Metal spinning cutter

A technology for machining knives and knives, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of poor workpiece hole roughness, slow processing efficiency, unsuitable for processing pistol bolts and muzzle caps. problem, to achieve the effect of simple operation and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

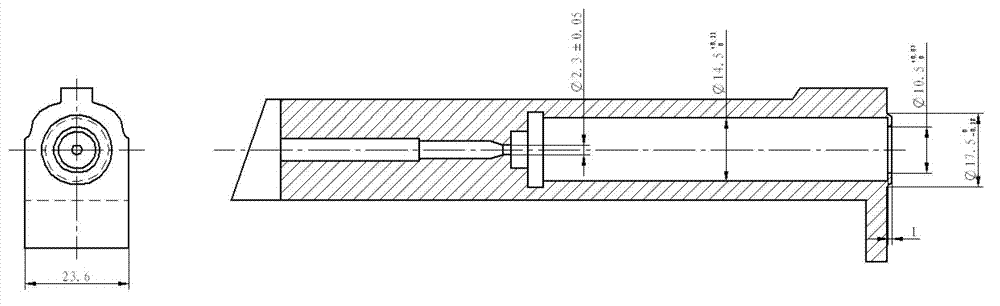

[0016] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

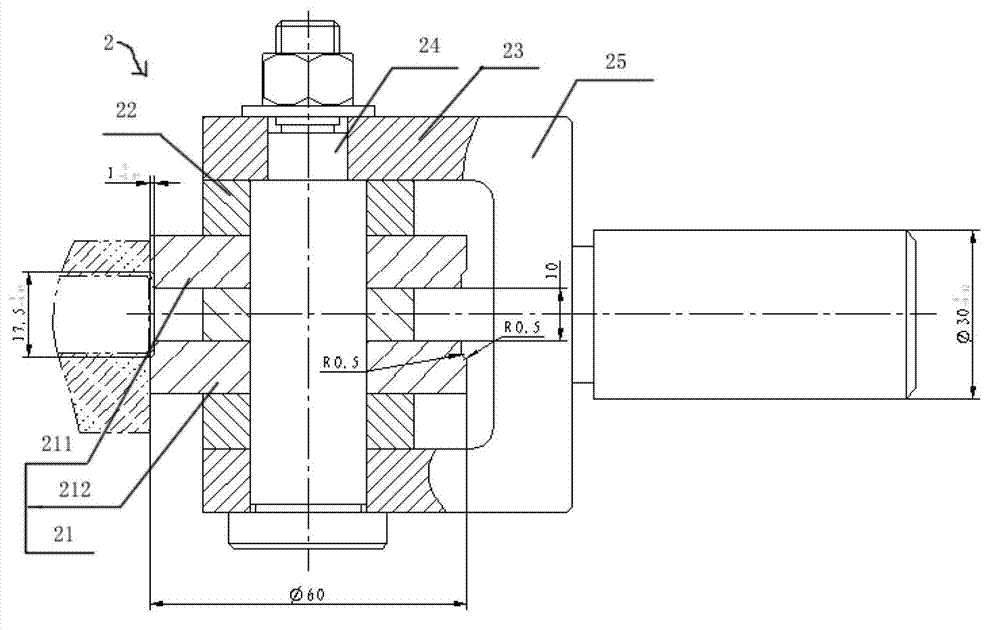

[0017] In the present invention, in the spinning process, two different blades need to be used together to carry out the spinning process on the workpiece, which will be referred to as the spinning angle tool 1 and the spinning tool 2 respectively.

[0018] The spinning angle tool 1 and the spinning tool 2 of the spinning tool of the present invention are introduced.

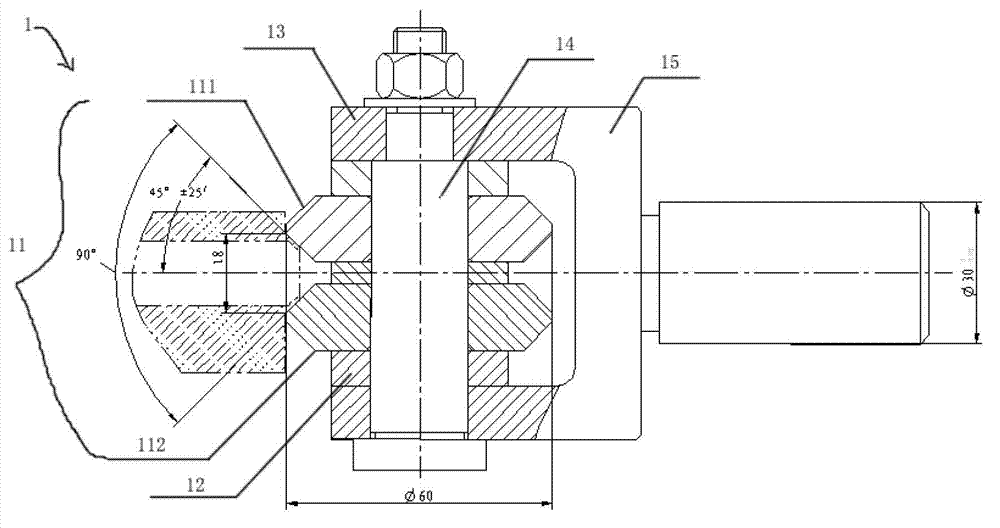

[0019] figure 1 It is a structural schematic diagram of the tool used for spinning angle in the present invention. Such as figure 1 As shown, the tool 1 used for spinning the muzzle into a certain angle spinning angle includes a tool holder 15, a mandrel 14, a middle gasket 13, gaskets 12 at both ends and a blade 11. Wherein the two ends of the blade 11 are in the shape of an inverted triangle, and the apex angle of the ends is about 45°. In order to make the force uniform and easy to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com