Metal spinning method for dynamic balance wheel

A wheel and precision spinning technology, applied in the field of wheel dynamic balance, can solve problems such as dynamic imbalance, increase in use cost, and affect the balance effect, and achieve the effects of high reliability, cost saving in use, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

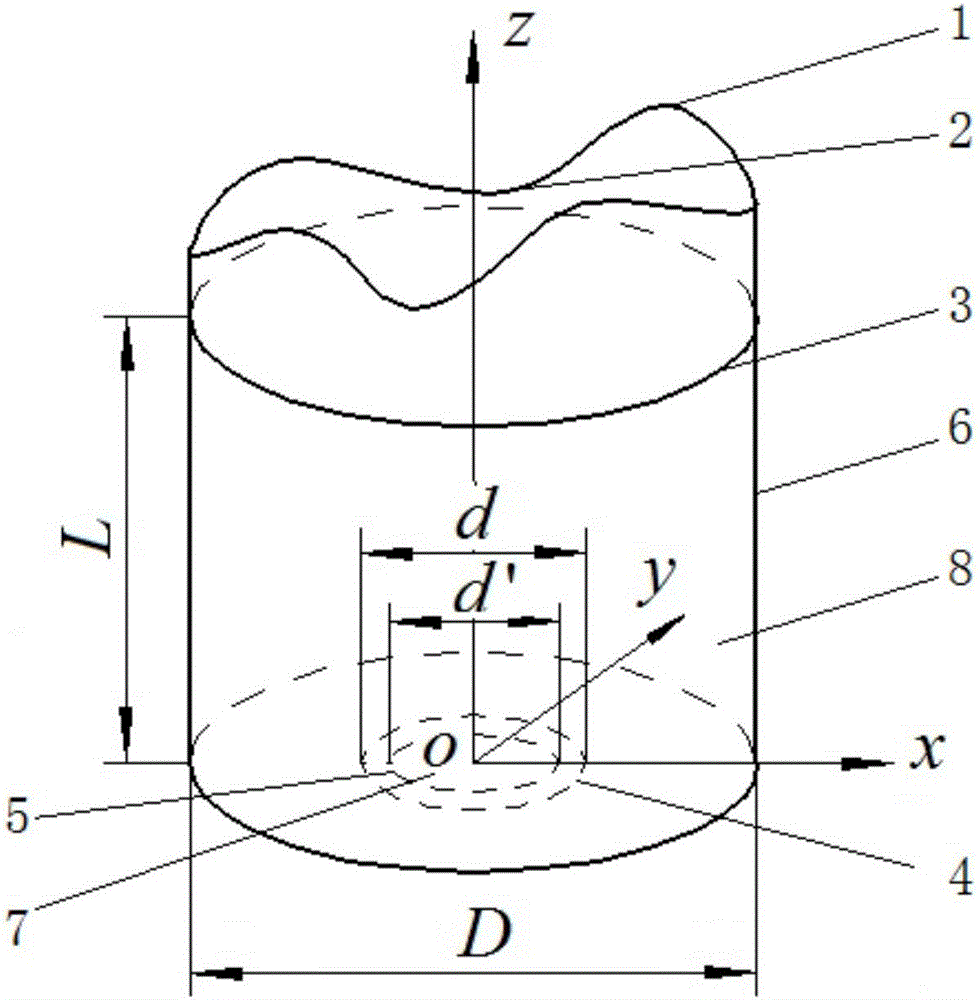

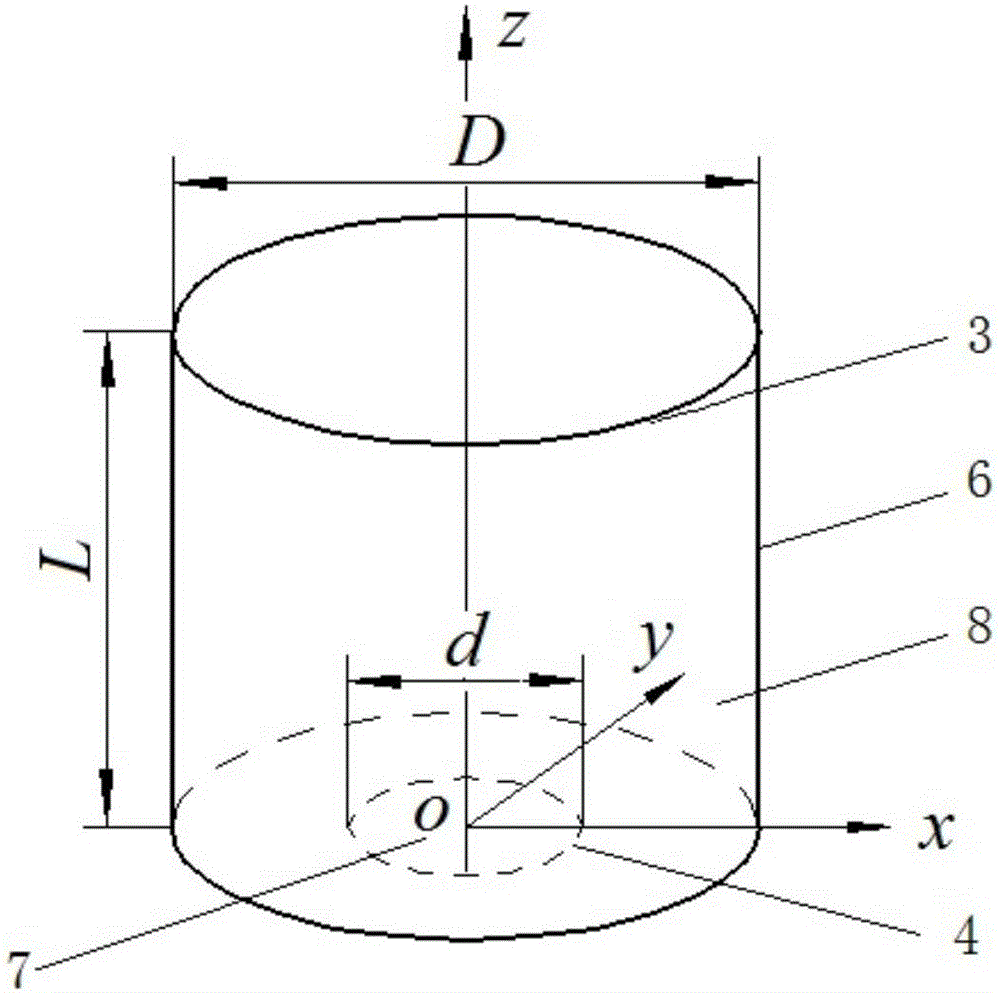

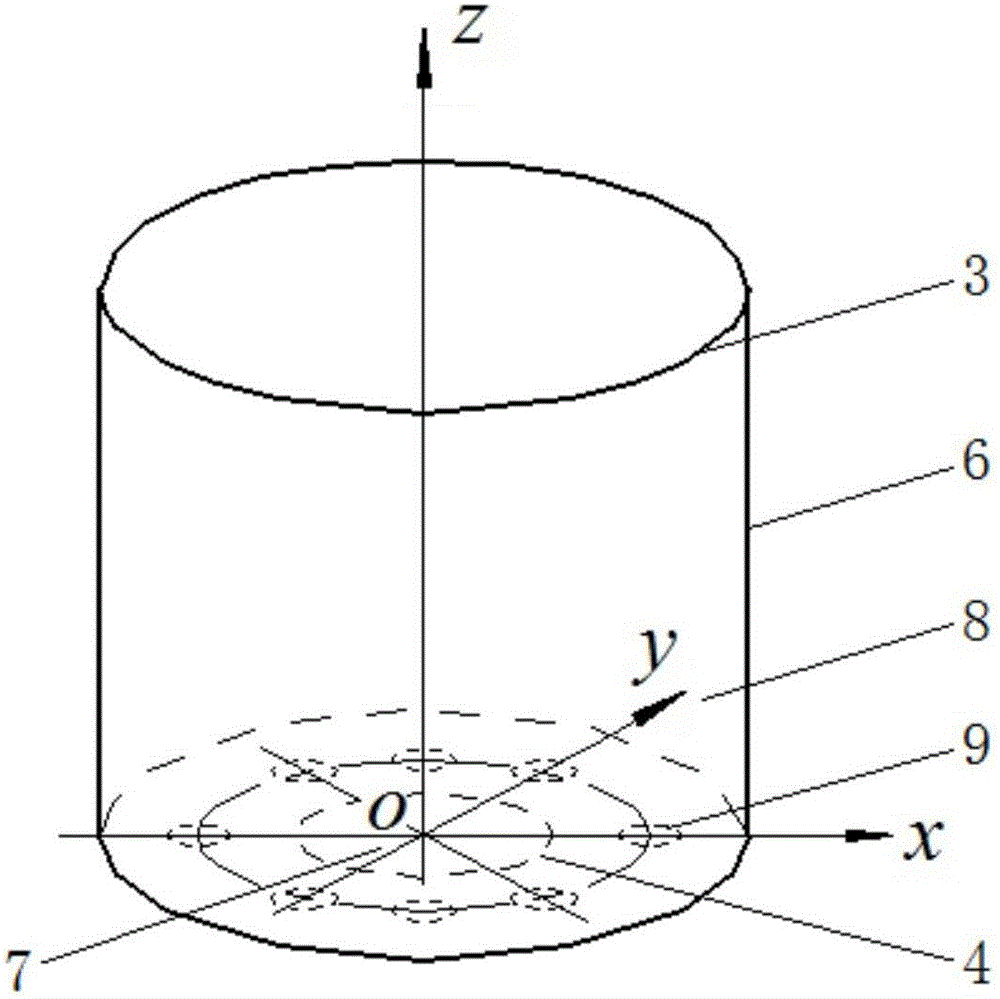

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The method for spinning the dynamic balancing wheel of the present embodiment comprises the following steps:

[0029] Step 1: Process n concave structures at the non-tire-covered, non-installation and non-connection parts of the blank material for spinning, where n is a natural number and n≥3; 8 circular through holes are evenly processed on the spokes of blank processing, such as Figure 5 , Figure 6 shown;

[0030] Step 2: Fill the concave structure described in step 1 with dynamic balance weights. The weights can be made of metal materials with a certain density. The distribution of the weights is as follows: Figure 5 shown;

[0031] Step 3: Perform rough spinning;

[0032] Step 4: Perform fine spinning; before spinning, you can also remove part of the material covered by the tire, such as image 3 , Figure 4 , Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com