Patents

Literature

39 results about "Metal spinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by hand or by a CNC lathe.

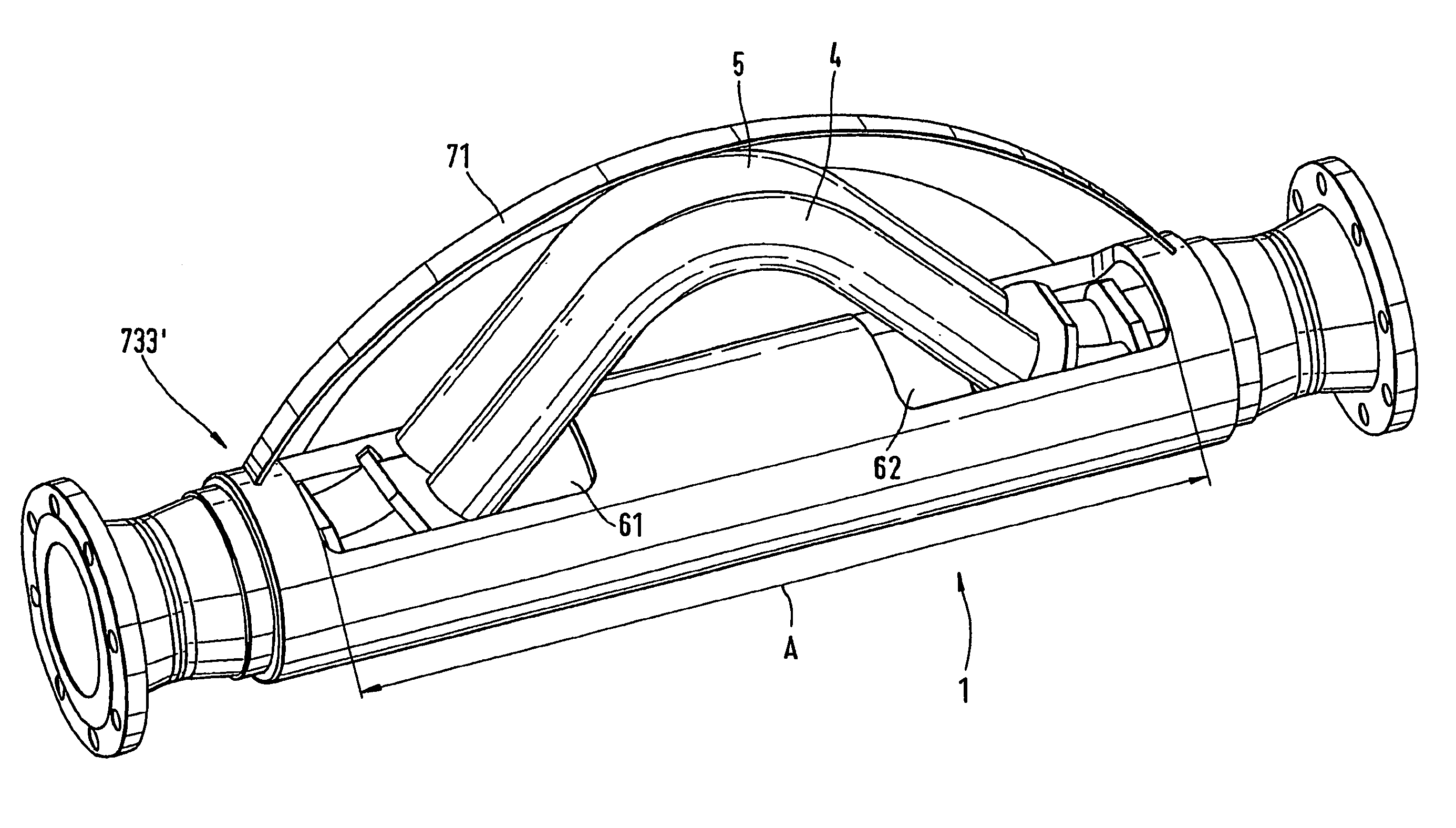

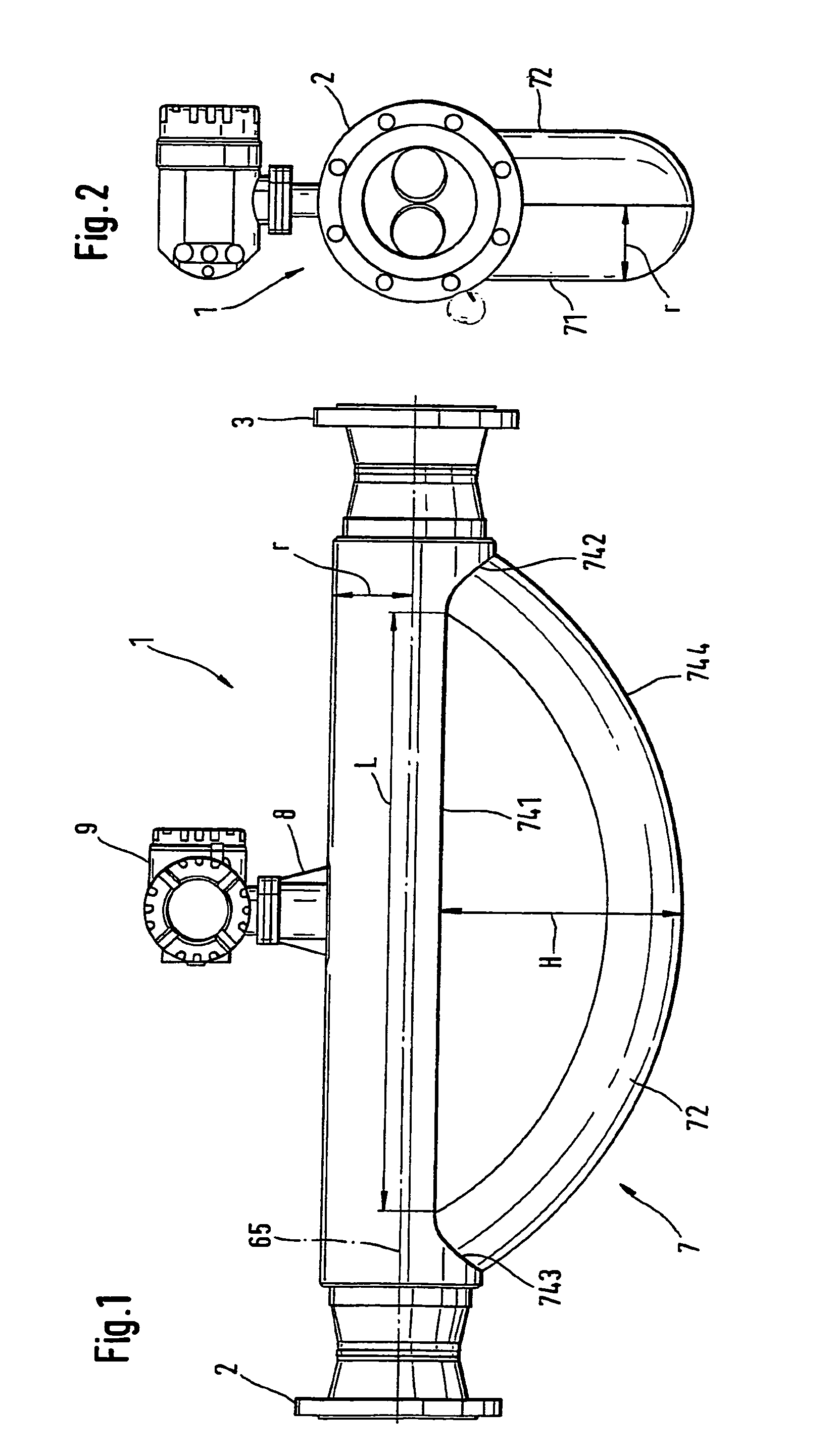

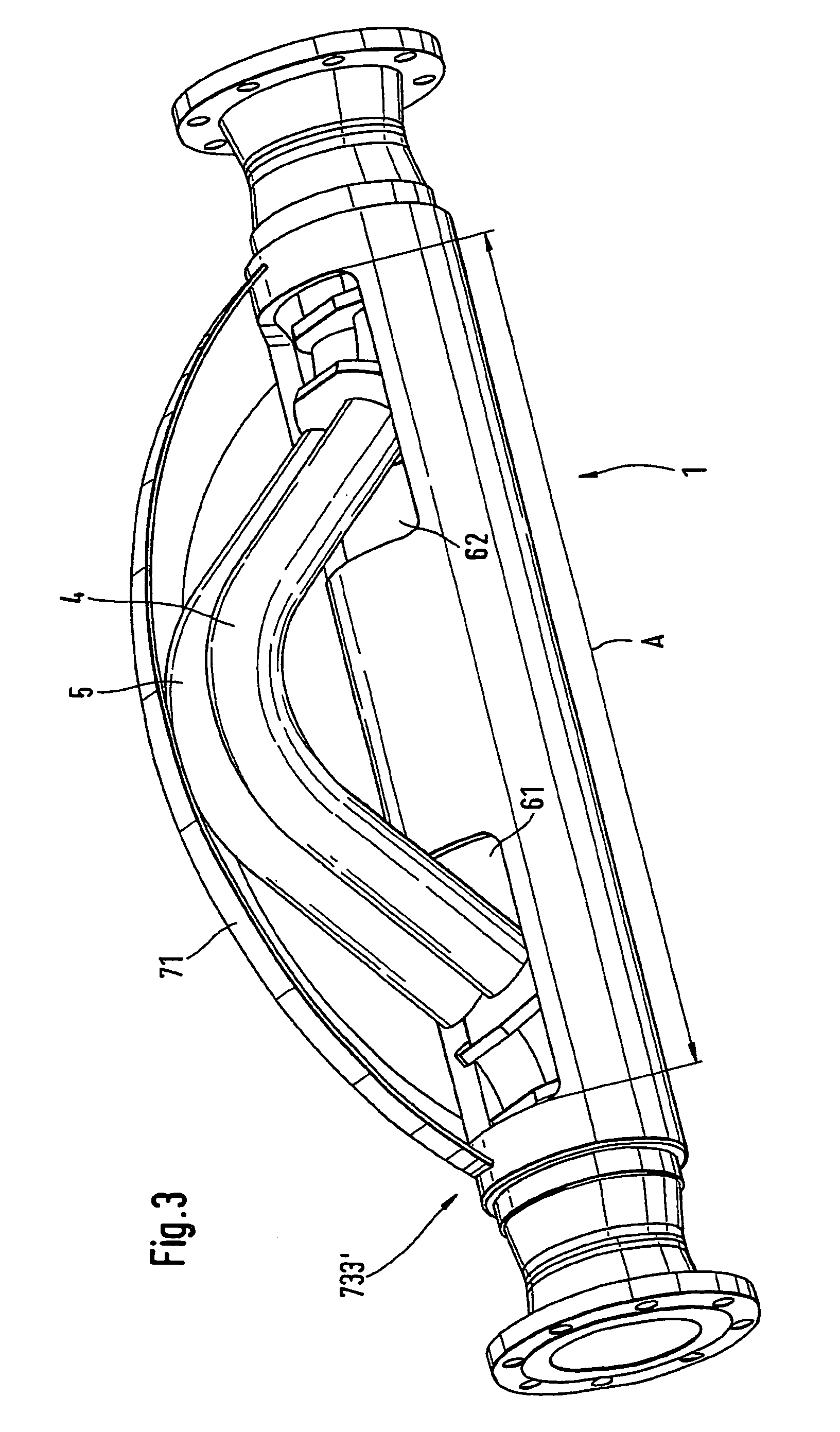

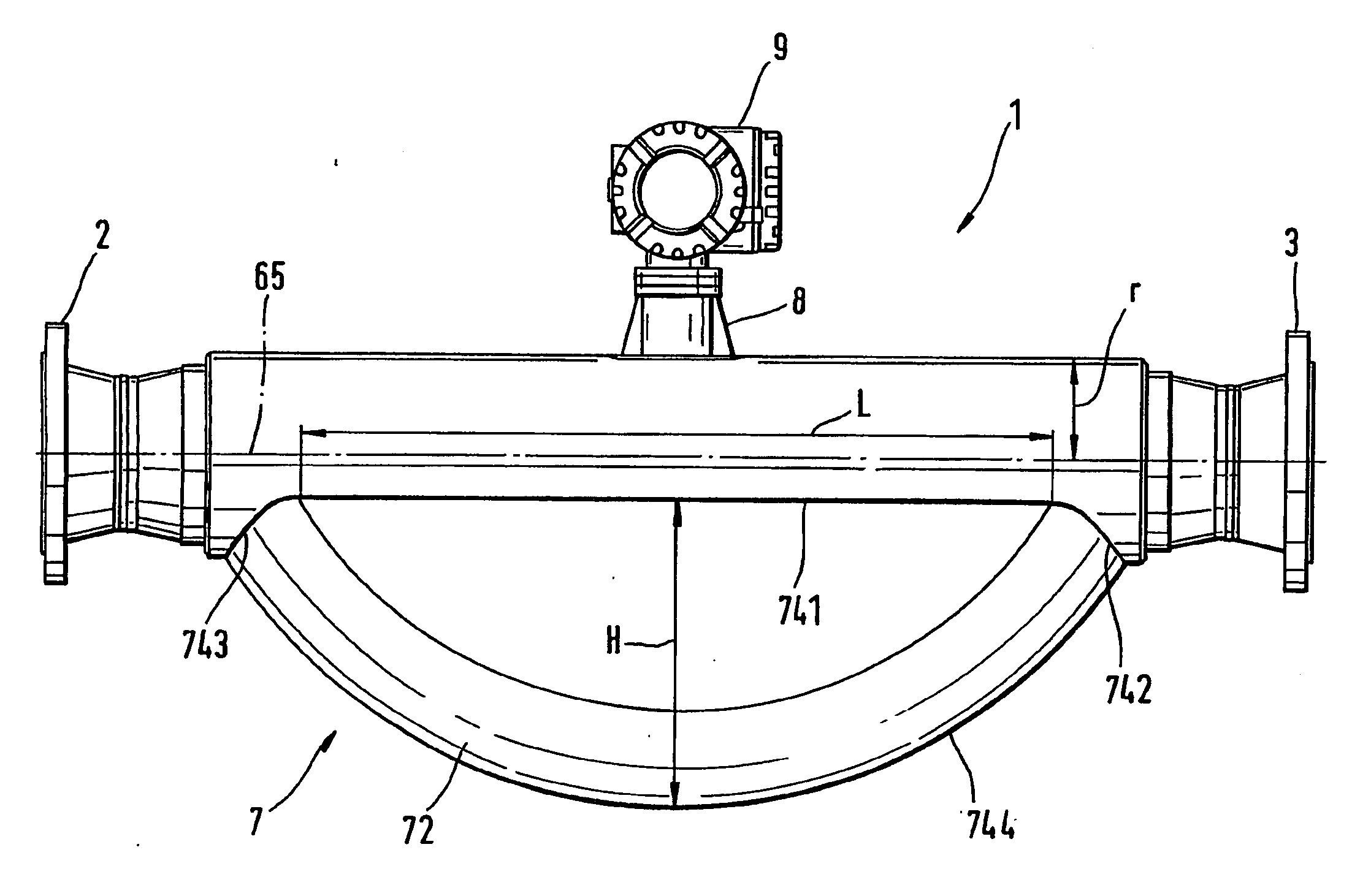

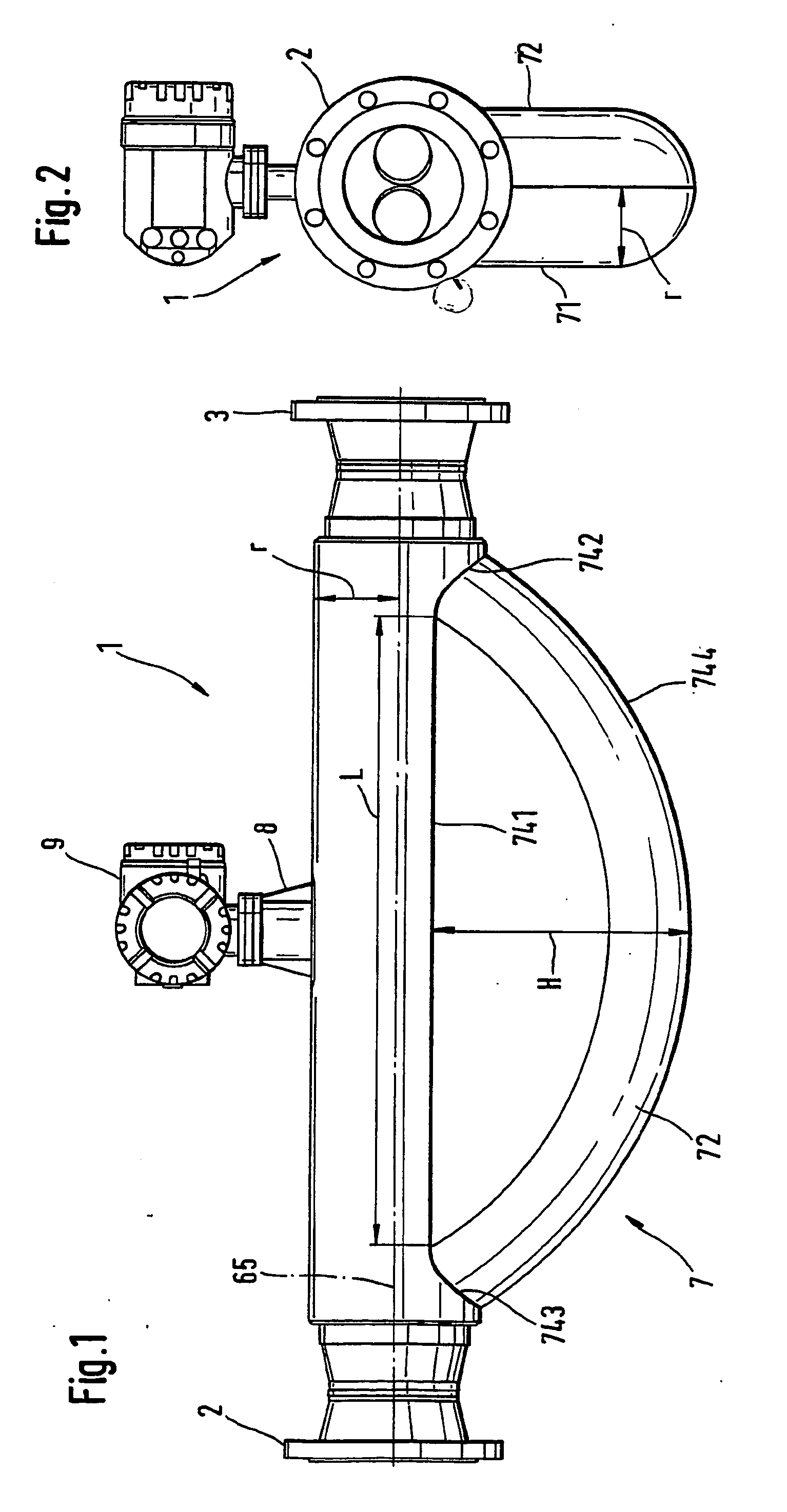

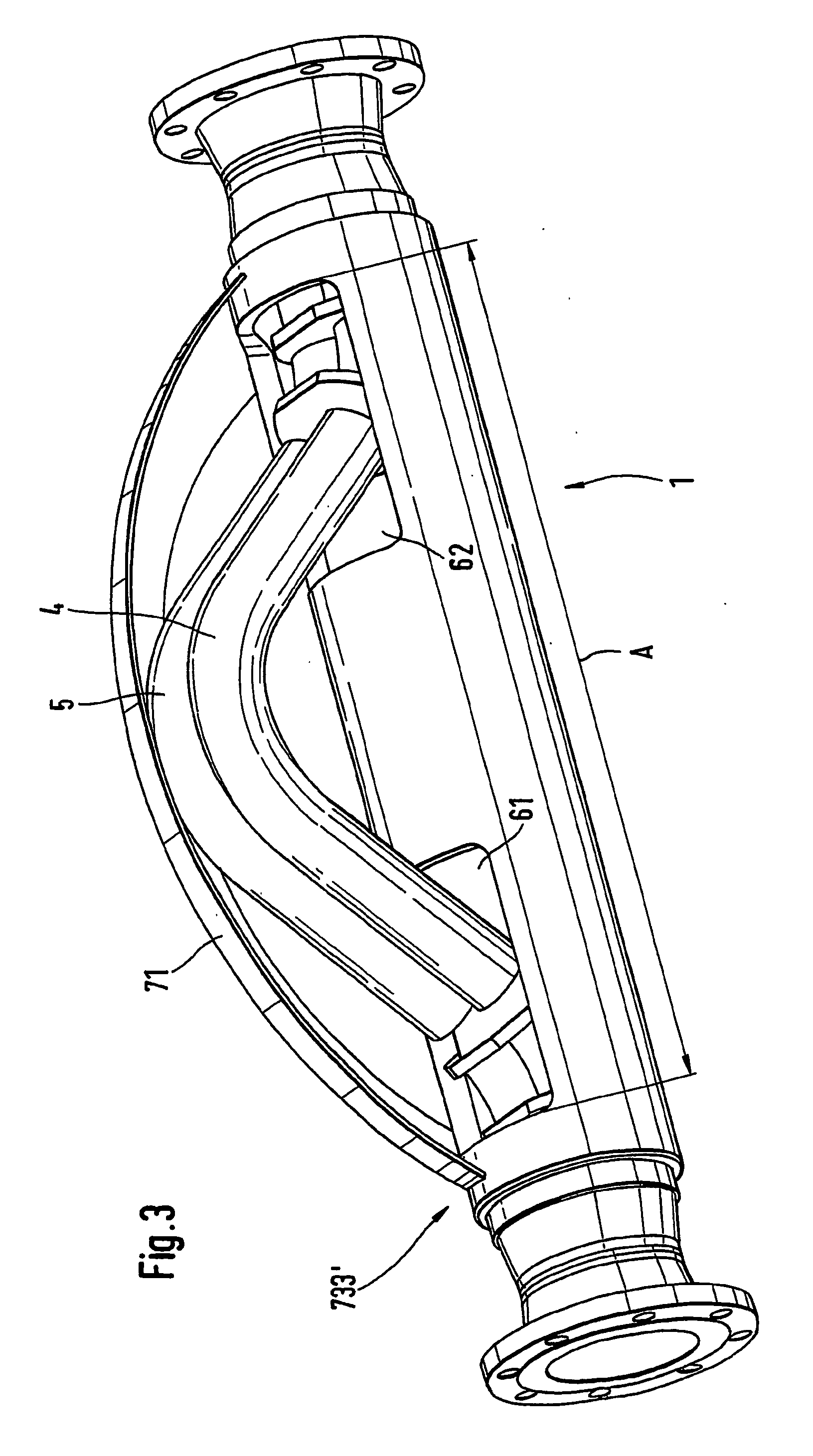

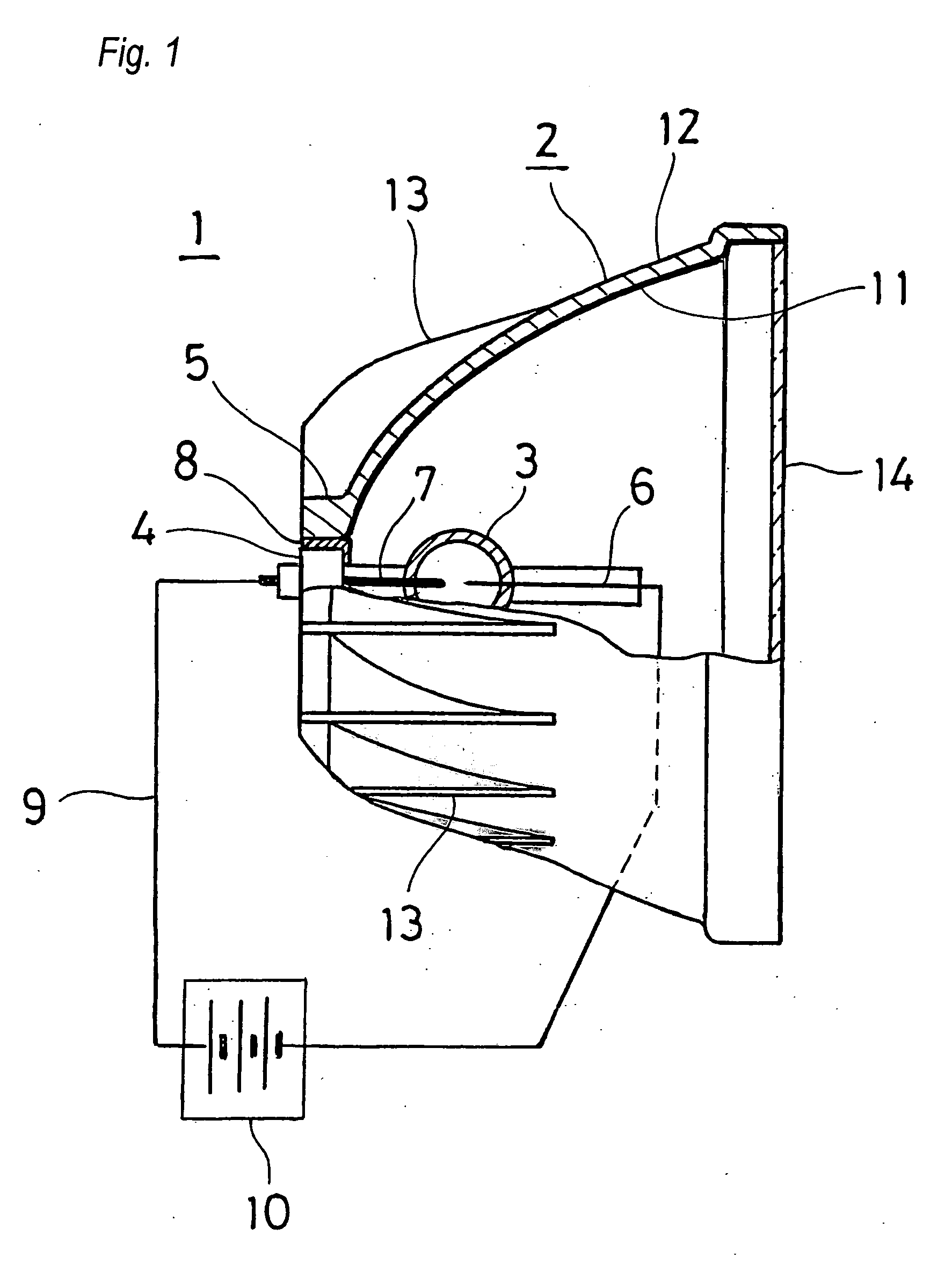

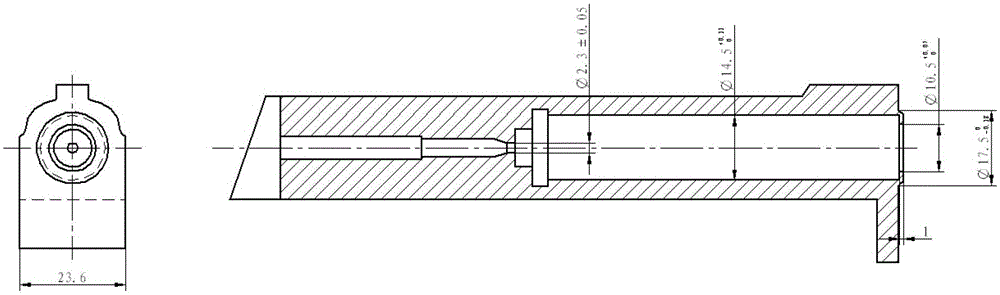

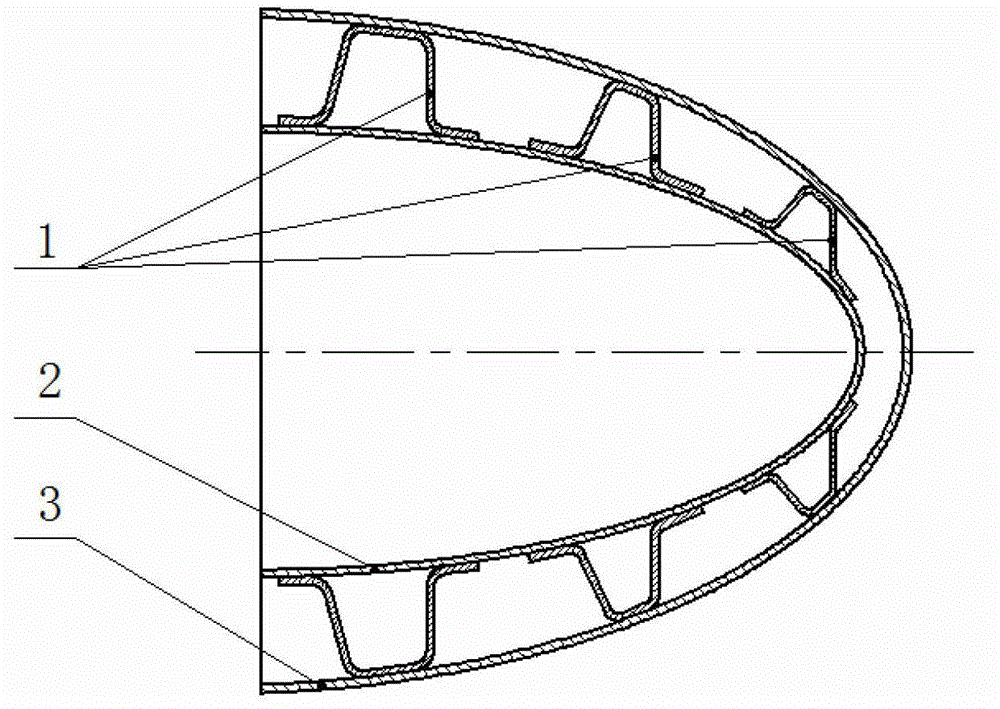

Vibration-type measuring sensor

InactiveUS7134347B2Low costReduce manufacturing costVolume meteringDirect mass flowmetersEngineeringMechanical engineering

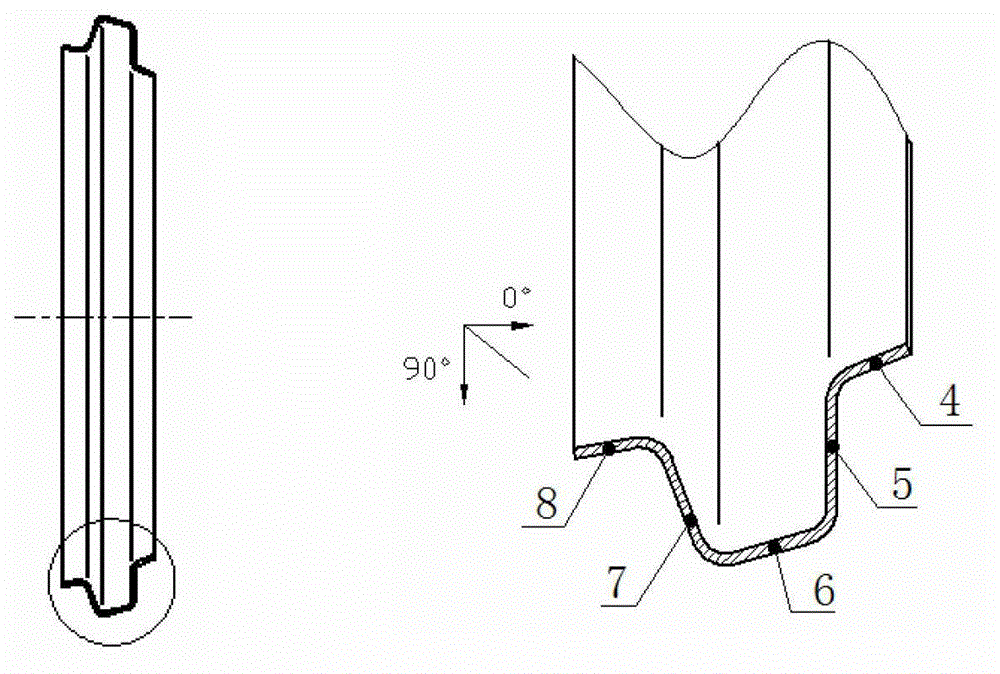

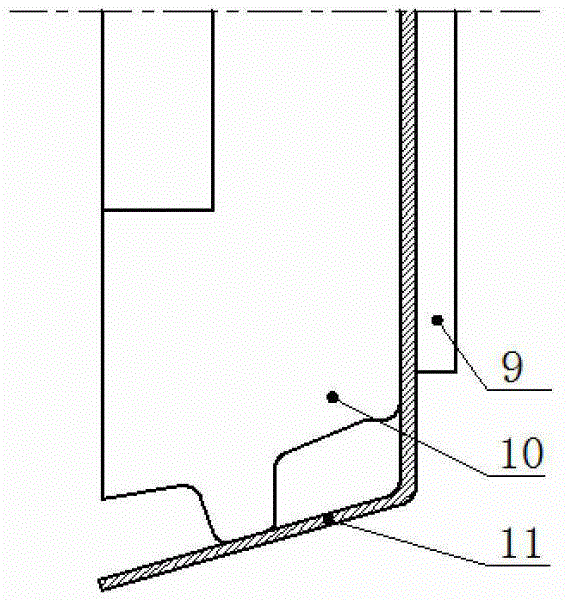

This sensor (1), for a fluid and suitable for use in a pipeline at least temporarily containing the fluid flowing therethrough, has at least one curved measuring tube (4, 5), which vibrates during operation and guides the fluid, and a housing enclosing the measuring tube. The housing is composed of a metal cap (7) of two cap halves (71, 72) and a supporting tube (6), in which the measuring tube is held at its inlet and outlet ends in a manner such that the tube can oscillate, and out of which a measuring tube segment protrudes sideways. Each cap half has an edge (73; 74) with, in each case, four edge portions (731, 732, 733, 734; 741, 742, 743, 744). The edge portions (731; 741) are straight, the edge portions (732, 733; 742, 743) are curved, and the edge portions (734; 744) have the shape of circular arcs. The edge portions (731, 732, 733; 741, 742, 743) are welded