90 single automatic wet-type serial clutch assembling production line

A technology for assembling production lines and clutches, which is applied in the direction of mechanically driven clutches, clutches, friction clutches, etc., can solve problems such as difficulty in improving production efficiency, increased production costs, and unstable quality, so as to improve product quality and output, improve product quality, The effect of reducing the temporary storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

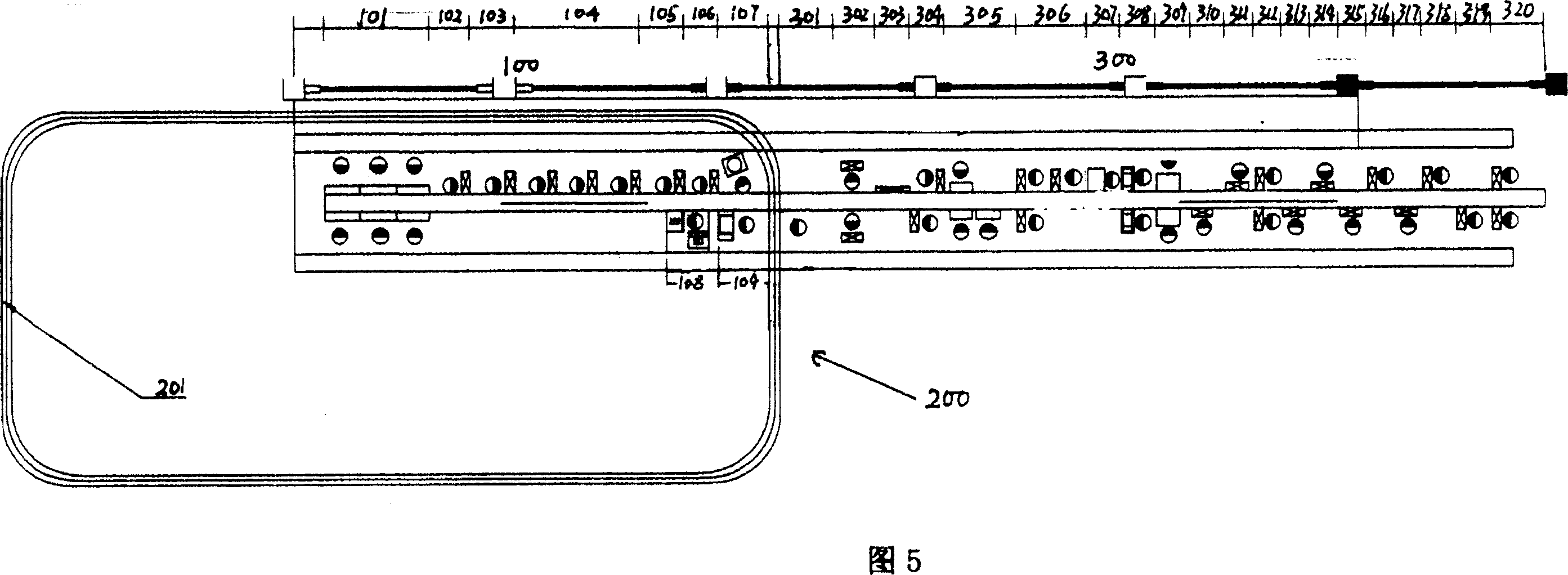

[0027] Referring to accompanying drawing 5, the structure of the 90 series clutch assembly production line is divided into three work areas, which are respectively the electroprinted outer cover logo and the driving disc assembly assembly work area 100 in the front section, and the middle outer cover and driving disc assembly cleaning work area 200 (This work area can be shared with other series such as C100 series clutch assembly assembly) and the clutch assembly assembly work area 300 of rear section. The work sections of each work area are arranged as follows:

[0028] The electroprinting outer cover logo and driving disk assembly assembly work area 100 consists of a flying block section 101, a repairing driving disk section 102, an inspection driving disk section 103, an upper flying block section 104, a limit ring section 105, and a parallel inspection section 106 , and sequentially connect the detection dynamic balance section 107, the outer cover inspection section 108 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com