Welding and forming method for shell of solid rocket engine

An engine casing and welding forming technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as large deformation of thin-walled barrel sections, engine casings that do not meet the overall index requirements, and difficulty in shape correction, etc., to achieve Avoid cold cracks, stable and reliable welded joint strength, small heat-affected zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

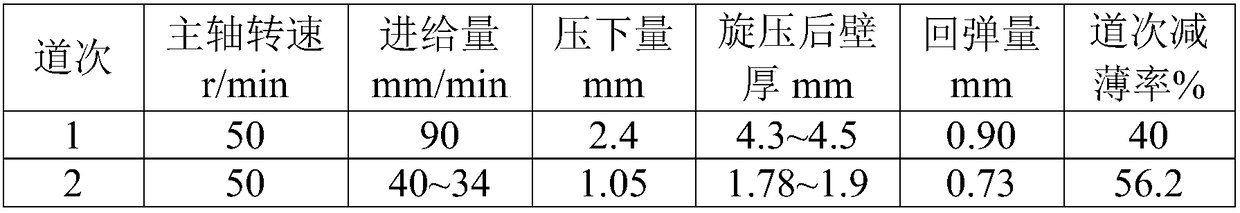

[0052] The welding method for the combustion chamber shell with a length of 1500mm and a barrel section wall thickness of 1.8mm is as follows:

[0053] 1) Determine the segmental welding structure of the shell

[0054] Divide the shell into front joint, cylinder and rear joint;

[0055] 2) Process front and rear joints

[0056] Forgings are used to process the front joint blank, and then the front joint blank is subjected to heat treatment to strengthen quenching and tempering after rough turning; after the front joint blank is heat treated, the outer diameter of the butt welding part with the cylinder is finished to ensure that the outer diameter of the butt welding part is consistent with the cylinder The outer diameter is consistent to form the front joint;

[0057] Among them, the heat treatment system is as follows: first, heat at 935°C for 45 minutes, then quench in oil, and then hold at 305°C for 3.5 hours, then air cool;

[0058] In the same way, forgings are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com