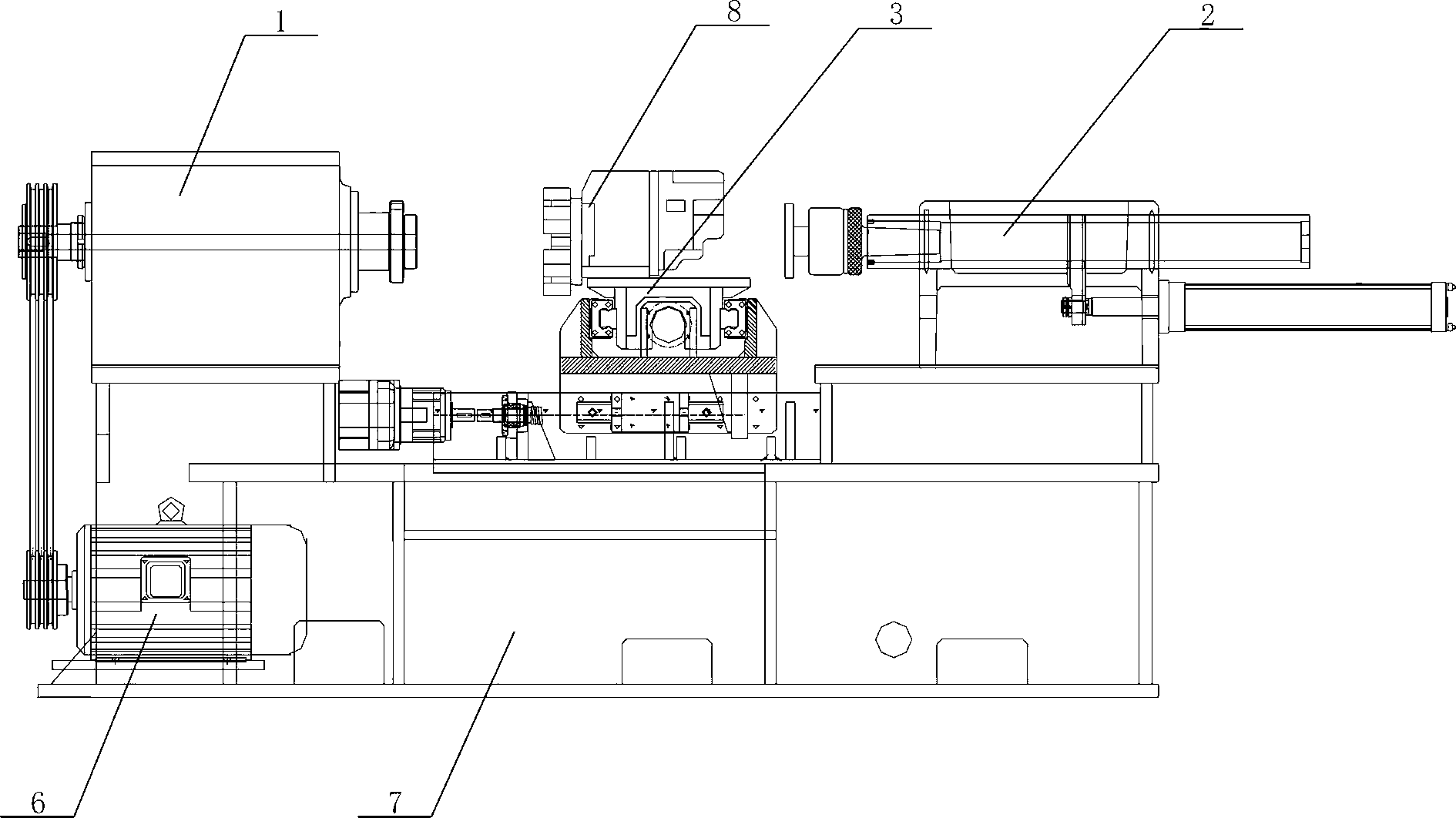

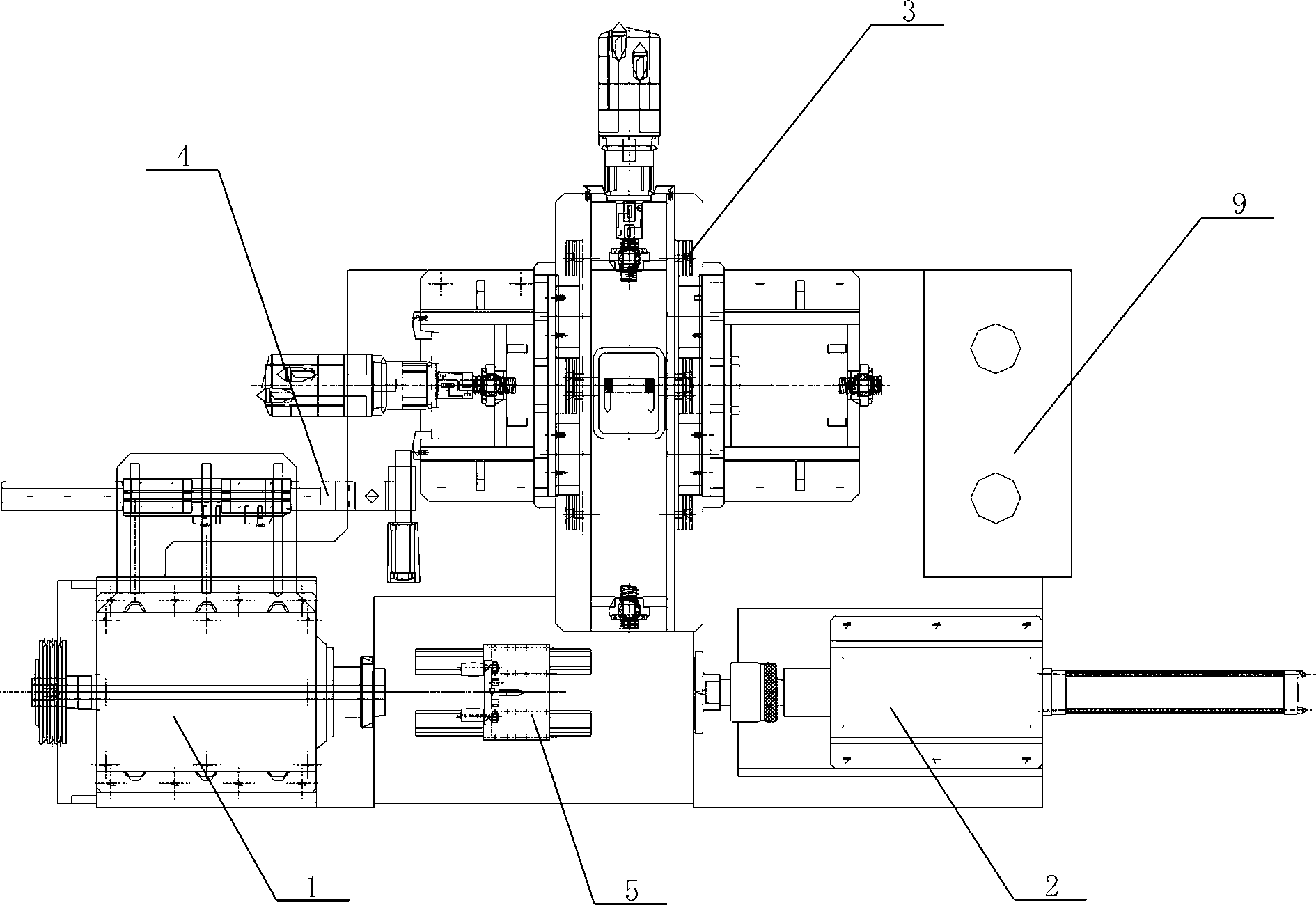

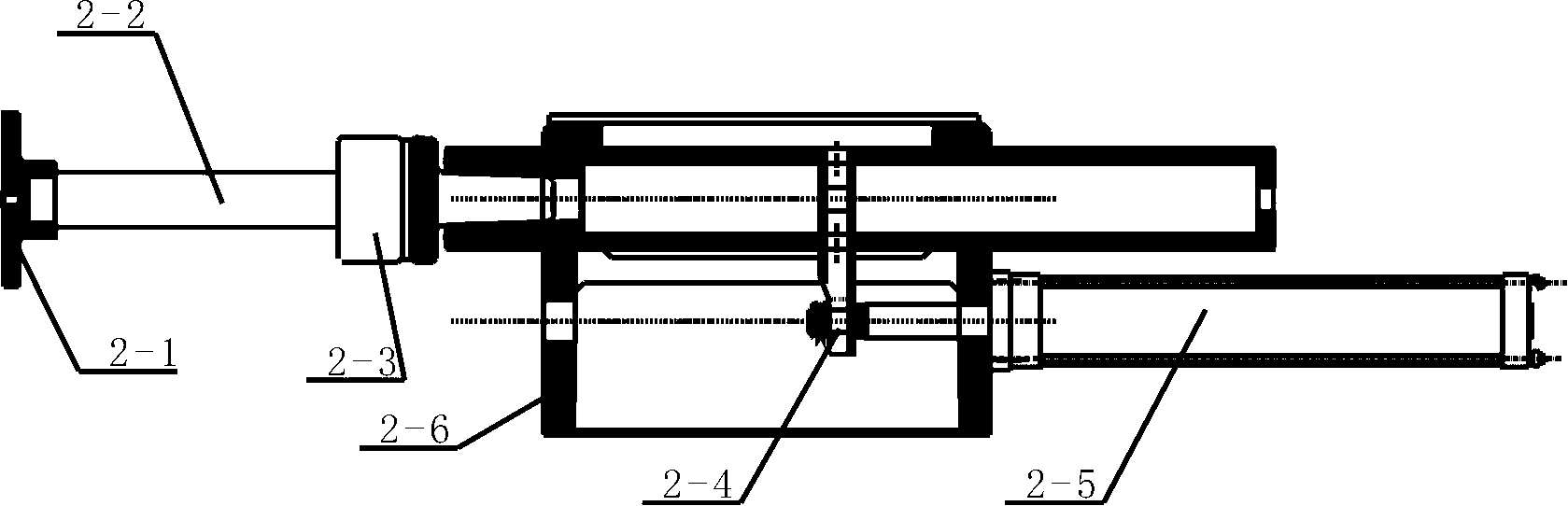

Numerical control metal spinning machine and software operating method thereof

A spinning machine and metal technology, applied in the field of spinning machines, can solve the problems of high technical difficulty and high software development costs, and achieve the effects of low cost, easy maintenance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Example: such as Figure 9 The product shown (any rotary shape is acceptable), for example, the maximum mouth diameter is 700mm (any is acceptable), the height is 300mm (any is acceptable), and the thickness is 5mm (any is acceptable).

[0038] If the current traditional stretching process is used to complete, 2 sets of equipment are required, one stretching machine and one punching machine, at least 3 sets of molds, 2 sets of stretching dies, 1 set of trimming dies, the investment in equipment is about 400,000, and the investment in molds is about 3 Ten thousand. Among them, the equipment is a fixed investment, while the mold investment is only for this specific product. When replacing products with different shapes, the mold will be calculated separately. Therefore, for many stamping parts manufacturers, there are dozens or even hundreds of products, so the mold investment alone can reach several million or even tens of millions. Based on 100 different products, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com