continuously to the supporting tube (6) and the edge portions (734; 744) are welded continuously to one another. The cap halves (71, 72) are cut out of a dish-shaped intermediate (70) having a formed, surrounding edge bead (701), provided with the shape of a quarter-torus by metal spinning.

Owner:ENDRESS HAUSER FLOWTEC AG

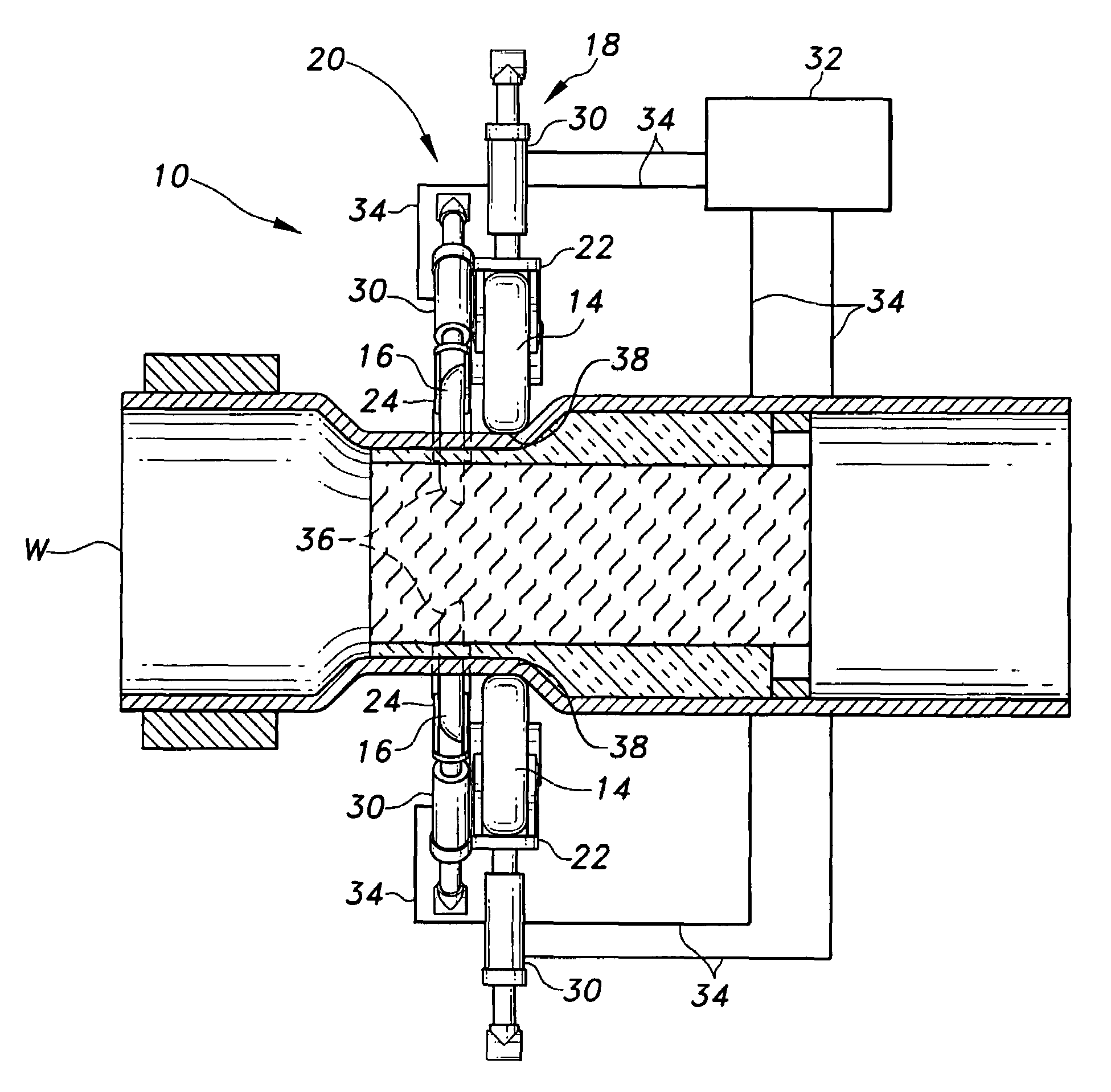

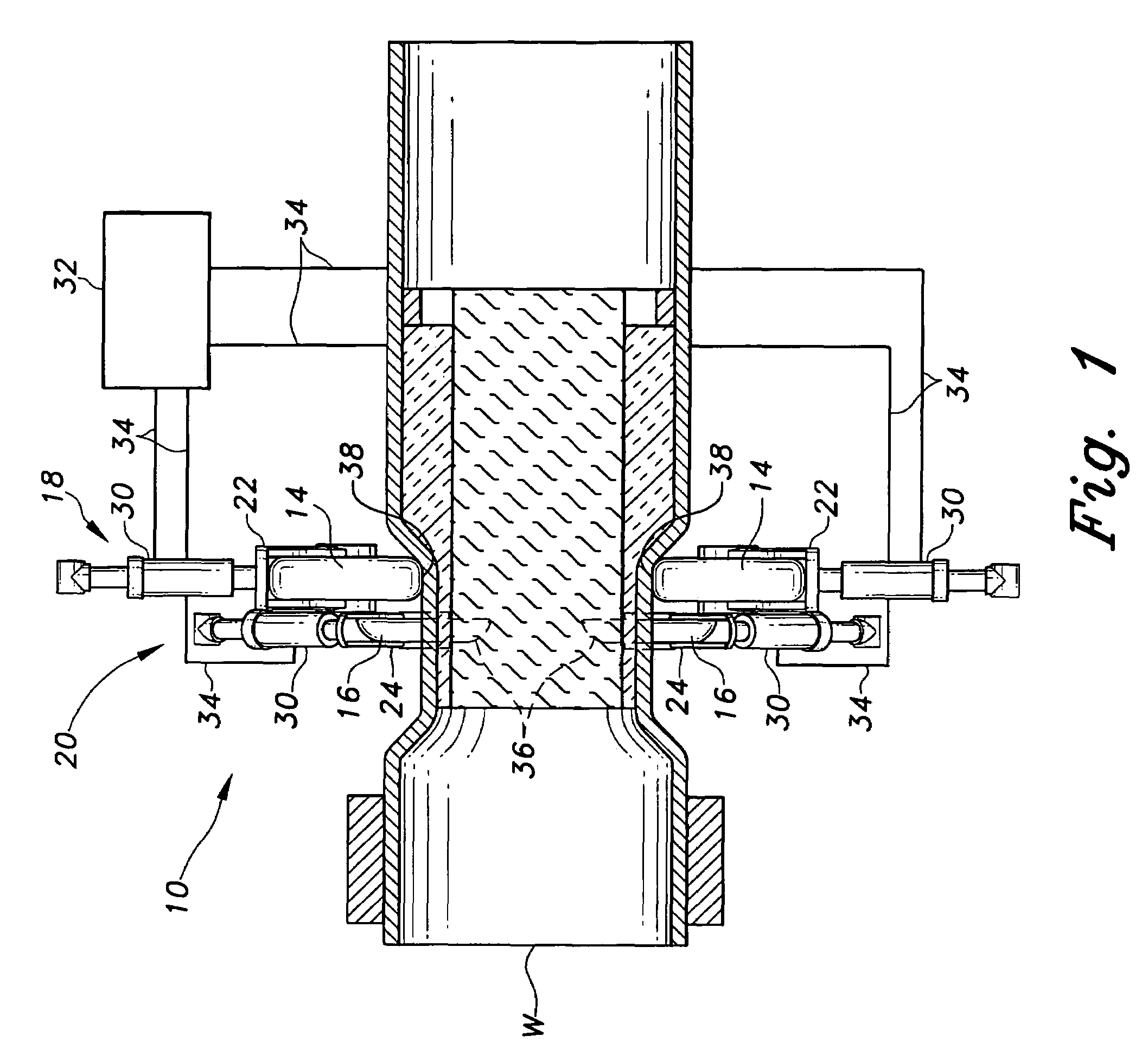

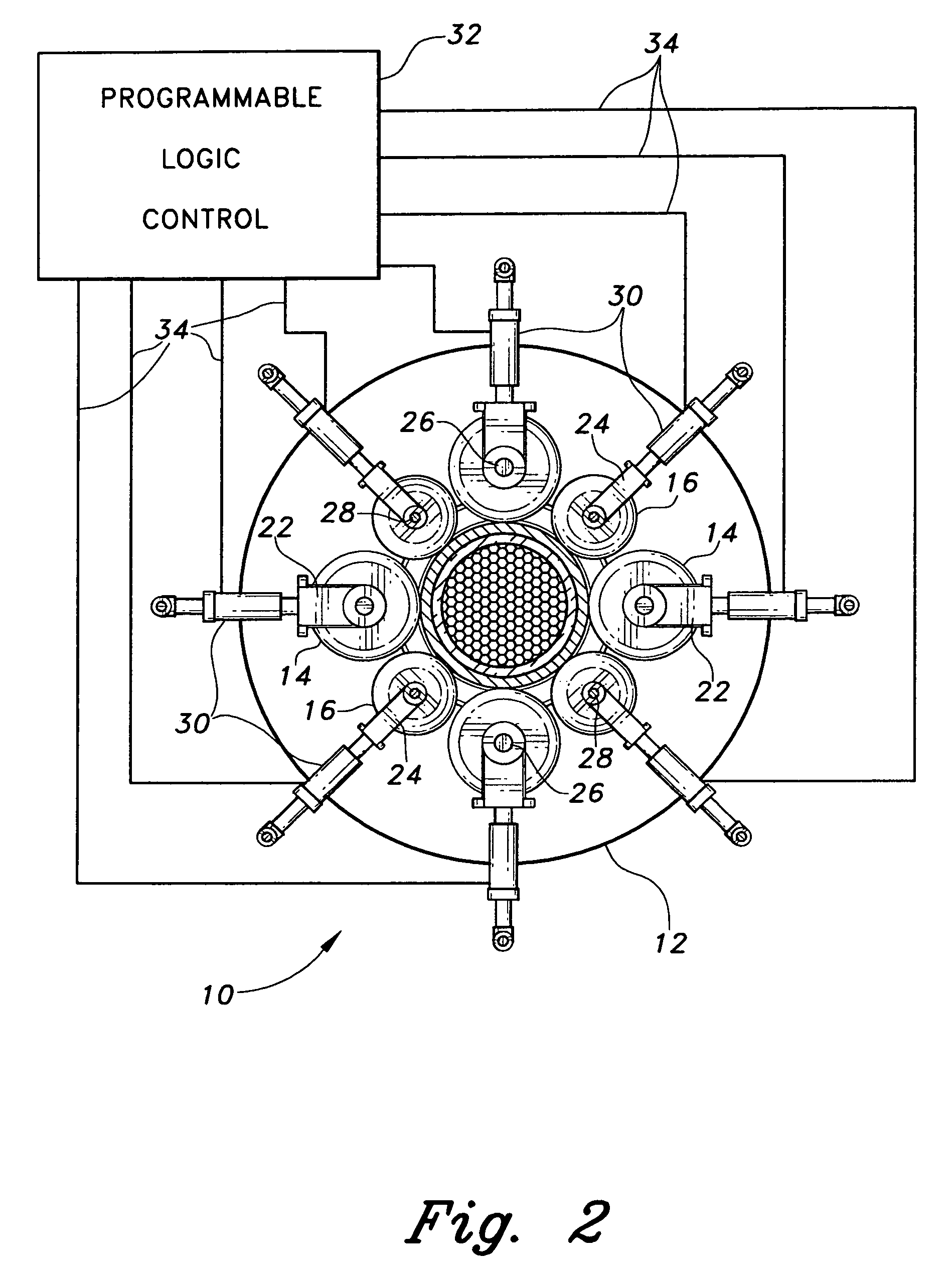

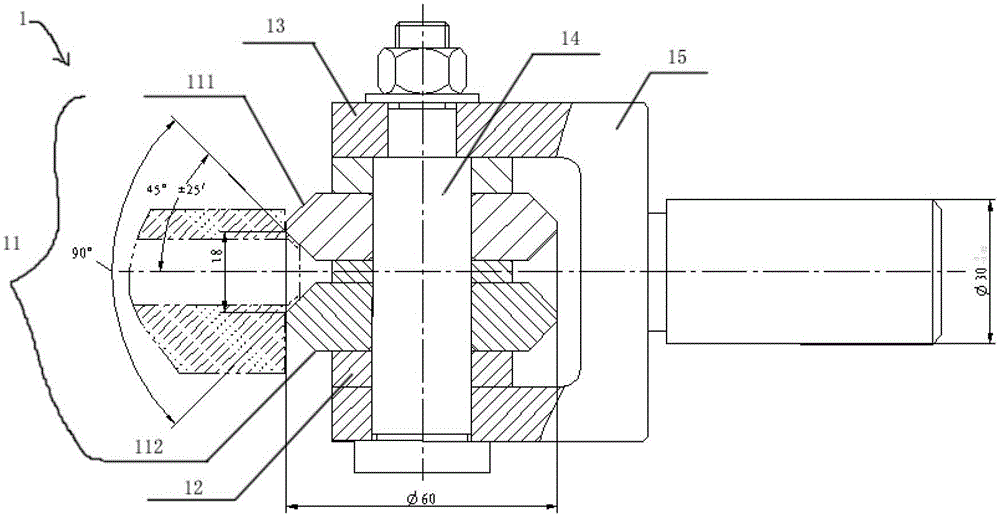

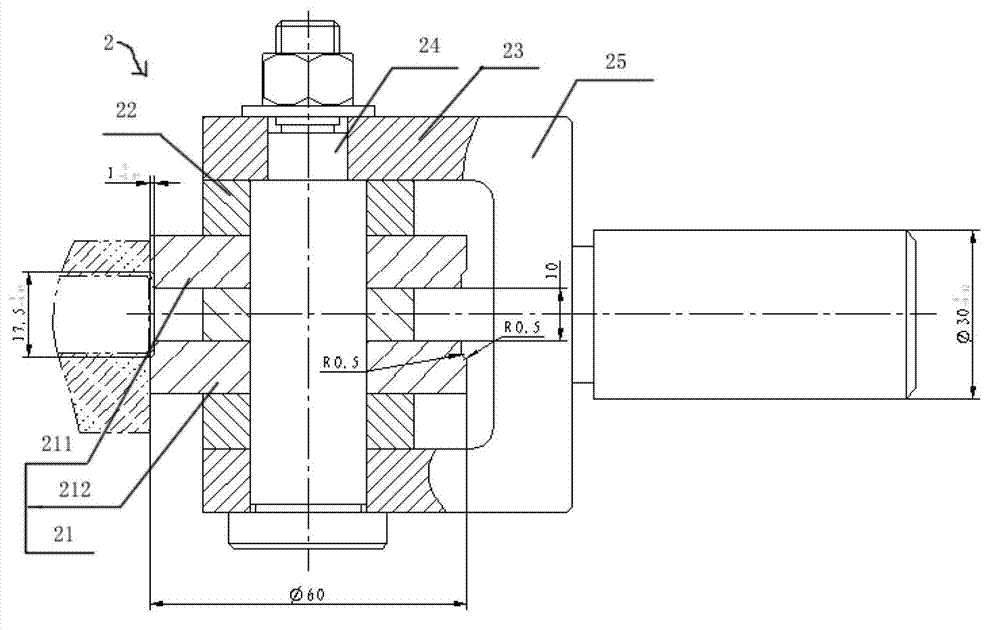

Metal spin forming head

InactiveUS7316142B2Rapid and accurate spin formingStart fastMetalworkingProgrammable logic controller

The present metal spin forming head includes two sets of rollers, with each set having a series of individual metal working rollers therein. The rollers of each set are circumferentially spaced evenly about the head, with each of the rollers of the second set being evenly positioned between corresponding rollers of the first set. The second roller set may be in a non-coplanar relationship with the first roller set. The first roller set comprises rollers having relatively broad widths, for forming the general contours of the workpiece. The second roller set comprises rollers having relatively narrow rims for forming circumferential grooves in the workpiece, resulting in corresponding beads within the workpiece for securing an article therein. The rollers are controlled independently of one another by a programmable logic control capable of driving the rollers cyclically as the workpiece (or spin forming head) rotates to form non-cylindrical shapes.

