A furnace cover lifting mechanism and a nitriding furnace using the mechanism

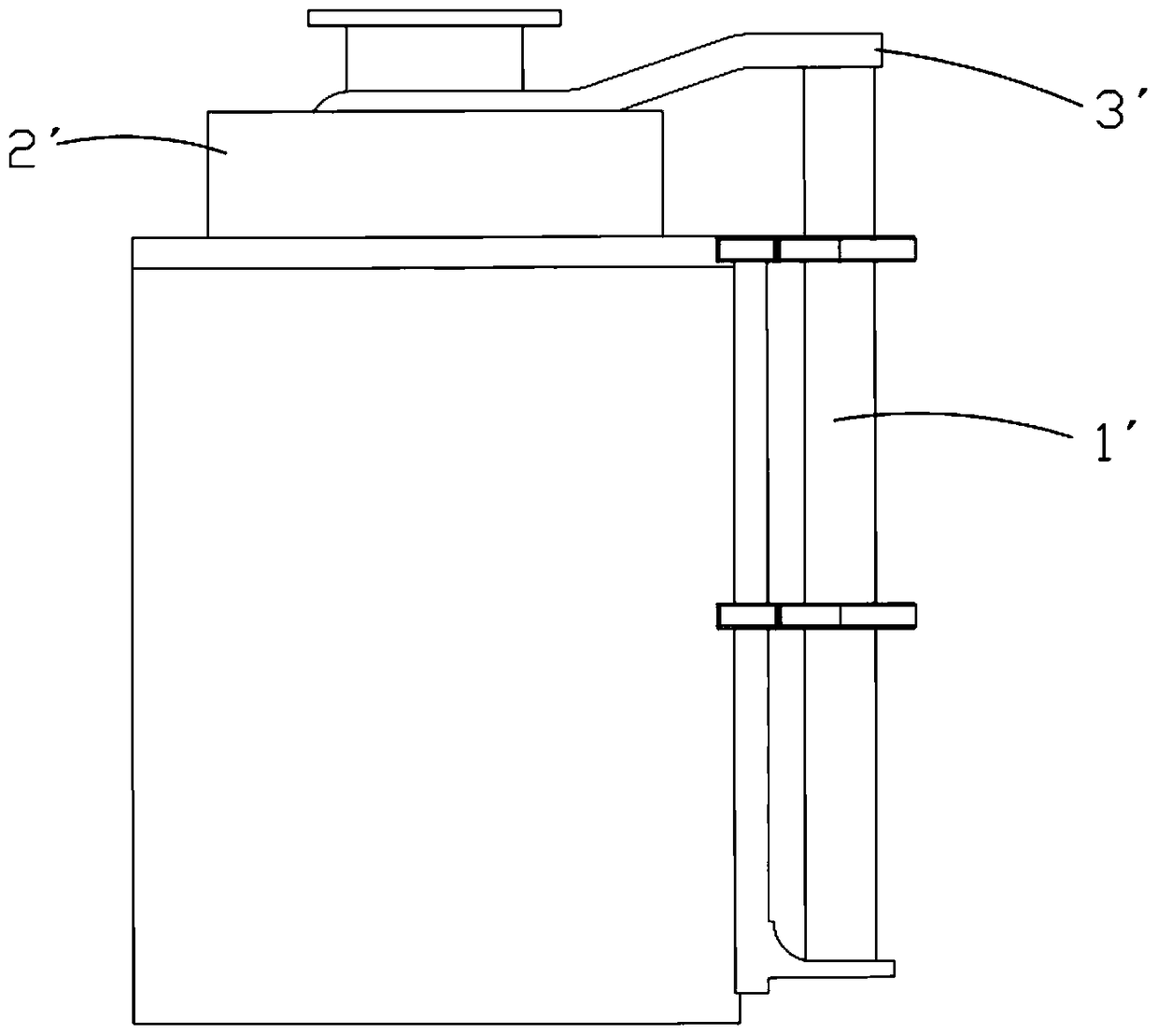

A lifting mechanism and furnace cover technology, which is applied in the field of nitriding furnaces, can solve problems such as unstable shaking of the furnace cover 2′, potential safety hazards, and reduced rigidity of the lifting shaft, so as to ensure rigidity and strength, eliminate distortion and deformation force, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

