Non-rotating metal spinning experiment platform

A metal spinning, experimental platform technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult to process non-rotating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

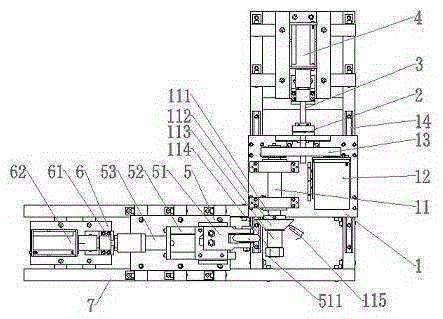

[0013] Such as figure 1 As shown, the non-revolving metal spinning experimental platform disclosed by the present invention includes a fuselage, a movable worktable (1) installed on the fuselage; a main shaft (11) and a drive main shaft ( 11) Rotating stepping motor (12), the two are placed in parallel, and the stepping motor (12) drives the main shaft (11) to rotate through the synchronous belt (13); there is a driving main shaft (11) behind the movable worktable (1) ) servo motor (4) for axial feeding, the servo motor (4) drives the movable worktable (1) along the Feed in Z axis direction.

[0014] The main shaft (11) is provided with a positioning ring (111) for fixing the ceramic mandrel (112), and the end of the main shaft is threaded. Cylinder clamping block (113) to withstand the billet, and then screw in the clamping nut (114) to tighten the jacking block to prevent the billet from shifting and falling during the rotation of the mandrel (112); the billet is fixed Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com