Owner:SCHALLER & CO

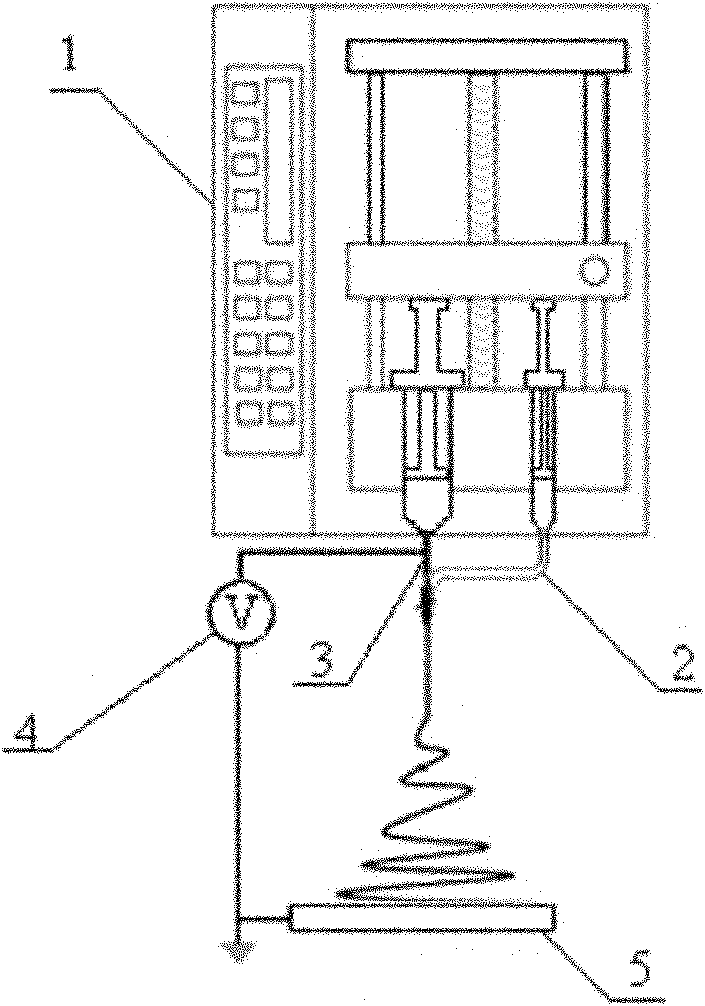

Solvent circulation electrostatic spinning device

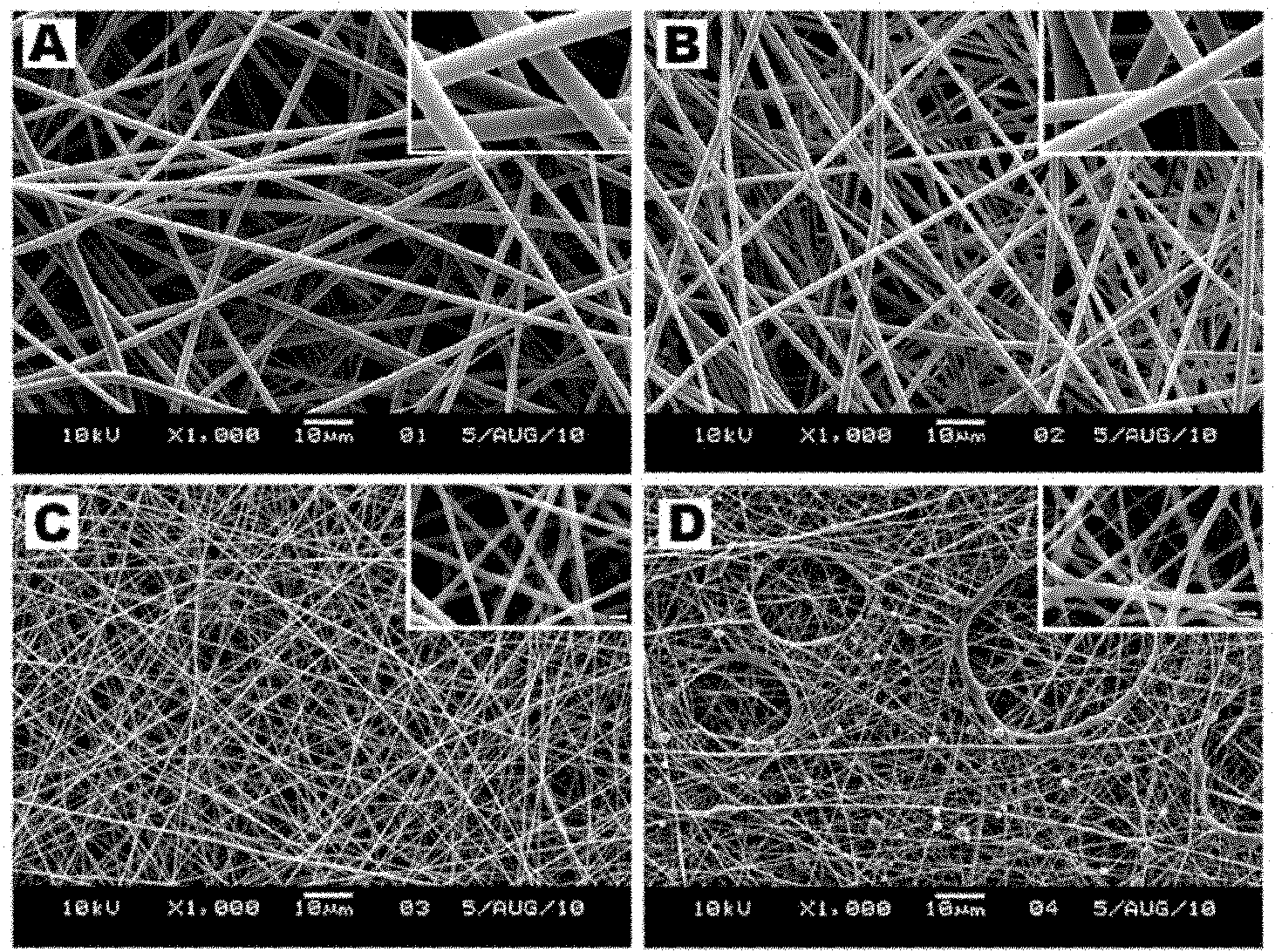

InactiveCN101979726APrevent precipitationAvoid stickingArtificial thread manufacturing machinesFilament/thread formingFiberElectrospinning

The invention relates to a solvent circulation electrostatic spinning device, which comprises a double-channel axial flow injection pump, a guide pipe, a metal spinning head, a high-pressure generator and a fiber collection plate. Polymer spinning solution is filled into one axial flow injector in the double-channel axial flow injection pump, and a circulation solvent is filled into the other axial flow injector in the double-channel axial flow injection pump, wherein the axial flow injector filled with the circulation solvent is connected with the guide pipe; the axial flow injector filled with the polymer spinning solution is connected with the metal spinning head; the metal spinning head passes through the side wall of the guide pipe; and a coaxial spinning head structure is formed by the metal spinning head and the guide pipe. The fiber collection plate is arranged below the coaxial spinning head structure. One end of the high-pressure generator is connected with the metal spinning head by a high-pressure joint, and the other end of the high-pressure generator is connected with the fiber collection plate and is earthed.

Owner:DONGHUA UNIV

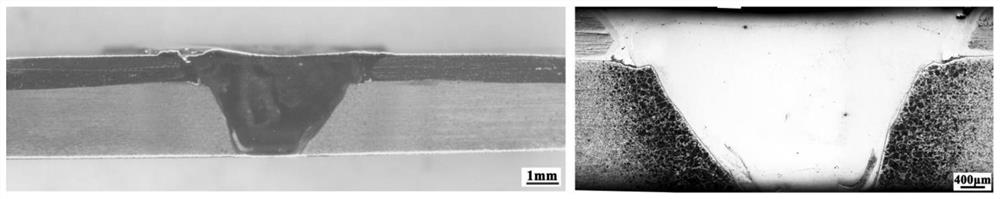

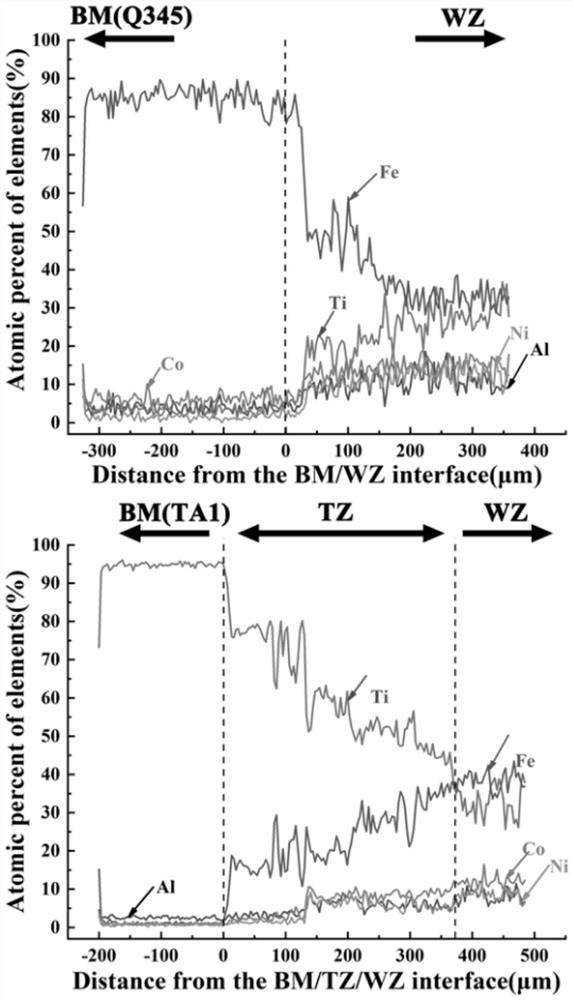

High-entropy alloy welding wire for welding titanium-steel and preparation method thereof

InactiveCN103567663AHigh strengthImprove toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesTO-18High entropy alloys

The invention discloses a high-entropy alloy welding wire for welding titanium-steel. The high-entropy alloy welding wire consists of the following components by atomic percent: 30 to 33 percent of Zr, 8 to 12 percent of Ti, 15 to 18 percent of Fe, 20 to 24 percent of Ni, 20 to 24 percent of Be, and the total percentage is 100 percent. The invention also discloses a preparation method of the high-entropy alloy welding wire for welding the titanium-steel. The preparation method comprises the following steps of step 1, melting master alloy; and step 2, preparing the amorphous high-entropy alloy welding wire by utilizing a metal spinning technology. By adopting the high-entropy alloy welding wire, the process for TIG welding titanium-steel is simiple, the welding wire is well matched with the titanium and steel, no crack exists in the welding area, the weld seam is basically single-phase solid-solution organization, and the comprehensive mechanical performance of a connector is high.

Owner:XIAN UNIV OF TECH

Metal spinning powder and preparation method thereof

ActiveCN104388155AEasy to cleanReduce friction damageLubricant compositionPotassium hydroxideHigh pressure

The invention discloses metal spinning powder and a preparation method thereof. The metal spinning powder is characterized by being prepared from the following raw materials in parts by weight: 100-300 parts of sodium carbonate or potassium carbonate, 1-5 parts of sodium benzoate, 300-600 parts of water, 10-60 parts of sulfonated castor oil, 5-30 parts of chlorcosane, 5-30 parts of tall oil, 2-15 parts of powdery sodium hydroxide or potassium hydroxide, and 5-30 parts of white carbon black. The invention also discloses the preparation method of the metal spinning powder. The metal spinning powder disclosed by the invention has the advantages of favourable lubricating property, corrosion resistance, high temperature resistance, high pressure resistance, lower cost and easy storage.

Owner:HENAN NORMAL UNIV

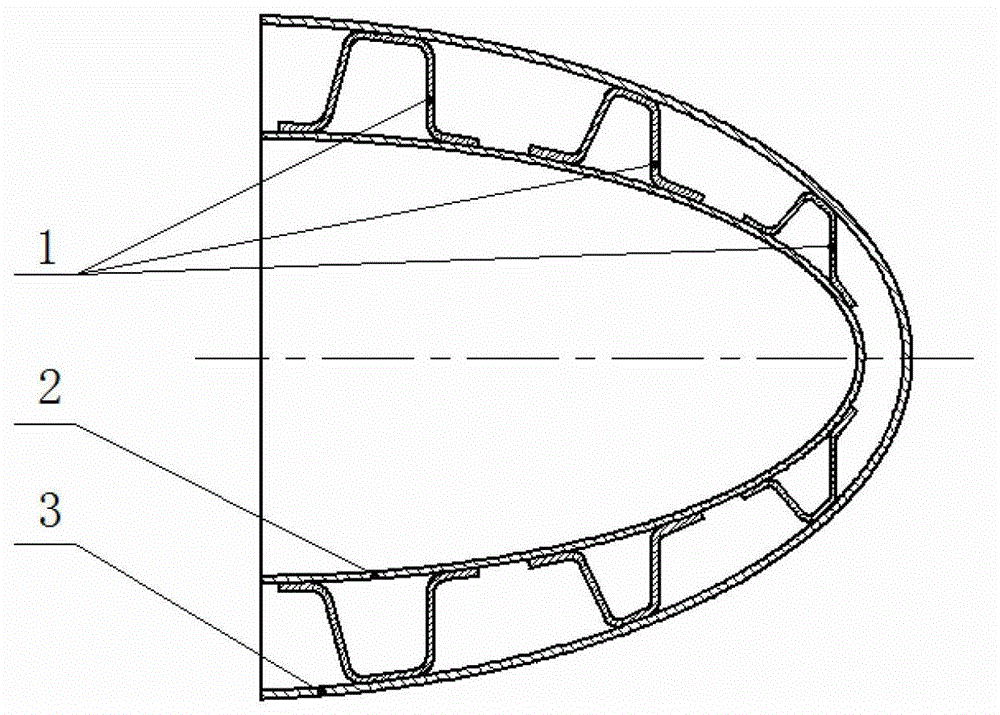

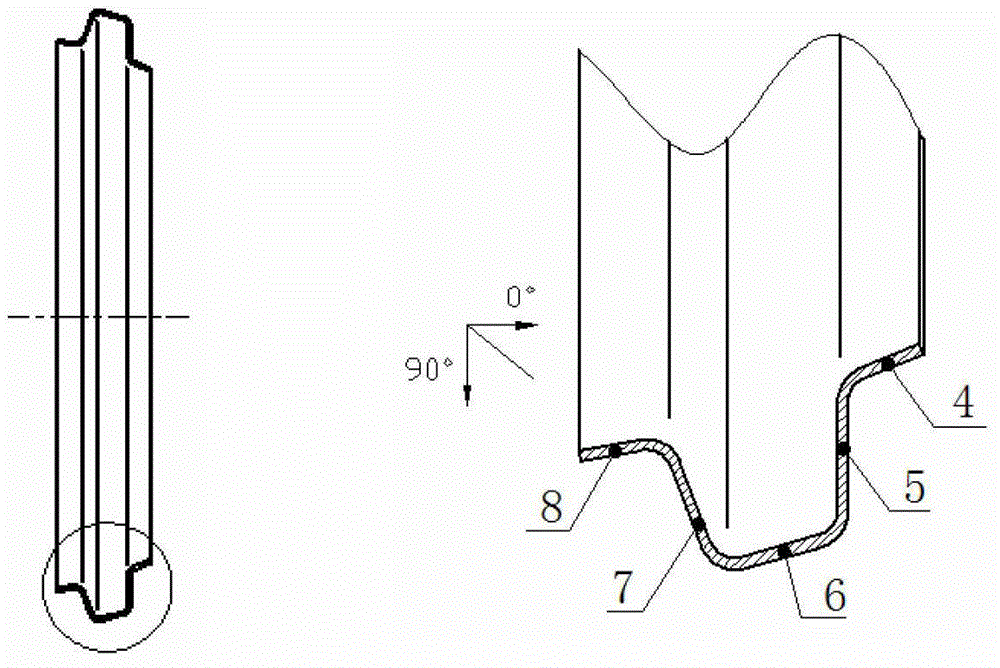

Method for pressing conical cover reinforcing ribs

The invention relates to a method for pressing conical cover reinforcing ribs. A sectioning mold same with the molded surface of a product is adopted, a common spherical turning lathe or a numerical control spinning machine is used, and a hot metal spinning mode is adopted. The characteristic that an aluminum alloy material has a good plasticity under a certain temperature while the strength and the toughness are obviously reduced is utilized, and a panel veneer used as a blank. Under the combined action of the radial force and the axial force of a spinning roller, through multi-pass spinning, the panel veneer is forced to deform, materials flow and form workpieces similar with the molded surface of the mold, and the spinning formation of an aluminum alloy annular-structure product with a section like the shape of Chinese character 'ji'. The characteristic that the sectioning mold is detachable is utilized to realize the separation of the 'ji'-shaped section annular-structure piece and the mold, and the completeness of the annular-structure piece is ensured. According to the method, the aluminum alloy annular-structure piece with the special-shaped section which is difficultly formed with processes such as general stamping, machining and the like can be formed. The method has the characteristics of low cost, low labor strength of workers, high processing efficiency and high material use ratio.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

High-entropy alloy welding wire for welding titanium-steel and preparation method thereof

InactiveCN103567663BHigh strengthImprove toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesTO-18High entropy alloys

The invention discloses a high-entropy alloy welding wire for welding titanium-steel. The high-entropy alloy welding wire consists of the following components by atomic percent: 30 to 33 percent of Zr, 8 to 12 percent of Ti, 15 to 18 percent of Fe, 20 to 24 percent of Ni, 20 to 24 percent of Be, and the total percentage is 100 percent. The invention also discloses a preparation method of the high-entropy alloy welding wire for welding the titanium-steel. The preparation method comprises the following steps of step 1, melting master alloy; and step 2, preparing the amorphous high-entropy alloy welding wire by utilizing a metal spinning technology. By adopting the high-entropy alloy welding wire, the process for TIG welding titanium-steel is simiple, the welding wire is well matched with the titanium and steel, no crack exists in the welding area, the weld seam is basically single-phase solid-solution organization, and the comprehensive mechanical performance of a connector is high.

Owner:XIAN UNIV OF TECH

Vibration-type measuring sensor

InactiveUS20070074585A1Low costReduce manufacturing costVolume meteringDirect mass flowmetersEngineeringMechanical engineering

This sensor, for a fluid and suitable for use in a pipeline at least temporarily containing the fluid flowing therethrough, has at least one curved measuring tube, which vibrates during operation and guides the fluid, and a housing enclosing the measuring tube. The housing is composed of a metal cap of two cap halves and a supporting tube, in which the measuring tube is held at its inlet and outlet ends in a manner such that the tube can oscillate, and out of which a measuring tube segment protrudes sideways. Each cap half has an edge with, in each case, four edge portions. The edge portions are straight, the edge portions are curved, and the edge portions have the shape of circular arcs. The edge portions are welded continuously to the supporting tube and the edge portions are welded continuously to one another. The cap halves are cut out of a dish-shaped intermediate having a formed, surrounding edge bead, provided with the shape of a quarter-torus by metal spinning.

Owner:ENDRESS HAUSER FLOWTEC AG

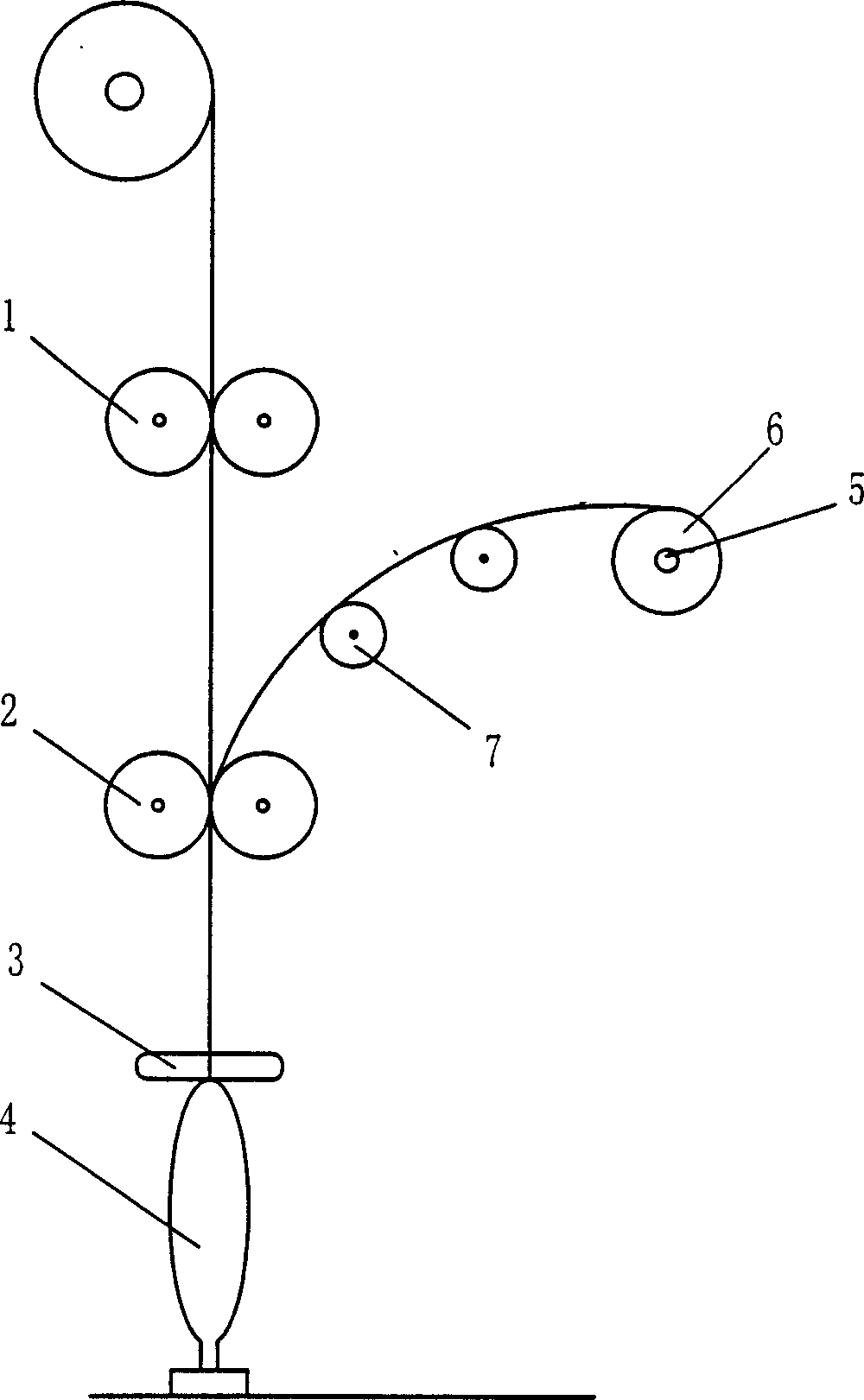

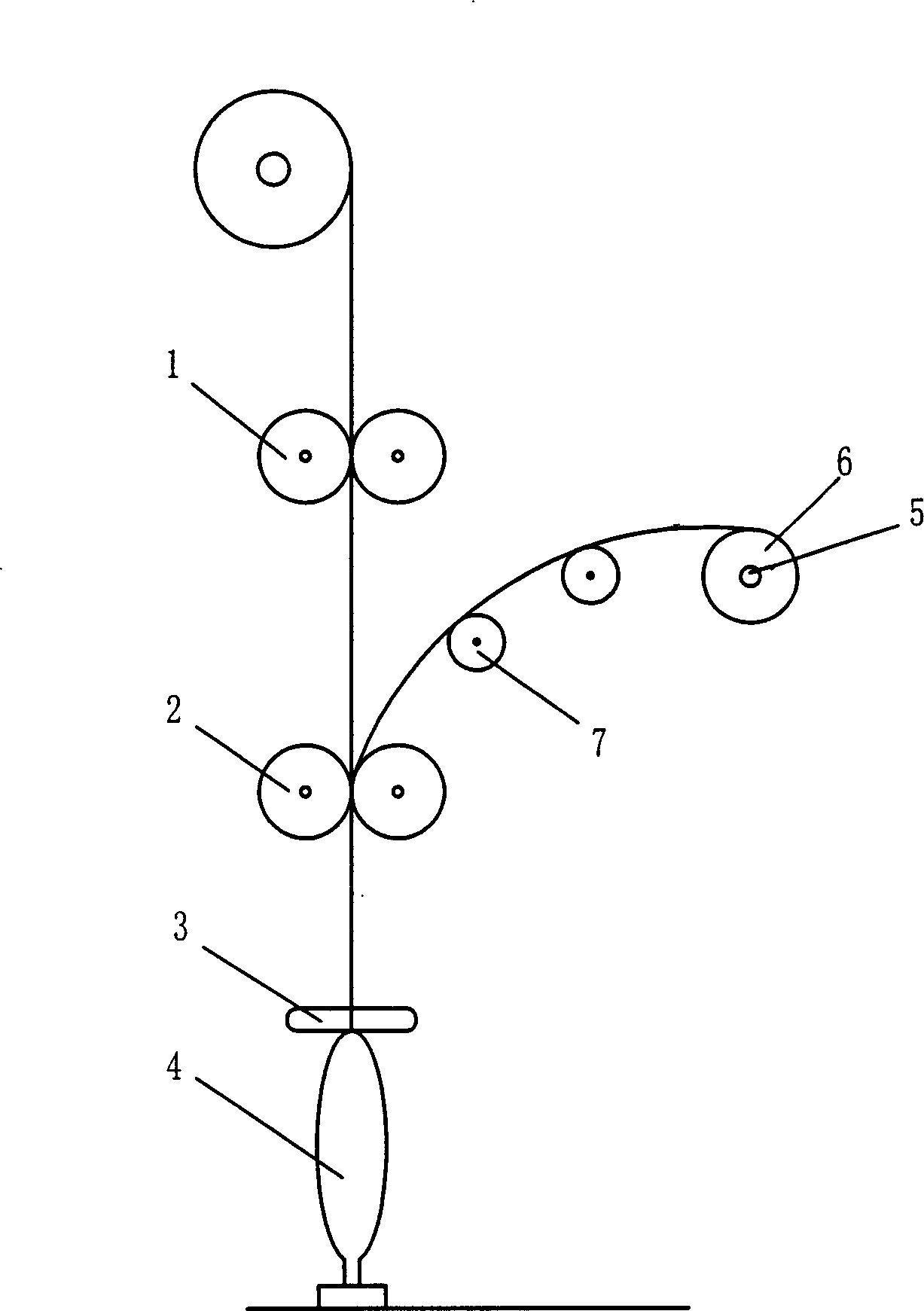

Magnetic therapeutic healthy composite woolen yarn and mfg. equipment thereof

This invention relates to a complex magnet therapeutic health care knitting wool and its production device. It includes the core yarn and the woolen yarn around the core yarn. The core yarn is the magnetic health care fibre, the weight of which is 20-25% taking the weight of magnet therapeutic health care knitting wool as reference standard, the other is woolen yarn. The device includes the drawing part of the wool and the twisting part of the yarn, there is feeding part of the wire between them, and this part has the dead axle on which the metal spinning pipe is fixed besides the drawing part. The sweater and trousers made of this complex knitting wool are felt soft, light and comfortable. The action of the magnetic field is homogeneous and it can massage to stimulate the whole skin which is covered by this material, so the skin can move lightly, stimulate the metabolism activity of the cells, and promote the microcirculation of the body. Its effect is same with the acupuncture, and it also has health care and physiotherapy ability at any time. It specially is suitable to women, wrinkly and older, and it has no minus effect. Its structure is simple and easy to operate.