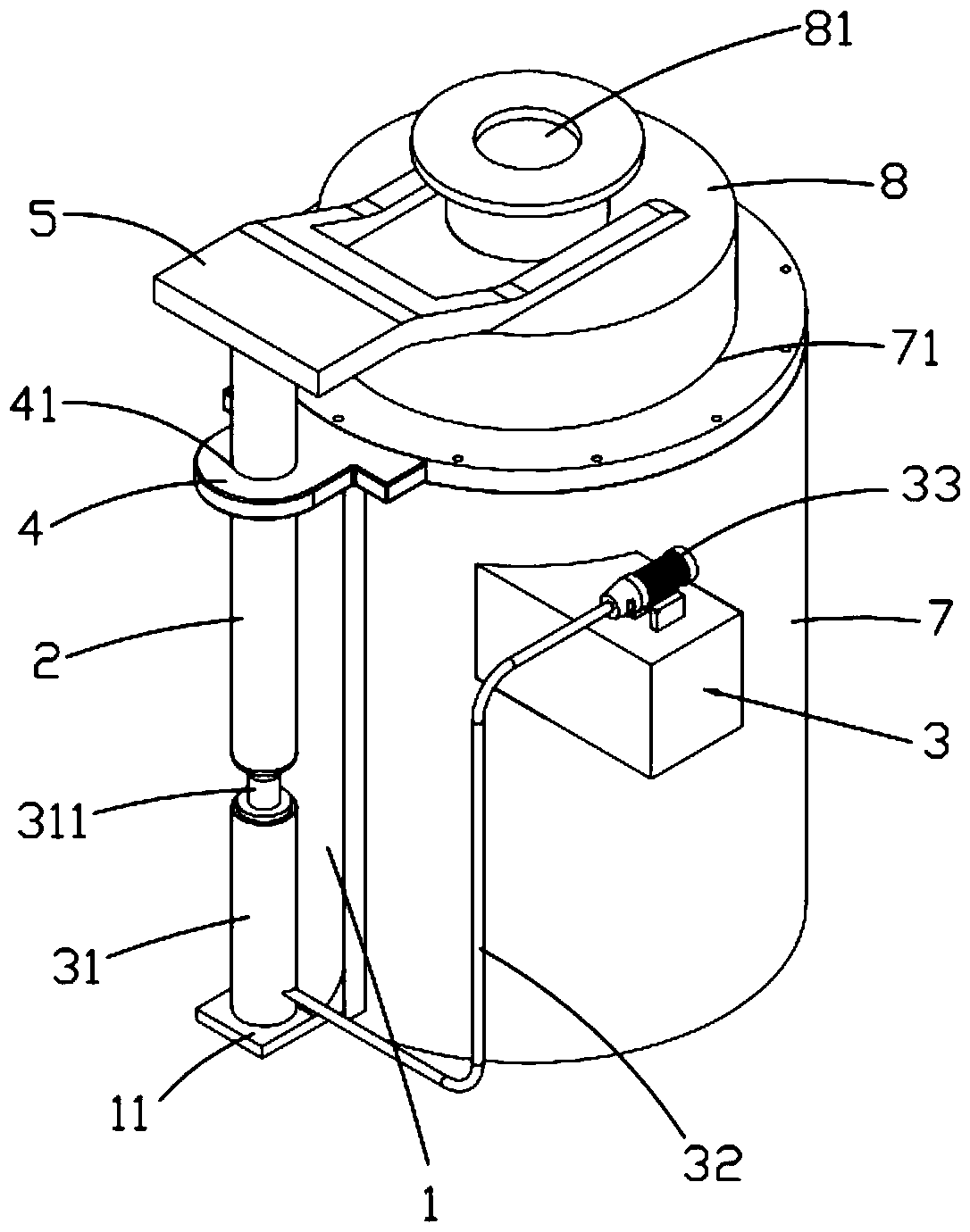

[0029] Such as image 3 and Figure 4 As shown, the present invention provides a furnace cover lifting mechanism, which includes a guide seat 1, a guide column 2 and a hydraulic lifting mechanism 3 for supporting the guide column 2 to lift. The guide seat 1 is provided with a first shaft perpendicular to it. Seat 4, the first shaft seat 4 is provided with a first shaft hole 41 matching the shape of the guide post 2, the guide post 2 vertically passes through the first shaft hole 41 and is slidably fitted in the first shaft seat 4, Its top is fixedly connected with the connecting crossbeam 5 that one end is connected with furnace cover 8 . The bottom end of the guide seat 1 extends outward horizontally to form a support 11. The hydraulic lifting mechanism 3 includes a hydraulic cylinder 31, an oil pipe 32 and an electric hydraulic pump 33. The hydraulic cylinder 31 is vertically installed on the support 11. The electric hydraulic pump 33 is connected, and the lifting shaft 31...

Embodiment 2

[0034] Such as Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and image 3The difference of the first embodiment shown is that in this embodiment, the guide seat 1 is also provided with a second shaft seat 9, which is sleeved on the outside of the hydraulic cylinder 31 to further increase the hydraulic cylinder capacity. 31 for strength and firmness. At the same time, a third shaft seat 10 is also provided on the guide seat 1, and the third shaft seat 10 is sleeved on the outside of the guide column 2 and placed under the first shaft seat 4, wherein the first shaft seat 4, the second shaft seat The second shaft seat 9, the third shaft seat 10 and the support 11 are all arranged in parallel and located in the same vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com