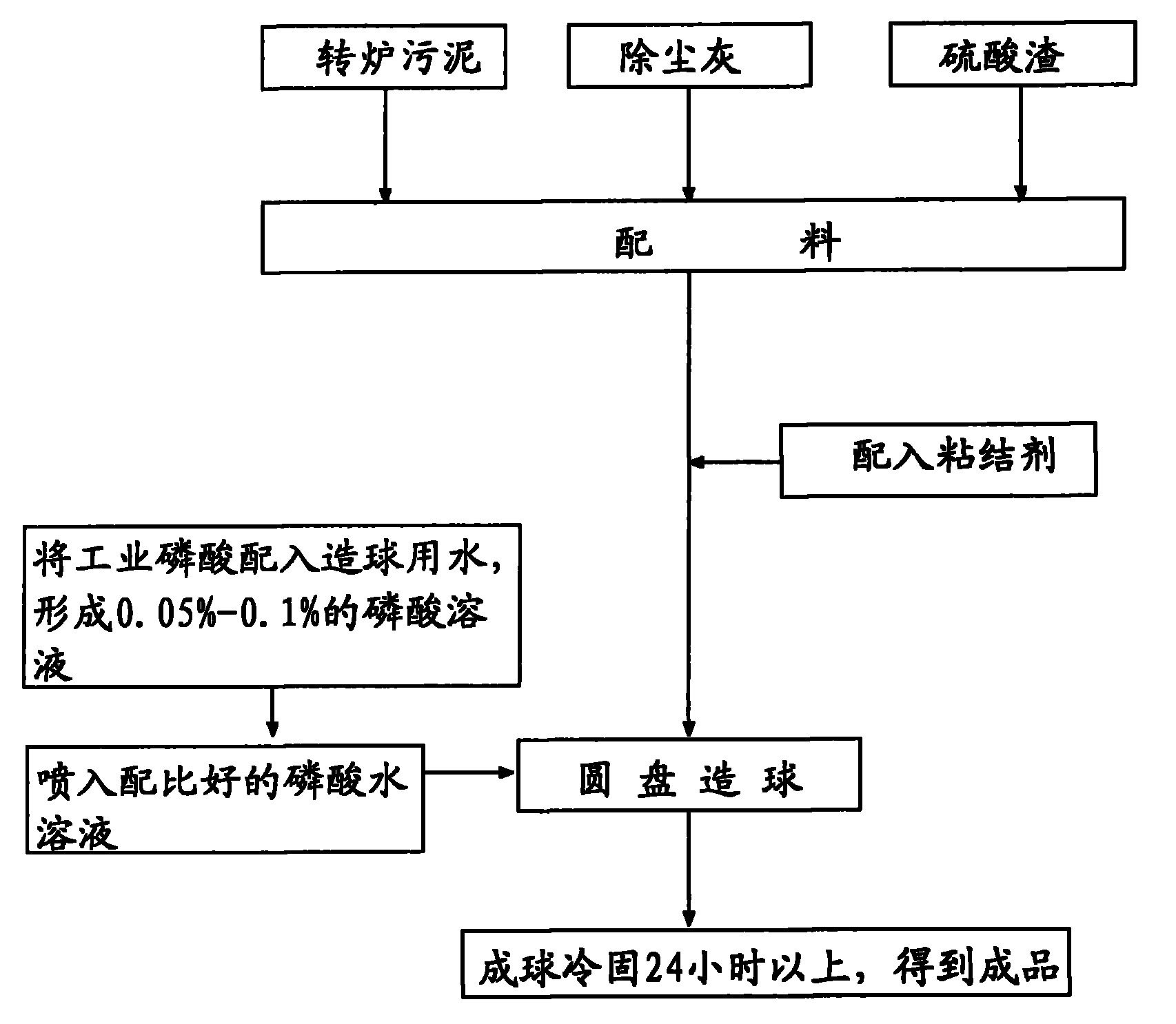

The invention discloses a fast-setting water-hardening sludge cold hardened pellet which is formed mainly by mixing converter sludge, settled dust, sulfuric acid residue and binder, and then adding 0.05-0.1 percent (in concentration) of phosphoric acid, then finally conducting disc pellet fabrication and cold hardening; the pellet is quite suitable to be served as the sintering materials of a belt-type sintering machine; in addition, the invention also provides a preparation method for the fast-setting water-hardening sludge cold hardened pellet; and the method ensures the integrity of particles when the cold hardened pellet enters the mixing materials, maintains the permeability of a sintered material layer, and can obtain stable economic indicators of sintering production technology.

Description

technical field [0001] The invention relates to the production technology of pelletizing in the metallurgical industry, in particular to a cold solidified pellet of rapidly setting water hardening sludge and a preparation method thereof. Background technique [0002] In the 1920s, Sweden used portland cement to produce water-hardening pellets. After a curing period, water-hardening pellets with a certain strength were obtained. Later, after the improvement of the former Soviet Union and the Japanese, different processes were formed, but the basic principle is the same, that is, calcium silicate hydrate and calcium ferrite hydrate gel are formed, and strength is obtained after a certain maintenance period. The more obvious problem in this method is that the freezing time is too long (more than 96 hours), and a large storage area is required to meet the needs of the maintenance period. [0003] At present, the production of pellets is to mix iron ore powder and bentonite, add...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28C7/04B28C5/08B28B1/02B28B11/24

Inventor 张明远万新袁晓丽杜长坤周书才朱虹

Owner CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com