Owner:王启发

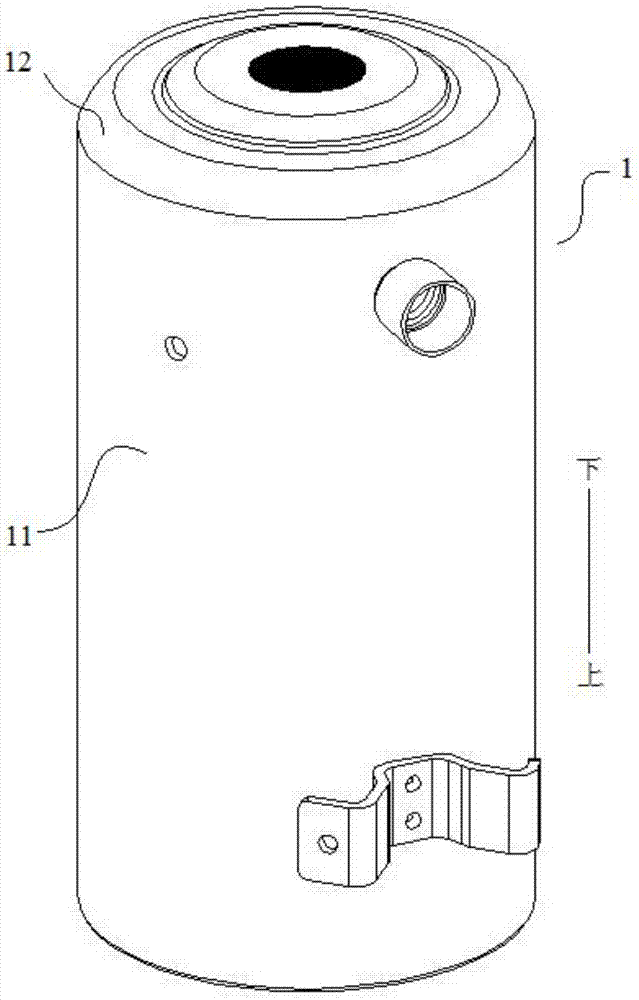

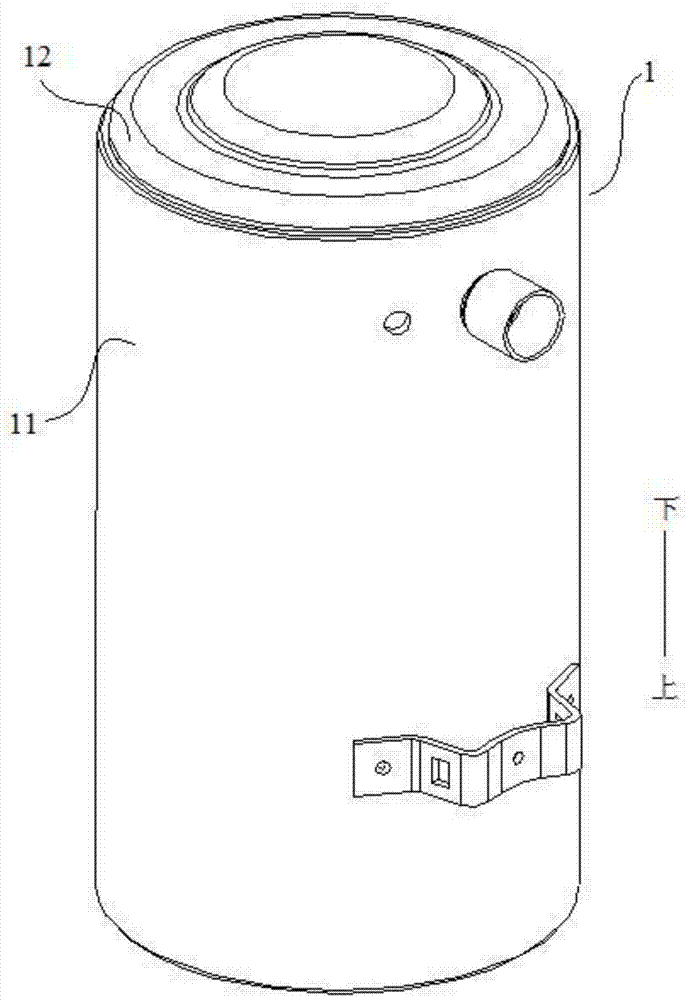

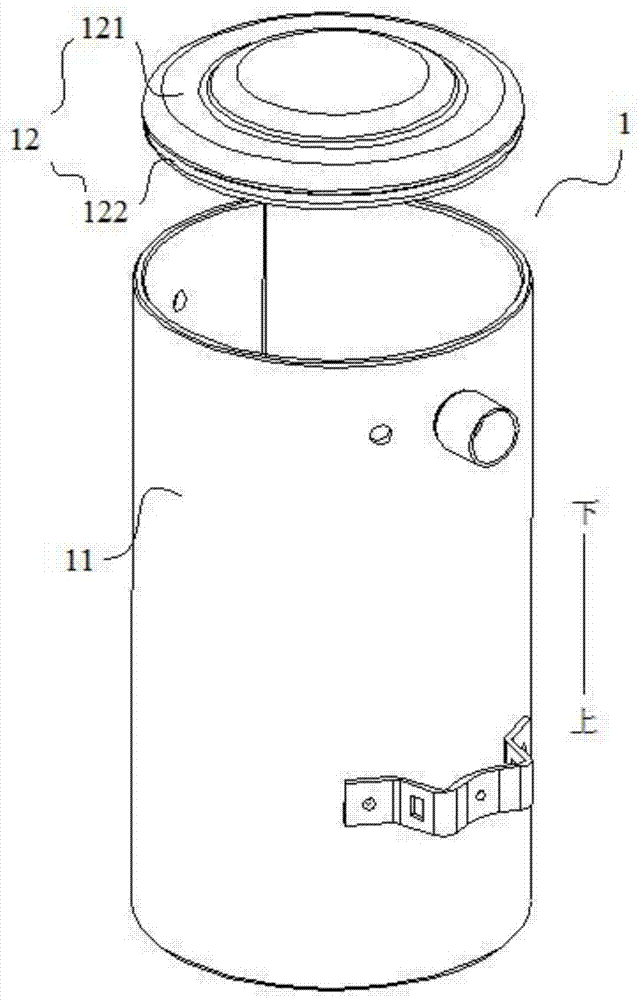

Method for manufacturing compressor

InactiveCN104265600AImprove assembly efficiencySimplify the assembly processPositive displacement pump componentsPiston pumpsElectric resistance weldingMachining

The invention discloses a method for manufacturing a compressor. The method includes the following steps that S1, a main shell body and a lower shell body are formed in a spinning mode or are connected into a whole in an electric resistance welding mode, so that a main shell body assembly is obtained; S2, a compressing mechanism is connected with a rotor so as to obtain a pump body assembly; S3, a stator and the pump body assembly obtained in the step S2 are located; S4, the stator and the pump body assembly located in the step S3 are fixed in the main shell body assembly obtained in the step S1; S5, an upper shell body is connected to the top of the main shell body. According to the method for manufacturing the compressor, the combined piece of the main shell body and the lower shell body are obtained through the metal spinning technology or the electric resistance welding machining technology, so that the technological manufacturability of the shell bodies is improved, the appearance of the shell bodies is good, and the leakage rate is low; meanwhile, the production cost of the shell bodies is lowered, the manufacturing difficulty is lowered, and the manufacturing efficiency is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

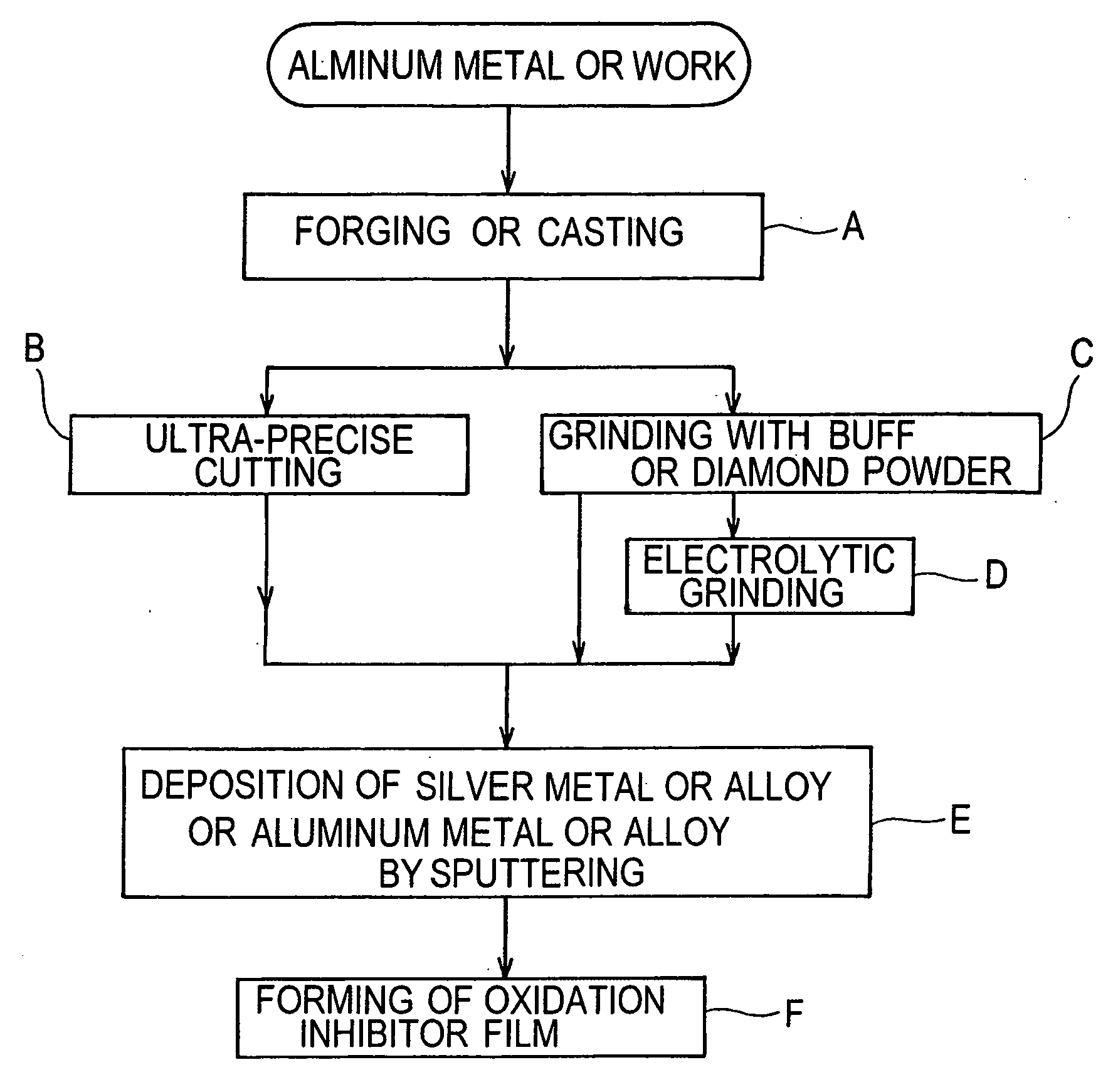

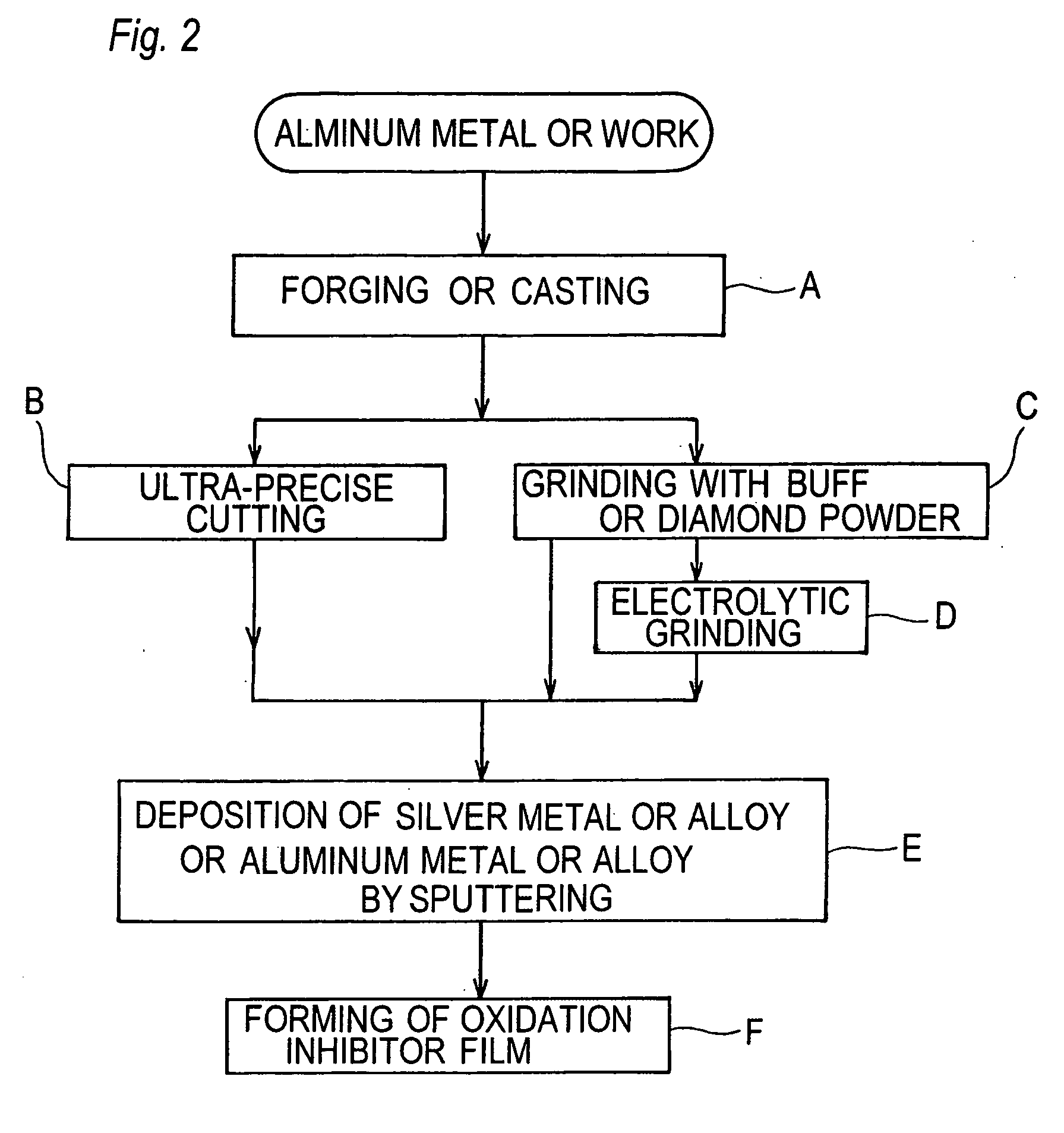

Reflector for light source of projector

InactiveUS20060197423A1Increase power consumptionGood heat conductivity of the aluminum metal or the like is not hamperedIncadescent screens/filtersMirrorsAlloyAluminum metal

A reflector for light source of a projector, comprises a cup-shaped part that is formed by forging or casting from aluminum metal or alloy or the like metal, inner face of the cup-shaped part being mirror finished by ultra-precise cutting technique or by grinding with buff or diamond powder as not to have grooves or distortion; and a barrel portion disposed at center of the cup-shaped part and configured to receive an electric-discharge lamp. Omitted thereby is a coating of silicone-based resin that is a must for a reflector formed by metal spinning technique as to cover up the grooves and distortion. Thus, good heat conductivity of the aluminum metal or the like is not hampered, as to achieve a reflector for high-luminance lamp with high power consumption.

