A semi-automatic assembly device for iron core short-circuit ring of AC contactor

An AC contactor and assembly device technology, applied in circuits, relays, electrical components, etc., can solve problems such as low precision, and achieve the effects of improving work efficiency, reducing costs, and ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

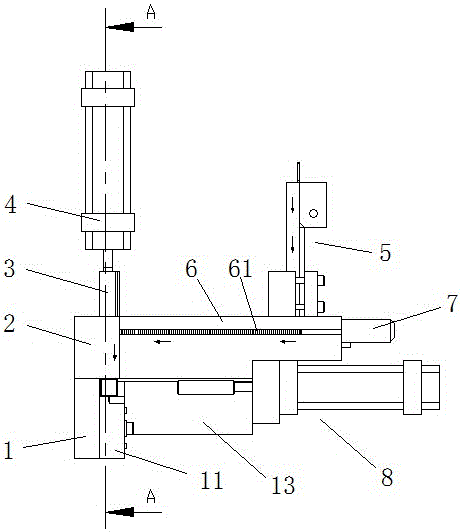

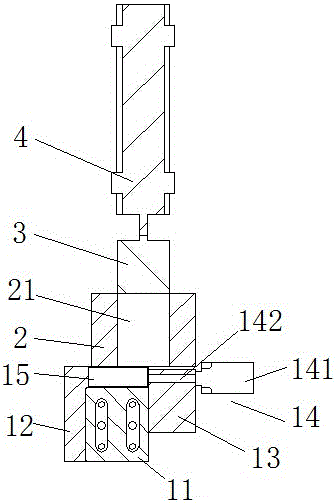

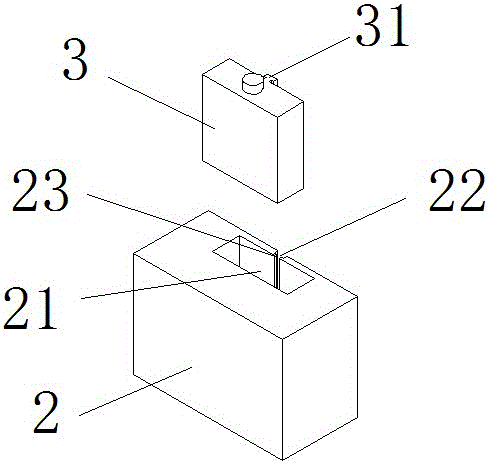

[0025] Example 1, such as Figure 1-2 As shown, a semi-automatic assembly device for the short-circuit ring of the iron core of the AC contactor includes a mounting seat 1 for placing workpieces. In the working area 15 , an ejection device 14 is provided on the back plate 13 corresponding to the position of the working area 15 ; the ejection device 14 includes a cylinder 141 arranged on the back plate 13 and a cylinder shaft 142 passing through the back plate 13 . like figure 2 As shown, the height of the bottom plate 11 is smaller than that of the side plates 12 to form two sides of the workpiece area 15 , and the other side of the workpiece area 15 is limited by the back plate 13 . A guide block 2 is set on the mounting base 1, a guide groove 21 is set at a position corresponding to the work area 15 on the guide block 2, and a briquetting block 3 for pressing the workpiece in the work area 15 is arranged above the corresponding guide groove 21. The pressure block 3 is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com