Adaptive connecting device used for main pump motor top shaft

A technology for connecting devices and pump motors, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., which can solve the problems of easy damage to the main pump motor, failure to adapt to ensure that the force is consistent with the axis line of the main pump motor, and equipment defects Deal with limitations and other issues to achieve the effect of self-adaptive adjustment, overcoming force tilt, and overall installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the drawings and embodiments.

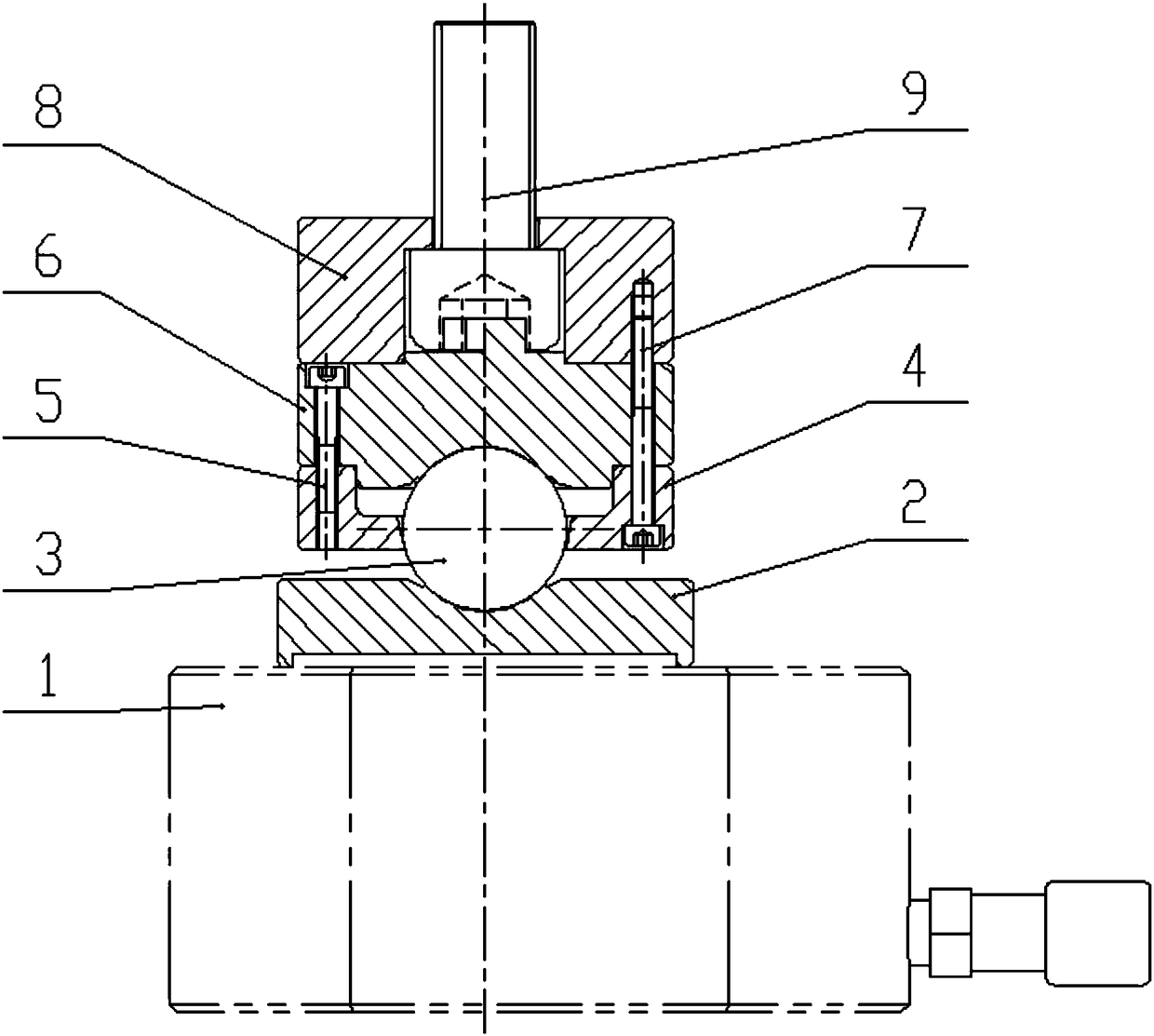

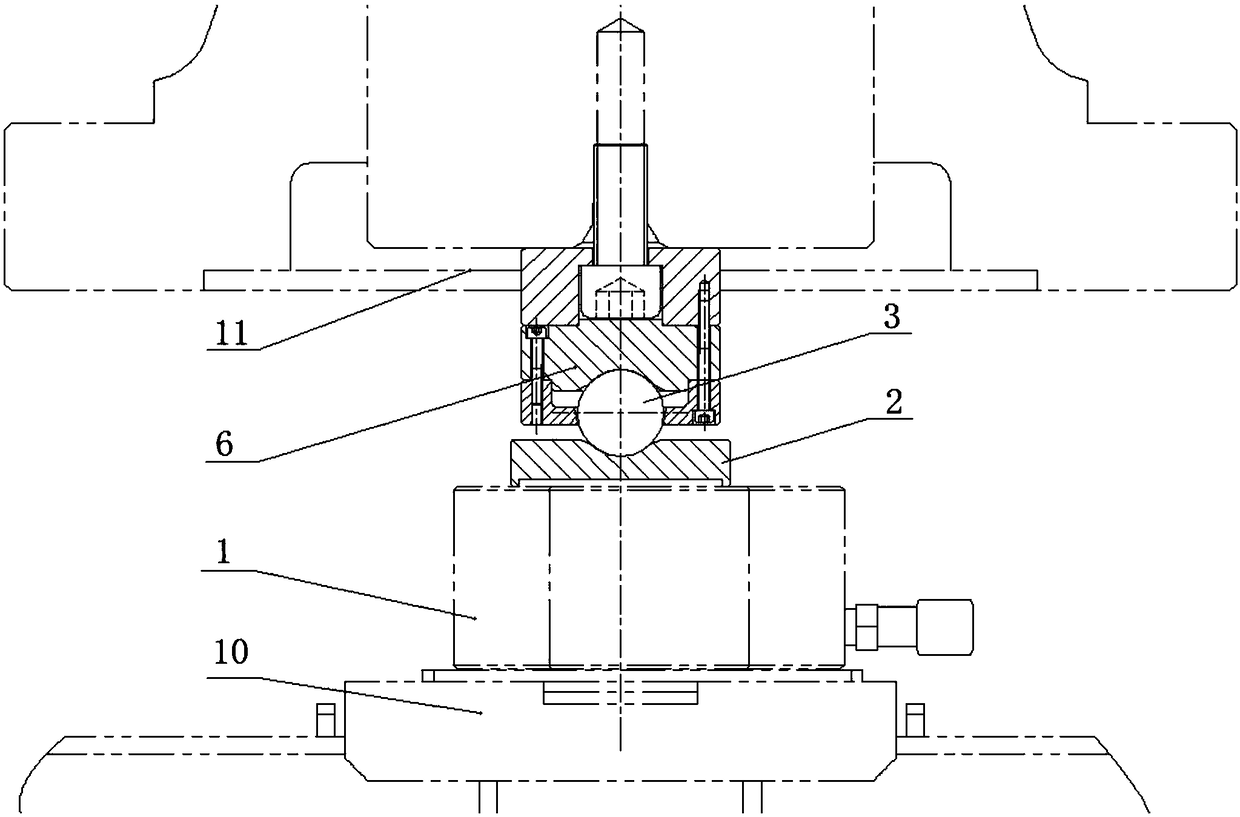

[0020] Such as figure 1 As shown, the present invention is an adaptive connection device for the top shaft of the main pump motor, which includes a top shaft connection device and a lower curved backing plate 2. The top shaft connection device includes a steel ball 3, a steel ball gland 4, and A The connecting screw 5, the upper curved backing plate 6, the B connecting screw 7, the connecting base 8, and the customized screw 9. During the working process, the lower curved backing plate 2 is aligned with and against the steel ball 3 of the top shaft connecting device.

[0021] The lower arc backing plate 2 is installed on the top of the jack 1 telescopic rod. The size of the lower arc backing plate 2 matches the top of the jack 1 telescopic rod. The telescopic movement of the jack 1 telescopic rod can drive the lower arc backing plate 2 to move up and down. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com