Owner:MUTSUKI ELECTRIC

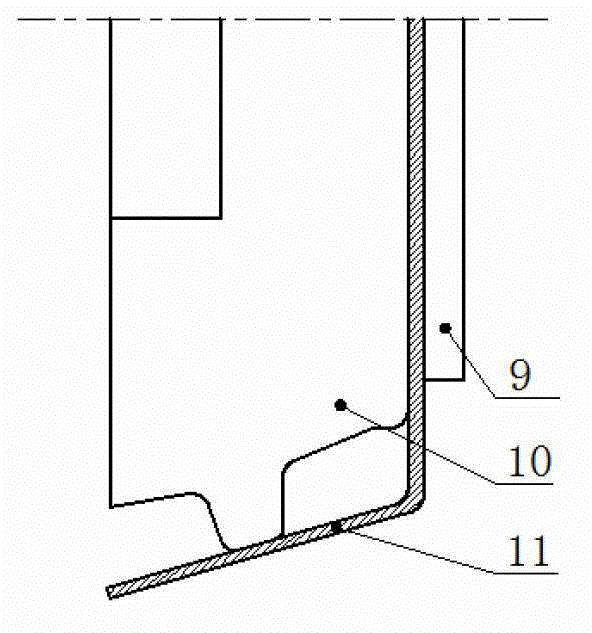

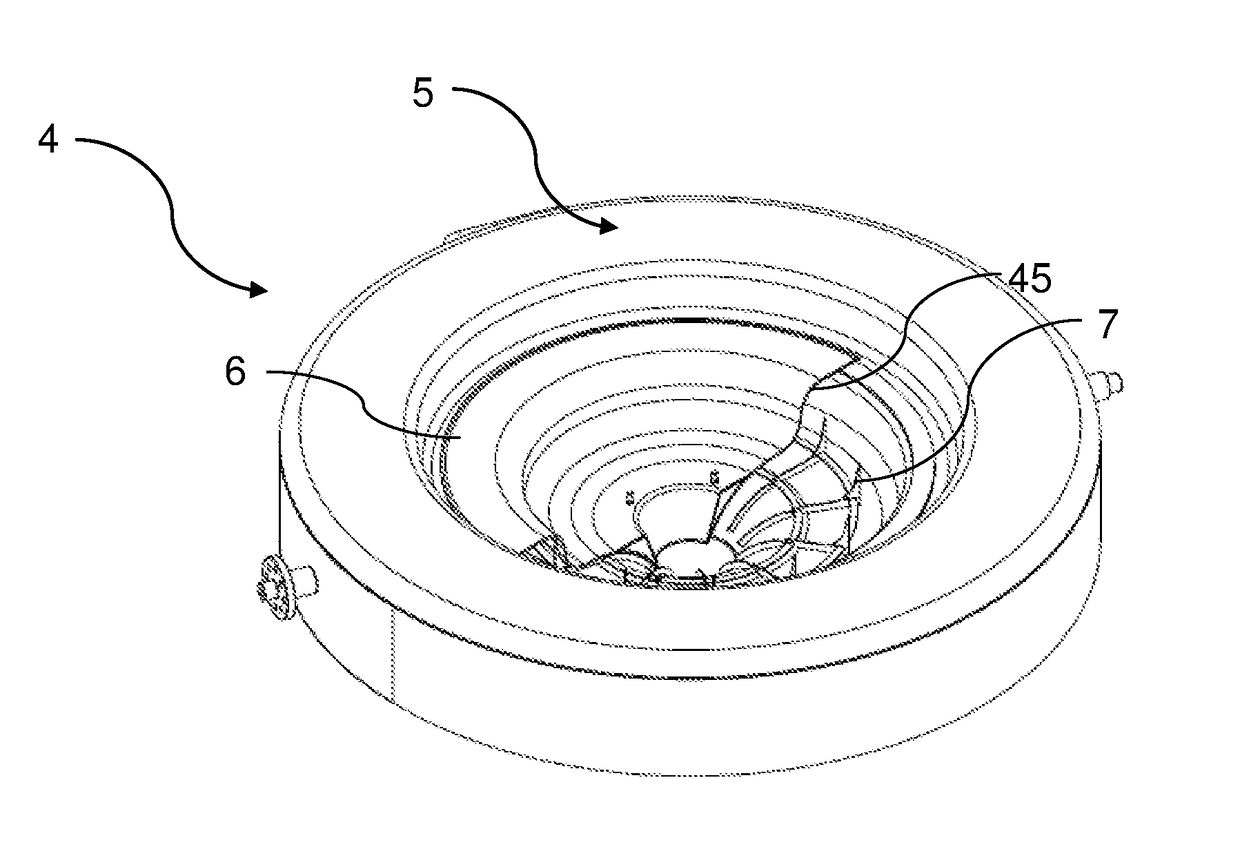

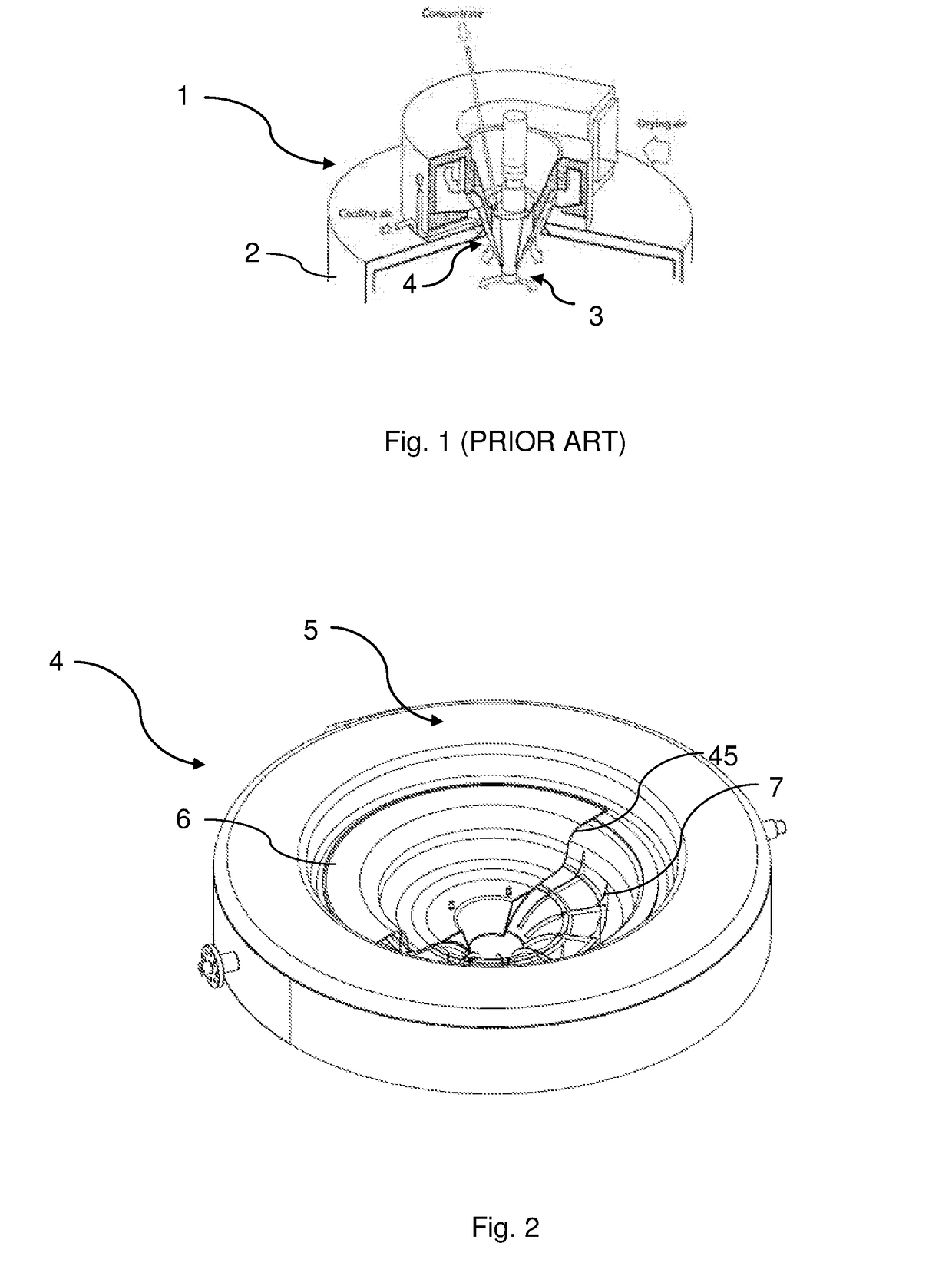

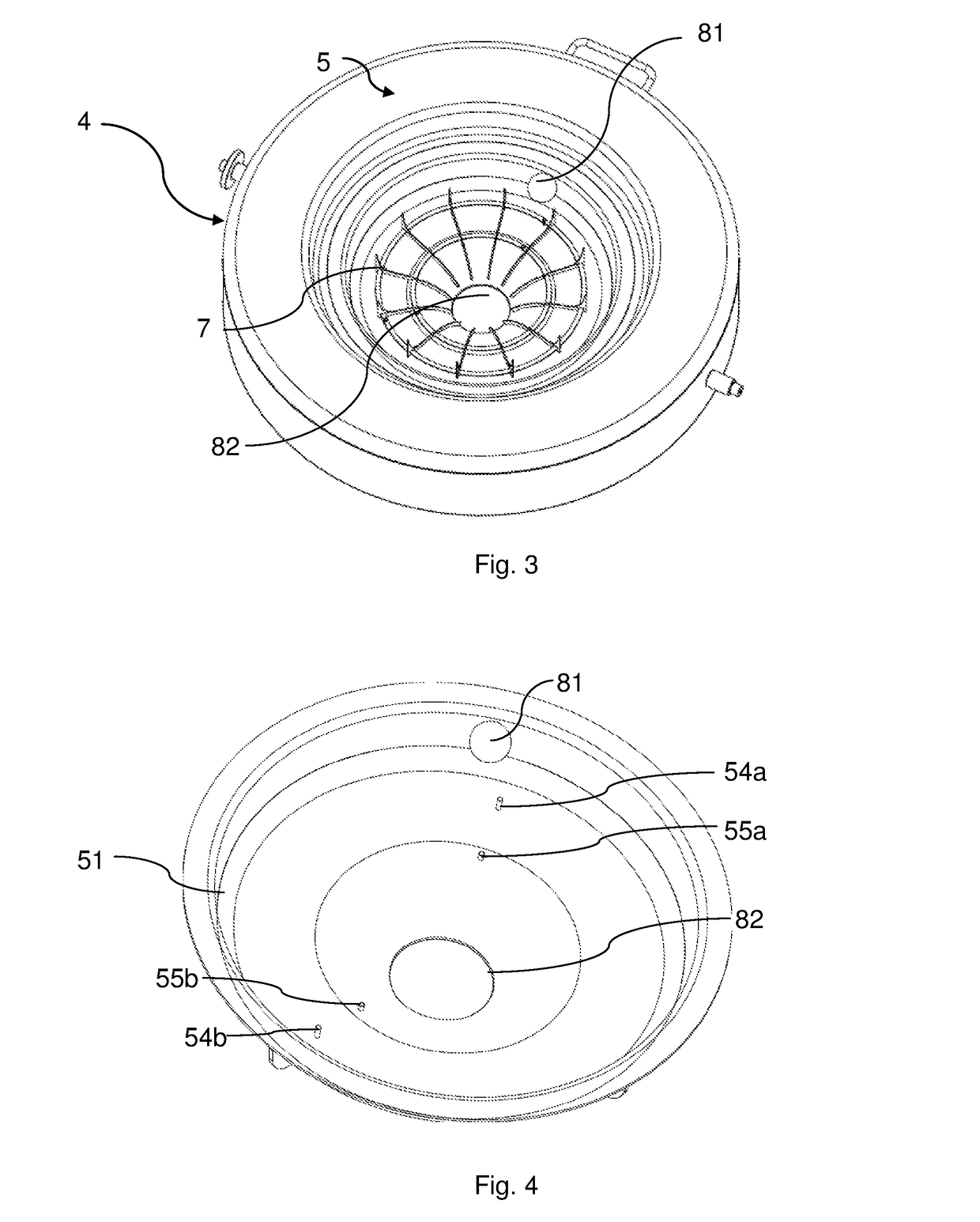

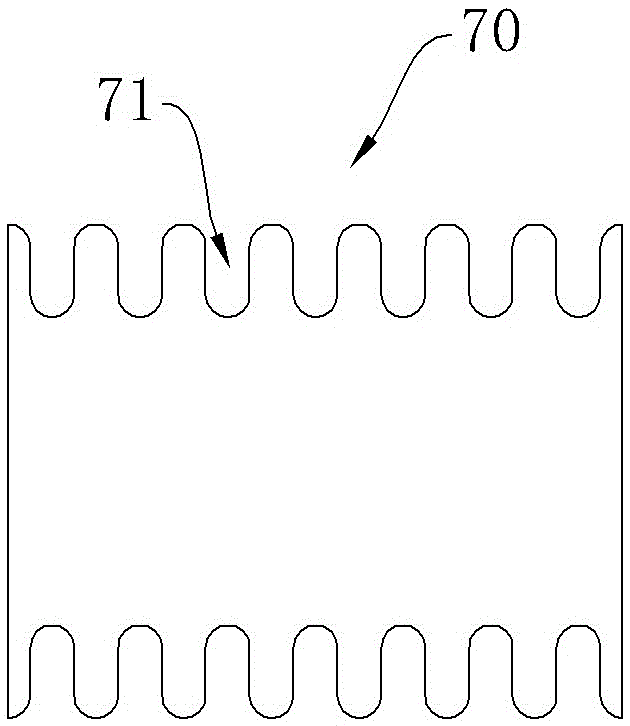

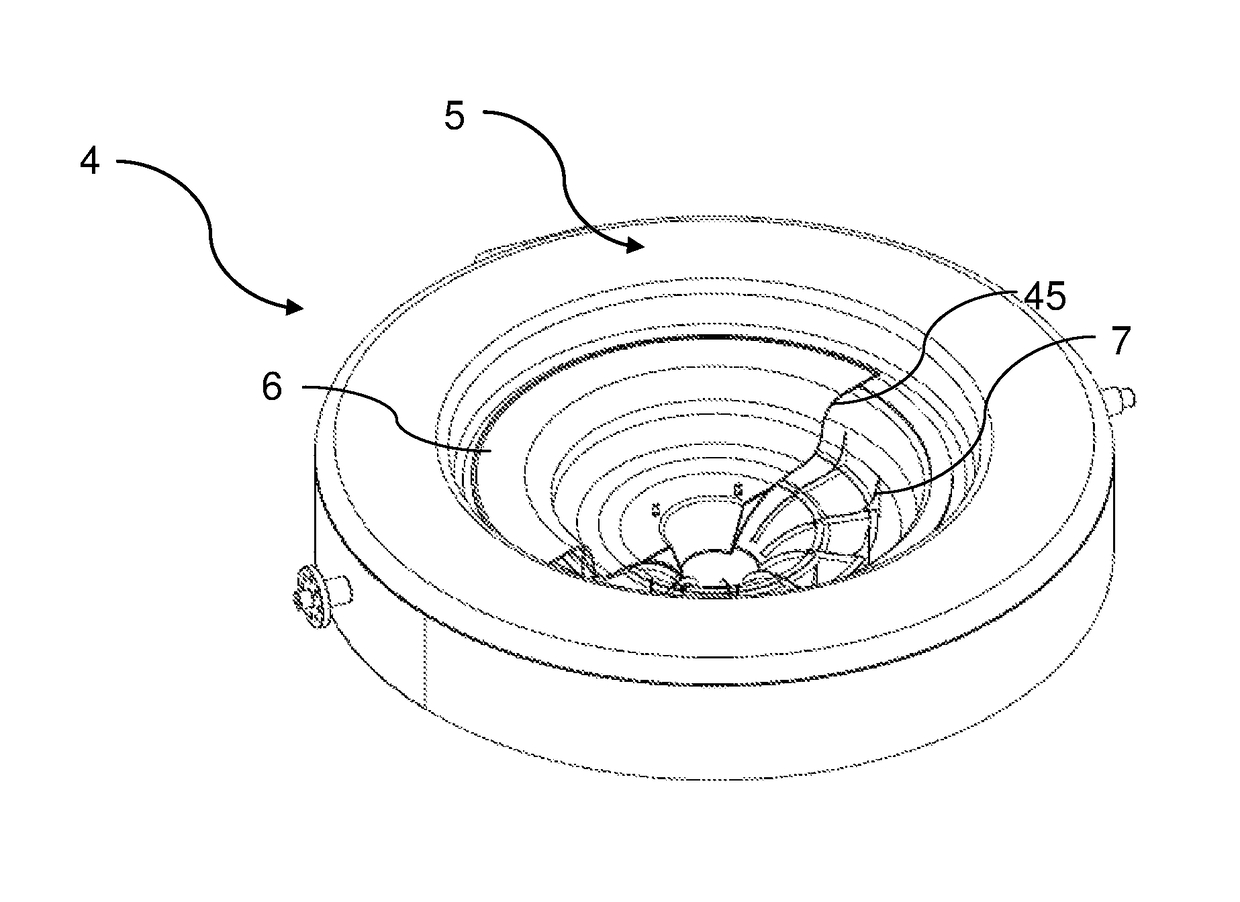

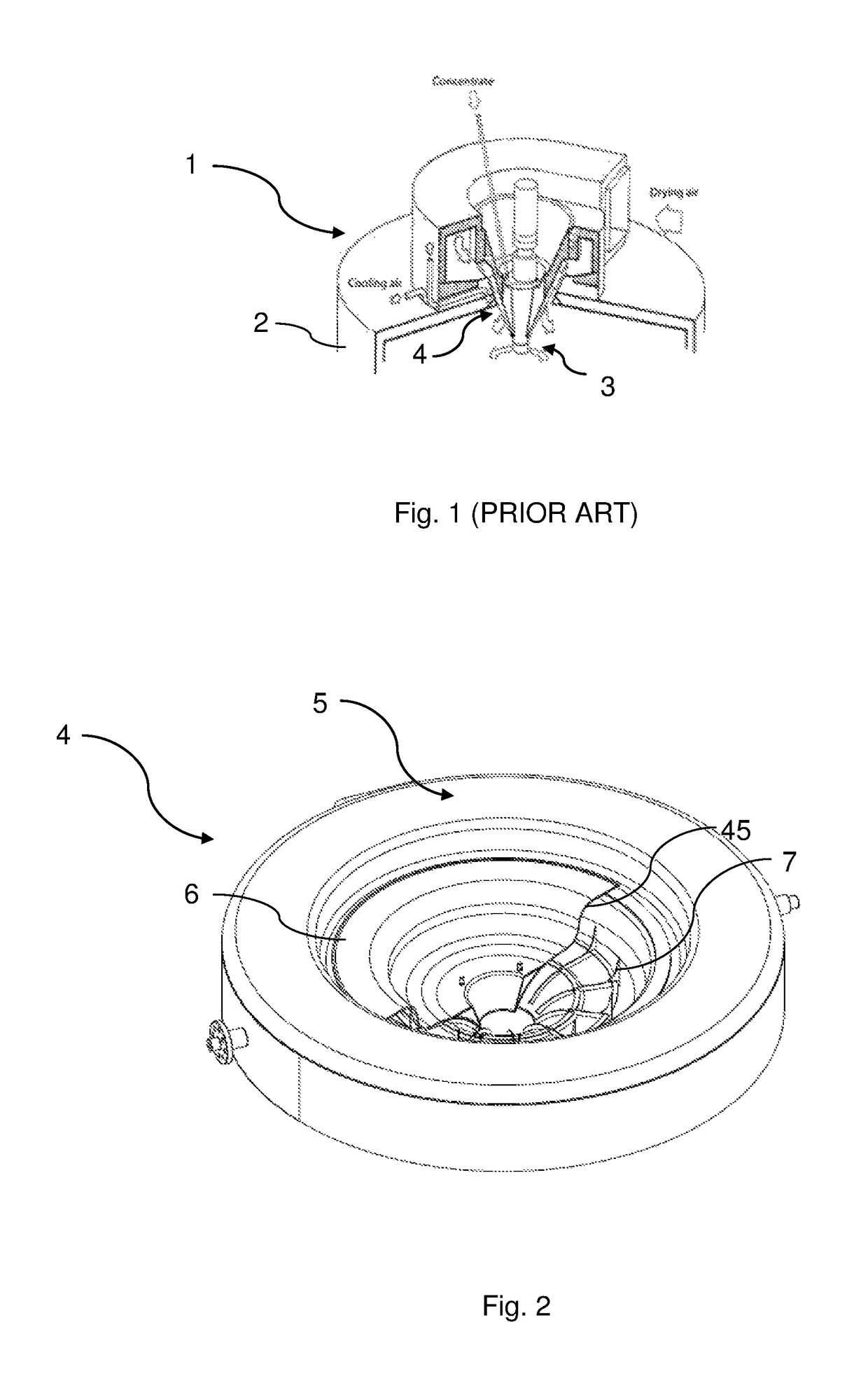

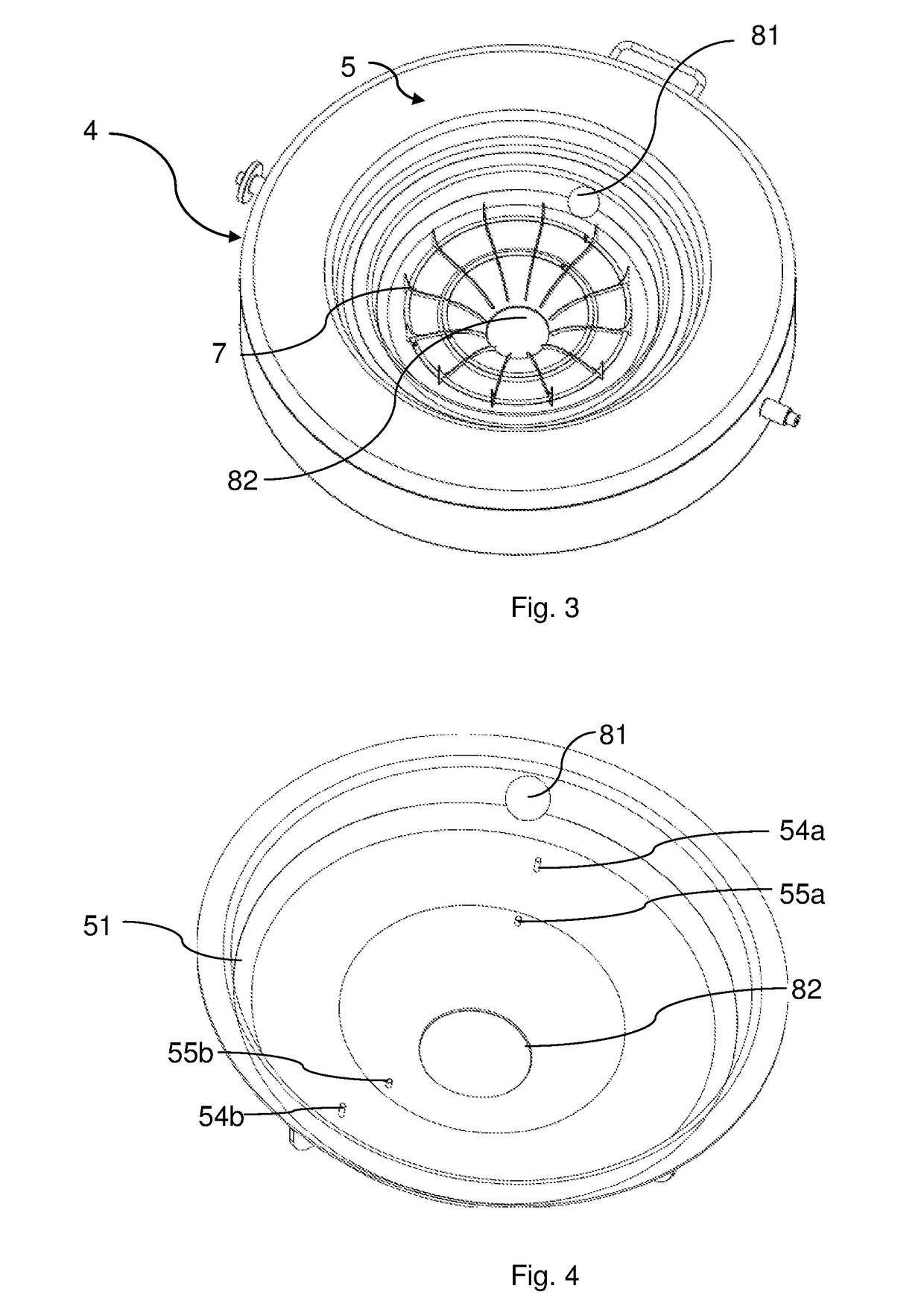

An air disperser for spray-drying, and a method for manufacturing an air disperser comprising metal forming

ActiveUS20170097190A1Good conditionImprove operationDrying solid materials with heatDrying gas arrangementsMetal formingEngineering

In the air disperser (4) having a number of components including a top, a boom and an outer circumferential wall forming a space (45) defined within an inner radius and an outer radius and having an air inlet (81), a set of guide vanes (7), and an air outlet (82) at said inner radius adapted to be positioned above a feed outlet from atomizing means, at least some of said components are formed by precision metal forming such as metal spinning.

Owner:GEA PROCESS ENG

Radiation proof composite woolen yarn and its production equipment

InactiveCN1861859AGood anti-static effectSoft touchMagnetic/electric field screeningYarnYarnEngineering

This invention relates to a complex radiation protection caddice and its preparation method. It includes the core line and the woolen yarn around the core line. The core line is the radiation protection spinning wire, the diameter of which is 59-64um, the weight of which is 12-20% taking the weight of complex caddice as standard, the other is woolen yarn. The equipment includes the drawing part of the wool and the twisting part of the line, there is receiver part of the wire between them. This receiver part has dead axle to fix the metal spinning pipe beside the drawing part. This caddice overcomes the shortcoming of the radiation protection materials on clothing, and it can be applied to various personality showing or beautiful clothes without changing any using habit and braided method. It also has good electrostatic prevention and could be washed as wool, and the efficiency of the radiation protection is not affected. It is felt soft and has good warm holding ability. The structure of the production device is simple, and it can be operated conveniently.

Owner:王启发

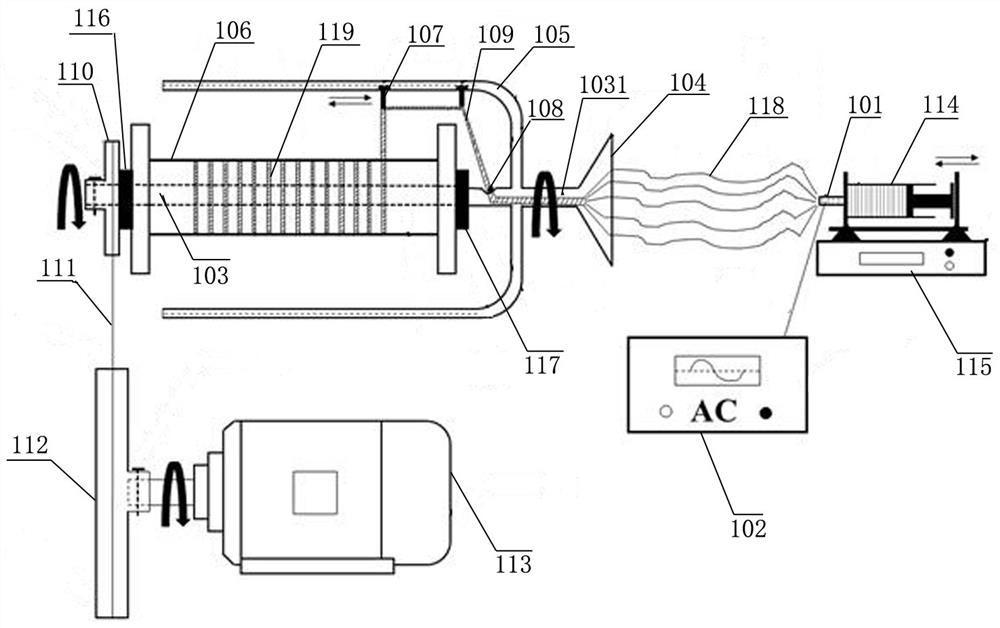

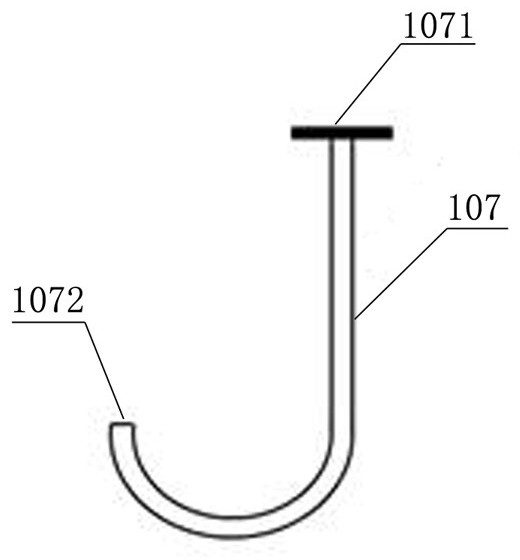

Electrostatic spinning device and device for efficiently preparing nanofiber yarns

ActiveCN111621886AConducive to agglomerationIncrease productivityElectro-spinningContinuous wound-up machinesYarnFiber

The invention provides an electrostatic spinning device for efficiently preparing nanofiber yarns. The device comprises a liquid supply system, a spinning system, a collecting system, and a driving system, wherein the liquid supply system is used for providing a spinning solution for the spinning system; the spinning system is used for drafting the spinning solution flowing out of a metal spinningneedle head into nano fibers under the action of electric field force and spraying the generated nano fiber bundles to a collecting system; the collecting system is used for twisting and forming thereceived nanofiber bundles and then collecting the nanofiber bundles; the driving system is used for driving the collecting system to work; the spinning system comprises the metal spinning needle headused for spraying nanofiber bundles, and the metal spinning needle head is connected with an alternating-current high-voltage generator to form a high-voltage electric field. The electrostatic spinning device disclosed by the invention has the advantages of high production efficiency and easily controlled production technique, and is suitable for the field of electrostatic spinning.

