Spinning forming device for metal thin-walled cylindrical workpiece

A cylindrical workpiece, spinning forming technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of low processing efficiency, inability to guarantee work processing accuracy, etc., and achieve convenient assembly, reliable rotation, and stable positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

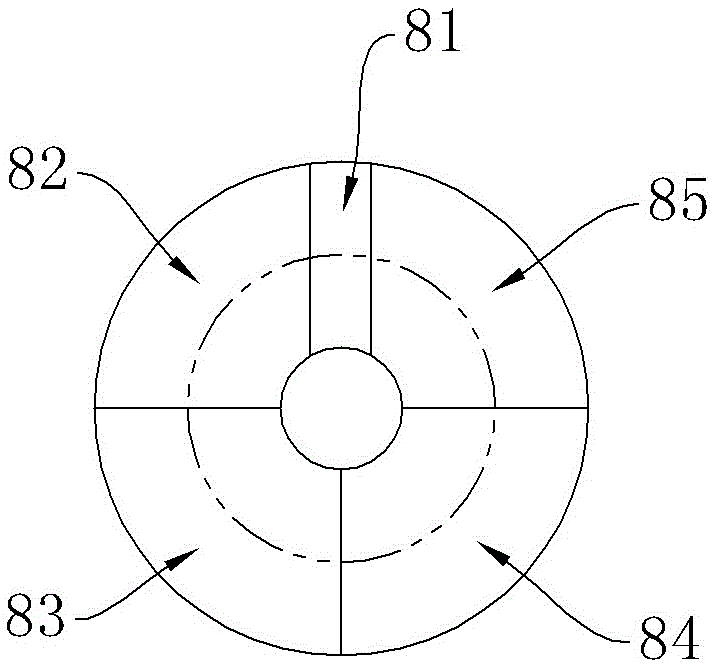

[0034] See Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9with Figure 10 The spinning forming device of the present invention includes a mandrel 10 and a spinning die, the spinning die includes a forming die 20 and a beading roller 40, the mandrel 10 passes through the shaft hole 210 of the forming die 20, and the forming die 20 is tightened by a positioning fastening device Fixed on the mandrel 10, the mandrel 10 is connected with the main shaft of the machine tool. During the spinning process, the forming die 20 rotates with the mandrel under the drive of the main shaft of the machine tool. The outer peripheral surface of the forming die 20 is provided with a forming surface 25. 40 is installed on the knife rest of lathe by beading wheel support 50, and the outer peripheral surface of beading roller 40 is the beading profile 42 that matches with whole forming surface, and beading roller 40 is axially parallel with forming die 20 and faces.

[0035] The beading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com