Self-adapting spinning mechanism of sheet metal spinning machine

A spinning machine, self-adaptive technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of heavy force on the roller assembly, easy damage, deformation and unevenness of the roller tool, so as to avoid rapid wear and save The effect of pressure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

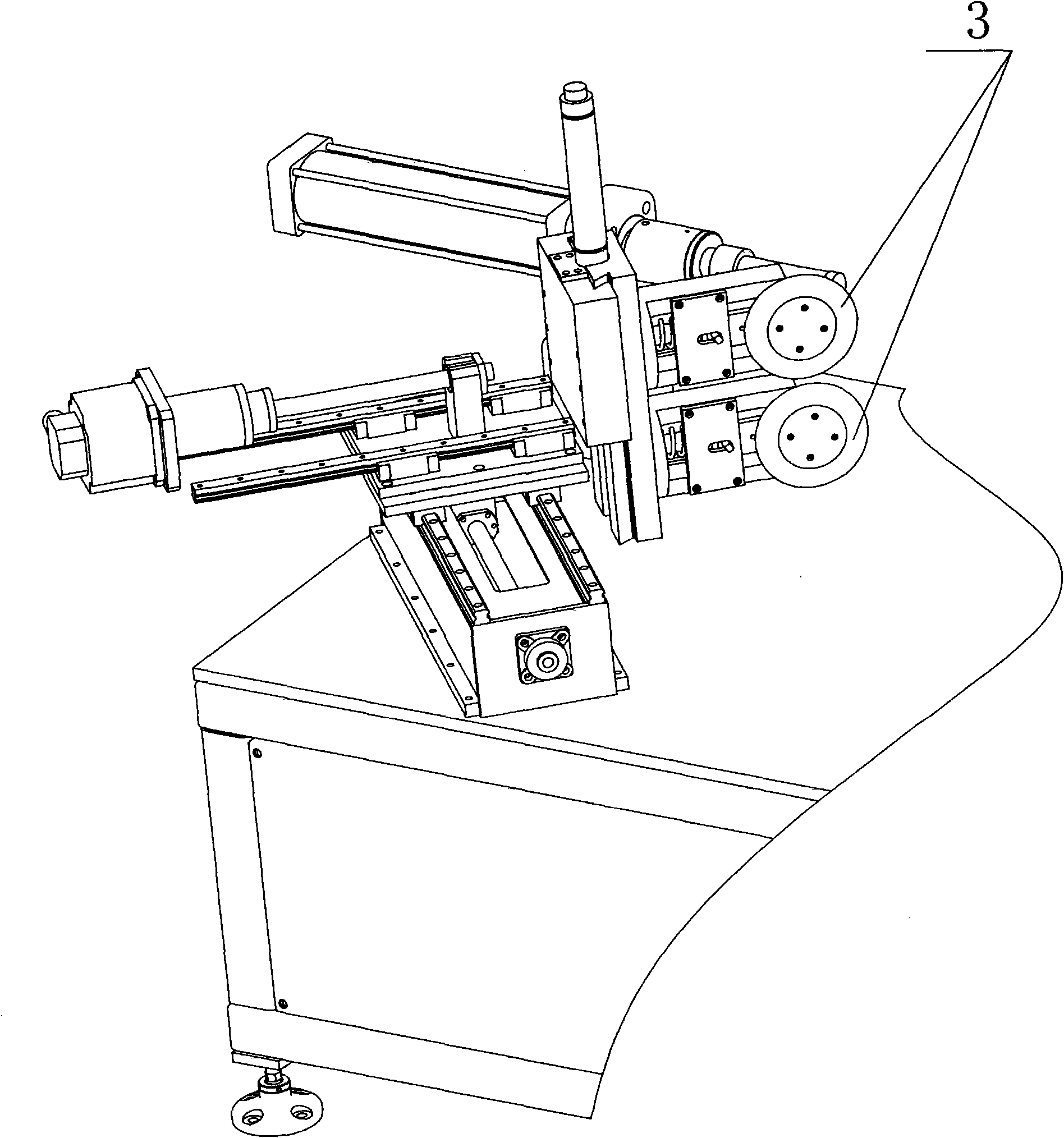

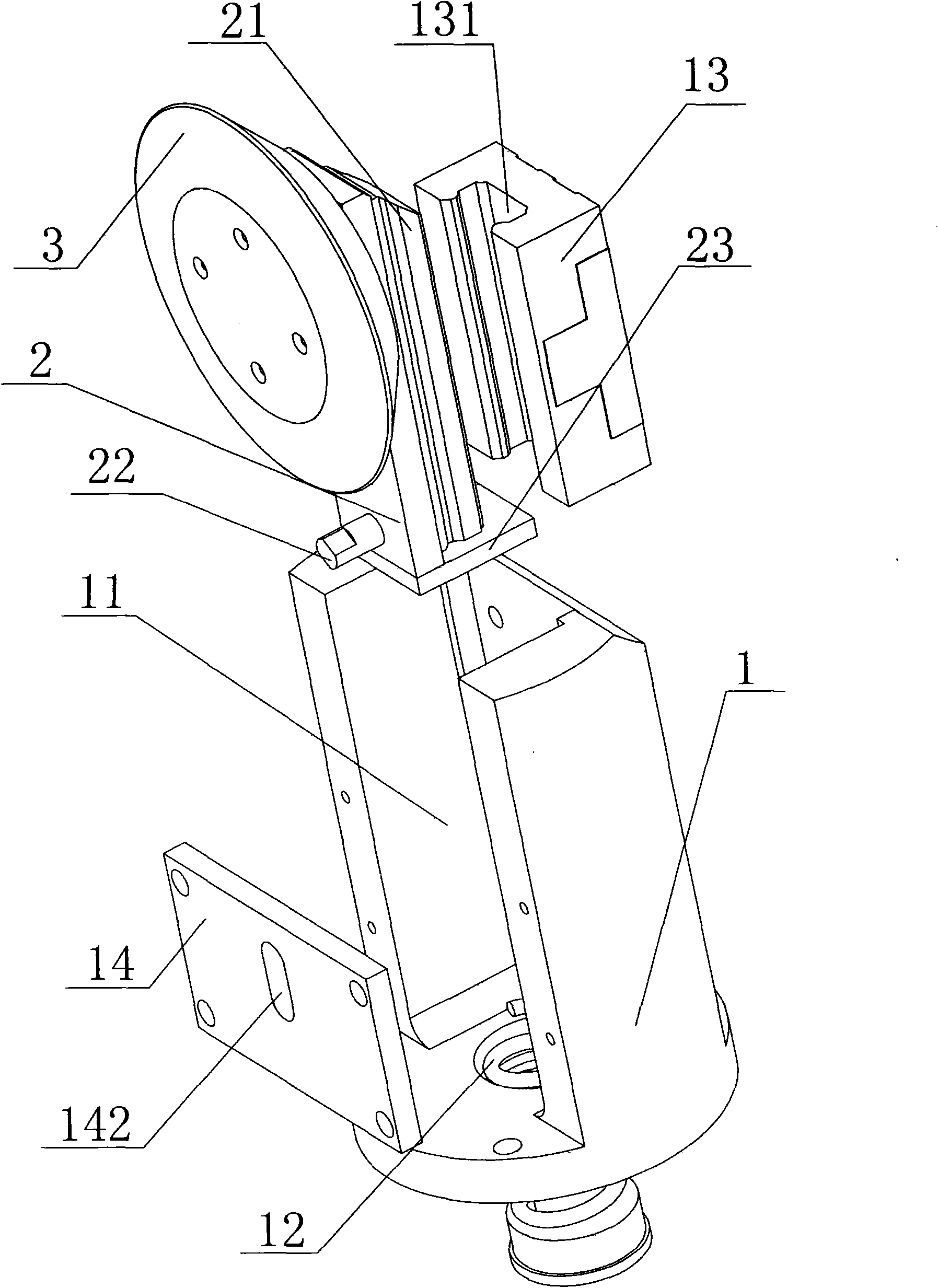

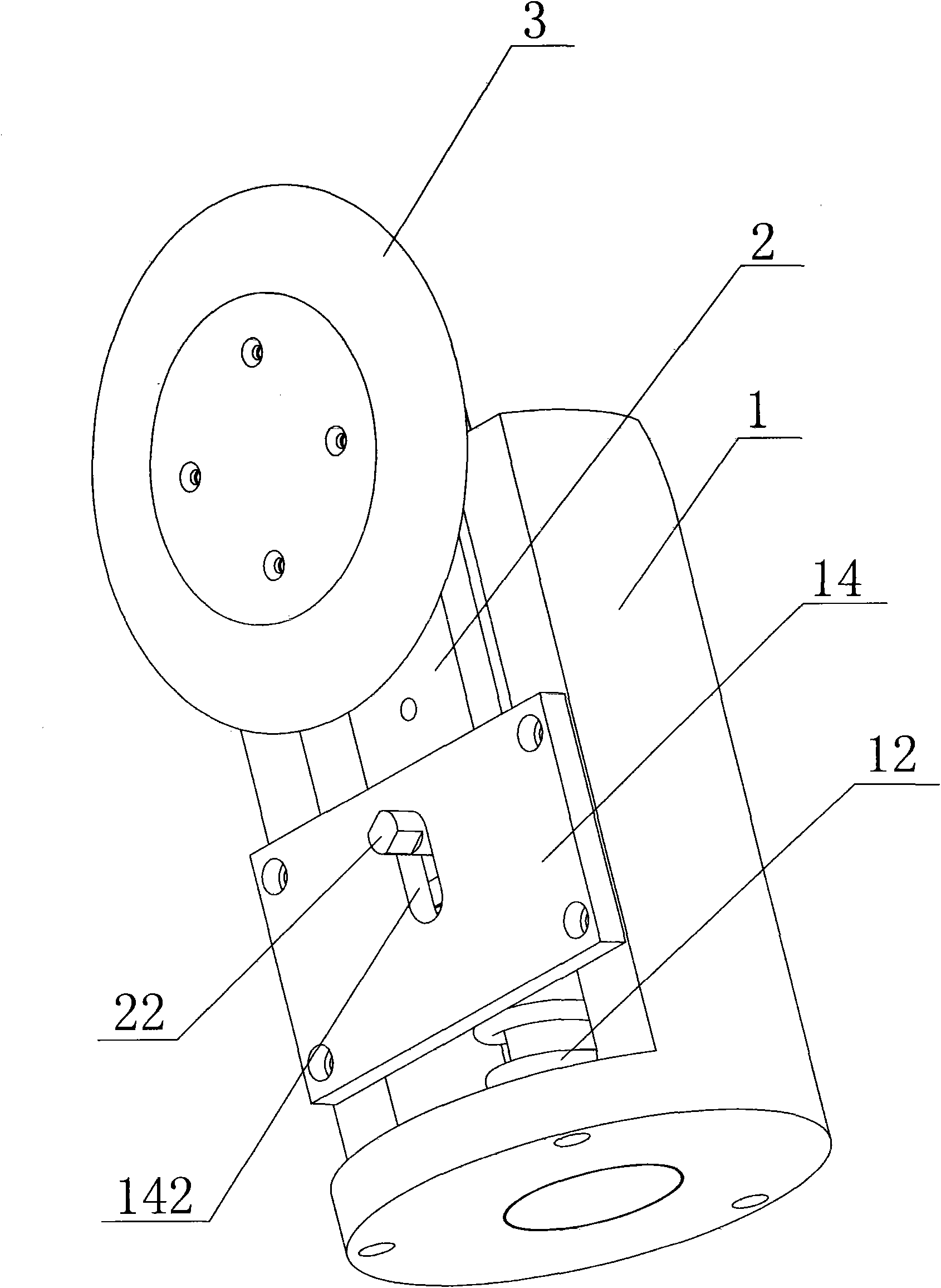

[0019] As shown in the figure, the adaptive spinning mechanism of the thin plate spinning machine includes a base body 1 and a slide plate 2 mounted on the base body 1 that can slide back and forth. The base body 1 is provided with a preload spring for pushing the slide plate 2 outward. 12. The slider 2 is equipped with a roller assembly 3 for applying pressure.

[0020] In the present invention, the seat body 1 is provided with a strip-shaped groove 11, and the sliding plate 2 is movable and clamped in the above-mentioned groove 11. The groove 11 is provided with a preload spring 12 for pushing the sliding plate 2 outward, and the sliding plate 2 The inner end is provided with a spring top plate 23, and the inner end of the groove 11 is threadedly connected with a screw rod with a spring mandrel 15. One end of the pretension spring 12 is pressed against the spring top plate 23, and the other end of the pretension spring 12 is set outside the spring mandrel 15. . The front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com