Owner:贺海军

Preparation method of multi-principal-element welding wire and high-entropy welding method

ActiveCN113210926AEasy to produceLow costArc welding apparatusWelding/cutting media/materialsHigh entropy alloysManufactured material

The invention provides a preparation method of a multi-principal-element welding wire and a high-entropy welding method. The preparation method of the multi-principal-element welding wire comprises the following steps that at least three kinds of metal wires are provided; and according to the preset quantity ratio, different metal wires are wound, and the rod-shaped multi-principal-element welding wire is prepared. According to the preparation method of the multi-principal-element welding wire, the multiple kinds of metal wires are wound according to the preset quantity ratio, the rod-shaped multi-principal-element welding wire is prepared, the situation that raw materials are molten to prepare high-entropy alloy, and then a wire material is prepared through metal spinning and spray deposition is avoided, the welding wire is prepared through winding of the pure metal wires, the alloying step can be omitted, needed components can be flexibly adjusted, the production process of the welding wire for high-entropy welding is greatly simplified, and cost is reduced.

Owner:EAST CHINA JIAOTONG UNIVERSITY

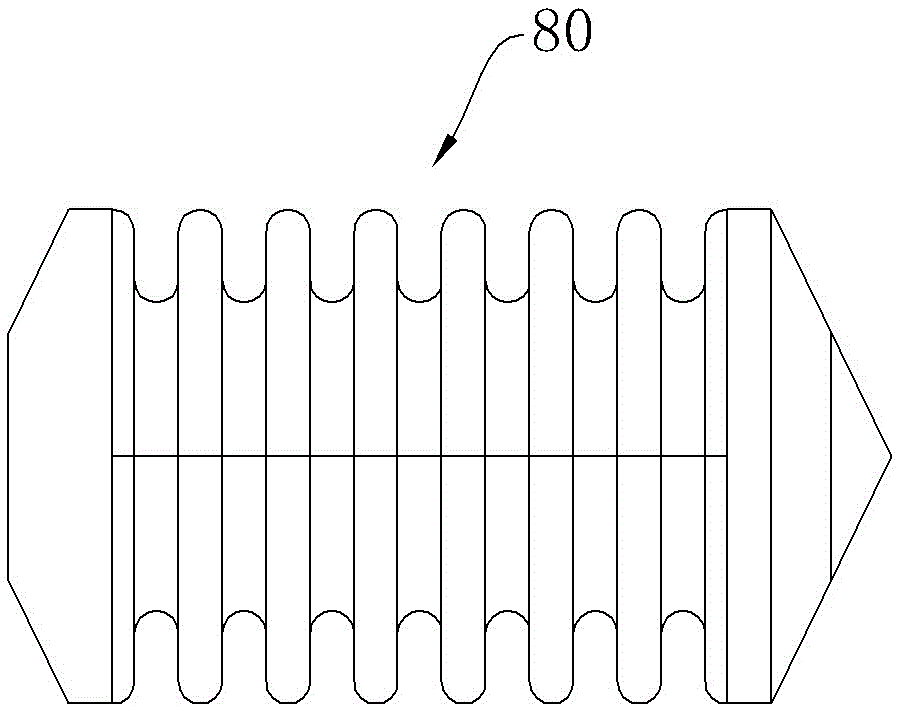

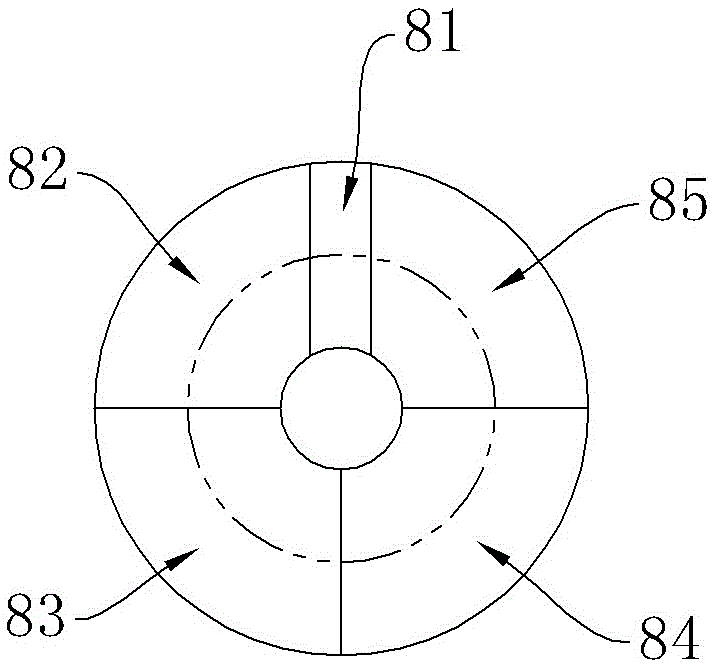

Metal spinning method for dynamic balance wheel

InactiveCN106734475ASolve the dynamic balance problemReduce use costMetal-working apparatusDynamic balanceEngineering

The invention discloses a metal spinning method for a dynamic balance wheel. The metal spinning method mainly comprises the following steps of machining a U-shaped structure, filling the U-shaped structure with a dynamic balance weight, rough metal spinning, fine metal spinning and removing an outer lug on the outer edge of the wheel and an inner lug at the position of a positioning center hole of the wheel which is obtained after the fourth step of fine metal spinning is carried out. According to the machining method, the dynamic balance problem of the finished product wheel is solved in the machining process, regulation of dynamic balance is not needed in the later using process, and the use cost of the product is saved. The finished product wheel is integrally formed in a metal spinning manner, welding is not needed, the structural strength is high, and reliability is higher.

Owner:吉林省宏展实业有限责任公司

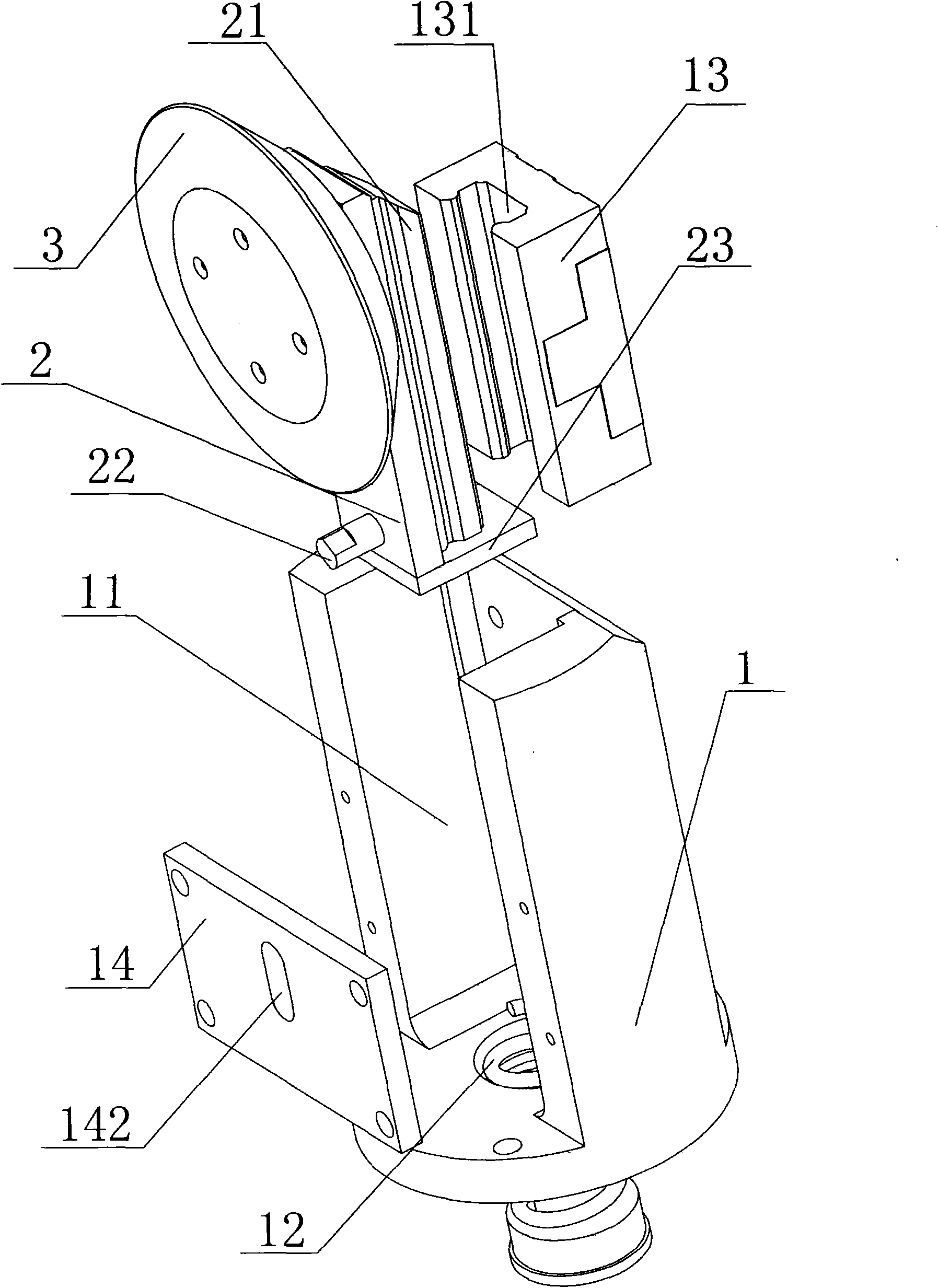

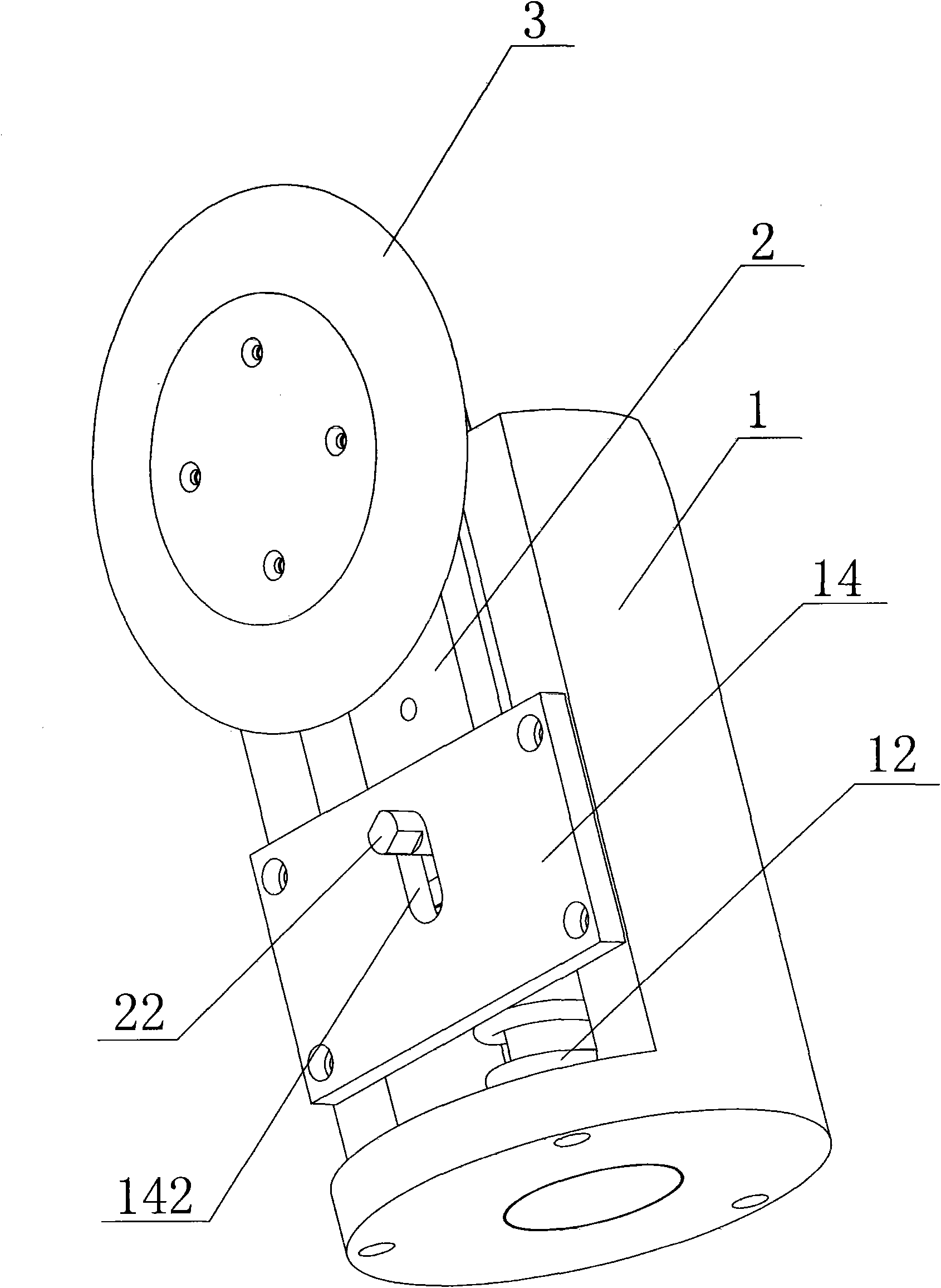

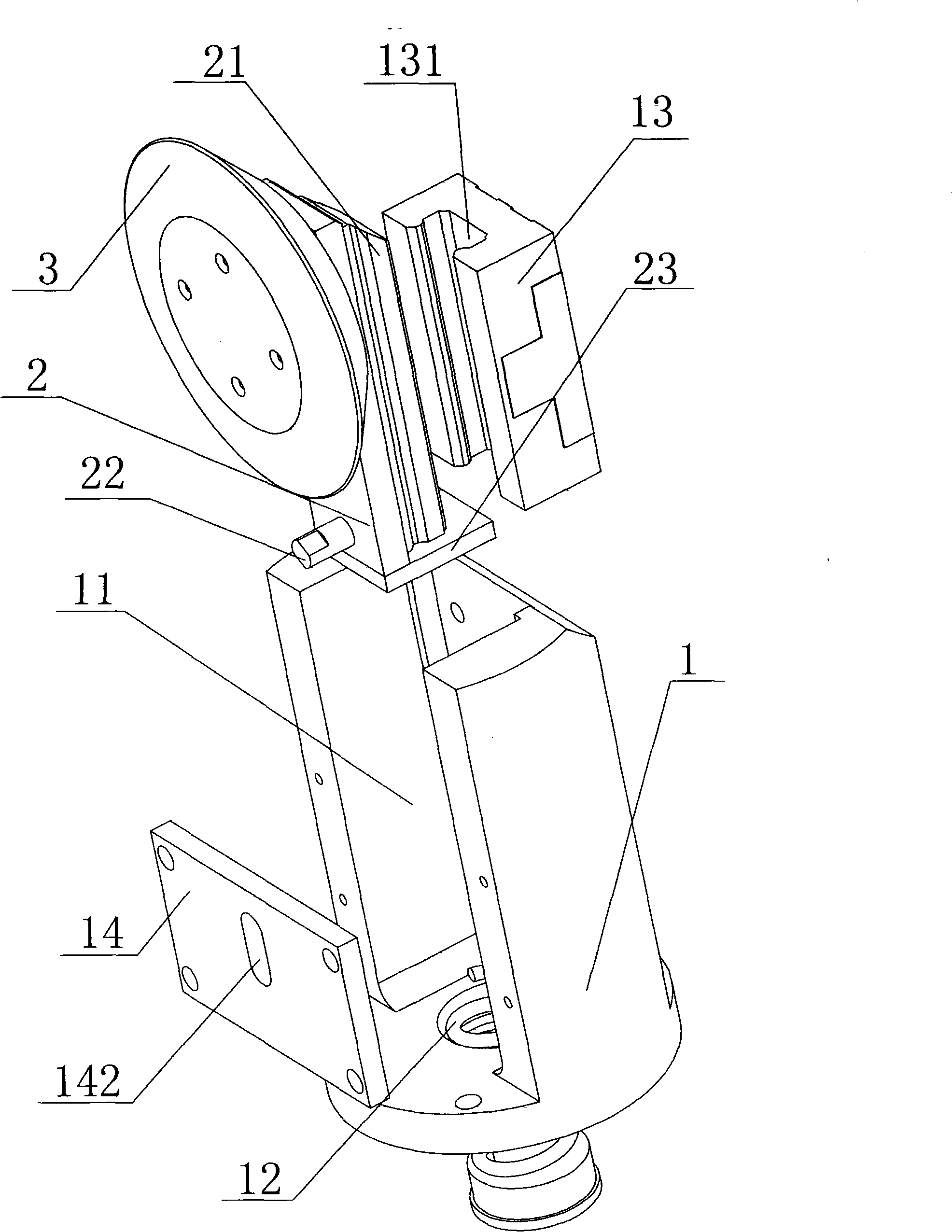

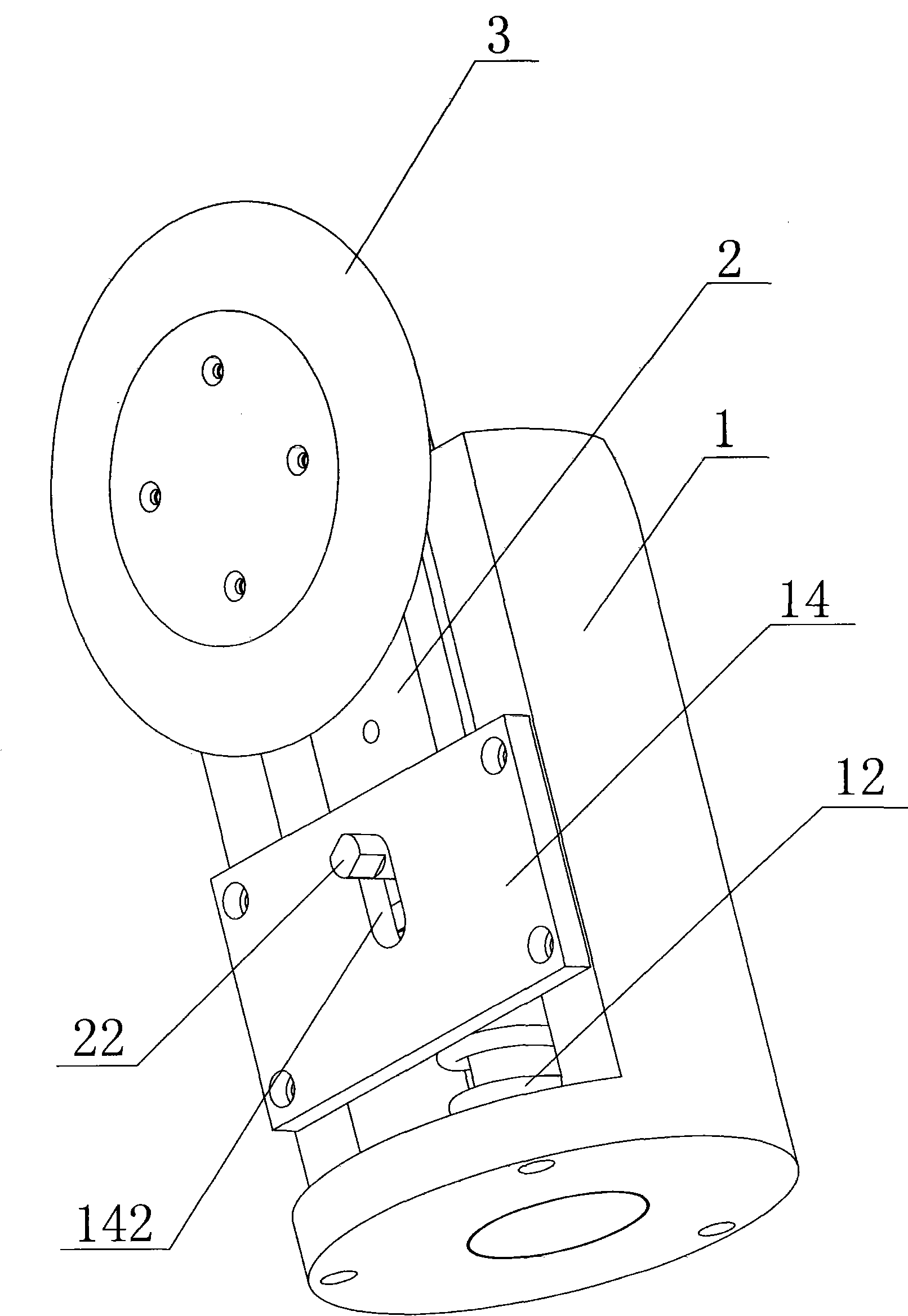

Self-adapting spinning mechanism of sheet metal spinning machine

ActiveCN101642786ARealize adaptive adjustment functionAvoid damageShaping toolsSlide plateEngineering

The invention discloses a self-adapting spinning mechanism of a sheet metal spinning machine. The design key point is that the self-adapting spinning mechanism of the sheet metal spinning machine comprises a base and a sliding plate which is arranged on the base and can slide back and forth, wherein the base is provided with a pretension spring for pushing the sliding plate outwards, and the sliding plate is provided with a roller wheel assembly for applying pressure. The invention aims to provide the spinning mechanism of the sheet metal spinning machine which has a simple structure and can be adjusted adaptively.

Owner:CHENZHOU ZHIZAO TECH CO LTD

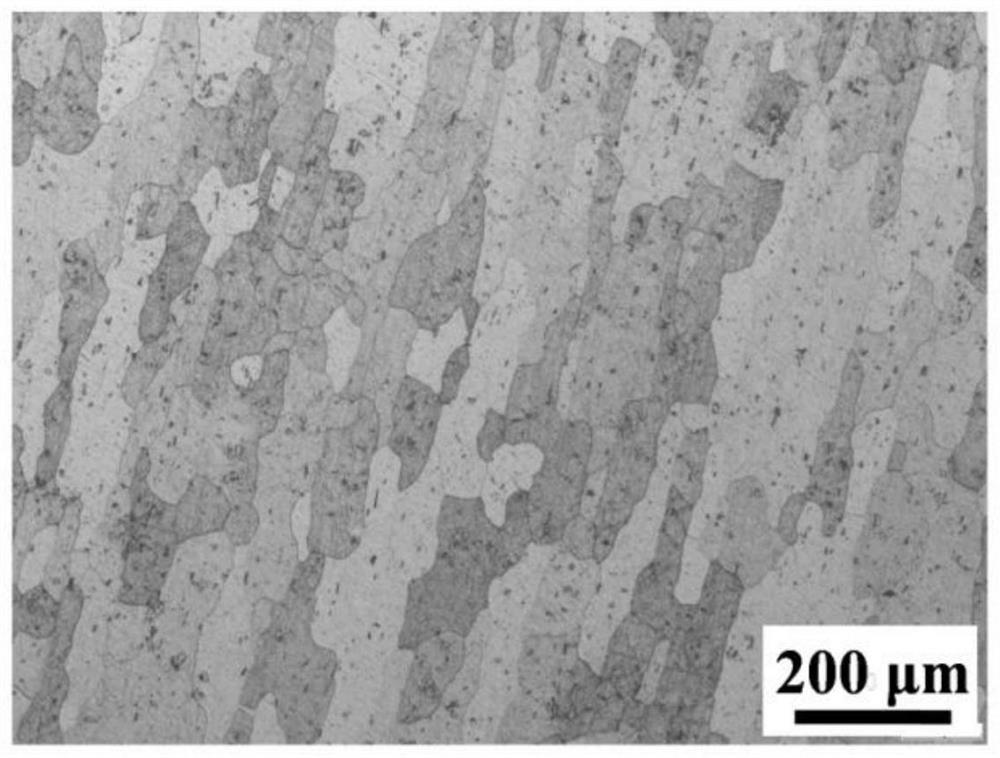

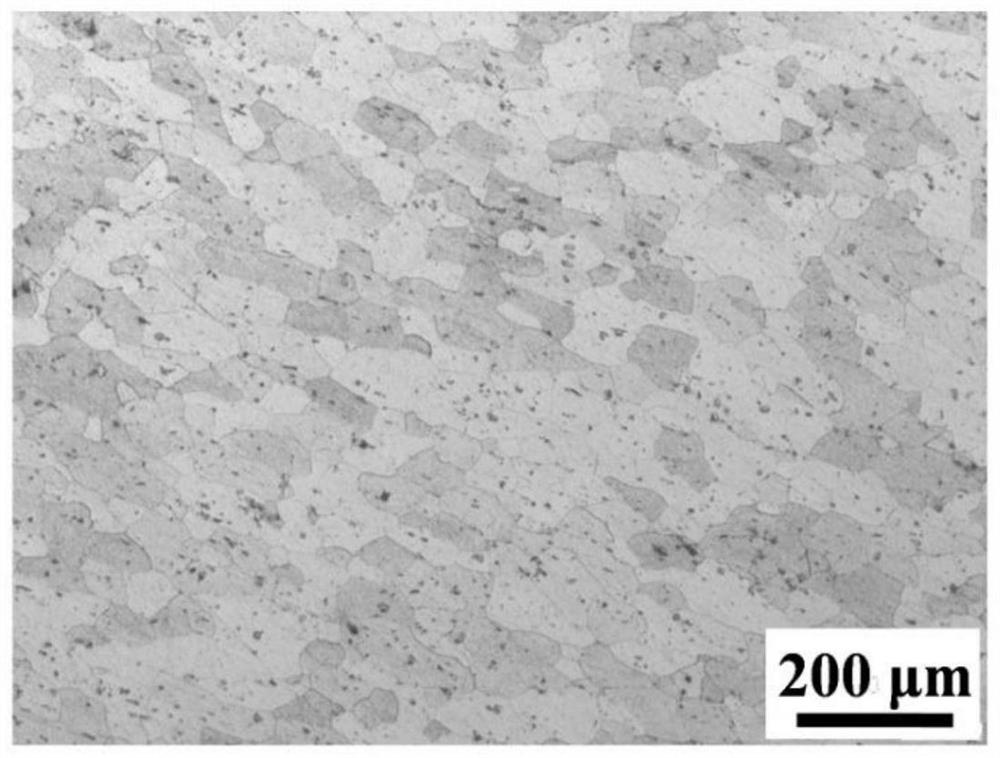

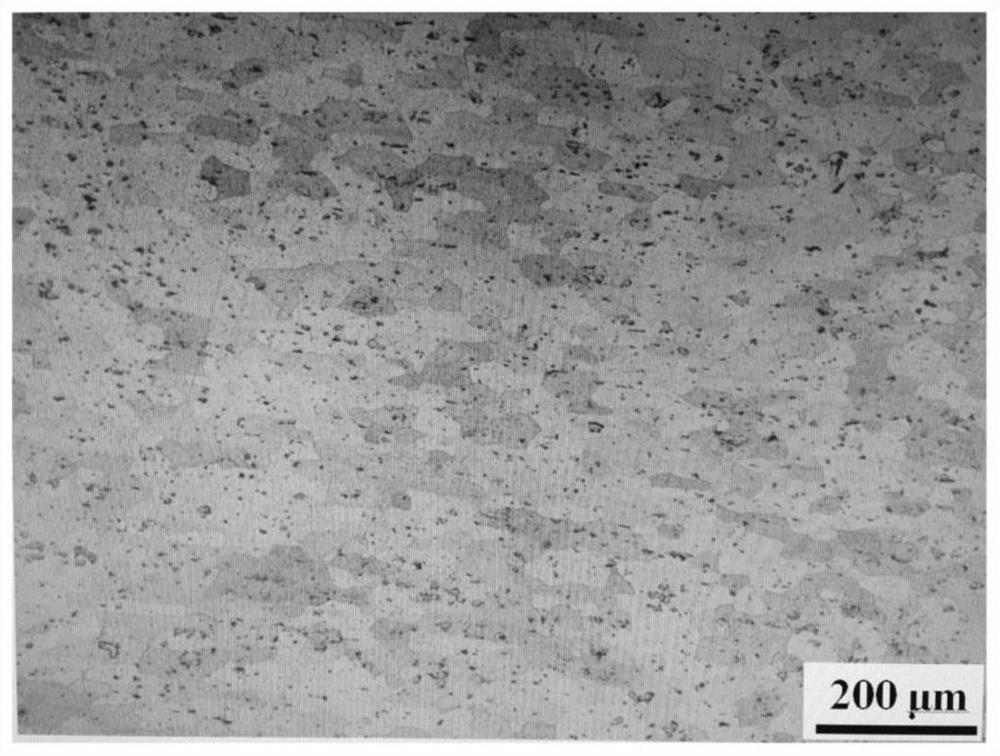

Manufacturing method of metal spinning part

The invention provides a manufacturing method of a metal spinning part. The manufacturing method of metal spinning parts comprises the following steps of 1, prestretching a metal raw material into a pie blank; 2, conducting first-pass spinning on the blank and then conducting complete annealing treatment on the blank to obtain a primary treated product; 3, conducting second-pass spinning on the primary treated product and then conducting incomplete annealing and quenching treatment to obtain a secondary treated product; and 4, conducting third-pass spinning on the secondary treated product andthen conducting quenching and aging treatment to obtain the metal spinning part. Through the manufacturing method, the crack sensitive rate of products can be eliminated or substantially reduced; thephenomena of surface cracking of spinning products manufactured through the method can be reduced by 90% or more; and the situation that the products are subjected to cold hardening in the spinning process badly, the crack depth of the outer surface of the spinning part is increased and the spinning part gets cracked and is scrapped is avoided.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

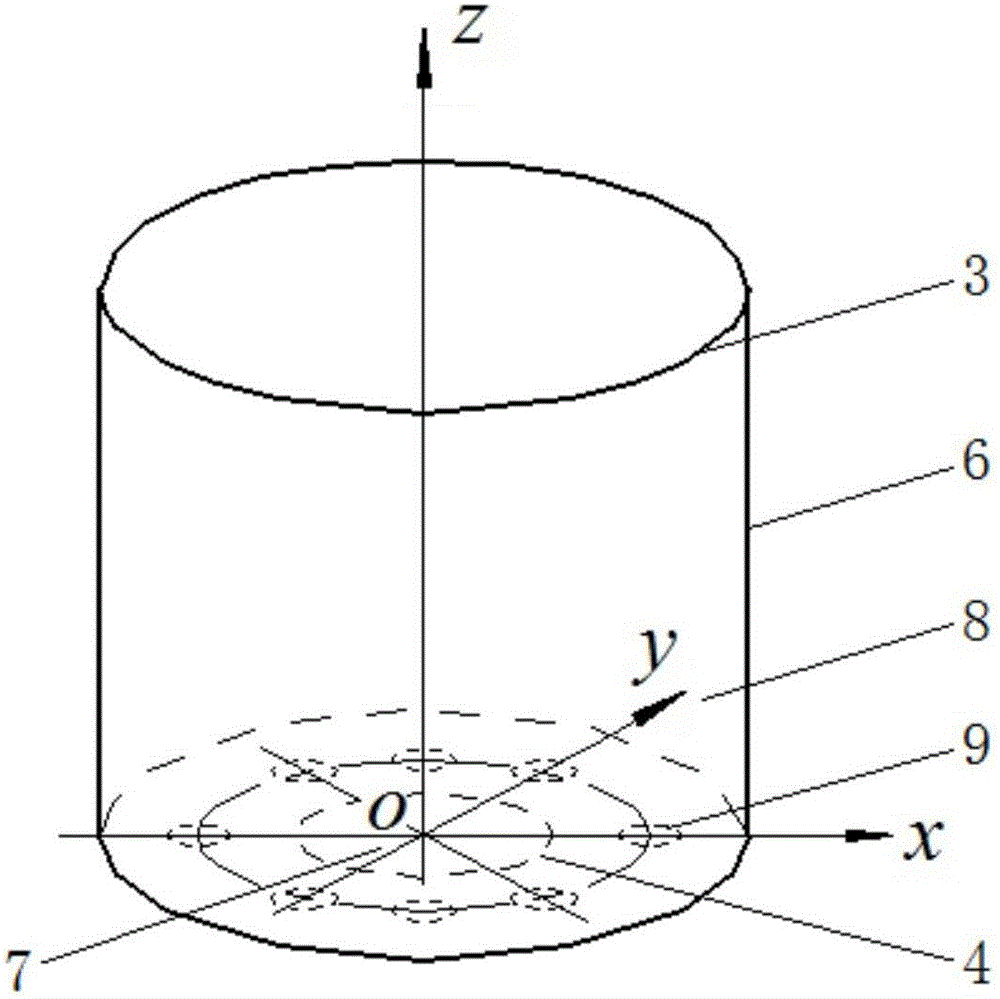

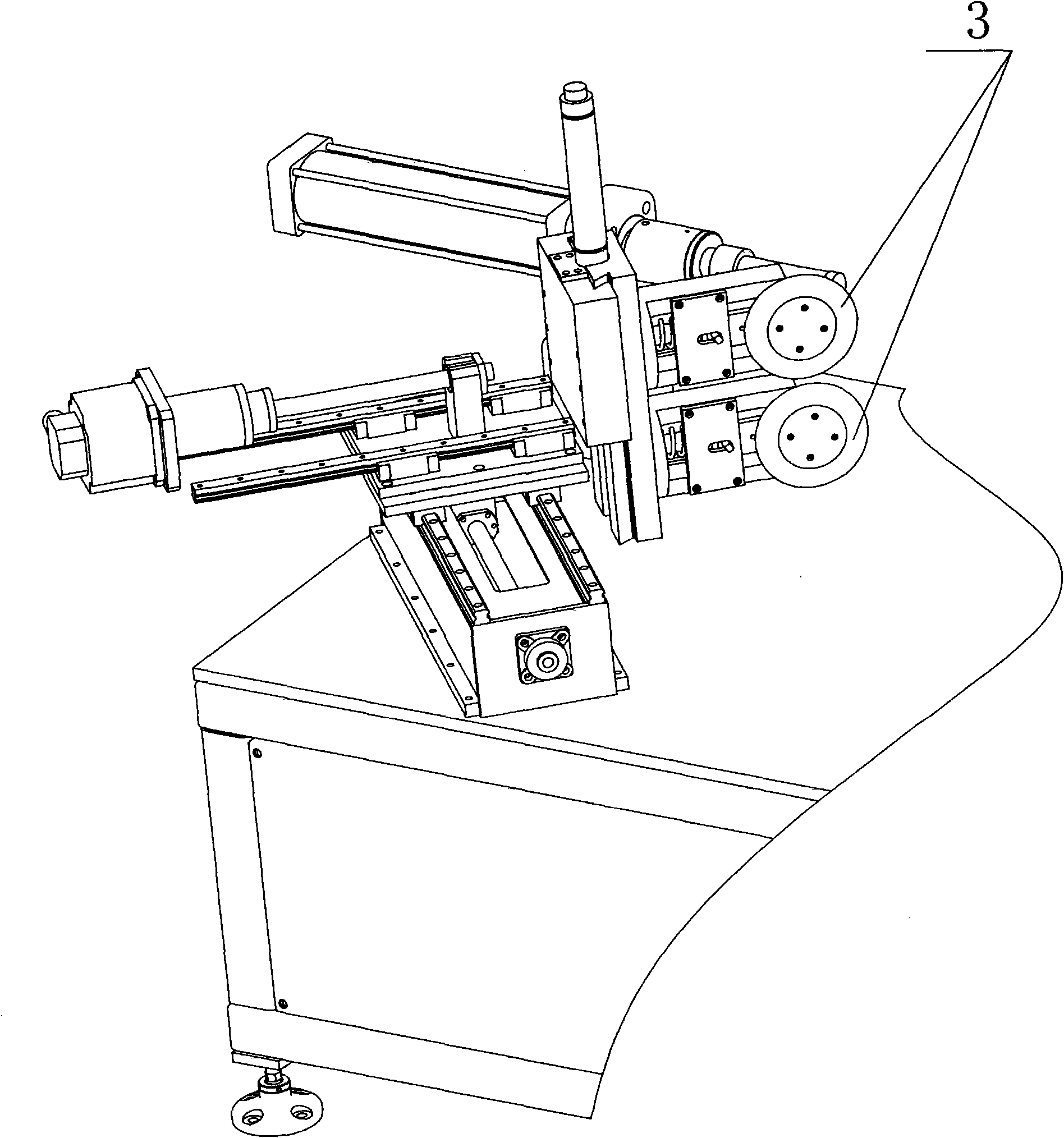

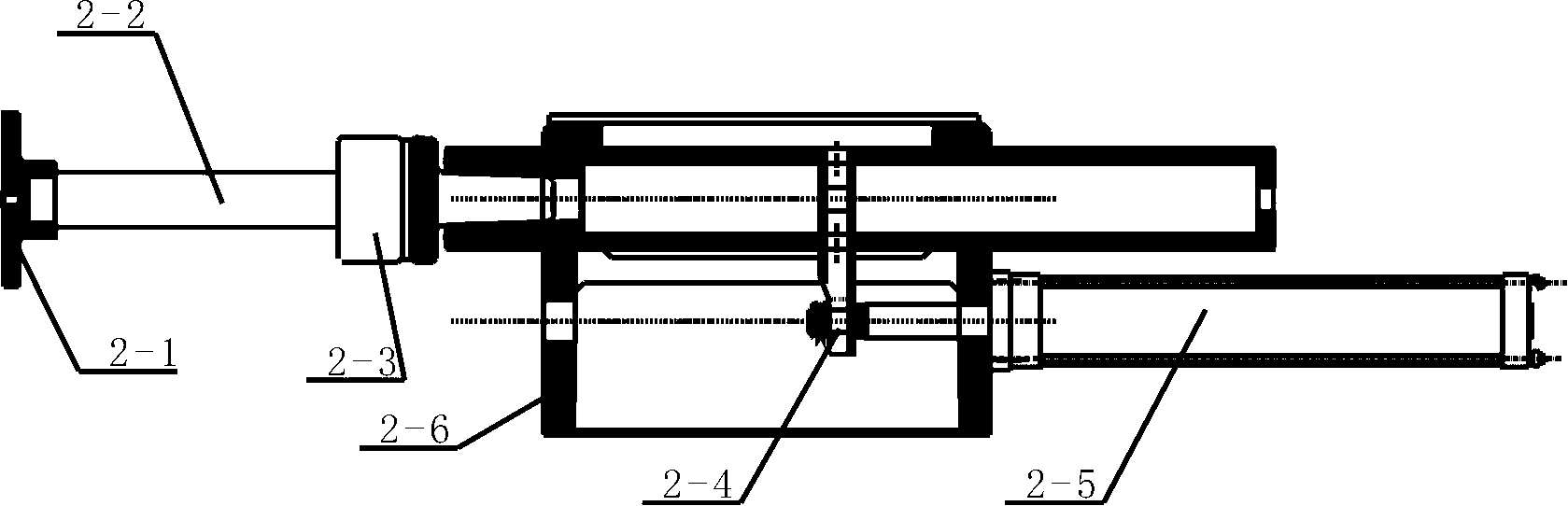

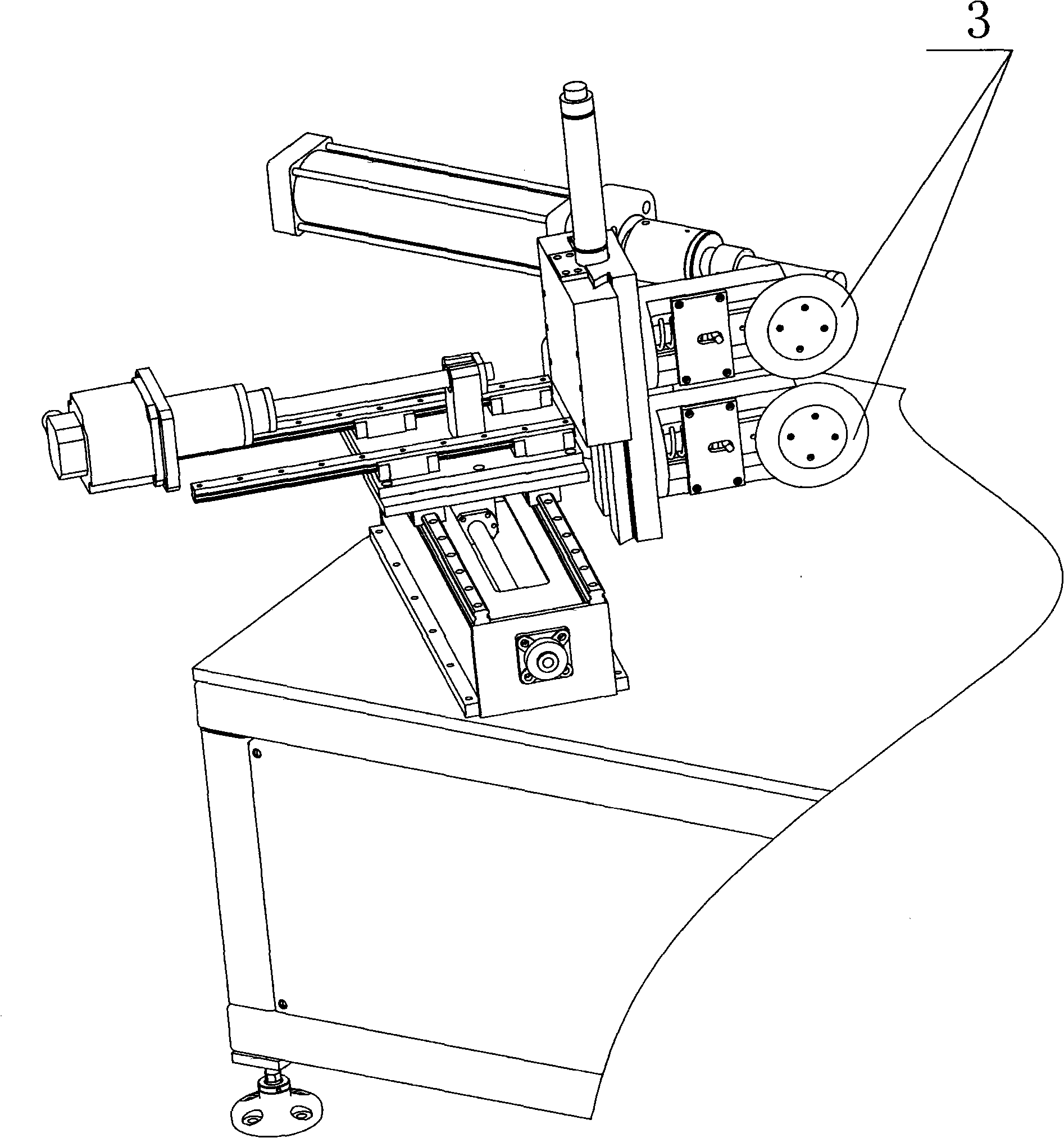

Non-rotating metal spinning experiment platform

InactiveCN106694673ARealize processingCompact and reasonable structure designMetal working apparatusNumerical controlEngineering

The invention relates to a non-rotating metal spinning experiment platform which comprises a machine body and a movable workbench installed on the machine body. The movable workbench is provided with a main shaft and a stepping motor for driving the main shaft to rotate. A servo motor for driving the main shaft to achieve axial feed is arranged behind the movable workbench. A blank self-blocking heating device is arranged on one side in the front of the main shaft, and the blank self-blocking heating device makes contact with a blank all the time through a leaf spring with a metal roller in the heating process. The other side in the front of the main shaft is provided with a spinning wheel feeding device. The spinning wheel feeding device is provided with an angle-adjustable spinning wheel frame and a servo motor for driving the spinning wheel to achieve feed. The stepping motor and the servo motor are both connected with a numerical control device which coordinates work of all the mechanisms. According to the non-rotating metal spinning experiment platform, by means of control over the feeding movement of the spinning wheel and the main shaft, spinning machining for non-rotating metal parts can be achieved.

Owner:SHANDONG UNIV OF SCI & TECH

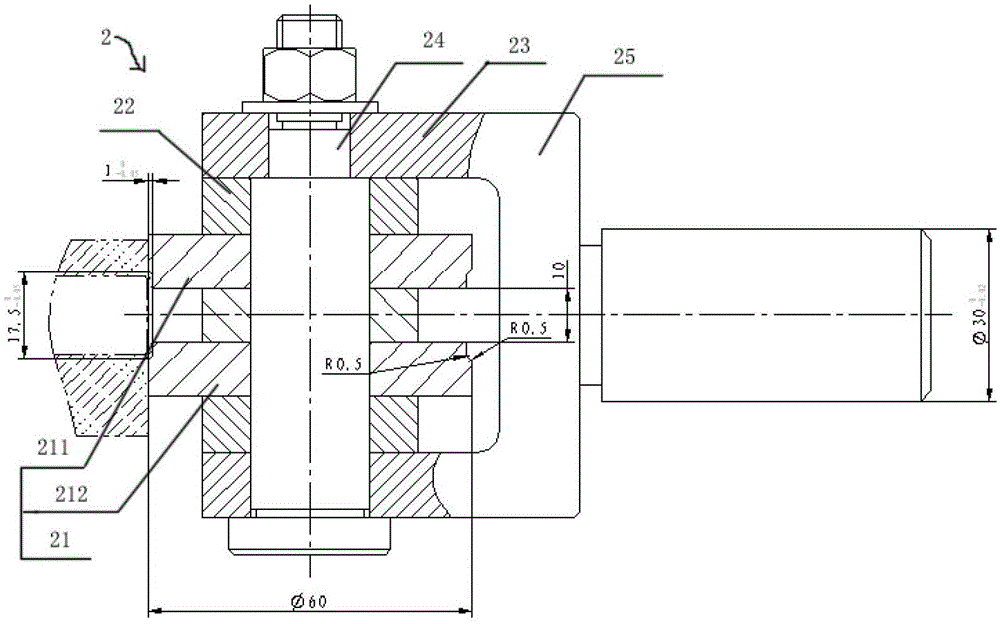

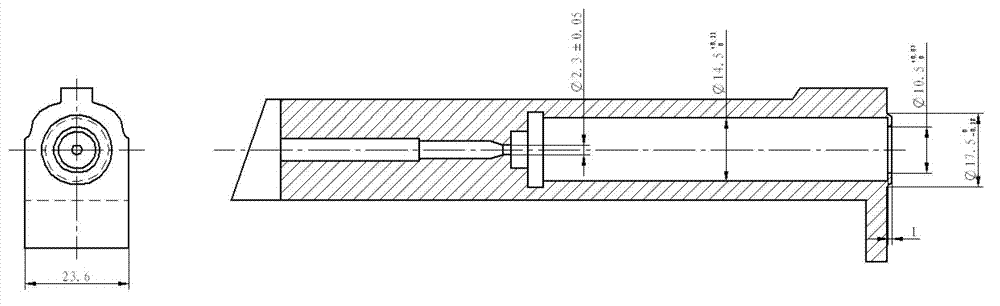

A spinning tool

The invention provides a metal spinning cutter. The metal spinning cutter is used for performing metal spinning for a firearm part with two small end holes, a middle large hole and a thin end. The metal spinning cutter is characterized by comprising a cutter saddle, a mandrel, a middle washer, two end washers and a blade, wherein the blade is limited in the middle of the mandrel by the two end washers, the two end washers are symmetrical with each other relative to the center line of a cylinder, which is connected with a tailstock of a lathe, of the cutter saddle, and the mandrel is connected onto the cutter saddle by nuts. The metal spinning cutter has the advantages that a muzzle can be machined by the metal spinning cutter, chipless metal spinning can be carried out according to plastic deformation of metal, metal spinning can be completed only by means of rotating a firearm bolt, and the metal spinning cutter is simple in operation and can be implemented easily.

Owner:CHONGQING JIANSHE IND GRP

Babbitt metal spinning lubricant composition

The invention discloses a Babbitt metal spinning lubricant composition. The lubricant composition uses an MVI 90 BS base oil and boride phosphate composite as base oil and is supplemented with a plurality of complex additives including an oily agent, a friction modifier, an extreme pressure agent, an antiwear agent, an antioxidant, a metal deactivator, an anti-rust agent, an oxidation and corrosion inhibitor, a tackifier and so on. The lubricant composition provided by the invention has advantages of good diffusibility, fluidity, carrying capacity, lubrication performance, cooling performance, rust prevention property and corrosion resistance and easiness in cleaning.

Owner:GUANGXI UNIV

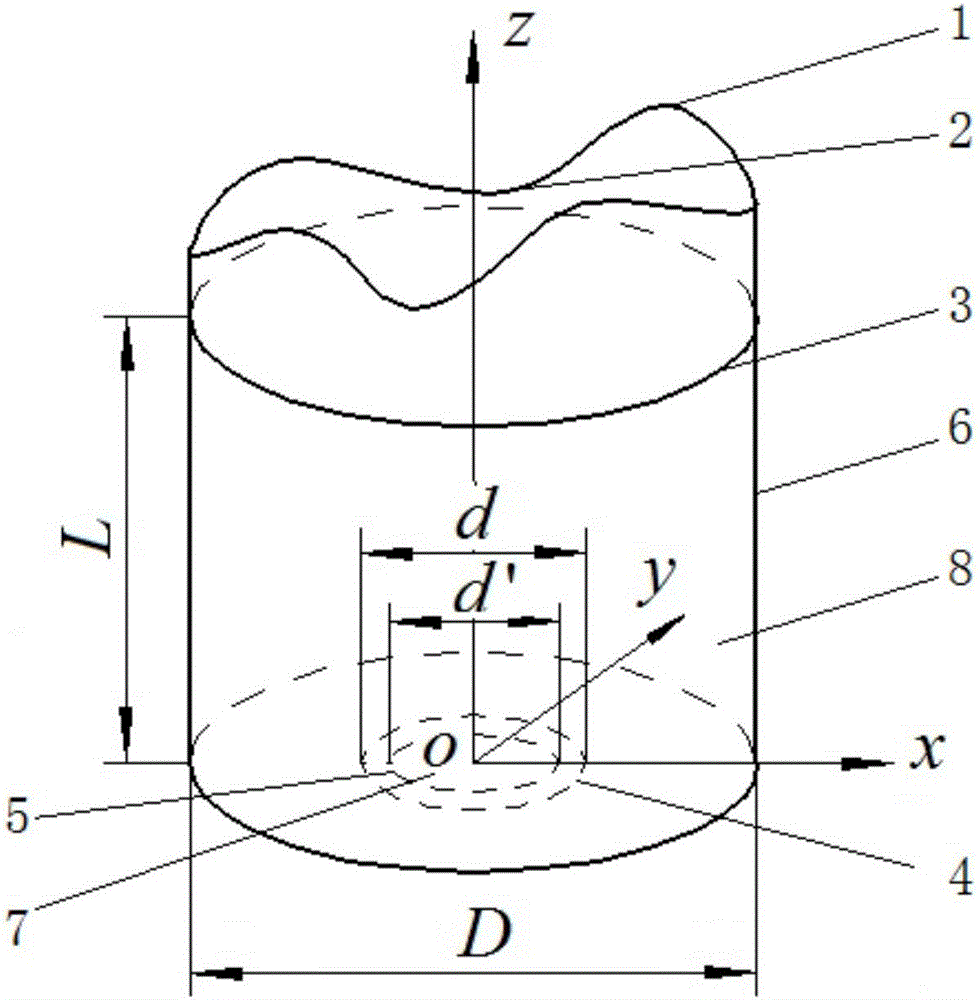

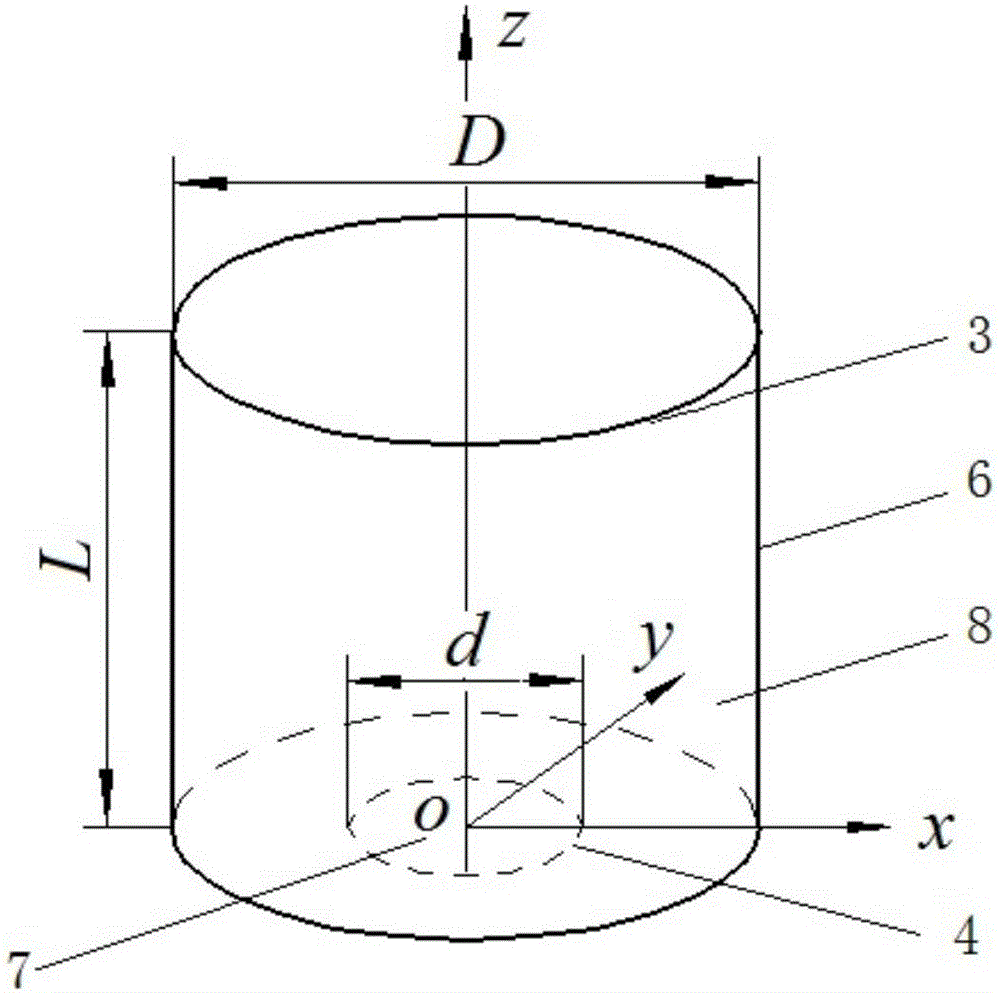

Spinning forming device for metal thin-walled cylindrical workpiece

ActiveCN104107853BGuaranteed forming qualityImprove processing efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachine tool

The invention provides a spinning forming device structure for metal thin-walled cylindrical workpieces, which can solve the problems of inability to guarantee working precision and low processing efficiency in traditional one-by-one spinning methods, and at the same time, unload the workpieces after the spinning processing is completed. It includes a mandrel and a spinning die. The spinning die includes a forming die and a bead roller. The mandrel runs through the shaft hole of the forming die. The forming die is fastened to the mandrel by a positioning fastening device, and the mandrel is connected to the main shaft of the machine tool through transmission. , during spinning, the forming mold rotates with the mandrel under the drive of the main shaft of the machine tool, and the outer periphery of the forming mold is provided with a forming surface. The outer peripheral surface of the machine is a beading profile matching the entire forming surface, and the beading roller is parallel to and facing the axis of the forming die.

Owner:WUXI DAWN DIE & STAMPING

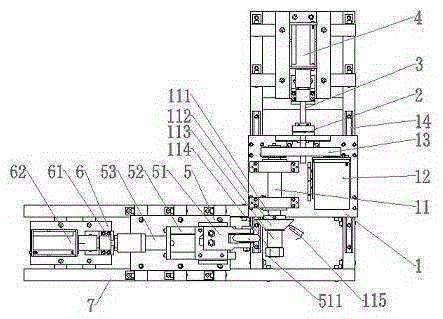

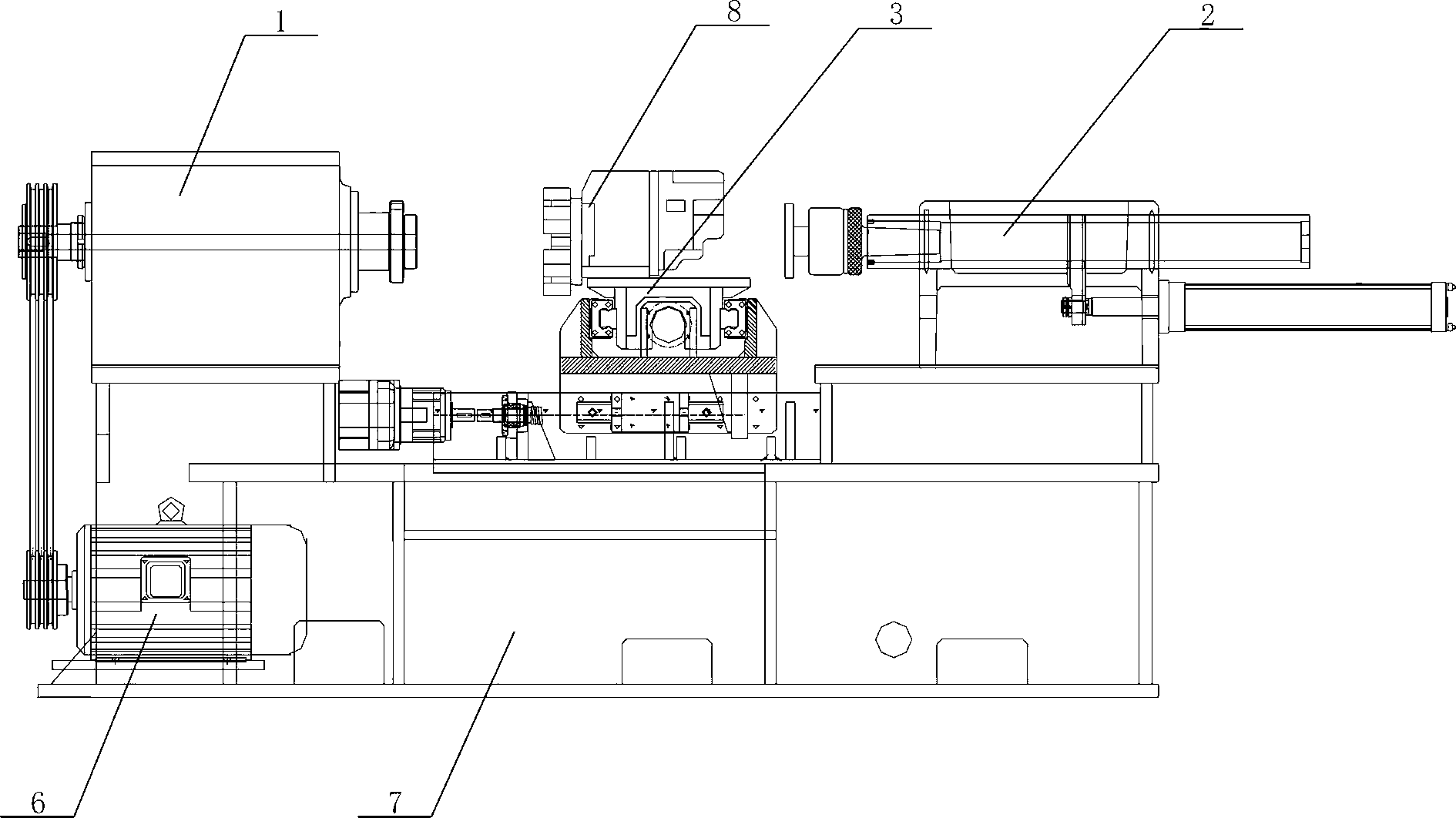

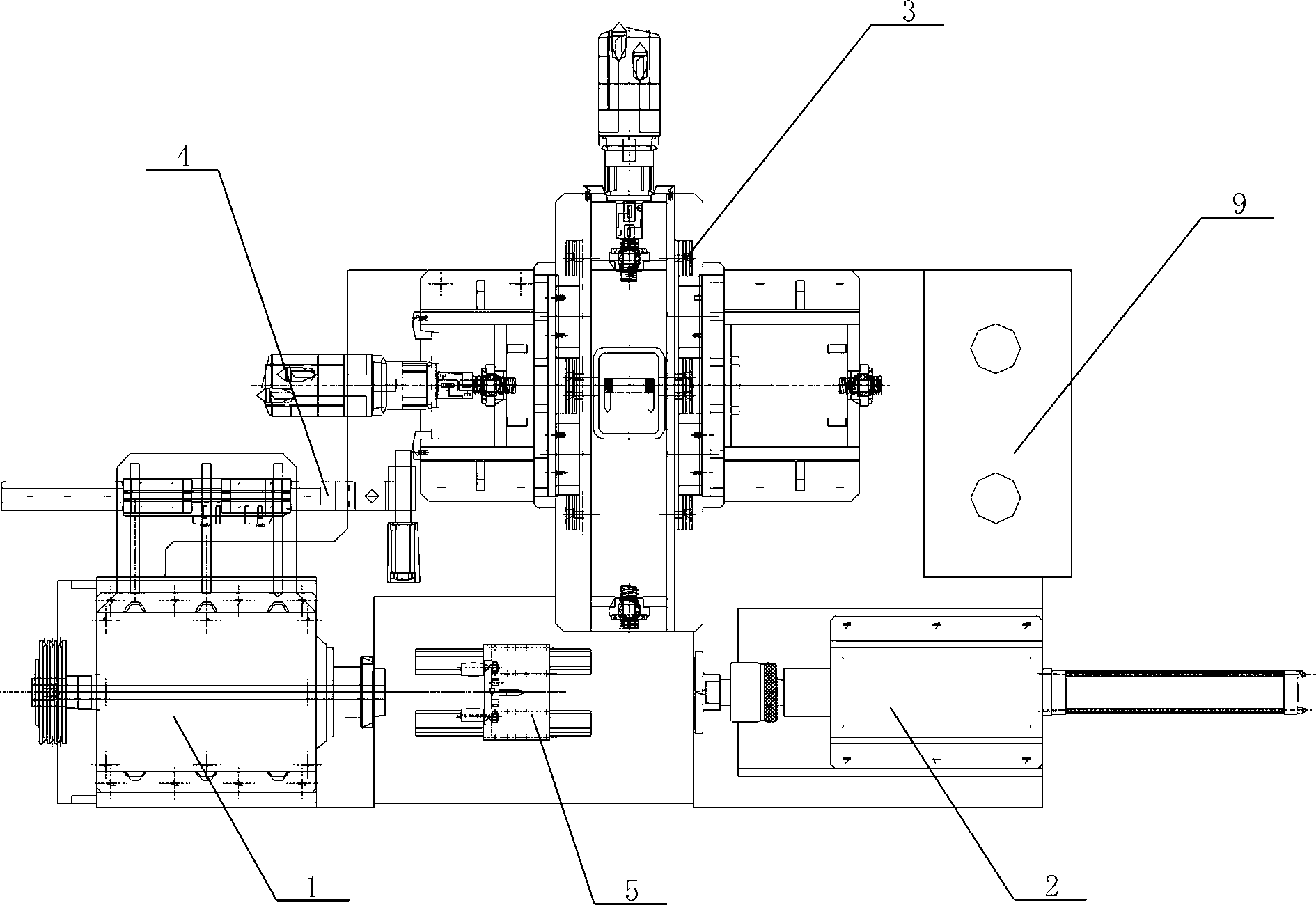

Numerical control metal spinning machine and software operating method thereof

InactiveCN102228925BHigh precisionIncrease thrustProgramme controlComputer controlElectric machineTailstock

The invention provides a numerical control metal spinning machine and a software operating method thereof, relating to a spinning machine. The numerical control metal spinning machine comprises a main spindle box (1), a tailstock (2), a cross-shaped thrust slipway (3), a carrier roller assembly (4) and a workpiece positioning device (5), a main motor (6), a base (7), a numerical control tool rest(8) and a control cabinet (9), wherein the main spindle box (1) and the tailstock (2) are respectively arranged at two sides of the base (7), the cross-shaped thrust slipway (3) is arranged above oneside of the middle of the base (7), the carrier roller assembly (4) is hung at one sides of the cross-shaped thrust slipway (3) and the main spindle box (1), the front end of the cross-shaped thrust slipway (3) is provided with the numerical control tool rest (8), the workpiece positioning device (5) is arranged below the inner side of the main spindle box (1), and the control cabinet (9) is arranged at the front side of the tailstock (2). The numerical control metal spinning machine has the characteristics of high precision, high thrust, high reliability, low cost and simpleness and convenience for maintenance, can be used for carrying out veneer spinning forming, spinning compression and spinning expansion, and has the functions of numerical control turning, hemming and trimming.

Owner:SHANGHAI OKAY MACHINE

A method of manufacturing metal spinning parts

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

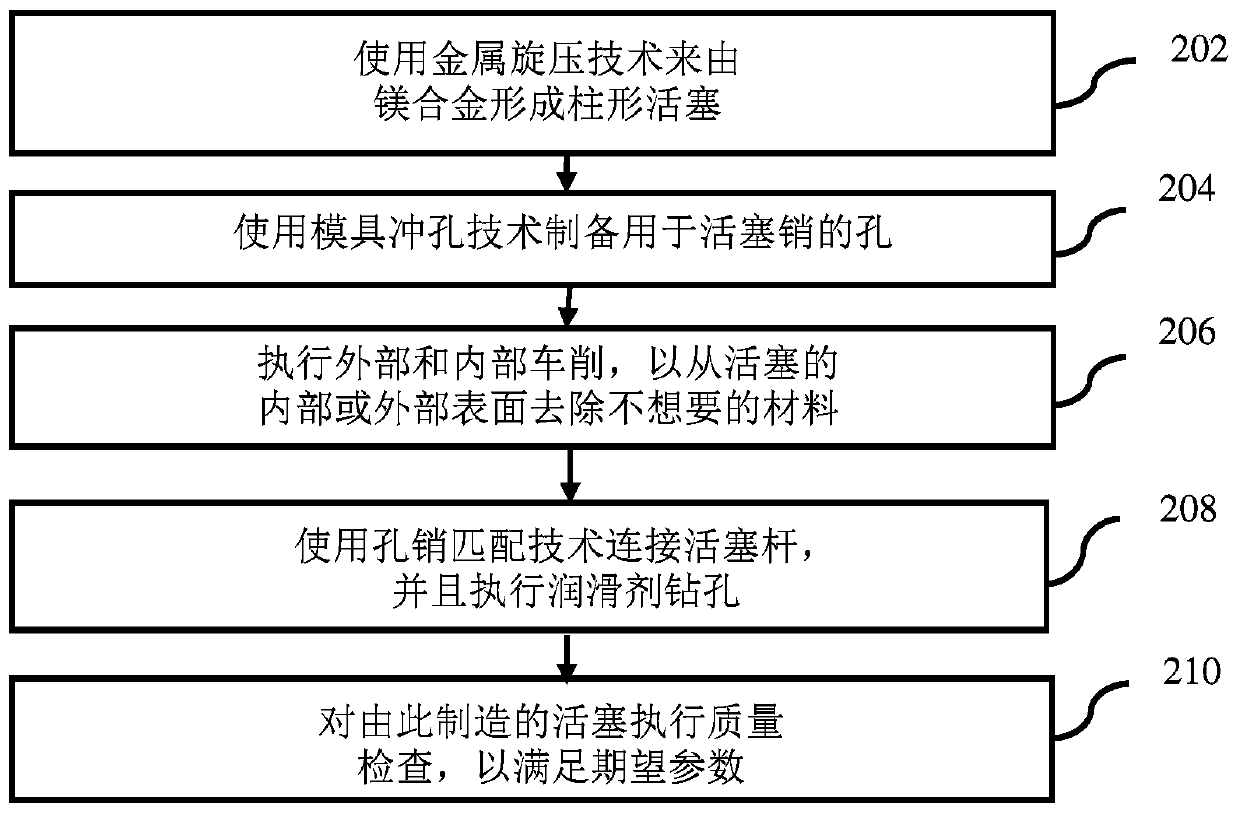

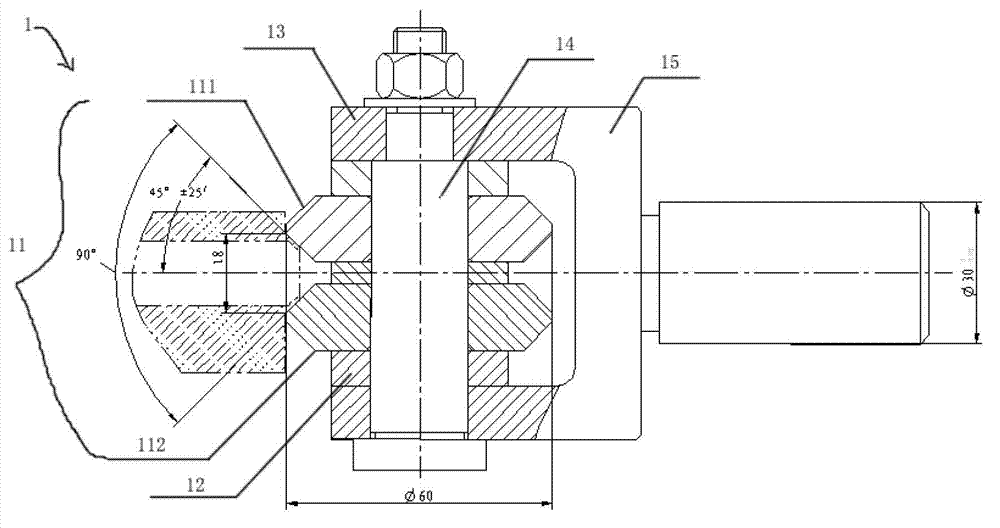

Lightweight piston

ActiveCN110520618ASmall inertia forceReduce weightConnecting rodsMachines/enginesPunchingInternal combustion engine

The embodiments herein provide a lightweight piston device for use in an internal combustion engine. According to an embodiment herein, the piston is made from a magnesium alloy. The piston made frommagnesium alloy is lighter in weight thereby reducing the inertia forces within the cylinder. By reducing the inertia forces, the efficiency of the engine increases which eventually increases the horse power. A method is provided for manufacturing piston from magnesium alloy using metal spinning or extrusion technique. Die punching is carried out on the cylinder shape of magnesium alloy in order to make a hole for piston pin. External and internal turning is performed using machining. The piston rod is then connected to matching hole pin and the lubricant hole drilling is performed.

Owner:O 达汉 +1

Metal spinning cutter

The invention provides a metal spinning cutter. The metal spinning cutter is used for performing metal spinning for a firearm part with two small end holes, a middle large hole and a thin end. The metal spinning cutter is characterized by comprising a cutter saddle, a mandrel, a middle washer, two end washers and a blade, wherein the blade is limited in the middle of the mandrel by the two end washers, the two end washers are symmetrical with each other relative to the center line of a cylinder, which is connected with a tailstock of a lathe, of the cutter saddle, and the mandrel is connected onto the cutter saddle by nuts. The metal spinning cutter has the advantages that a muzzle can be machined by the metal spinning cutter, chipless metal spinning can be carried out according to plastic deformation of metal, metal spinning can be completed only by means of rotating a firearm bolt, and the metal spinning cutter is simple in operation and can be implemented easily.

Owner:CHONGQING JIANSHE IND GRP

Method for pressing conical cover reinforcing ribs

The invention relates to a method for pressing conical cover reinforcing ribs. A sectioning mold same with the molded surface of a product is adopted, a common spherical turning lathe or a numerical control spinning machine is used, and a hot metal spinning mode is adopted. The characteristic that an aluminum alloy material has a good plasticity under a certain temperature while the strength and the toughness are obviously reduced is utilized, and a panel veneer used as a blank. Under the combined action of the radial force and the axial force of a spinning roller, through multi-pass spinning, the panel veneer is forced to deform, materials flow and form workpieces similar with the molded surface of the mold, and the spinning formation of an aluminum alloy annular-structure product with a section like the shape of Chinese character 'ji'. The characteristic that the sectioning mold is detachable is utilized to realize the separation of the 'ji'-shaped section annular-structure piece and the mold, and the completeness of the annular-structure piece is ensured. According to the method, the aluminum alloy annular-structure piece with the special-shaped section which is difficultly formed with processes such as general stamping, machining and the like can be formed. The method has the characteristics of low cost, low labor strength of workers, high processing efficiency and high material use ratio.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Air disperser for spray-drying, and a method for manufacturing an air disperser comprising metal forming

ActiveUS10066872B2Good conditionImprove operationDrying solid materials with heatDrying gas arrangementsMetal formingMetal

In the air disperser (4) having a number of components including a top, a bottom and an outer circumferential wall forming a space (45) defined within an inner radius and an outer radius and having an air inlet (81), a set of guide vanes (7), and an air outlet (82) at the inner radius adapted to be positioned above a feed outlet from atomizing means, at least some of the components are formed by precision metal forming such as metal spinning.

Owner:GEA PROCESS ENG

A kind of metal drawing powder and preparation method thereof

ActiveCN104388155BEasy to cleanReduce friction damageLubricant compositionPotassium hydroxideChlorinated paraffins

The invention discloses metal spinning powder and a preparation method thereof. The metal spinning powder is characterized by being prepared from the following raw materials in parts by weight: 100-300 parts of sodium carbonate or potassium carbonate, 1-5 parts of sodium benzoate, 300-600 parts of water, 10-60 parts of sulfonated castor oil, 5-30 parts of chlorcosane, 5-30 parts of tall oil, 2-15 parts of powdery sodium hydroxide or potassium hydroxide, and 5-30 parts of white carbon black. The invention also discloses the preparation method of the metal spinning powder. The metal spinning powder disclosed by the invention has the advantages of favourable lubricating property, corrosion resistance, high temperature resistance, high pressure resistance, lower cost and easy storage.

Owner:HENAN NORMAL UNIV

Self-adapting spinning mechanism of sheet metal spinning machine

ActiveCN101642786BRealize adaptive adjustment functionAvoid damageShaping toolsEngineeringSlide plate

The invention discloses a self-adapting spinning mechanism of a sheet metal spinning machine. The design key point is that the self-adapting spinning mechanism of the sheet metal spinning machine comprises a base and a sliding plate which is arranged on the base and can slide back and forth, wherein the base is provided with a pretension spring for pushing the sliding plate outwards, and the sliding plate is provided with a roller wheel assembly for applying pressure. The invention aims to provide the spinning mechanism of the sheet metal spinning machine which has a simple structure and can be adjusted adaptively.

Owner:CHENZHOU ZHIZAO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com